As the core transmission component of industrial automation, linear slide modules have been widely used in the following fields with their high precision, high efficiency and flexible customization:

I. Core application areas

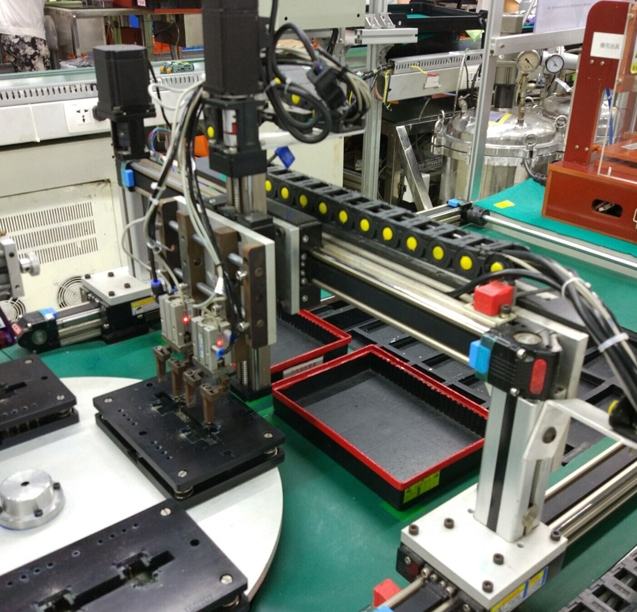

Electronics and semiconductor manufacturing

Chip packaging and patch: Achieve micron-level positioning accuracy for wafer cutting, chip mounting and testing processes 14

Circuit board testing: Cooperate with sensors to complete automated electrical testing and improve yield rate 59

Automobile manufacturing

Welding and assembly lines: Perform high-repetitive precision tasks (such as ±0.05mm) in body welding and engine assembly 12

Parts handling: Transfer and positioning of heavy parts such as car doors and batteries through multi-axis combination 89

General machinery and equipment

Laser processing equipment: Drive the laser head to complete the precise trajectory movement of cutting and welding 38

3D printing and CNC machine tools: Control the print head or tool to achieve complex path processing 39

Packaging and logistics

Automated sorting: High-speed cargo handling (up to 2m/s), integrated visual system recognition and classification 69

Palletizing and packing: Load capacity up to 450kg, replacing manual stacking of heavy objects 10

II. Emerging expansion areas

Medical equipment:

Surgical robot joint drive, biochemical analyzer sample positioning (accuracy ±5μm) 710

New energy and photovoltaics:

Silicon wafer transmission and positioning in solar panel lamination equipment 59

Scientific research experiments:

Simulation of rail transit testing, high-frequency motion control of ocean current research equipment (speed up to 8m/s) 10

III. Technical advantages support application expansion

Advantages Application value examples Source

High-precision positioning (±0.01mm) Chip mounting avoids micron-level deviation 48 48

High-speed response (1–8m/s) Sorting line efficiency increased by 30% 69 69

Flexible multi-axis combination XYZ platform realizes curved surface spraying/inspection 58 58

High load capacity (450kg+) Heavy handling of automotive parts 10 10

IV. Drive system selection reference

Select the drive mode according to the scene requirements:

Ball screw drive: high precision (±0.005mm), heavy load (such as machine tools), high maintenance cost 1314

Synchronous belt drive: long stroke (2.5m), high speed (1.5m/s), suitable for packaging and sorting lines 1314

Linear motor drive: ultra-high speed (8m/s), high-frequency motion (10Hz), used for scientific research equipment 1013