Pressure 0-300KG

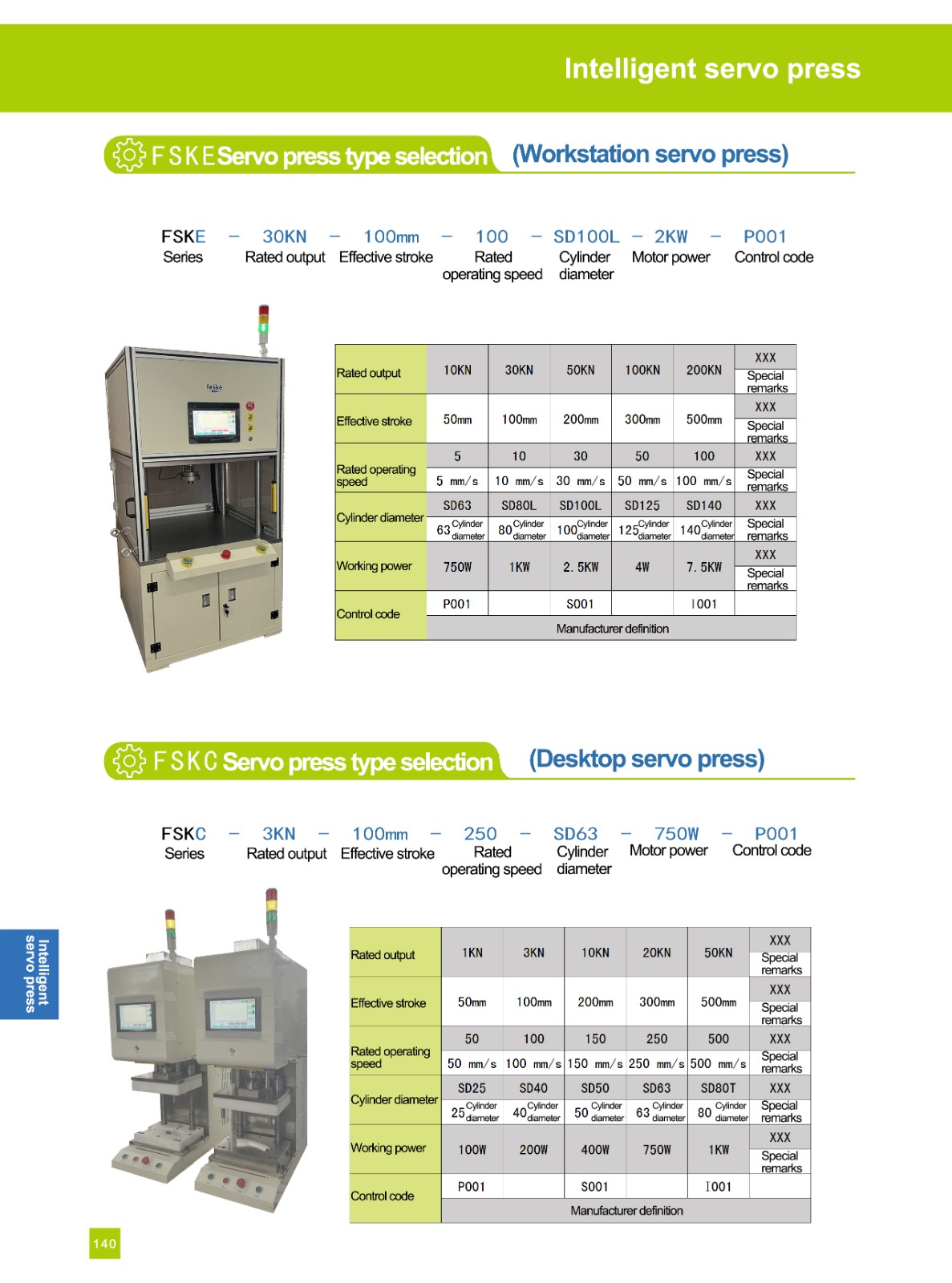

Model: FSKC desktop servo press

Repeat positioning accuracy: +0.02 mm

Pressure accuracy:0.5%FS

Customized stroke: within 350MM

Composition structure

