The core advantages of servo electric cylinders compared to hydraulic cylinders are reflected in the following aspects:

1、 Control accuracy and dynamic performance

The closed-loop control accuracy can reach ± 0.01mm, which is significantly better than the hysteresis of hydraulic systems and the response speed of hydraulic valves through servo motor drive and encoder real-time feedback.

Wide speed adjustment range (0.5-1500mm/s), more stable acceleration control, and no stick slip phenomenon in hydraulic systems.

Seamless compatibility with control systems such as PLC, supporting complex motion sequence programming, without the need for electro-hydraulic interfaces or temperature compensation design required for hydraulic systems.

2、 Energy conservation, environmental protection, and operating costs

Reduce energy consumption by 50% -77%, only consume power during operation, and have no energy loss when stopped; The hydraulic system needs to continuously maintain oil pressure, and its annual power consumption is 2-3 times that of an electric cylinder.

No risk of hydraulic oil leakage, avoiding environmental pollution, and meeting the requirements of clean industries such as food and medicine.

Low maintenance cost, no need to replace hydraulic oil, filter elements or seals, and long-term usage cost is only one-third of the hydraulic system.

3、 Reliability and environmental adaptability

The protection level reaches IP66, and it can work stably in extreme environments ranging from -20 ℃ to 120 ℃, with much stronger anti pollution ability than hydraulic systems.

Low failure rate and long lifespan, ball screw structure with low friction, designed for millions of cycles; Hydraulic cylinders are greatly affected by the wear of seals.

Power off automatic locking function, ensuring safety through brake motors or mechanical self-locking, without the need for complex anti backlash devices of hydraulic cylinders.

4、 Structural and functional expansion

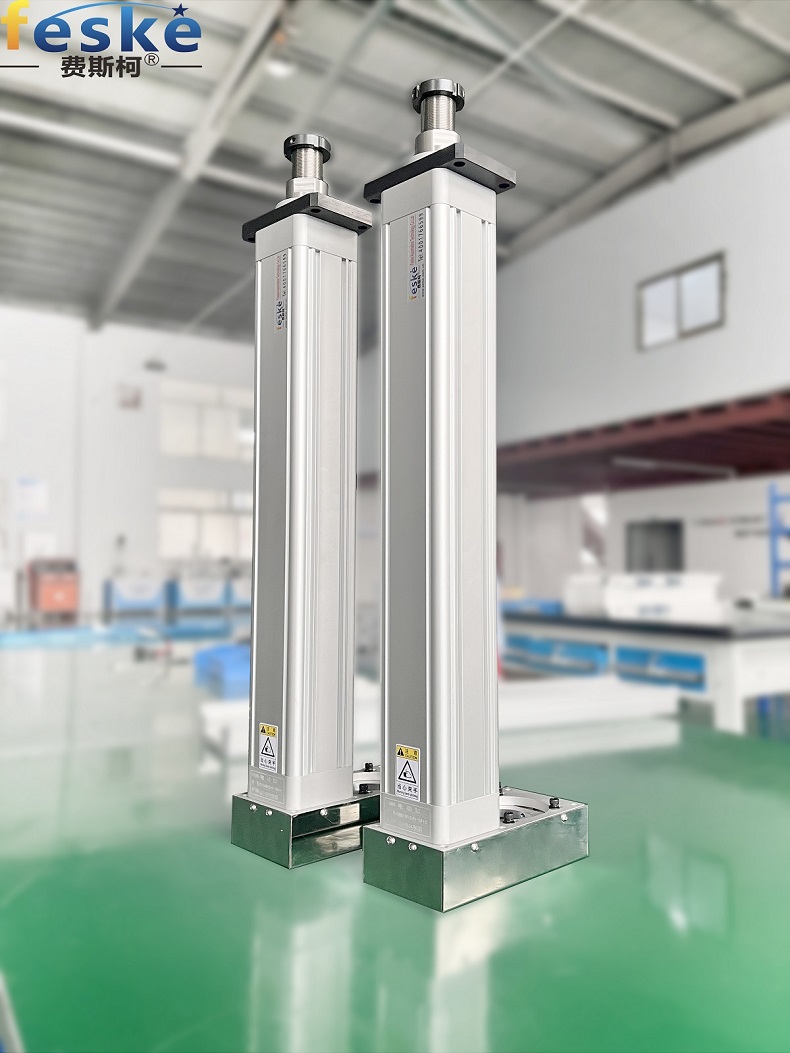

The volume is reduced by 30% -50%, and the integrated design reduces the space for pipelines and fuel tanks, resulting in higher installation flexibility.

The load range covers 5N-350kN, supporting customized design to meet special scenario requirements, while super large loads still rely on hydraulic systems.

Noise reduction of 15-20 decibels, no oil pump operation noise, suitable for quiet scenarios such as laboratories and medical equipment.

5、 Economic comparison

Although the initial procurement cost of servo electric cylinders is relatively high, their 5-year comprehensive cost (including energy consumption and maintenance) is 40% -60% lower than that of hydraulic systems, and the investment return period is usually less than 2 years