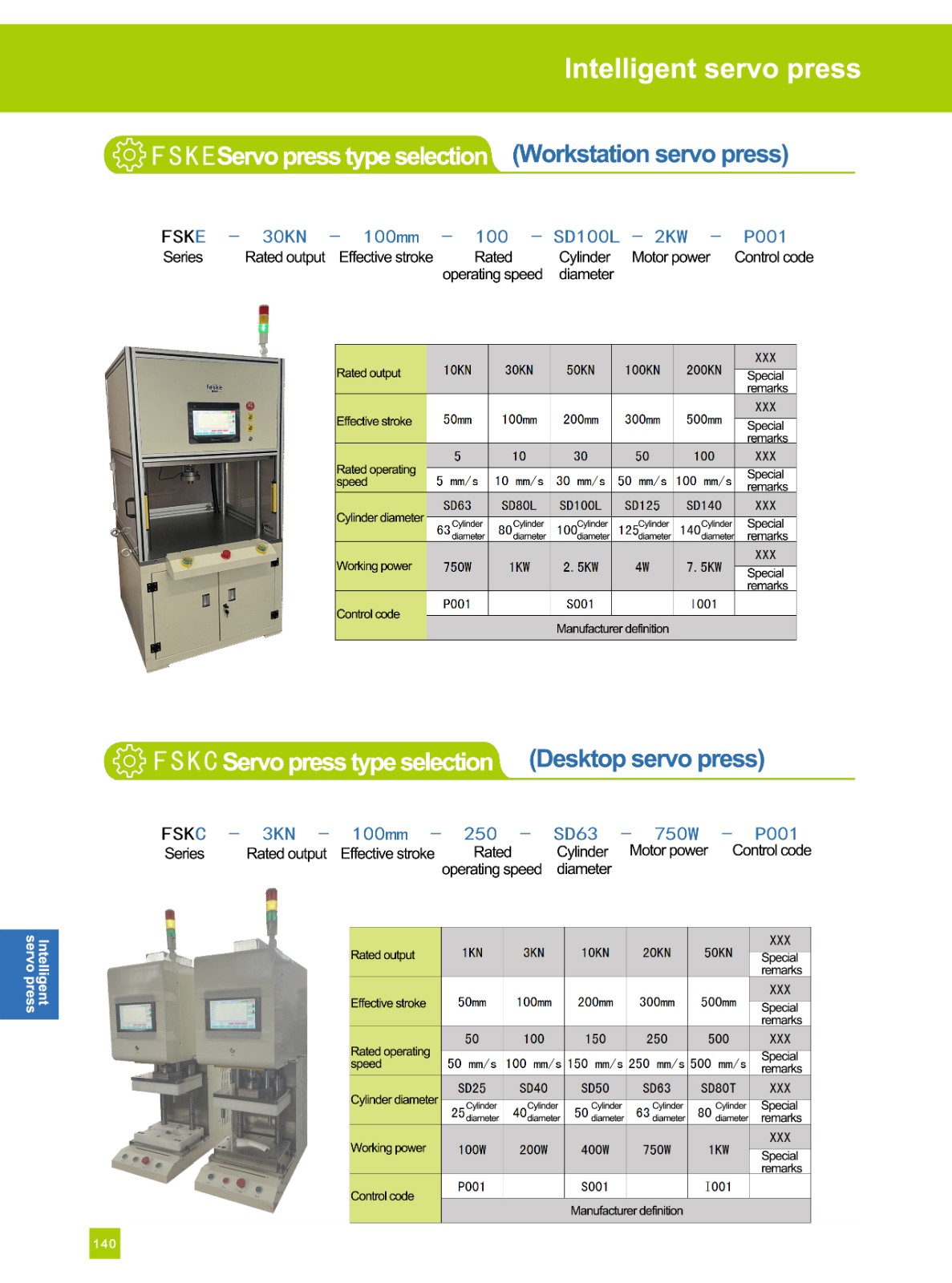

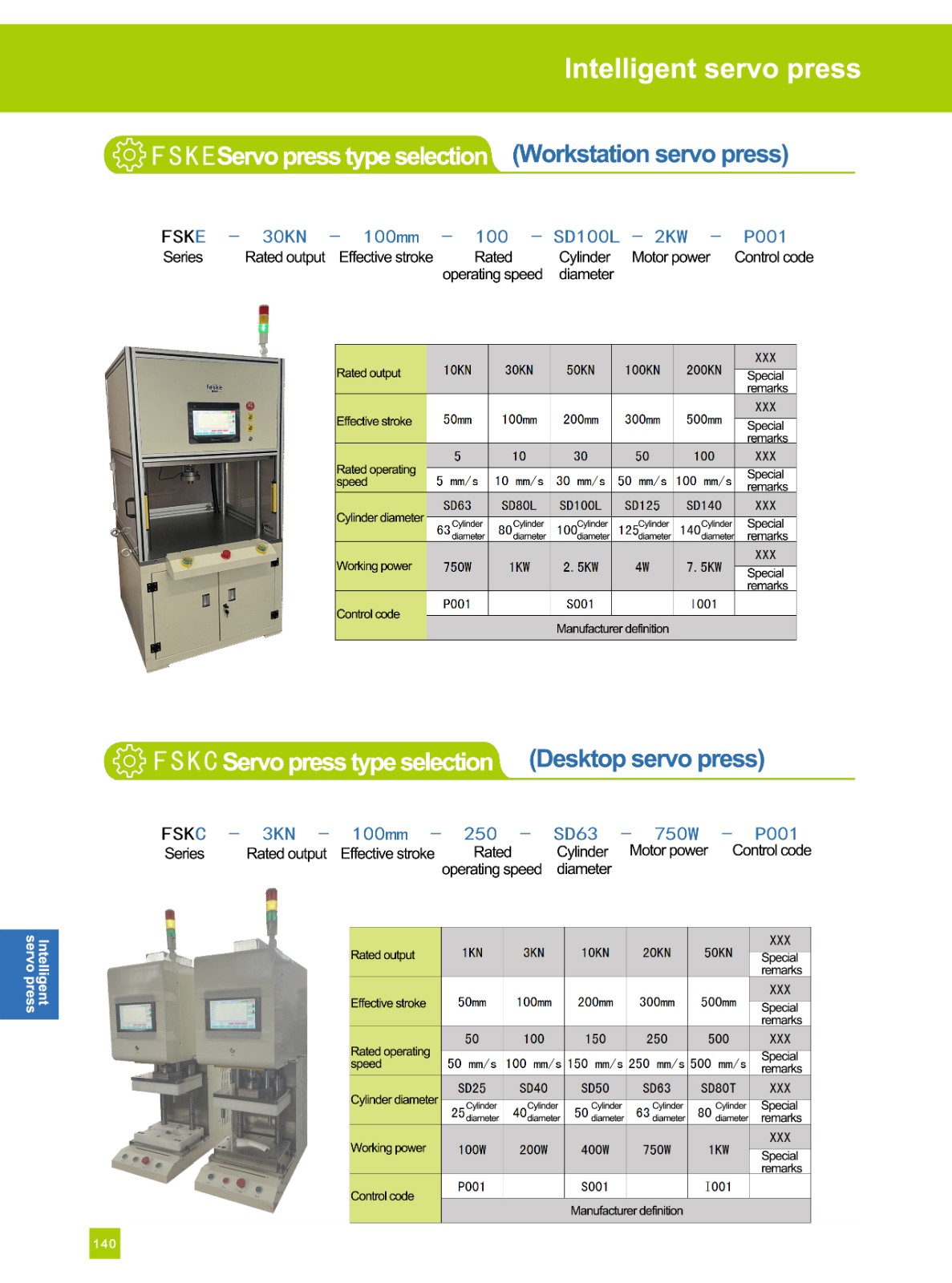

FSKC(Series) — 3KN (Rated output) — 100mm(Effective stroke) — 250(Rated operating speed) — SD63( R cylinder diameter) — 750W (Motor power) — PO01(Control code)

