Industry sectors where belt modules are widely used:

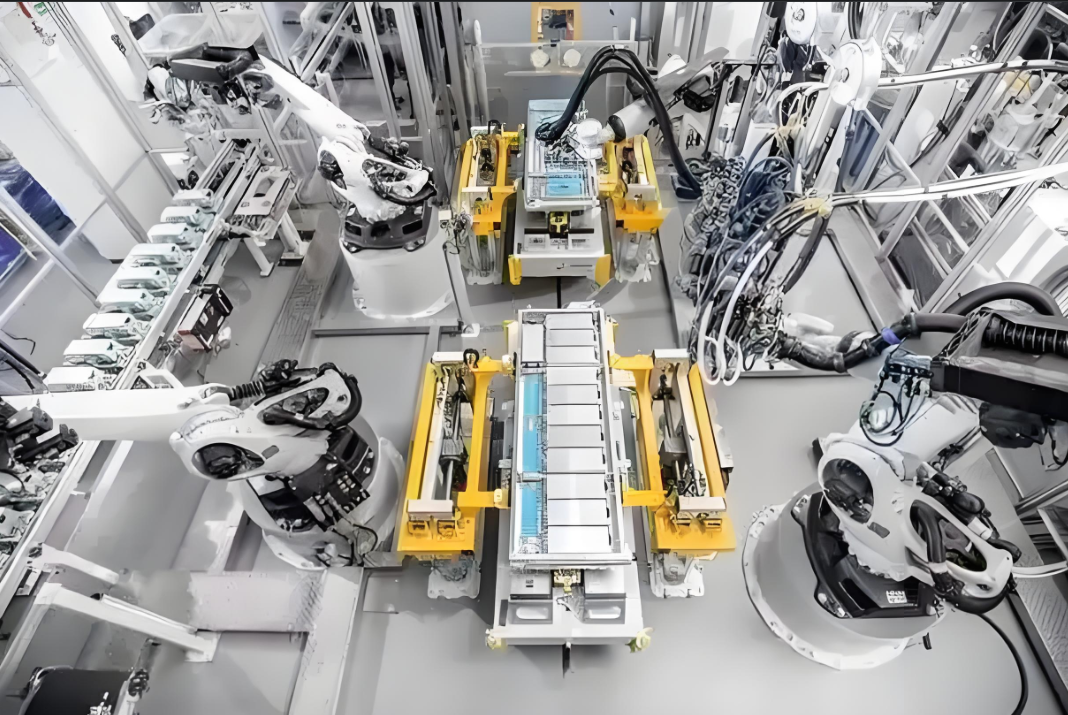

1、 Automotive manufacturing field

Core applications

Assembly workshop: Convey large components such as engines and transmissions to the assembly station, supporting a repeat positioning accuracy of ± 0.1mm

Power battery production: Using fire-resistant and flame-retardant belt modules to transport battery packs, anti-static design enhances safety

Stamping workshop: Avoid surface scratches when transporting steel plate coils, increase waste recycling efficiency by 40%

2、 3C Electronics Industry

Typical scenario

SMT production line: anti-static belt module for conveying PCB boards, with surface resistance controlled within the range of 10 ⁶ -10 ⁹ Ω

Mobile phone assembly: Flexible positioning fixture combined with belt module to achieve screen fitting accuracy of ± 0.05mm

Semiconductor packaging: cleanroom grade module (Class 100 standard) handling wafer carrier, dust concentration<100 particles/cubic foot

3、 Logistics and Packaging Industry

Technical adaptation

Warehouse sorting: 5m/s high-speed operation supports 3000 pieces/hour sorting efficiency, AI visual recognition SKU code

Food packaging: modular design compatible with vertical/horizontal installation, dust-proof structure meets GMP standards

Medical packaging: Low noise (<60dB) characteristics meet the requirements of sterile workshop environment

4、 Mining and Heavy Industry

Pain point resolution

Belt foreign object sorting: Intelligent robot equipped with high-speed module, grasping success rate ≥ 90% (belt speed 4m/s)

Equipment inspection: Track type module integrated temperature and humidity/deviation monitoring, replacing manual inspection in high-risk environments

Ore conveying: The wear-resistant belt module has a lifespan of over 20000 hours, reducing the frequency of downtime and maintenance

5、 Expanding into emerging fields

Innovative applications

New energy: The photovoltaic panel laminating machine adopts a high-temperature resistant belt module (capable of withstanding 120 ℃)

Medical equipment: Linear motor drive module is used for CT machine slip ring system, with motion stability reaching μ m level

Smart Home: Low cost Belt Module for Silent Automation of Curtains and Security Equipment

Industry application trends

Driving factor technology demand represents the industry

Intelligent manufacturing upgrades to high-speed (≥ 5m/s) and long-range (6m) automotive/3C manufacturing

Green production requires energy conservation (energy consumption reduced by 41%)+low noise (<60dB) in food/medicine

Replacing explosion-proof/corrosion-resistant/remote control mining/metallurgy in high-risk scenarios

Through modular design, high environmental adaptability, and significant cost advantages, belt modules are accelerating their penetration into the entire industrial automation scene.