Manual mode, automatic mode

Monitoring display, program setting

Massive variety, diverse processes

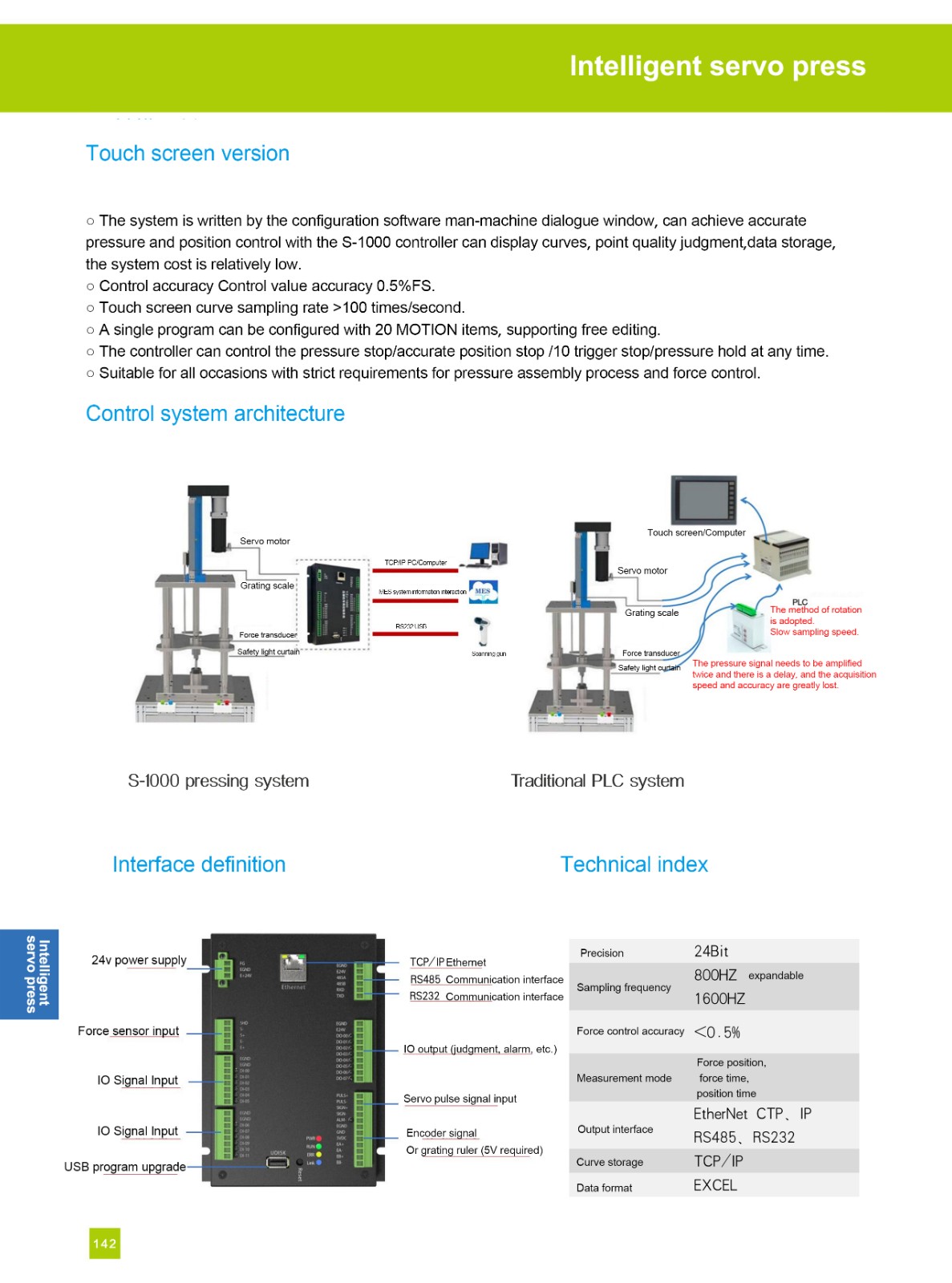

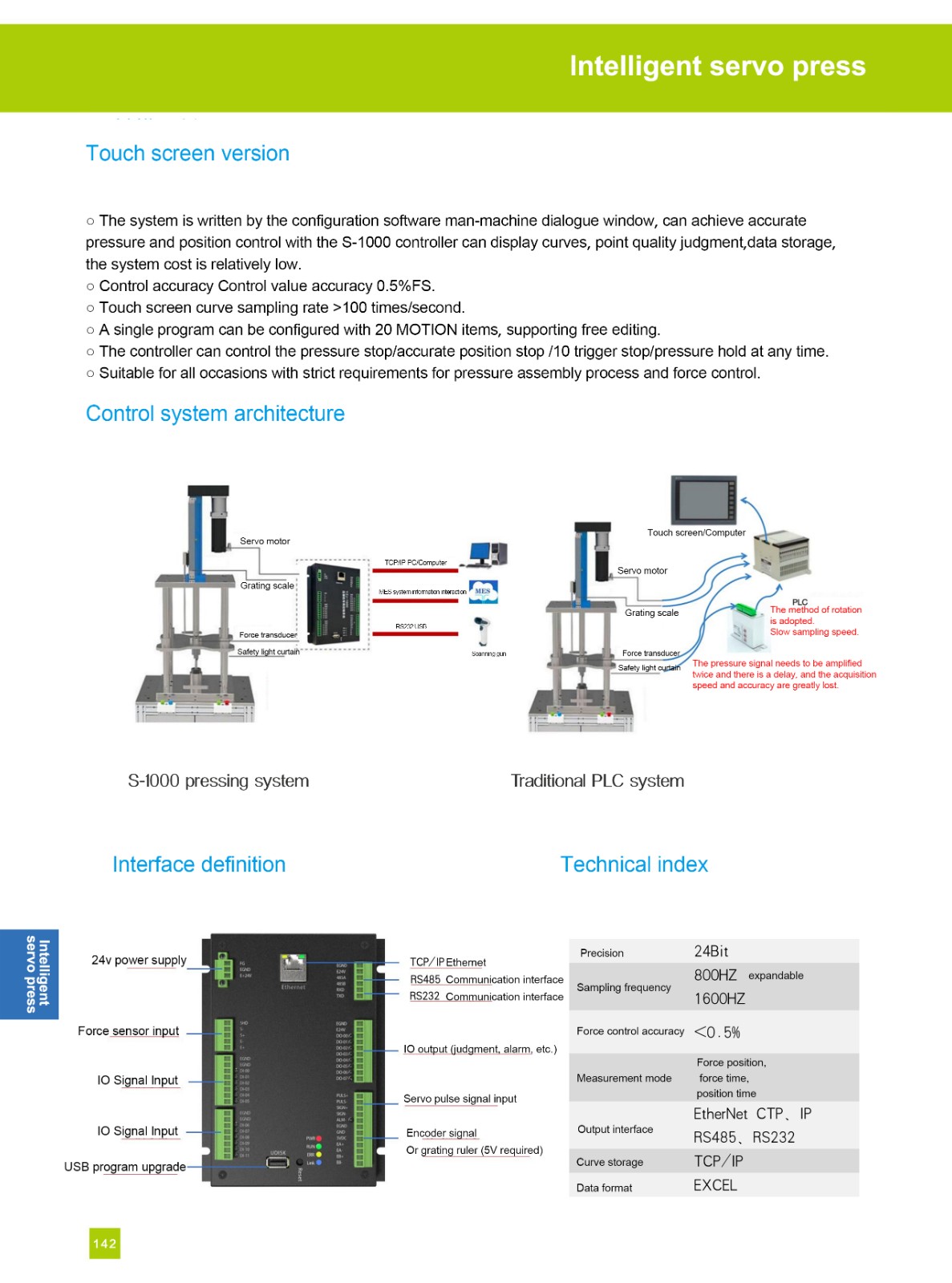

S-1000 Series Intelligent Pressing Controller

S-1000 is a motion controller specially tailored for servo presses based on ARM Cortex-M4 processing chip. The controller sends pulse signals to control the servo motor to achieve precise control of position and pressure.