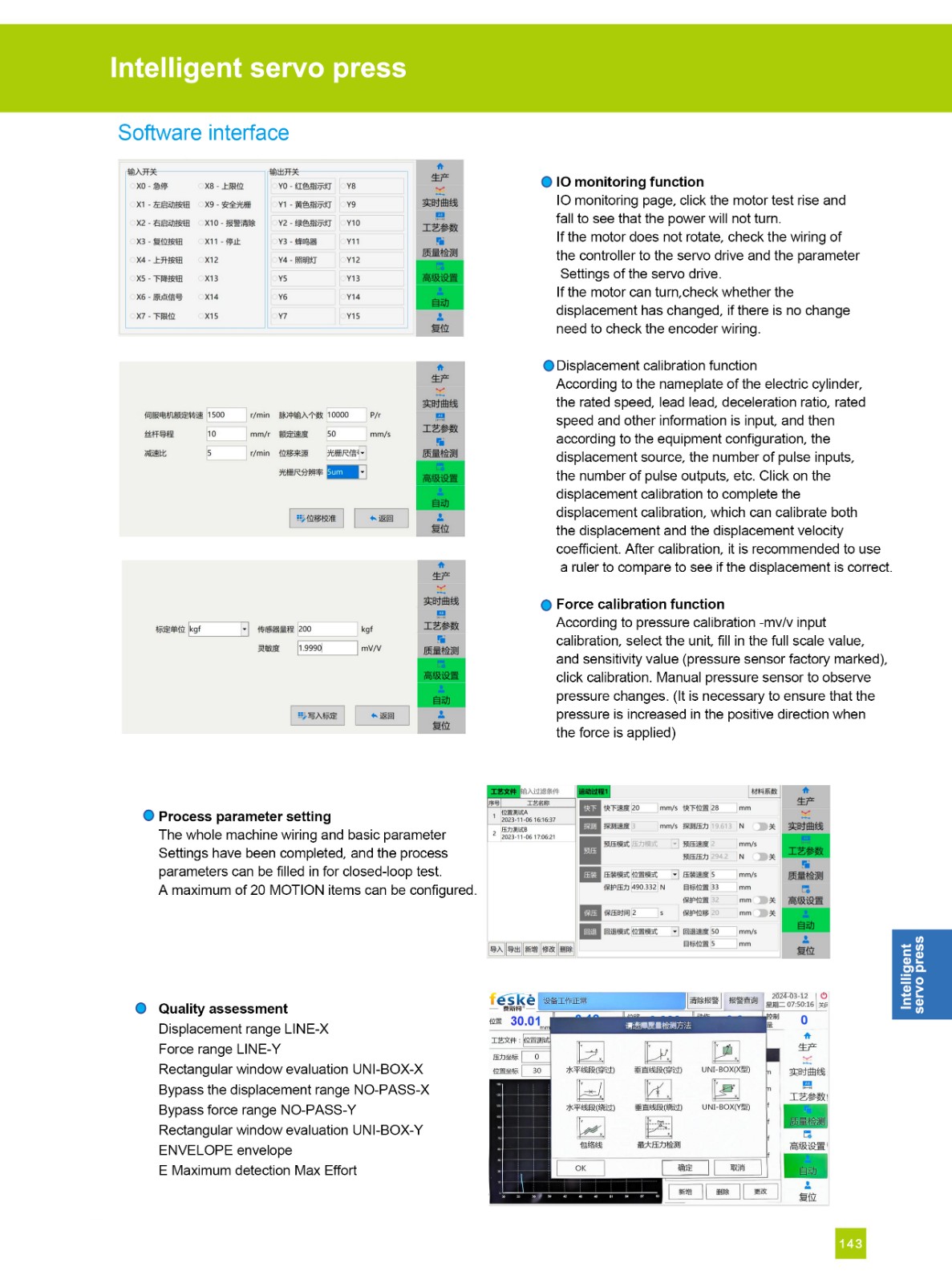

Software functions

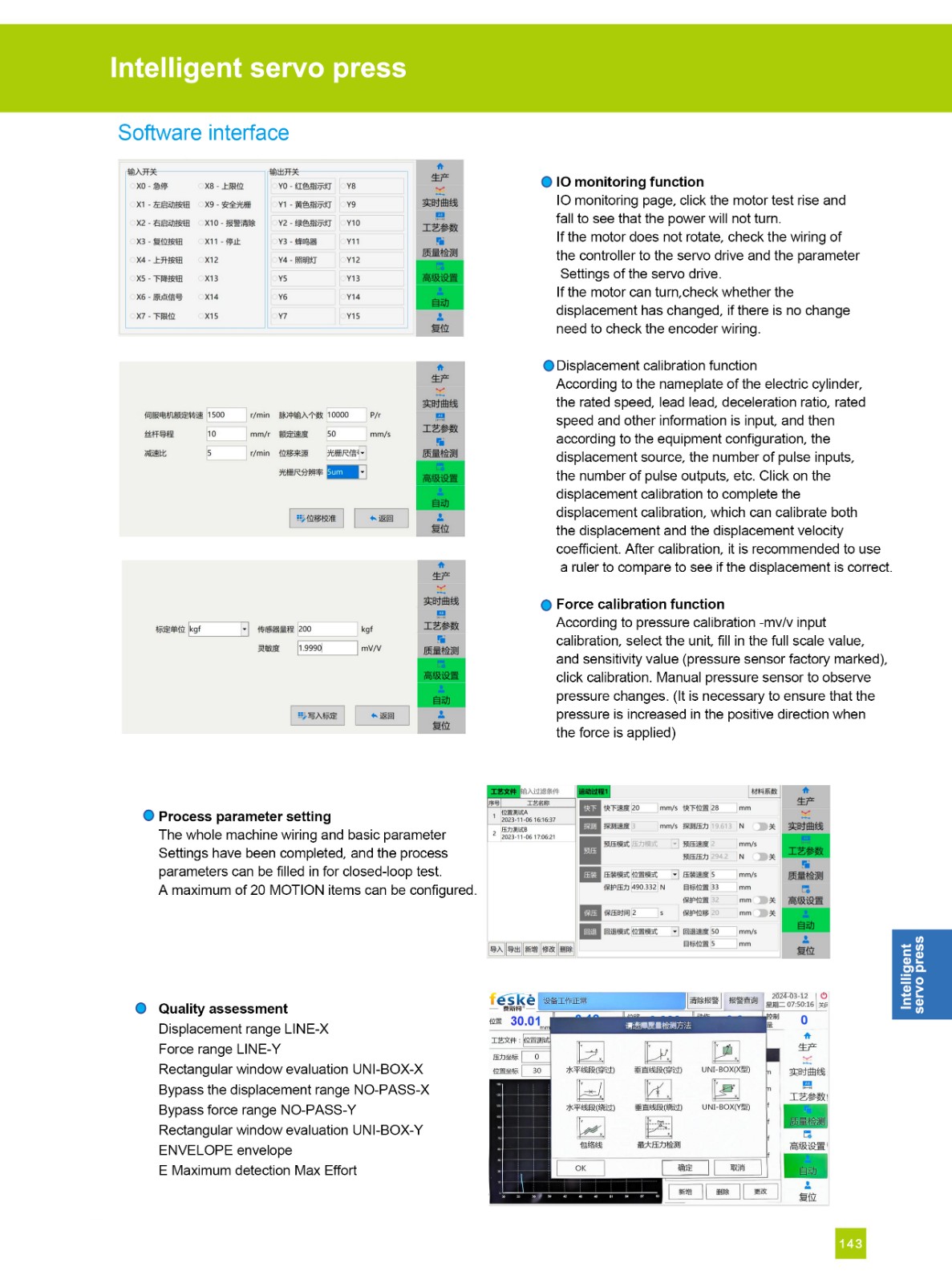

PC version

The system is a special software developed by C++, C#, Delphi and other high-level languages

Connect to PC through Ethernet port to read curve data, curve quality judgment, storage and control functions in realtime

The maximum curve sampling rate>1600 times/second:

A single program can support adding 8 evaluation windows at the same time:

A single program can be configured with 20 MOTION items, supporting free editing. The system can be connected to a barcode scanner to realize product data recording and quality tracking functions:

Optional PLC communication interaction, control system function through LAN or 485 communication:

Optional MES system data docking:

Optional continuous pressing of multiple processes (freely edit the product process, press in the process sequence, no need to manually select the program) Optional high-precision pressure holding function for more than 24 hours

