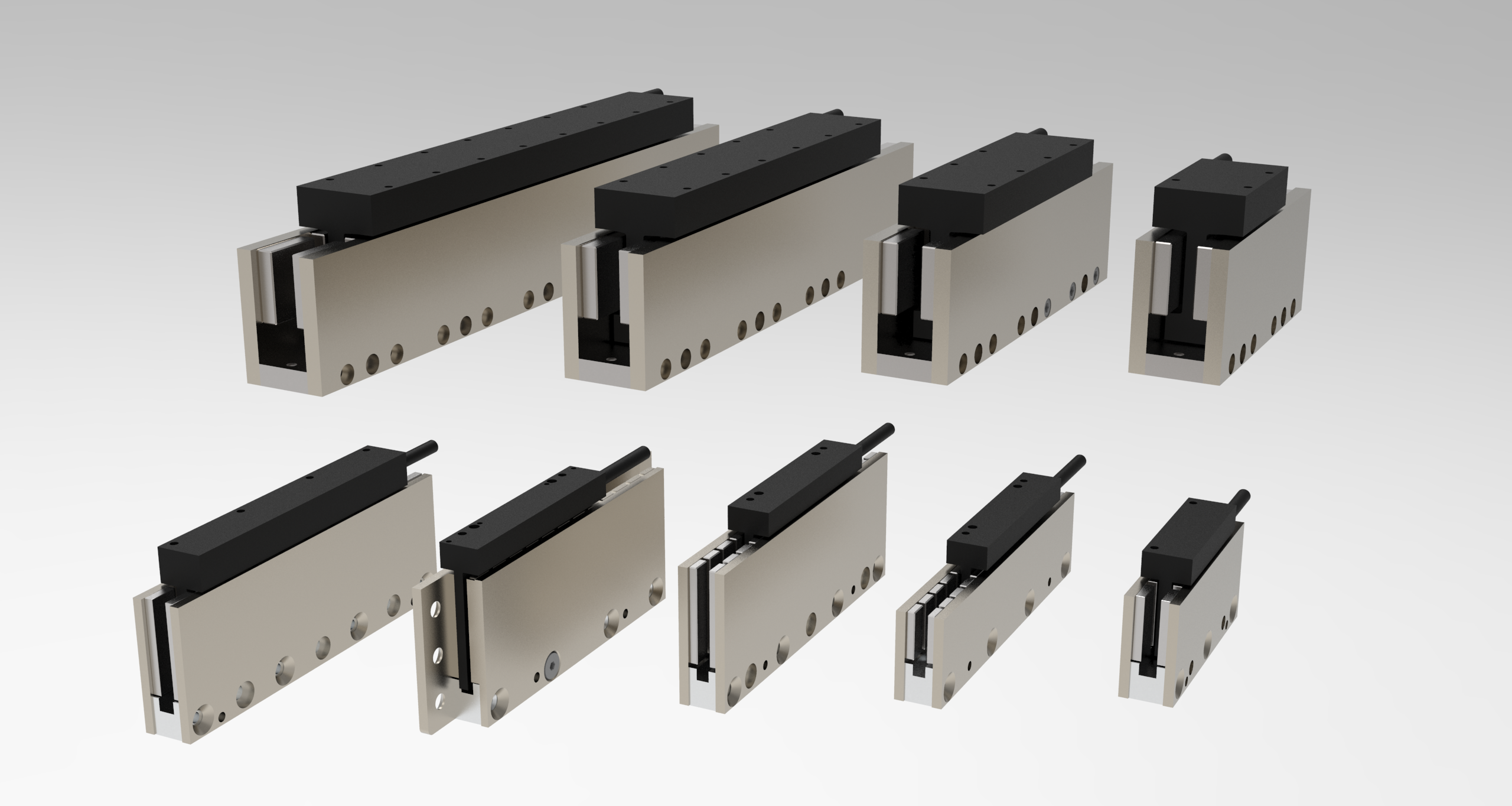

Today, as the wave of Industry 4.0 sweeps across the globe, a technological revolution about "motion control" is quietly rewriting the rules of manufacturing. Linear motor module - this core technology, known as the "industrial robot joint", is causing a wave of applications in high-end fields such as semiconductors, new energy, and biomedicine with its breakthrough performance.

