——High precision and intelligent technology empower industrial upgrading

1、 Technological breakthrough: Innovative advantages of servo electric cylinders

With the accelerated advancement of the Industry 4.0 era, servo electric cylinders, with their three core advantages of high precision, high efficiency, and intelligence, are becoming a key technological equipment for upgrading the manufacturing industry.

Precise control: Through the collaboration of servo motors and high-precision encoders, servo electric cylinders can achieve a positioning accuracy of 0.01mm and a force control sensitivity of 0.1N. For example, in the process of fitting mobile phone screens, dynamically adjusting the pressing force can increase the yield rate to 99.5%.

Energy Efficiency Revolution: Compared to traditional hydraulic systems (with an energy efficiency of less than 40%), servo electric cylinders adopt electric direct drive technology, with a comprehensive energy efficiency of over 85%. After being applied in a certain construction machinery enterprise, a single device can save over 20000 kWh of electricity annually.

Quick response: The closed-loop control system of the servo electric cylinder can achieve millisecond level dynamic response, with a speed range covering 0.1mm/s to 2m/s, meeting the requirements of high-speed packaging, precision assembly and other scenarios.

2、 Application scenarios: From traditional manufacturing to emerging fields

The flexibility of servo electric cylinders makes them shine in fields such as industrial automation, robotics, new energy vehicles, aerospace, etc

Industrial automation:

In automobile manufacturing, it is used for engine assembly and component testing, with positioning errors controlled within ± 0.02mm.

In electronic device production lines, high-precision operations such as chip packaging and PCB board soldering are achieved.

Humanoid robot:

Tesla humanoid robots use miniature servo electric cylinders to drive agile hands and joints, integrating reducers, hollow cup motors, and sensors, combining the characteristics of "miniaturization" and "high load".

New energy vehicles:

In the assembly of power batteries, servo presses use high-precision pressing technology to improve the battery pack life and increase the yield rate by 30%.

Aerospace:

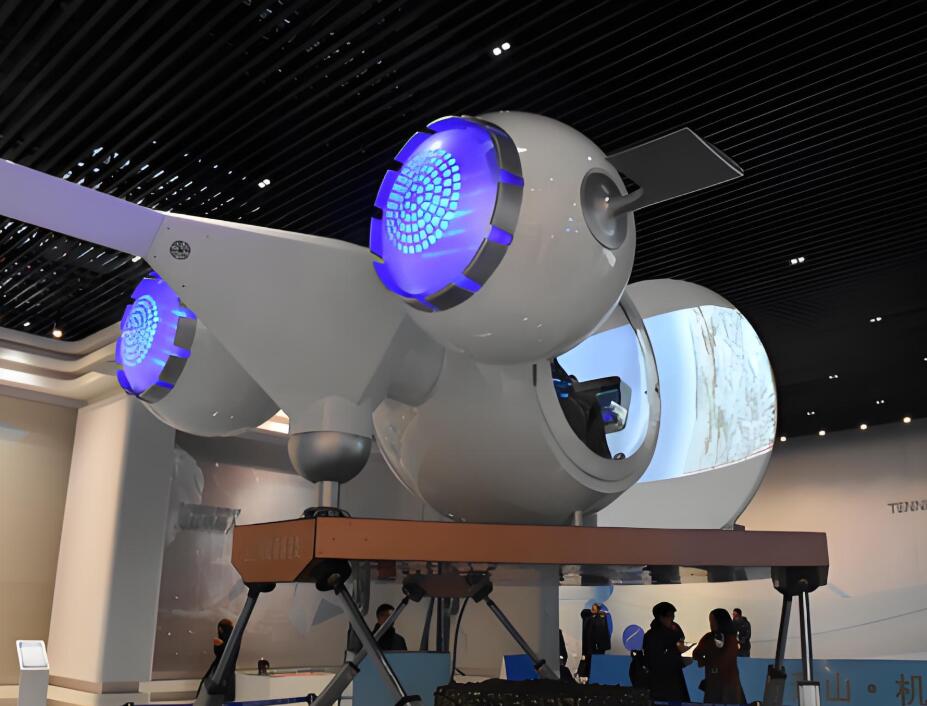

Used for satellite deployment mechanisms, spacecraft attitude adjustment, and withstanding extreme temperature differences and vacuum environments.

3、 Industry benchmark case: Practical verification of technology implementation

Sany Heavy Industry: In excavator boom testing, servo electric cylinders replaced traditional hydraulic systems, saving over 20000 kWh of electricity per unit per year and reducing maintenance costs by 60%.

4、 Future prospects: Integration of intelligence and ecology

With the penetration of 5G and AI technologies, servo electric cylinders will evolve towards networked and adaptive control:

Predictive maintenance: Real time monitoring of device status through the Internet of Things, early warning of faults, and reducing downtime losses.

Multi axis collaboration: In smart factories, multiple servo electric cylinders can synchronously execute complex trajectory movements to meet the needs of flexible production.

Conclusion

Servo electric cylinder is not only the "core joint" of industrial automation, but also the core driving force for promoting the transformation of manufacturing towards green and intelligent. In the future, with technological iteration and scenario expansion, this technology will continue to unleash its potential and inject new momentum into global industrial upgrading