The application of intelligent servo presses in industrial automation relies primarily on their high

precision, programmable control, and flexible production capabilities. Specific application scenarios are as follows:

I. Core Application Areas

Automotive Manufacturing

Key Component Pressing: Used for precision press-fitting of engine components (such as crankshaft

bearings) and body structural parts (such as door hinges), with pressure control accuracy reaching 0.1%,

ensuring assembly consistency.

Power Battery Production: Achieves millimeter-level positioning during the stamping and lamination of

lithium battery pole pieces, preventing damage to the electrode active material and increasing

production efficiency by 30%.

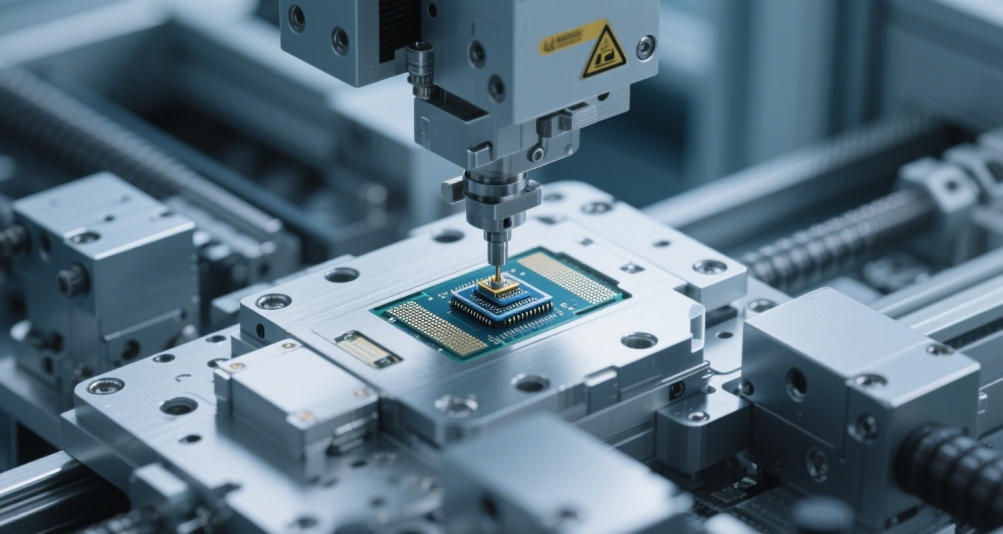

Electronic Component Manufacturing

Micro-Component Assembly: In chip packaging and sensor placement, micron-level displacement

control (with a repeatability of ±5μm) reduces assembly defects in micro-capacitors and resistors.

Connector Pressing: Servo presses offer programmable press stroke and force adjustment, accommo

dating various USB connector and FPC cable terminal specifications.

Aerospace and Precision Machinery

Turbine Blade Forming: Titanium alloys Real-time adjustment of the pressure curve during hot pressing

of blades prevents material stress cracks.

Bearing Preload Control: A closed-loop feedback system precisely applies bearing preload, extending

the life of high-end machine tool spindles.

II. Technological Advantages Drive Innovation

Flexible Production: Programs can quickly switch press parameters, supporting small-batch orders for

multiple varieties. For example, a single production line can handle both mobile phone case stamping and automotive brake pad molding.

Energy Efficiency Optimization: Servo motors consume energy only when in motion, and a sleep mode

reduces standby power consumption, saving over 40% compared to traditional hydraulic presses.

Data Fusion Application: Integrated IoT sensors enable real-time monitoring of the press process, and

big data analysis predicts mold wear trends, reducing unplanned downtime.

III. Future Development Trends: Intelligent servo presses are being integrated with digital twin techno

logy. For example, simulating stamping process parameters in a virtual environment optimizes actual

production line setup cycles. Furthermore, modular design is gaining popularity. For example, desktop

precision servo presses are already used for laboratory prototyping and small part trial production.