Innovate the efficiency of automated production! The all-new generation of linear motor module is launched with shock

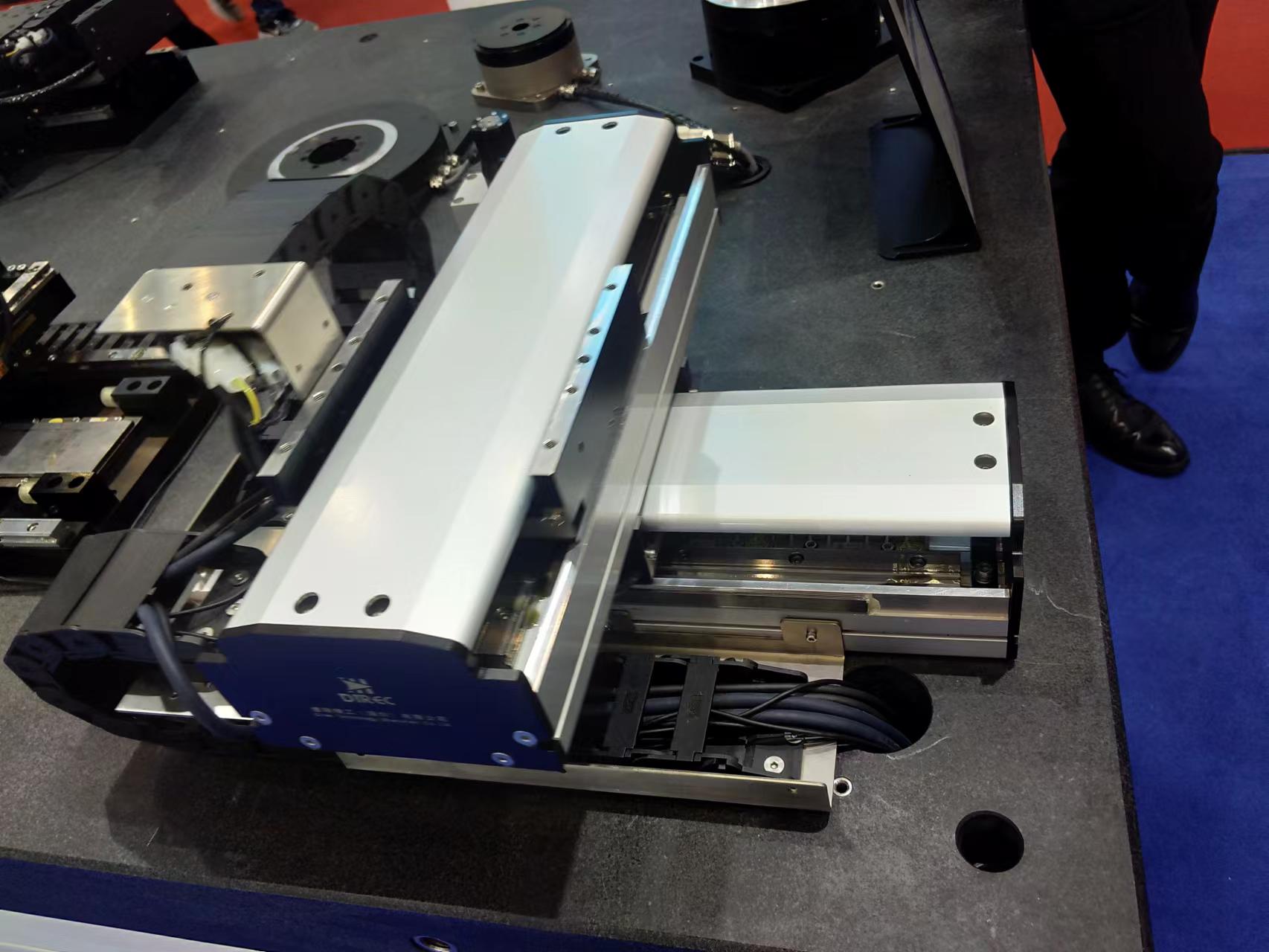

In today's rapidly developing industrial automation, efficient and precise transmission technology has become the core for enterprises to enhance their competitiveness. XXX Technology (fictional company name) has officially launched a new generation of LMS series linear motor modules, redefining the standard of linear motion control with breakthrough technology and helping the manufacturing industry move towards an intelligent future.

Product core advantage: Direct drive technology empowers efficient production

Traditional transmission systems rely on mechanical contact and suffer from pain points such as wear and accuracy degradation. The LMS series linear motor module adopts contactless direct drive technology, which directly drives the load through an electromagnetic field to achieve zero backlash and zero friction motion. Its core advantages include:

Ultra high speed response: The maximum speed can reach 5m/s, the acceleration exceeds 10G, and the production efficiency is increased by more than 30%;

Nano level accuracy: repeatability accuracy of ± 1 μ m, suitable for high-precision scenarios such as semiconductor and optical detection;

Long life maintenance free design: with no mechanical wear and tear, the service life exceeds 100000 hours, significantly reducing operation and maintenance costs.

Modular design, flexible adaptation to diverse scenarios

The LMS series offers multiple models including standard, high rigidity, and vacuum environment specific, supporting horizontal, vertical, and multi axis parallel installation. Users can customize their itinerary (50mm-5m), thrust (50N-3000N), and control system according to their needs, which are widely applicable to:

Precision manufacturing: chip packaging, laser cutting, 3C product assembly;

Medical equipment: CT machine slides, automated testing instruments;

New energy: battery welding, high-speed sorting of photovoltaic panels.

Intelligent interconnection, creating the foundation of future factories

This module is equipped with EtherCAT high-speed bus interface, which can seamlessly integrate into the industrial Internet of Things platform to monitor vibration, temperature, and load status in real time. With the MotionStudio software independently developed by XXX Technology, users can quickly complete parameter debugging and trajectory planning through a graphical interface, shortening the device development cycle by 60%.

Instantly experience and embark on an efficient production revolution

"The linear motor module is not only a transmission component, but also a key to intelligent upgrading." - Zhang Hua, CEO of XXX Technology, said, "We are committed to providing customers with 'zero compromise' operation control solutions through continuous innovation."