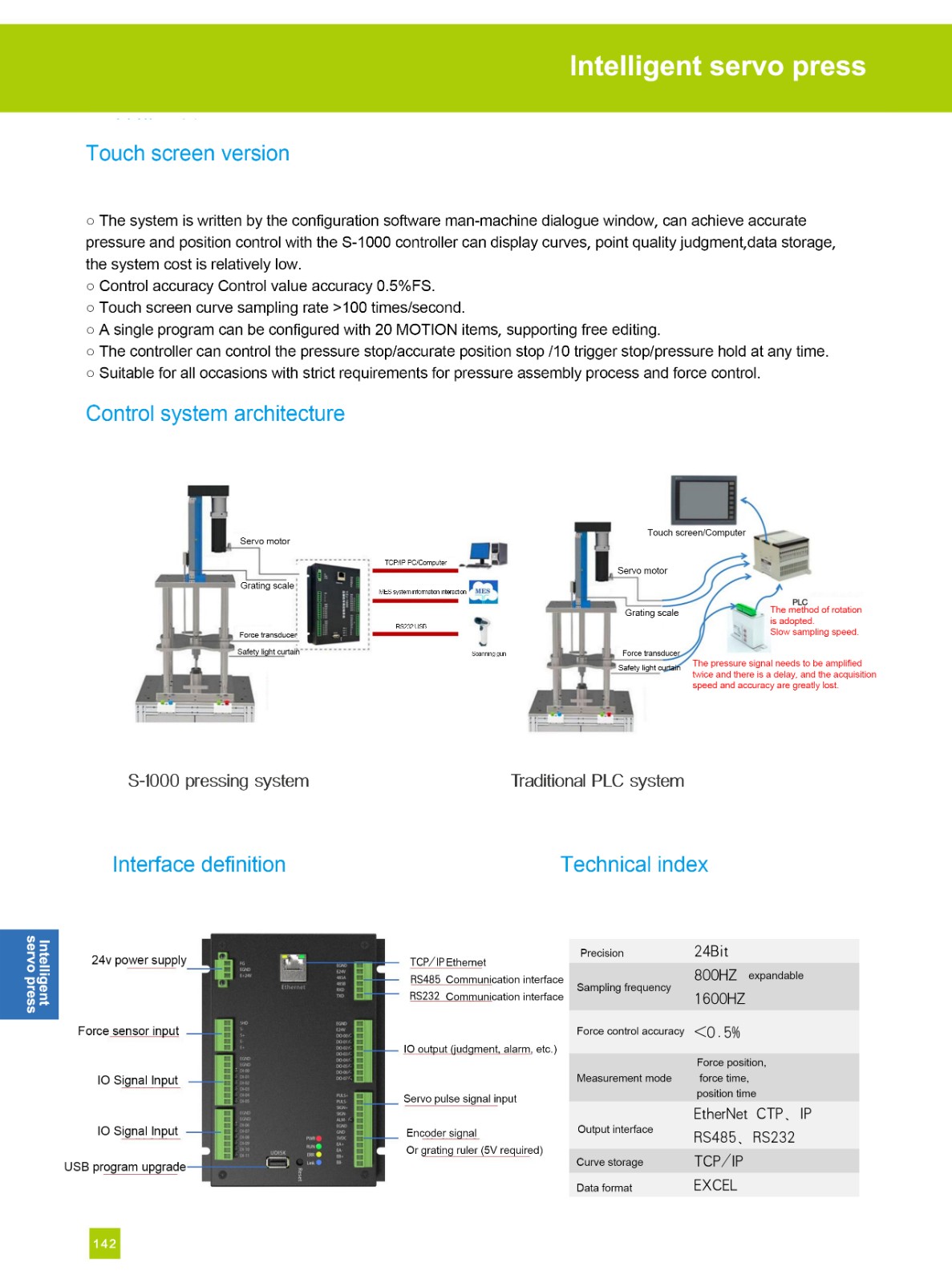

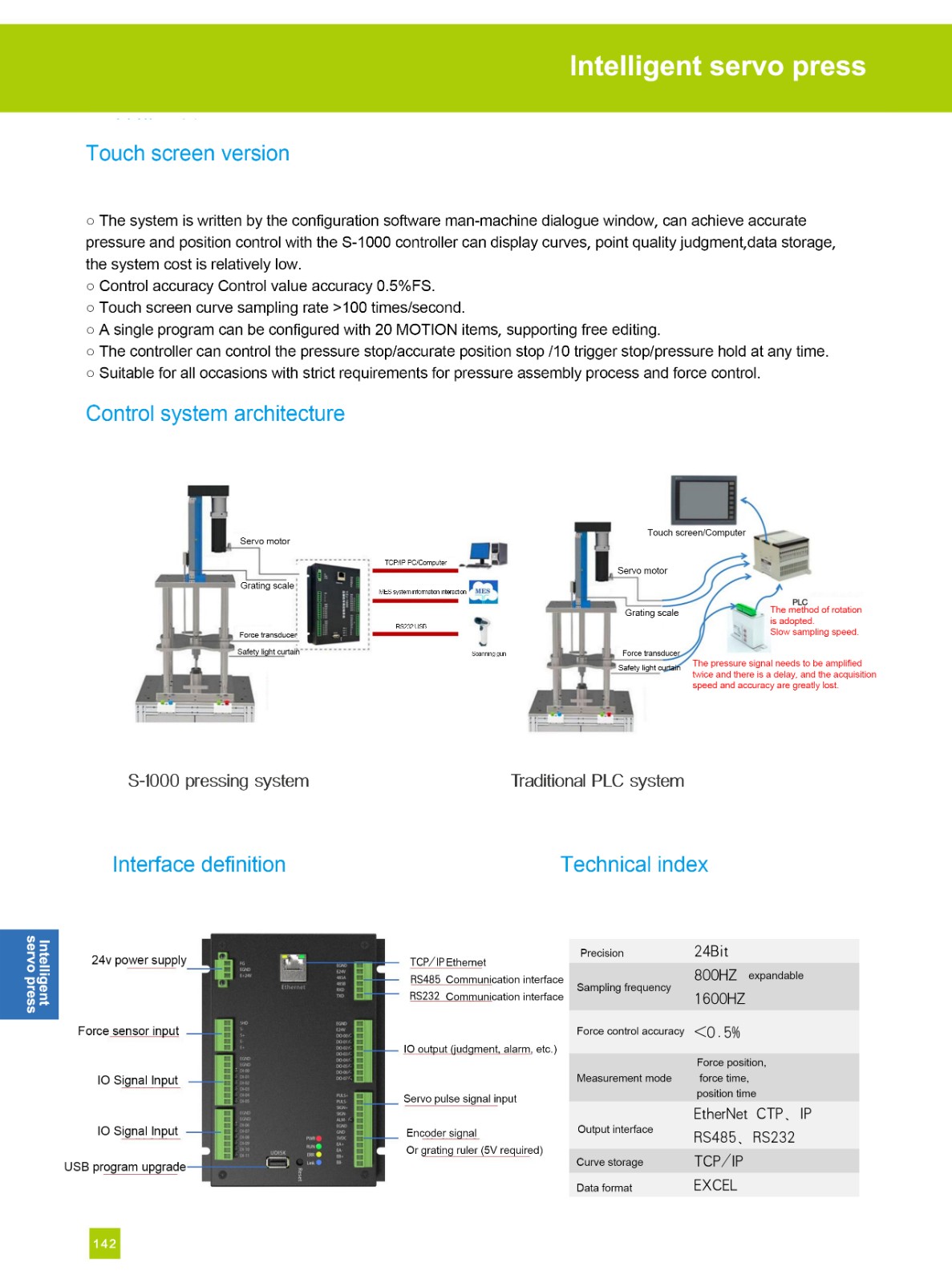

Touch screen version

It can realize accurate pressure and position control system with S-1000 controller. The human-machine dialogue window is programmed by configuration software, which can display curves, point quality judgment, and data storage. The system cost is relatively low:

Control accuracy Control force value accuracy 0.5%FS:

Touch screen curve sampling rate>100 times/second:

A single program can configure 20 MOTION items and support free editing:

The controller can control pressure stop/accurate position stop/10 trigger stop/pressure hold at any time

Applicable to all occasions with strict requirements on press-fitting process and force control.

Detection unit

Force sensor

Optional range: 0-100-50T

Measurement accuracy: 0.3-0.05%FS

Sensitivity: 1-3mv/v

Working temperature: -20℃~60℃ (higher temperature can be customized)

Protection level: IP65

Overload capacity: 150%

Output signal directly enters YZJ controller, no amplifier required

Special size can be customized

Displacement sensor

Optional range: 0-50-300-1000mm

Measurement accuracy: 0.5-1-5 u

Output signal: differential signal, SSI, RS422

Working temperature: -20℃~60C

Protection level: IP65

Pressure calibrator

Portable high-precision force calibrator, a good helper for press calibration!

