Direct crossing robotic arm: precision "hands" for industrial intelligence, unlocking new heights of automation

——Analyzing structural design and multi scenario applications

In recent years, as the global manufacturing industry accelerates its transformation towards intelligence and flexibility, industrial robots have become the core driving force for upgrading production lines. Among them, the orthogonal manipulator has emerged in the field of intelligent manufacturing due to its high precision, high stability, and flexible programmability. Whether it's precise grasping on automotive assembly lines or micro level operations in the semiconductor industry, orthogonal robotic arms are reshaping the operation mode of modern factories with the posture of "invisible champions".

1、 Structural design: a perfect balance between modularity and rigidity

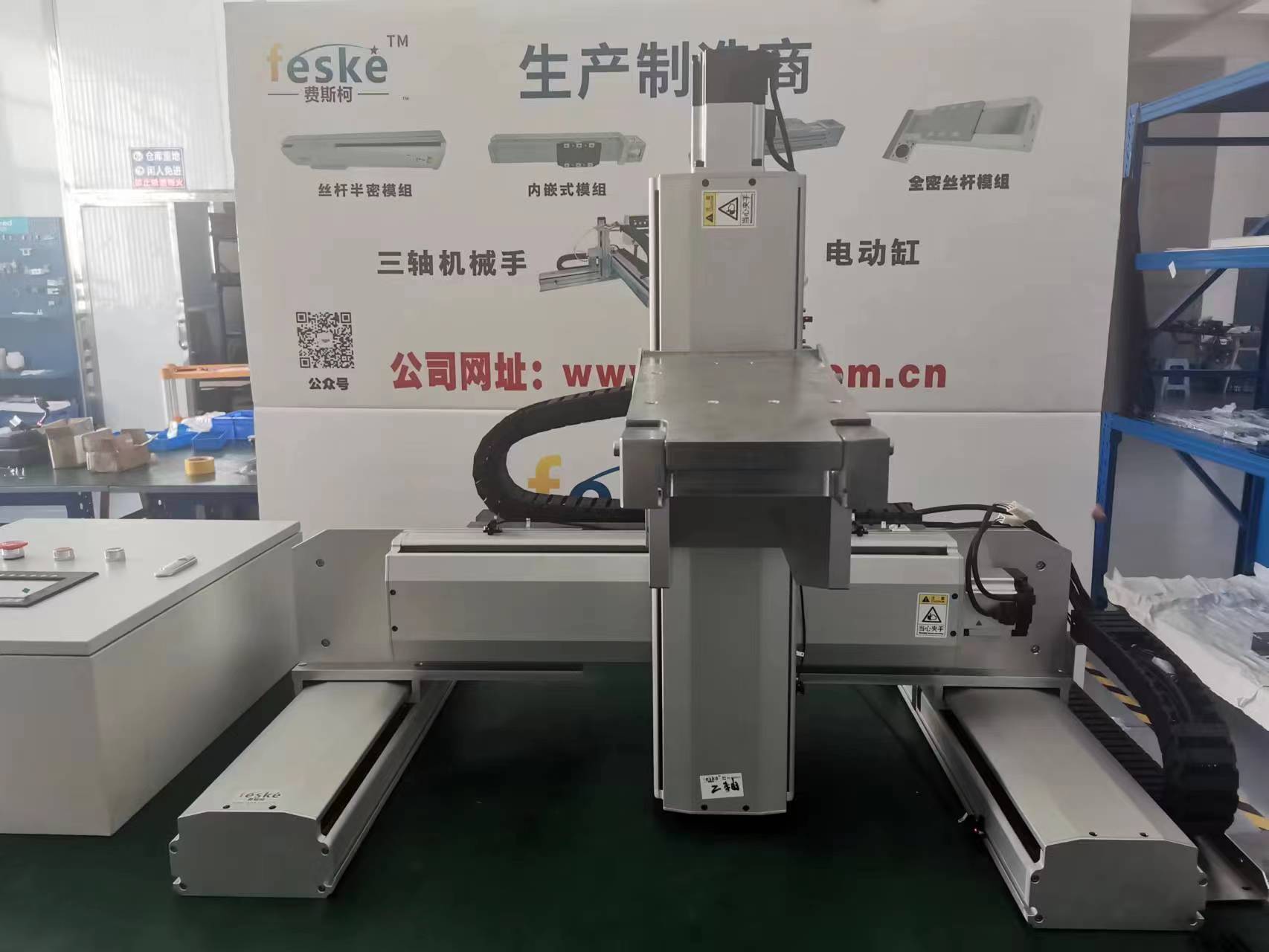

Cartesian Robot, also known as Cartesian coordinate robot, has a core structure based on a linear motion system with three orthogonal axes of X, Y, and Z, and achieves multi-dimensional precise control through modular design.

Rigid skeleton, precision guarantee

Guide rail and drive system: High precision linear guide rail and ball screw transmission are used to ensure that the robotic arm maintains micrometer level positioning accuracy even during high-speed motion. Some high-end models are equipped with linear motors to further reduce friction losses and noise.

Lightweight materials: The application of aluminum alloy frames and carbon fiber composite materials, balancing structural strength and dynamic response efficiency, is suitable for long stroke and high load scenarios.

Intelligent control, flexible expansion

Through PLC or dedicated motion controller, complex trajectory planning can be achieved through programming, supporting multi axis linkage and multi robotic arm collaborative operation.

Modular design allows users to freely increase or decrease the number of axes or replace end effectors (such as suction cups, grippers, visual cameras) according to their needs, adapting to multitasking scenarios such as handling, welding, and inspection.

Security and compatibility

Equipped with force feedback sensors and collision detection systems to ensure real-time human-machine cooperation safety.

Open interface compatible with mainstream industrial protocols such as EtherCAT and Profinet, seamlessly integrating into the IoT ecosystem of smart factories.

2、 Application scenarios: From industrial workshops to emerging fields

Direct crossing robotic arms, with their customizable and highly reliable characteristics, have penetrated into the automation chains of multiple industries

