Modules are widely used and critical in the semiconductor industry, encompassing power semiconductors, packaging and testing, automated production, and other processes. Their core advantages and technical features are as follows:

1. Power Semiconductor Modules

High Integration and High Performance

Power semiconductor modules (such as GaN and SiC modules) significantly improve energy conversion

efficiency by integrating devices such as MOSFETs and IGBTs, meeting the high power density and low

loss demands of electric vehicles and new energy vehicles.

Power semiconductors account for 55% of all-electric vehicles, far exceeding the 21% of traditional fuel

-powered vehicles.

Modular design simplifies PCB layout and reduces R&D cycles. For example, 5G RF front-end modules

(such as PAMiD and FEMiD) integrate PAs, LNAs, and other components.

Material and Process Upgrades

The application of third-generation semiconductor materials (such as silicon carbide and gallium nitride) is driving module performance improvements. For example, SiC modules perform better in high-temperature and high-frequency scenarios.

II. Packaging and Inspection Modules

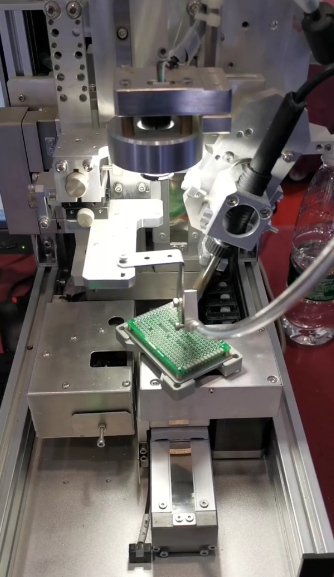

High-Precision Motion Control

Linear modules (such as marble linear modules) are used in semiconductor inspection equipment, provi

ding micron-level positioning accuracy and high-speed motion capabilities, making them suitable for

scenarios such as visual inspection and wafer scanning.

Feichuang's marble linear modules achieve a 600mm travel in just 2-3 seconds with speed fluctuations

of less than 5% during AI-powered intelligent inspection.

Die Bonder and Packaging Equipment

Die bonder modules use visual positioning and high-speed precision control to achieve precise placem

ent of chips on substrates. For example, Dekewell's remote I/O modules are used for signal acquisition

and drive in IC die bonders.

III. Intelligent and Automated Production

5G+ Industrial Internet Applications

5G modules enable intelligent operations and maintenance in semiconductor factories. For example,

Chongqing Unicom's 5G+ visual inspection solution has reduced defective product rates by 15% and

increased production efficiency by 20%.

Independent and Controllable Technology

Domestic companies (such as Fuchuang Precision) are using module products to achieve localization of

key components for semiconductor equipment, covering core processes such as etching and photolitho

graphy.

IV. Market Trends

Coexistence of Modular and Discrete Devices: In the 5G era, the markets for high-end modules (such as

RF front-ends) and discrete devices are growing simultaneously, and core components such as filters

face high technical barriers.

Accelerating Domestic Substitution: Semiconductor equipment modules (such as metal components

and gas pipelines) are gradually achieving independent control, reducing dependence on imports.

In summary, semiconductor modules continue to drive the industry towards efficiency, reliability, and

autonomy through material innovation, high-precision integration, and intelligent upgrades.