*Built-in imported 24-bit ADC acquisition chip can collect mV-level force sensor signals more accurately and quickly

*Closed-loop control with a maximum sampling frequency of 1600HZ:

*The maximum force resolution is 1/100000, and the control force value accuracy is 0.5%FS:

*The controller contains multiple communication methods, such as RS485, RS232, and TCP/IP communication:

*Accepts high-resolution grating rulers or servo drive encoder signals with AB orthogonal encoding signals, with a displacement control accuracy of 0.01mm;

*The largest multi-functional I/0 interface, real-time interactive system operation status and external control signals, can be coordinated with cylinder clamping, positioning and other actions

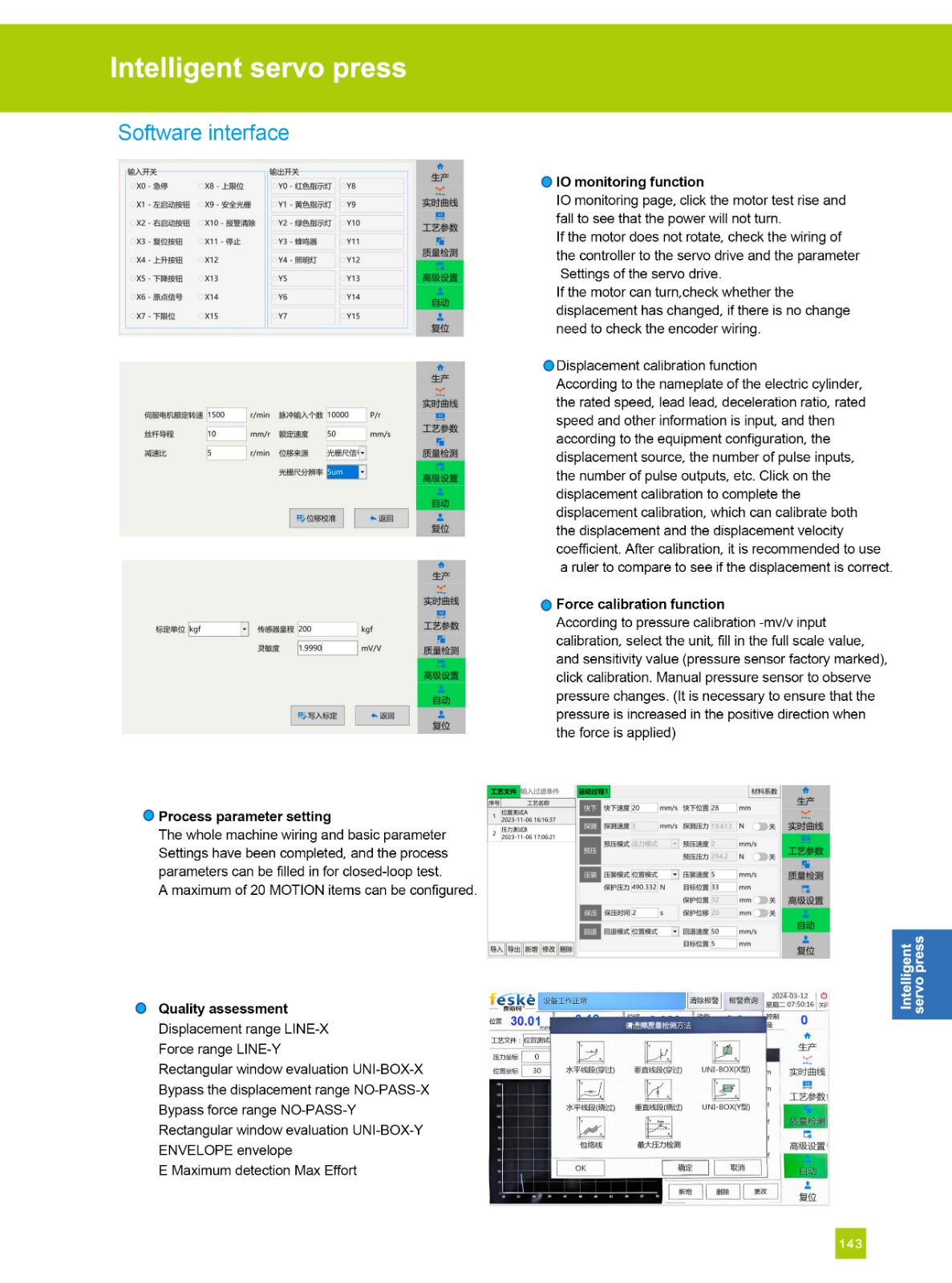

Features:

The equipment is sturdy and reliable, and the equipment platform is easier to use:

The repeatability can reach ±0.02mm;