Integrated display, 24-bit ADC high-precision acquisition module

Measurement accuracy: 0.1%FS, from rated range 20% to 100%

Multiple operation modes: peak, sensitivity, real-time value

Multiple unit switching: kg, KN, T

Battery powered, wireless Bluetooth module

6.5-digit digital display module

Optional range: 0~5T~30T~50T

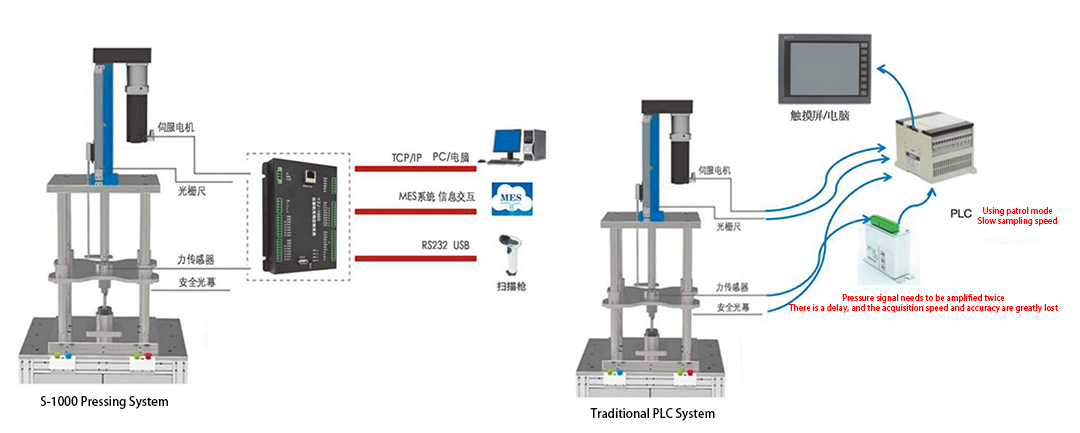

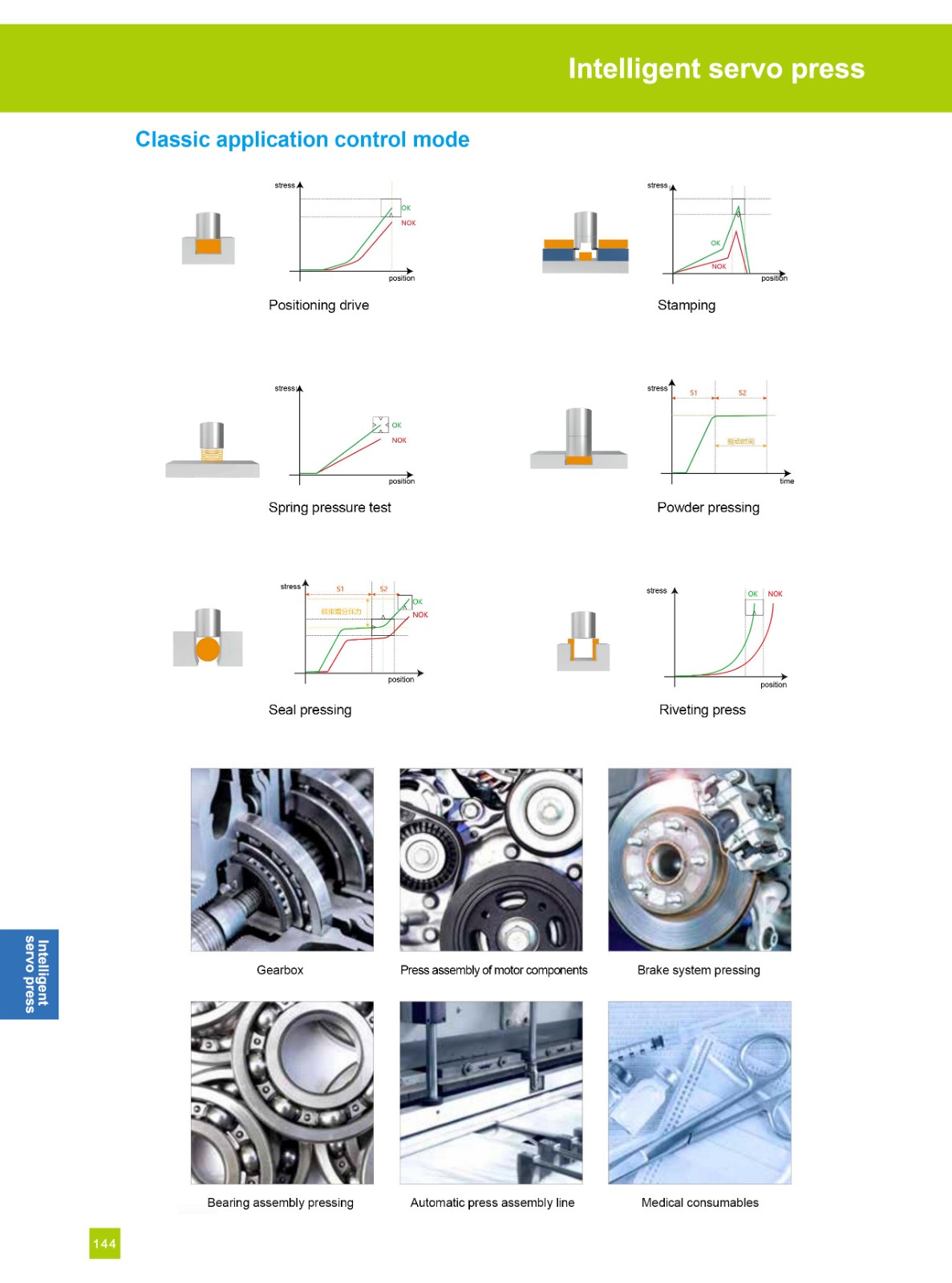

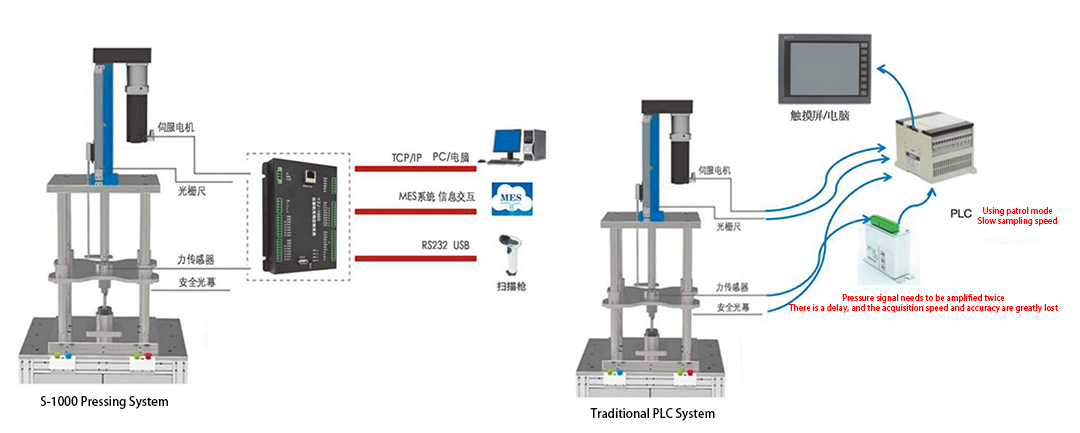

Control system architecture

The advantages of servo press machines compared to traditional hydraulic presses are mainly reflected in the following aspects:

1. Environmental Protection: Electric drives significantly reduce carbon emissions and harmful gas emissions, aligning with the trend of green manufacturing. Hydraulic systems can pose a pollution risk due to leaks, while electric designs eliminate the need for hydraulic oil, thus reducing environmental impact.

2. High Efficiency and Energy Saving: The simplified electrical structure improves energy conversion efficiency and reduces energy waste. Intelligent control technologies (such as servo motors) enable precise pressure regulation, thereby improving production accuracy and response speed.

3. Low Maintenance Costs: The electromechanical structure is simpler than hydraulic systems, resulting in a lower failure rate and easier maintenance. Hydraulic systems require regular replacement of hydraulic oil and seals; electric solutions reduce the need for these consumables.

4. Noise Control: Electric drives are quieter at low speeds, improving working comfort.

5. Servo Press Machine Intelligent Integration

Servo Press is compatible with CNC systems (such as Dell DA53/DA58) to enable automated operation and data monitoring, thereby improving productivity.