1、 Semiconductor Manufacturing: The Invisible Hand of Nanoscale Precision

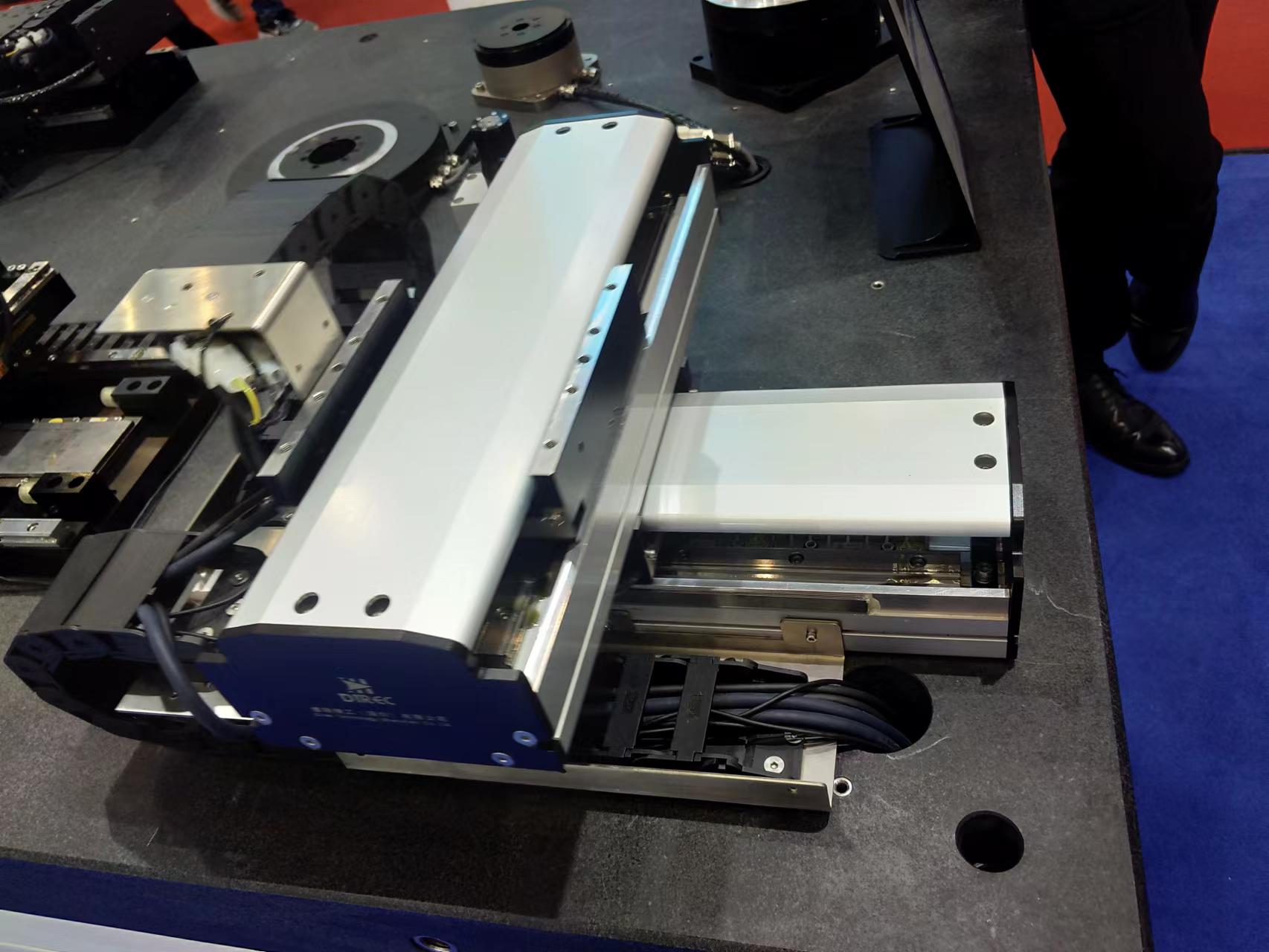

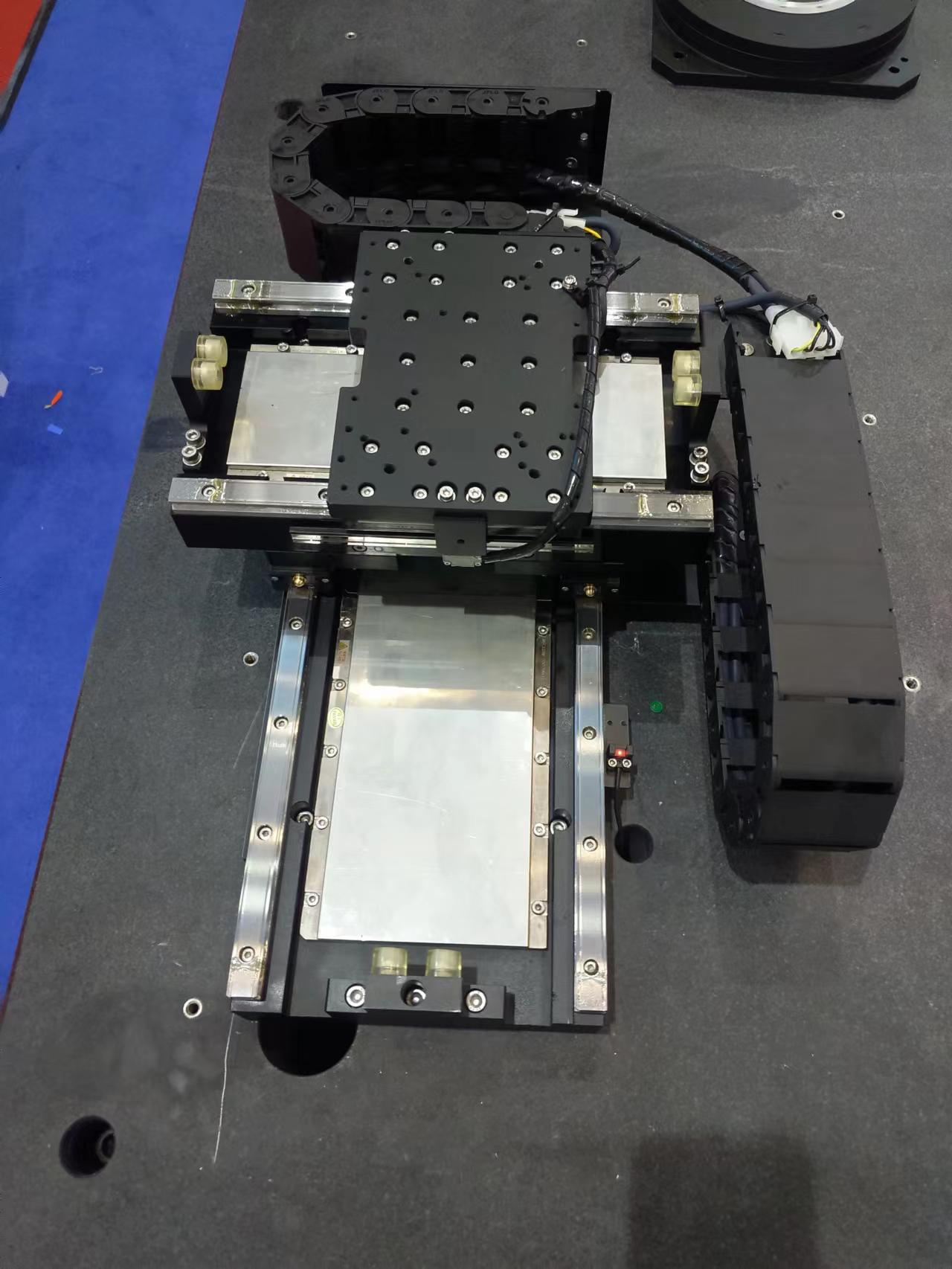

In the vacuum chamber of the chip lithography machine, the linear motor module is completing the "fingertip ballet" of wafer transfer with a repeated positioning accuracy of 0.1 microns. Compared to traditional screw drive, the direct driving characteristics of linear motors completely eliminate backlash, and with the help of air bearing technology, achieve nanoscale motion control in a completely dust-free environment. A semiconductor equipment company in Shanghai revealed that after adopting linear motor modules, the throughput of its wafer inspection equipment has increased by 40%, and the yield rate has exceeded 99.99%.

2、 Lithium battery intelligent manufacturing: the "power heart" with instant response

The explosive growth of the new energy vehicle industry has put forward strict requirements for power battery production equipment. The linear motor module demonstrates amazing strength in the pole ear welding process: with a peak speed of 3m/s and a positioning accuracy of ± 5 μ m, the processing time of each cell is reduced to 0.8 seconds. In the latest super factory put into operation by CATL, the winding machine equipment equipped with linear motors has successfully pushed the production capacity of 21700 cylindrical batteries to a new industry height of 300 units per minute.

3、 Precision medicine: the "intelligent tentacles" of minimally invasive surgery

At the end of the seventh axis of the da Vinci surgical robot, the linear motor module is completing ultra fine operations that are difficult for human doctors to achieve. Through electromagnetic direct drive technology, the module achieves precise torque control of 0.01N within a 3cm stroke, and with the help of an AI vision system, successfully controls the diameter of the prostate biopsy incision within 1.2mm. In Siemens Healthineers' latest generation CT equipment, the detector array driven by a linear motor compresses the imaging time of cardiac imaging to a single cardiac cycle.