Pressure detection accuracy ±2%

Information management

Good flexibility

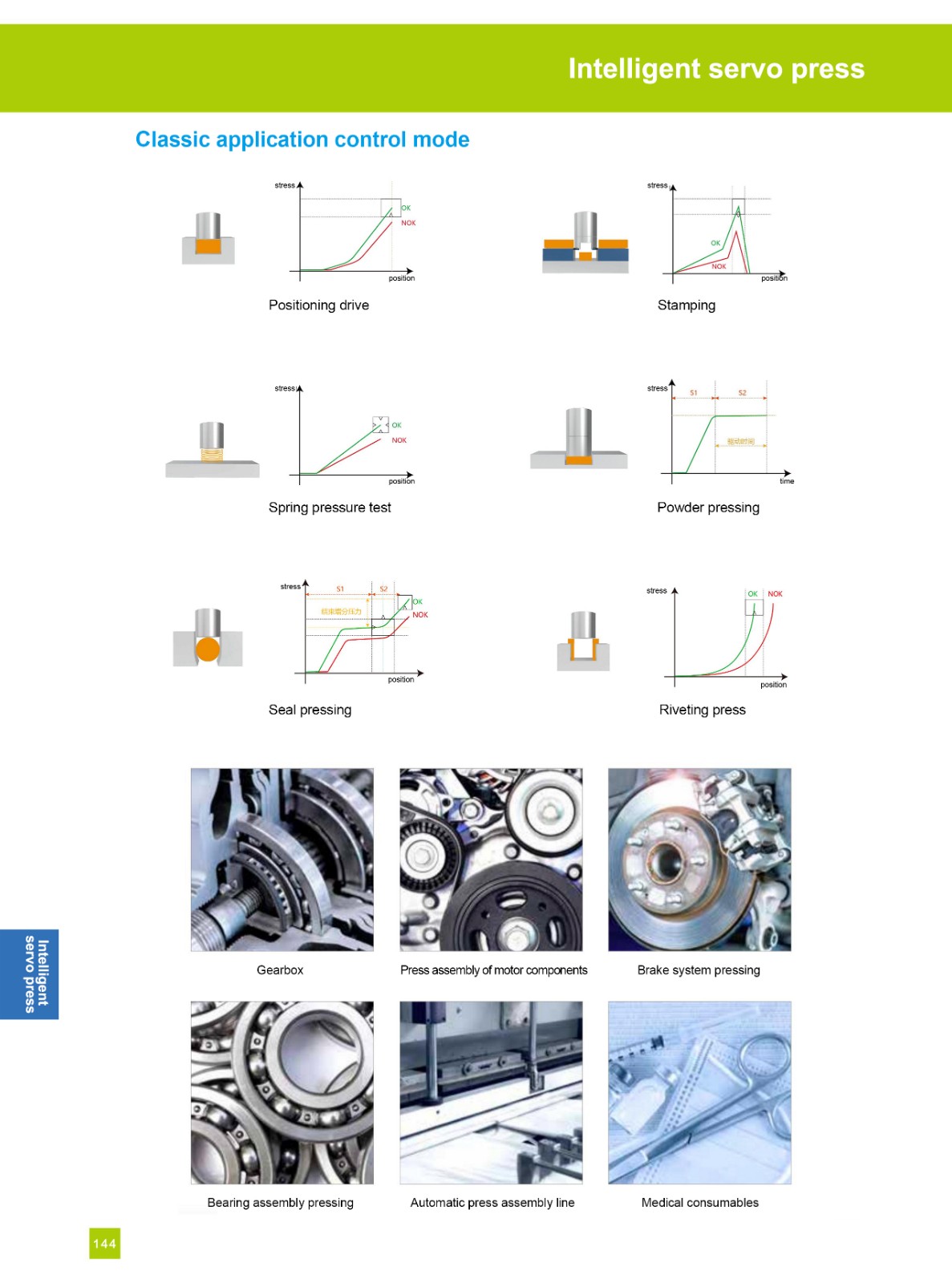

It can adapt to a variety of products, switch the target program by itself, and achieve flexible production requirements. High-speed and high-height press-fitting process multi-stage speed setting ensures that the assembly process is controllable:

The interface is easy to operate. Users can input parameters such as speed, displacement, pressure, etc. to achieve intelligent flexible output curves, which is easy to use

