The core difference between electric cylinder and servo motor lies in the form of motion, structural

composition and application scenarios. The specific comparison is as follows:

⚙️ 1. Essential functional differences

Movement form

Electric cylinder: Converts rotary motion into precision linear motion, and outputs precise thrust or pull

through transmission mechanisms such as screws and synchronous belts. 12

Servo motor: Directly outputs controllable rotary motion to achieve high-precision angle, speed and

torque control. 1820

Structural composition

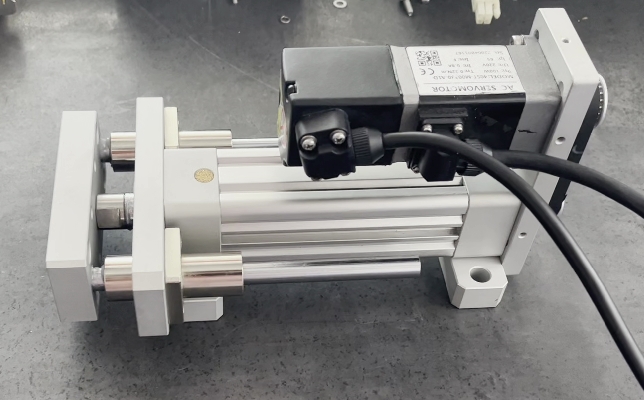

Electric cylinder: It is an integrated module that includes servo motor, transmission mechanism (ball

screw/synchronous belt/planetary roller screw), guide device and other components. 315

Servo motor: An independent unit, the main body contains motor, encoder, and driver, and requires

an external mechanical structure (such as coupling, gear) to drive the load. 1620

🏭 2. Comparison of application scenarios

Equipment type Applicable scenarios Typical fields Electric cylinder High-precision linear push-pull,

positioning CNC machine tool feeding, robotic arm joints, automated assembly lines38

Servo motor Rotational motion control (continuous speed regulation, angle positioning) Robot joints,

conveyor belt drives, precision turntables1820

⚖️ 3. Differences in performance characteristics

Accuracy and response Electric cylinder: Linear positioning accuracy can reach ±0.01mm, thrust control

accuracy ±1% (pressure sensor required), response speed is affected by lead (the larger the lead, the

faster the movement speed at the same speed)1421.

Servo motor: Rotational positioning accuracy reaches arc seconds, fast dynamic response (small

electromechanical time constant), suitable for high-speed continuous motion1619.

Load capacity Electric cylinder: Wide thrust range (up to 114,000N), strong impact resistance, suitable

for heavy-load linear push-pull1315.

Servo motor: stable output torque, strong overload capacity (can withstand 3 times rated torque)22.

Environmental adaptability Electric cylinder: high protection level (IP66), corrosion-resistant, suitable for

harsh environments such as oil, moisture, etc.2122.

Servo motor: requires additional protection, generally not suitable for direct exposure to highly polluted

environments22.

🔧 4. Technical relevance Electric cylinder is essentially an extension of the function of servo motor:

servo motor is the core driving source of electric cylinder, and its rotational output is converted into

linear motion through the transmission mechanism. Therefore, the performance of electric cylinder

(such as thrust, speed) is directly affected by the parameters of servo motor, and the thrust calculation

formula is:

F = 2π × η × i × T × 1000 / Ph

(η: transmission efficiency; i: reduction ratio; T: motor torque; Ph: screw lead)623.

💎 Summary

Comparison Dimensions Electric Cylinder Servo Motor

Core Functions Linear Motion Control Rotary Motion Control

System Composition Servo Motor + Transmission Mechanism + Guide Device Motor Body + Encoder +

Driver

Advantage Scenarios Precision Push-Pull, Heavy-Load Linear Positioning High-Speed Rotation, Continu

ous Angle Adjustment

Dependency Requires Servo Motor Drive Can Be Independent or as a Power Source for Electric Cylinders

In short, the servo motor is the power core, and the electric cylinder is its integrated actuator for linear

motion. The two work together to meet complex automation needs