Upgrading traditional manufacturing industry

Automotive industry: used for engine assembly, body welding, and component handling, replacing manual labor to complete high-intensity repetitive tasks, with a yield rate increase of over 30%.

3C Electronics: In precision processes such as chip mounting and screen inspection, it achieves 0.01mm level operations, significantly reducing labor costs and product losses.

The 'efficiency engine' of emerging industries

Photovoltaics and lithium batteries: In processes such as photovoltaic panel lamination and lithium battery lamination, orthogonal robotic arms have become the core equipment for large-scale production due to their long stroke and high stability.

Medical and Food: Drug sorting and food packaging in a sterile environment, meeting hygiene standards while achieving 24-hour continuous operation.

Laboratory and Research Innovation

In fields such as biological experiments and material testing, orthogonal robotic arms equipped with visual systems can automatically capture samples and record data, promoting a leap in scientific research efficiency.

3、 Industry Outlook: Integration of Intelligence and Collaboration

According to market research firm Interact Analysis, the global industrial robot market is expected to exceed $50 billion by 2025, with the penetration rate of orthogonal robotic arms in small and medium-sized enterprises continuing to rise due to their high cost-effectiveness advantage. Future technological development focuses on two major directions:

AI empowers intelligent decision-making

The combination of deep learning algorithms and machine vision enables robotic arms to have adaptive grasping, defect recognition, and other capabilities, further replacing complex manual operations.

New ecology of human-machine collaboration

Lightweight and low-power design promotes the use of orthogonal robotic arms in flexible production lines, sharing workspace with workers and achieving safe collaboration through "human-machine integration".

Conclusion

The evolution history of orthogonal robotic arms from "steel giant arms" to "precision and skillful hands" is a microcosm of the development of industrial automation. Under the wave of intelligent manufacturing, this technology will continue to break through application boundaries and become a key tool for enterprises to reduce costs, increase efficiency, and compete for market discourse power. In the future, with the deep integration of technologies such as 5G and digital twins, orthogonal robotic arms may move from the workshop to a broader sky, ushering in a new era of automation.