Structure

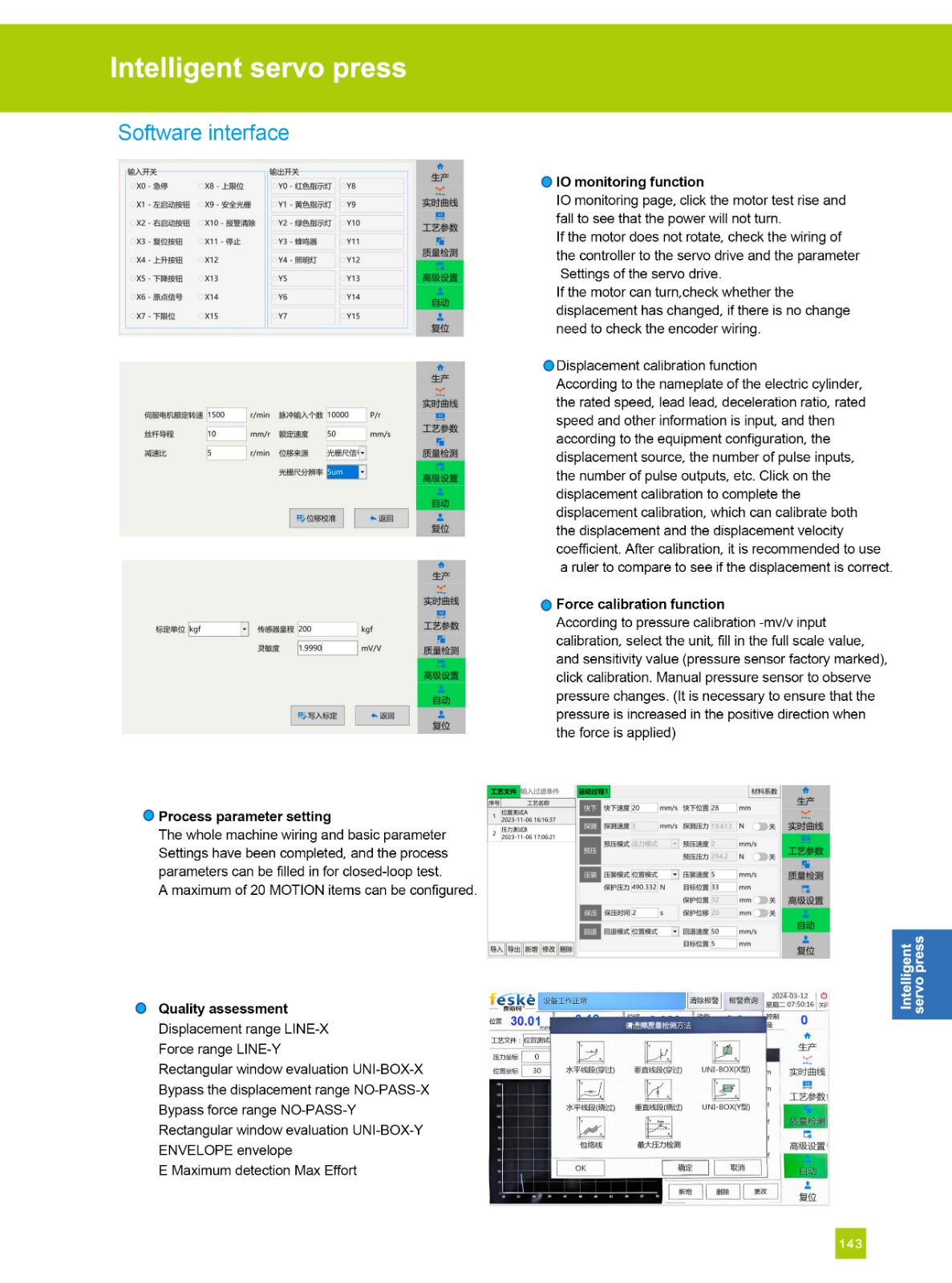

Manual mode: you can manually set and adjust the relevant parameter information

Automatic mode: start the button, the servo press starts to run according to the set parameters and operates automatically

Monitoring display: monitor the entire pressing process of the servo press, count production information, and generate pressure curves

Program setting: allow editing and running programs and setting judgment conditions:

Massive variety: you can easily call the set programs, massive storage space, to adapt to different specifications of press products

Various processes: in the process of press assembly, you can set a variety of conditions, such as: segmented control of the speed of press; fast, slow, precise and other types of press; press stop position setting, you can accurately set the position of press and precisely control it; pressure control, you can also set the pressure for press.

