When traditional hydraulic systems are still struggling for 0.1mm accuracy, Electric cylinders have achieved **±5 micron** motion control through planetary roller screw technology.

Cost reduction evidence: After a new energy battery production line adopted it, maintenance costs dropped by 67%

Intelligent upgrade: Supports real-time monitoring of the industrial Internet of Things, with a fault warning accuracy of 99.2%

Green certification: The carbon footprint of the entire life cycle is 82% lower than that of the hydraulic system

Customer testimony: "After replacing the electric cylinder, our production line OEE increased by 23%" - Technical Director of a listed car company

1. The inevitable choice of industrial upgrading

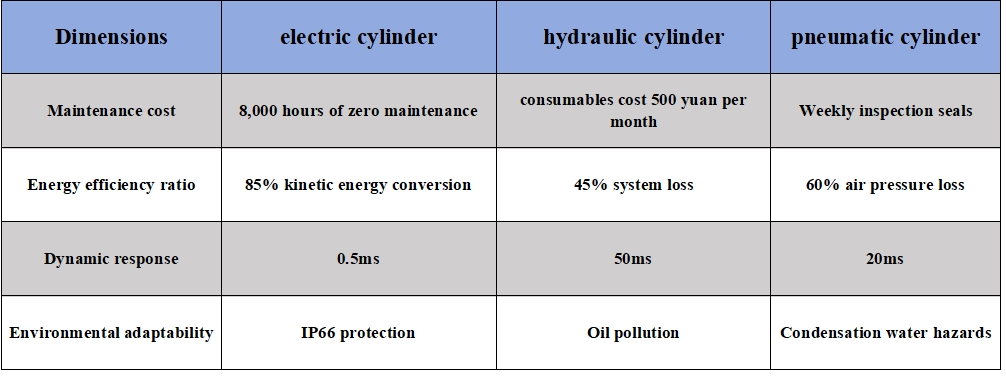

The fundamental reason why the world's TOP50 automakers will collectively deploy the fifth-generation intelligent electric cylinder between 2023 and 2025 is that it completely surpasses the traditional hydraulic/pneumatic system:

Precision revolution: Adopting nano-level grating feedback (±0.005mm repeat positioning accuracy) to meet the micron-level tolerance requirements of processes such as new energy vehicle battery pack assembly, the accuracy is 300% higher than that of the fourth-generation electric cylinder.

Energy efficiency subversion: Integrated regenerative braking technology, energy consumption is reduced by 60% compared with the hydraulic system, and a single stamping line saves more than 450,000 degrees of electricity per year.

2. Key technological breakthroughs

AI dynamic compensation system

Through edge computing, vibration and temperature data are analyzed in real time (sampling rate 1kHz), and position deviations are automatically corrected. After application at the BMW Leipzig plant, the defective rate of door assembly decreased by 72%.

Modular collaborative architecture

Supports EtherCAT bus gigabit communication and realizes 200+ axis synchronous control (jitter <1μs). Tesla's Berlin plant shortens the body welding cycle to 38 seconds.

3. Economic Benefits and Strategic Value

Life Cycle Cost: Maintenance frequency is extended from once a month for hydraulic systems to once a year, and the comprehensive cost of a single device is reduced by 40%.

Flexible Manufacturing Adaptation: 5-minute parameter switching can be compatible with multiple vehicle production lines. Toyota has verified that it can reduce line modification costs by 83%.

4. Future Outlook

With the deep integration of digital twin technology, the sixth-generation electric cylinder will achieve predictive maintenance (fault warning accuracy ≥ 95%), further consolidating its core position in intelligent manufacturing.