Introduction

Driven by the wave of Industry 4.0, automated production has become the core engine for the transformation and upgrading of the global manufacturing industry. In this process, the linear module slide table has quietly become an indispensable "invisible pusher" in many intelligent production lines due to its high precision, high efficiency, and high stability. From precision electronic assembly to heavy machinery handling, from medical equipment testing to new energy battery production, the linear module slide table is driving automation production to a higher level with the attitude of an innovator.

Core technological breakthrough: How can the linear module slide reshape production efficiency?

The linear module slide table is a precision motion unit that integrates linear guides, drive motors, transmission mechanisms, and control systems. It achieves precise positioning, high-speed movement, and repetitive operations of materials through programmed control. Its core values are reflected in three dimensions:

Efficiency leap: The transmission chain of traditional mechanical structures is long and accumulates large errors, while the linear module slide adopts an integrated design, which is driven by servo motors or stepper motors. The fastest speed can reach 2m/s or more, and the repeated positioning accuracy can reach ± 0.01mm, greatly shortening the production cycle. For example, after a certain automotive parts company introduced a linear module slide table, the efficiency of the assembly line increased by 40%, and the yield rate exceeded 99.5%.

Flexible adaptation: The modular design supports multi axis combinations and can be easily expanded into XYZ three-axis platforms or series connected multi station systems to meet different scene requirements. In the 3C industry, flexible production lines can quickly switch production programs through slide tables, achieving mixed production of multiple categories such as mobile phones and tablets, and increasing equipment utilization by 30%.

Stable and reliable: Equipped with high-strength aluminum alloy or steel body and dust-proof sealing technology, the linear module slide table can operate continuously in harsh environments ranging from -20 ℃ to 80 ℃, with an average time between failures (MTBF) of over 50000 hours, becoming the "steel backbone" of 24-hour unmanned workshops.

Industry Application Graph: Cross disciplinary Penetration from Manufacturing to Intelligent Manufacturing

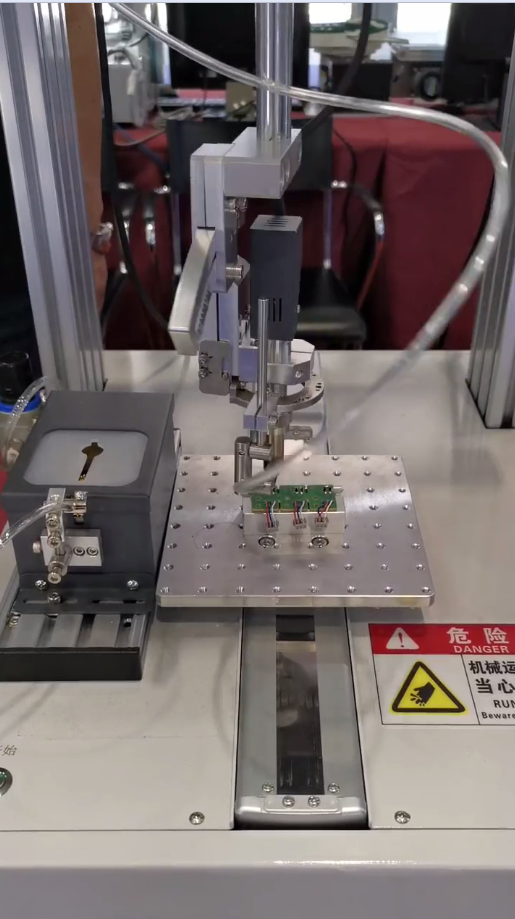

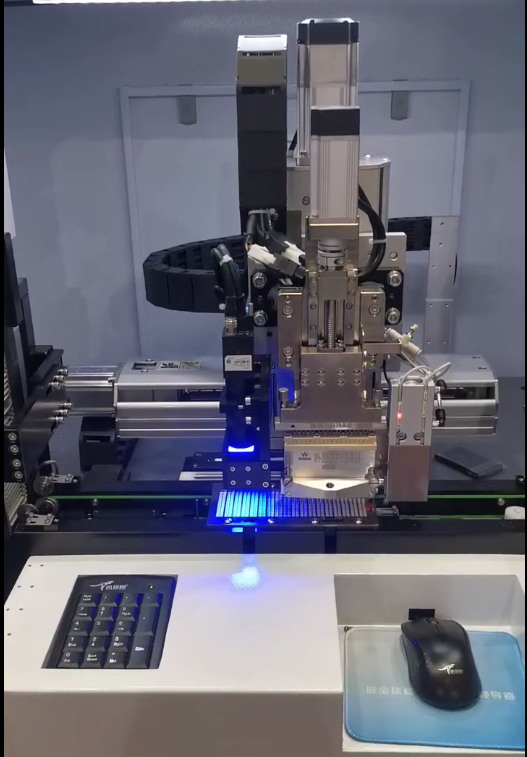

Semiconductor packaging: In nanoscale processes such as chip mounting and wire bonding, the linear module slide table is equipped with a vision system to achieve micrometer level positioning accuracy, helping domestic chips break through the "bottleneck" technology bottleneck.

New energy track: In the stacking process of power battery modules, the heavy-duty sliding table with a load capacity of 200kg accurately transports battery cells at a frequency of 0.5 times per second, with a daily production capacity of over 100000 per line.

Medical automation: In the fields of nucleic acid testing equipment, surgical robots, etc., the silent linear module slide not only ensures laboratory level cleanliness, but also achieves sub micro upgrading and precise dispensing of trace reagents.

According to authoritative institutions, the global market size of linear modules has exceeded 5 billion US dollars in 2023. China, as the largest application market, has a compound annual growth rate of 18.6%, becoming a driving force for industry innovation.

Intelligent Upgrade: The Future Evolution Direction of Linear Module Sliding Platform

With the deep integration of Industrial Internet of Things (IIoT), the new generation of linear module slide tables is evolving from a "single execution unit" to an "intelligent decision-making node":

AI algorithm empowerment: By using built-in sensors to collect real-time vibration, temperature, and load data, combined with AI predictive maintenance algorithms, the accuracy of equipment fault warning exceeds 90%;

Digital twin interconnection: Virtual debugging technology enables the slide table to complete motion trajectory simulation before production, shortening equipment delivery cycle by more than 50%;

Green energy-saving breakthrough: adopting low resistance guide rails and energy efficiency optimized drive systems, energy consumption is reduced by 35% compared to traditional solutions, responding to the sustainable development needs under the "dual carbon" goal.

Conclusion

From "manufacturing" to "intelligent manufacturing", the linear module slide table is not only the precise cornerstone of automated production, but also a strategic tool for enterprises to improve quality and efficiency, and seize market opportunities. Faced with the vast ocean of intelligent manufacturing, the continuous innovation of linear module technology will surely open up broader imagination space for the global manufacturing industry. In the future, with the deep integration of technologies such as collaborative robots and digital twins, the role of this' invisible pusher 'is destined to shine even brighter.

Guangdong Feske Automation Technology Co., Ltd., as a leader in the field of linear module sliding tables, has always adhered to independent technological research and development, providing customers with customized solutions with high cost-effectiveness. Click on the official website to learn more about industry application cases and embark on your journey of upgrading intelligent manufacturing!