4、 Smart Logistics: 24-hour non-stop 'lightning sorting'

In the three-dimensional sorting system of Cainiao unmanned warehouse, a high-speed balance wheel matrix composed of 128 linear motor modules is creating a sorting myth of 80000 pieces per hour. The modular magnetic levitation drive structure not only achieves an astonishing acceleration of 50m/s ², but also operates stably in extreme environments ranging from -20 ℃ to 80 ℃ with IP67 protection level. This system has increased the peak processing capacity of single warehouses by three times during the "Double 11" period, and reduced the manual intervention rate to below 0.3%.

According to authoritative institutions' predictions, the global market size of linear motors will exceed 5 billion US dollars in 2023, with a compound growth rate of 28.6% in the Chinese market. With the development of direct drive technology towards multi degree of freedom and intelligence, linear motor modules are breaking through the constraints of physical boundaries - from precision focusing mechanisms in space telescopes to low-temperature workbenches in quantum computers, this innovative transmission technology is redefining the limits of "precision motion".

On the track of intelligent manufacturing upgrade, linear motor modules are not only the driving force of efficiency revolution, but also the key to unlocking future factories. When traditional transmission methods encounter physical bottlenecks, this "zero contact" driving solution is opening up unprecedented possibilities for industrial automation. As German Industry 4.0 expert Schmidt said, "Whoever masters the high ground of linear drive technology holds the discourse power of the next generation of intelligent equipment