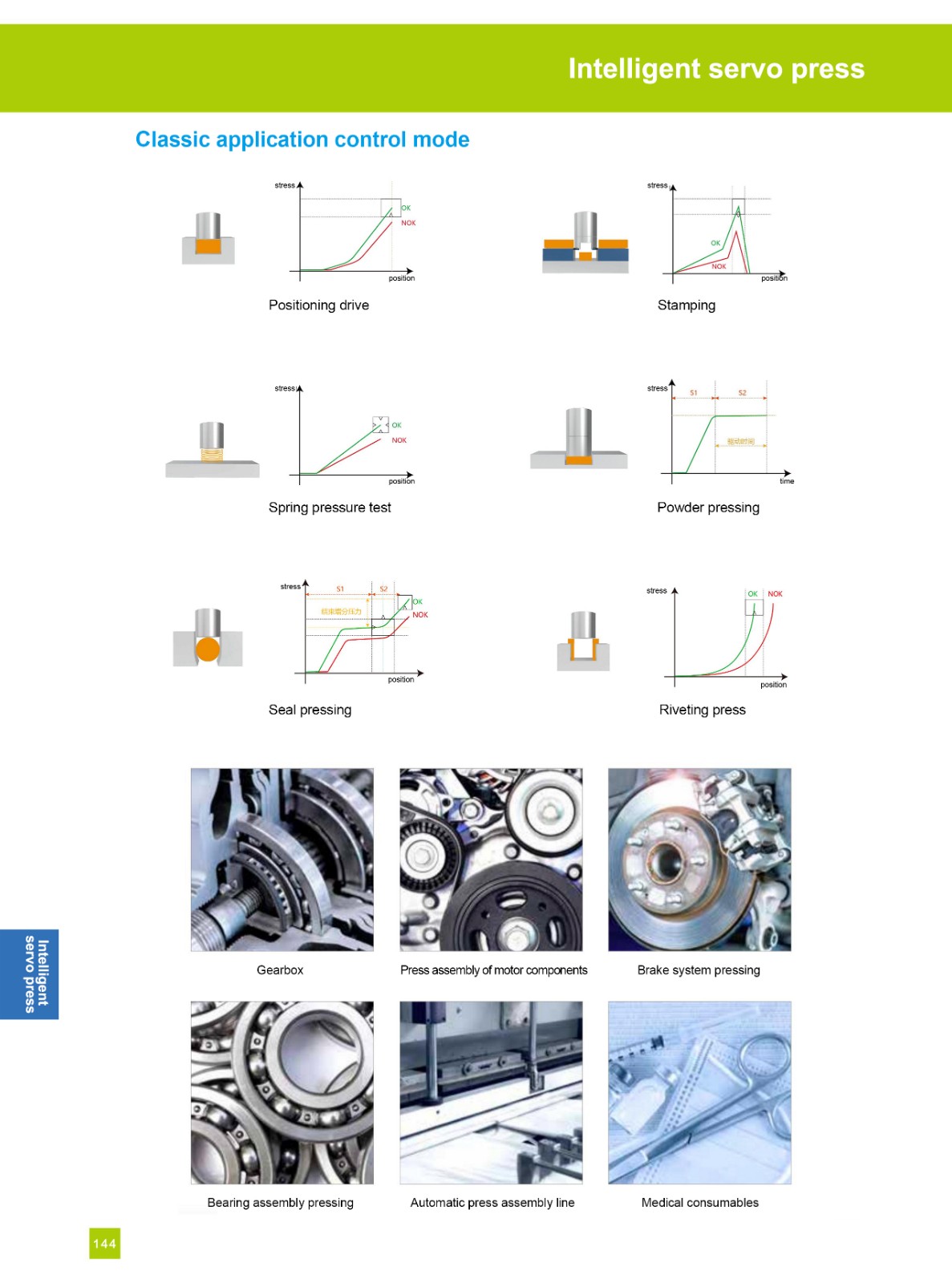

Compared to traditional hydraulic presses, the column-mounted high-precision intelligent servo press offers the following significant advantages:

1. High-Precision Control: Utilizing servo motor drive and high-precision ball screws, the repeatability reaches ±0.01mm, meeting the requirements of precision assembly. The closed-loop control system monitors pressure and displacement in real time, ensuring stable pressing and preventing product defects.

2. Energy Saving and Environmental Protection: The servo motor supplies power on demand, reducing energy consumption by more than 30% compared to traditional hydraulic presses.

The servo press avoids the risk of hydraulic oil leakage, reducing environmental pollution and maintenance costs.

3. Intelligent and Automated: Supports PLC or CNC control, can store pressing data and generate force-displacement curves, enabling quality traceability. Online monitoring and audible/visual alarm functions enhance production safety.

4. Flexibility and Efficiency of Servo Presses: Servo presses' adjustable programs meet the needs of multi-variety, small-batch production and allow for rapid switching of process parameters. The column-type structure (C-type or four-column) provides highly rigid support, making servo presses suitable for large-tonnage (1-30 tons) metal or plastic molding.

5. Low Maintenance Costs of Servo Presses: The simplified mechanical structure eliminates the need for regular hydraulic system oil and seal changes, significantly reducing maintenance workload. Some servo press models utilize a block-type stroke adjustment mechanism to prevent thread wear and extend equipment life.

6. Wide Applications of Servo Presses: Servo presses are suitable for high-precision applications such as automotive parts (bearings, gears), electronic components, and aerospace.

7. Cost-Effectiveness of Servo Presses: Although the initial investment is higher, long-term operating costs (energy consumption, maintenance) are lower, resulting in a shorter payback period.

In conclusion, this ervo press machine surpasses traditional hydraulic presses in terms of precision, efficiency, environmental friendliness, and intelligence, making it an ideal choice for upgrading intelligent manufacturing.