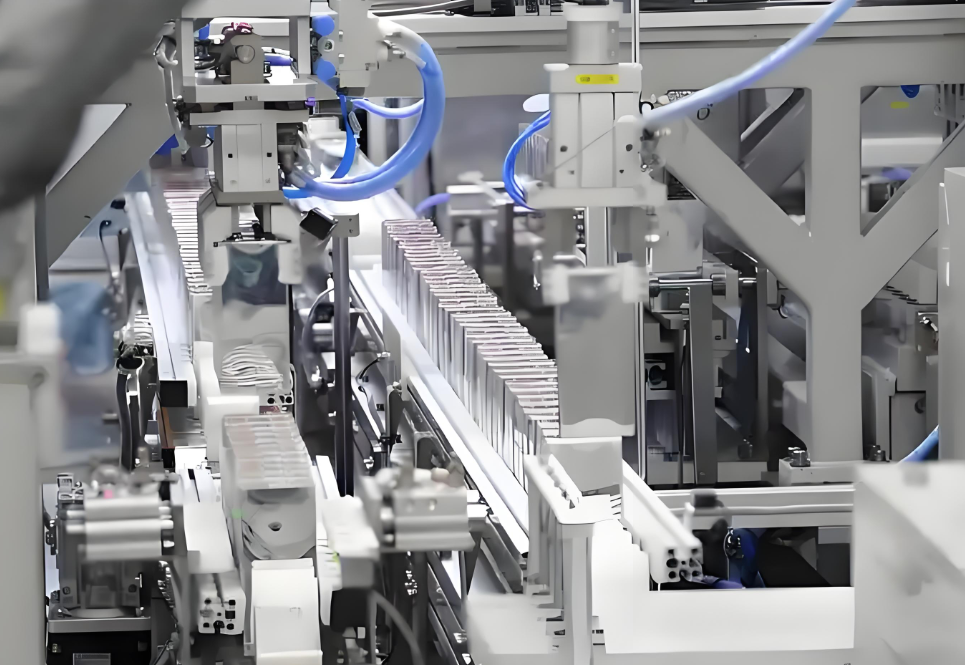

the belt linear module, as the core component of automated transmission, is sweeping the manufacturing industry with its advantages of high precision, low noise, and long life. Recently, a leading domestic enterprise launched a new generation of belt linear module solution, which improves transmission efficiency to 98% and reduces noise by 15 decibels through the application of dynamic tension adjustment technology and composite synchronous belt materials, providing better production line kinetic energy support for fields such as 3C electronics and new energy battery assembly.

Technological breakthrough highlights

Modular design: supports plug and play installation, compatible with multiple brands of robotic arms and control systems

Intelligent maintenance system: Built in wear monitoring sensor, can provide early warning of belt fatigue status

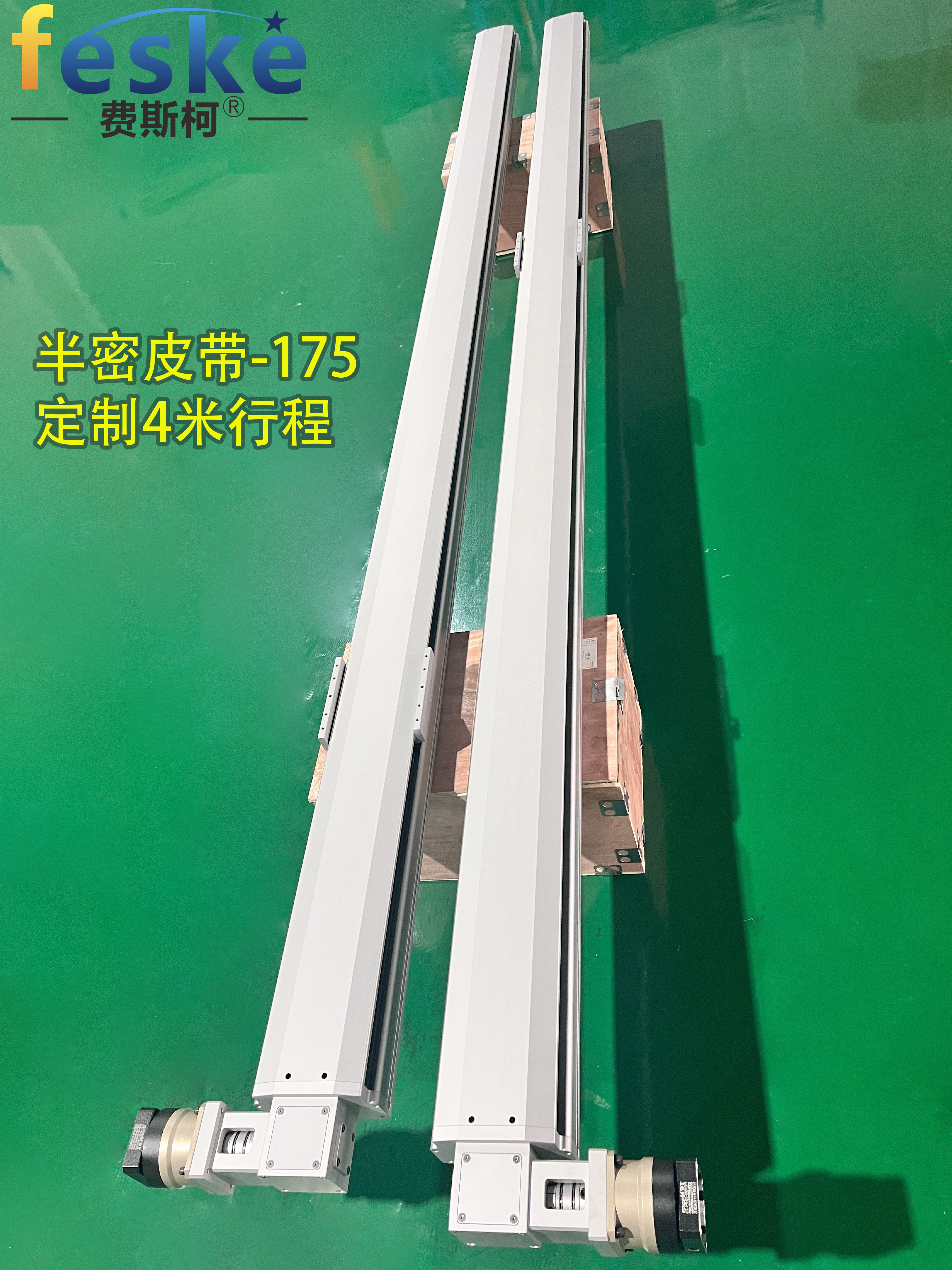

Advantages of ultra long travel: The effective travel of the single-mode group can reach 10 meters, breaking through the distance limitation of traditional screw transmission

According to industry analysts' predictions, the global market size of belt linear modules will exceed 5 billion yuan by 2025, with China accounting for over 35% of the market share. This technology is particularly suitable for scenarios such as high-speed sorting, precision dispensing, and photovoltaic panel handling. After adopting it, a certain photovoltaic enterprise's production capacity increased by 22% and the yield rate increased by 1.8 percentage points.

Future prospects

With the mass production of carbon fiber reinforced belts, the next generation of products will achieve a weight reduction of 30% while increasing load-bearing capacity by 20%, providing better solutions for ultra clean environments such as semiconductor equipment.