In recent years, with the rapid development of industrial automation, robotics technology, and high-end equipment manufacturing, servo electric cylinders, as the core components of precision linear motion control, are penetrating from traditional industrial fields to a wider range of industries. With advantages such as high precision, energy conservation and environmental protection, and intelligence, servo electric cylinders are regarded as one of the key technologies that will change the manufacturing industry landscape in the next decade. Industry forecasts suggest that the global servo electric cylinder market will exceed $5 billion by 2030, with a compound annual growth rate of over 12%. Its technological iteration and innovative application scenarios have become the focus of market attention.

Technological Innovation: From Hardware Breakthrough to System Integration

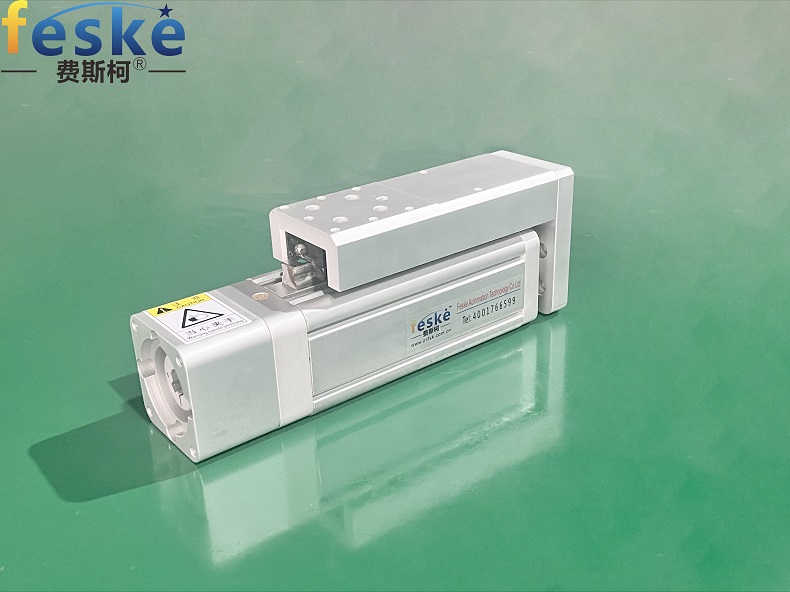

The evolution of servo electric cylinders is first reflected in breakthroughs in core technologies. Traditional electric cylinders rely on a simple combination of servo motors, ball screws, and sensors, while the new generation of products is upgrading towards "lightweight, modular, and intelligent" direction. For example, using carbon fiber composite materials instead of metal shells can reduce weight by 30% while maintaining strength; Integrating high-precision magnetic encoders and AI algorithms, the positioning accuracy reaches ± 0.01 millimeters, and the response speed is improved to millisecond level.

What deserves more attention is the solution that integrates software and hardware. International leading enterprises such as SMC and Thomson have launched intelligent electric cylinders with built-in edge computing units, which can analyze load changes in real time and adjust output parameters independently. The intelligent electric cylinder products recently released by Bosch Rexroth in Germany even support seamless integration with the Industrial Internet of Things (IIoT) platform, enabling remote diagnosis and predictive maintenance, significantly reducing equipment downtime risks.

Application scenario: From industry to people's livelihood, cross-border integration accelerates

The application boundaries of servo electric cylinders are being redefined. In the field of new energy vehicles, Tesla's Gigafactory integrates servo electric cylinders into battery module assembly lines, increasing production line cycle efficiency by 40%; The medical industry leverages its high cleanliness characteristics to promote the upgrading of equipment such as surgical robots and CT positioning systems. The medical grade electric cylinder developed by Yamaha in Japan has passed ISO 13485 certification and has been successfully applied to the joint drive module of the da Vinci surgical robot.

The explosive growth of the civilian market is even more remarkable. In the field of smart homes, servo electric cylinders have become the core driving components of high-end electric beds and intelligent lifting tables. The annual sales growth of LINAK's household product line has exceeded 200%. In the aerospace field, the customized high-pressure electric cylinder in the fuel valve control system of SpaceX starship spacecraft solves the precise control problem in extreme environments, marking the official entry of this technology into space exploration scenarios.

Green Revolution: Energy Efficiency Upgrade Promotes Sustainable Development

Driven by the global carbon neutrality goal, the energy-saving advantages of servo electric cylinders are further highlighted. Compared with traditional hydraulic systems, it reduces energy consumption by 60% -70% and completely avoids oil contamination. The latest Industrial Energy Efficiency Directive issued by the European Union has included electric cylinders as a recommended alternative solution. The stamping workshops of German car companies such as Volkswagen and BMW have reduced carbon emissions by up to 800 tons per year on a single production line by fully replacing hydraulic drive equipment.

Chinese companies are also rapidly rising on this track. The rare earth permanent magnet synchronous motor developed by Huichuan Technology drives the electric cylinder, with an energy efficiency conversion rate exceeding 92%; Eston's regenerative braking energy recovery system can convert the kinetic energy of equipment braking into electrical energy storage, reducing overall energy consumption by another 15%. This technological breakthrough not only responds to the global demand for emission reduction, but also makes servo electric cylinders a new hotspot for ESG (Environmental, Social and Corporate Governance) investment.

Future challenges and opportunities

Despite its broad prospects, servo electric cylinders still face challenges such as cost control and standardization. At present, the high-end market is still dominated by Japanese and German companies, but Chinese manufacturers are narrowing the gap through vertical integration of the industrial chain. For example, the planetary roller screw electric cylinder launched by Changzhou Kaide has achieved import substitution in the 3C electronics industry, reducing costs by 35% while maintaining the same performance.

Industry experts pointed out that with the popularity of 5G+industrial Internet, servo electric cylinder will be deeply integrated into intelligent manufacturing scenarios such as digital twins and virtual debugging. In the future, "cognitive electric cylinders" with self-learning capabilities may emerge, which can achieve cross device collaborative work through real-time data interaction and truly become the "flexible joints" of smart factories.

It can be foreseen that at the intersection of manufacturing transformation and upgrading and the global energy revolution, servo electric cylinders are evolving from a single executing component to a "hidden engine" driving industrial change. This innovation led by precision control technology may redefine the efficiency and possibilities of industrial production.