The application of servo electric cylinders in robots is mainly reflected in the following fields and technical characteristics:

1、 Core application scenarios

Human like robot dexterous hand and joint drive

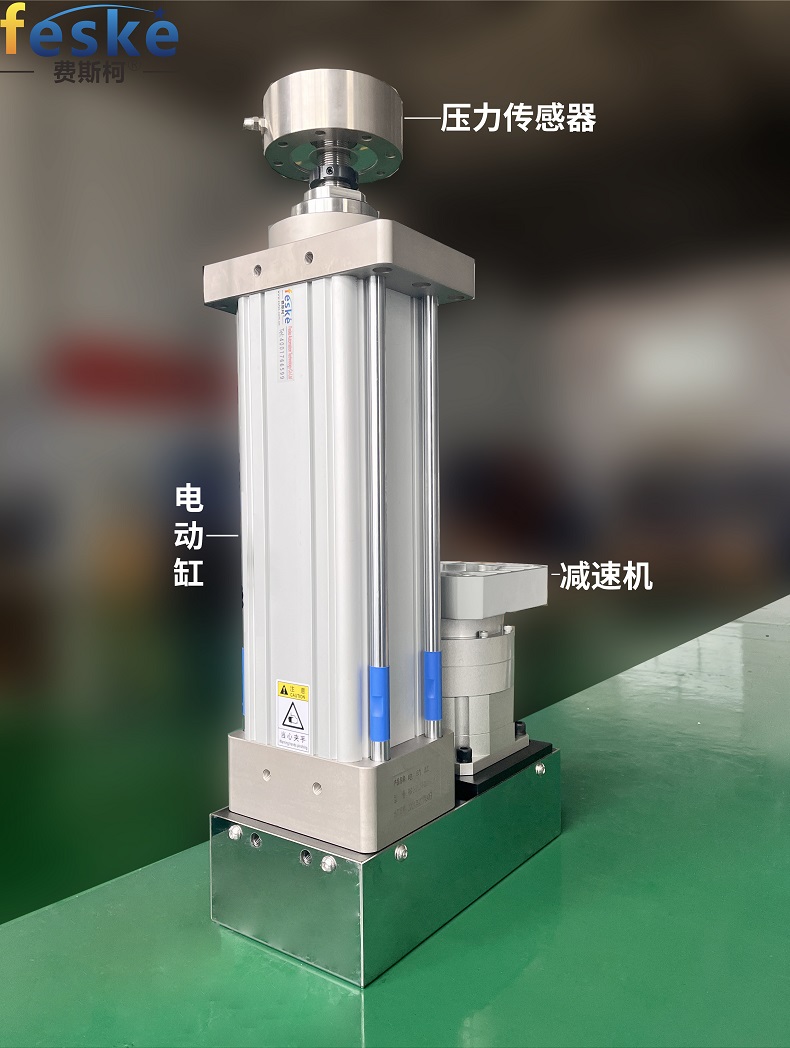

The servo electric cylinder replaces traditional pneumatic/hydraulic drive solutions by integrating high-precision reducers, hollow cup motors, and sensors, solving the problems of miniaturization, high precision, and reliability of dexterous hands. Typical applications include Tesla's humanoid robot dexterous hand, which features miniature servo electric cylinders distributed in its joints that enable biomimetic movement of human like muscles.

Precision operation of industrial robotic arms

3C electronic assembly: In the assembly of mobile phone camera modules, the servo electric cylinder closed-loop control accuracy reaches ± 0.005mm, which is more than 20 times higher than the cylinder accuracy;

Automotive welding: Real time adjustment of welding gun pressure (5N ± 0.2N) through force control mode to avoid welding defects caused by a 50ms delay in the hydraulic system.

Flexible Control of Collaborative Robots

In dynamic work scenarios, servo electric cylinders support multi axis linkage and real-time trajectory correction. For example, the food packaging robotic arm is made of stainless steel material (IP67 protection), which meets the requirements of clean workshops and avoids the risk of hydraulic system leakage.

2、 Key technological advantages

Improvement of feature technology implementation compared to traditional solutions

High precision control encoder+force sensor closed-loop system, real-time compensation for position error, cylinder accuracy increased by 20 times, eliminating "spring effect"

Dynamic response capability based on Arm Cortex-M7 core servo control system, achieving millisecond level response speed 30 times faster than hydraulic system

Environmental adaptability without oil leakage risk, supporting wide temperature range operation from -20 ℃ to 80 ℃ to avoid hydraulic system seal failure and pollution, reducing maintenance costs by 30%

Long term economic 5-year cycle energy consumption and maintenance costs are 40% lower than pneumatic solutions, reducing spare parts replacement frequency by 50%

3、 Typical application cases

Tianyu electric cylinder: designed specifically for industrial robotic arms, achieving a repeat positioning accuracy of 0.01mm during handling operations;

Flexible hand of adaptive robot: 12 joint coordinated control is achieved through 6 micro servo electric cylinders, with a weight of only 530 grams but capable of carrying several kilograms of load.

Currently, servo electric cylinders are developing towards higher integration (such as built-in motion control algorithm 1) and stronger environmental tolerance (IP69K protection level 7), becoming the core upgrade direction of robot actuators