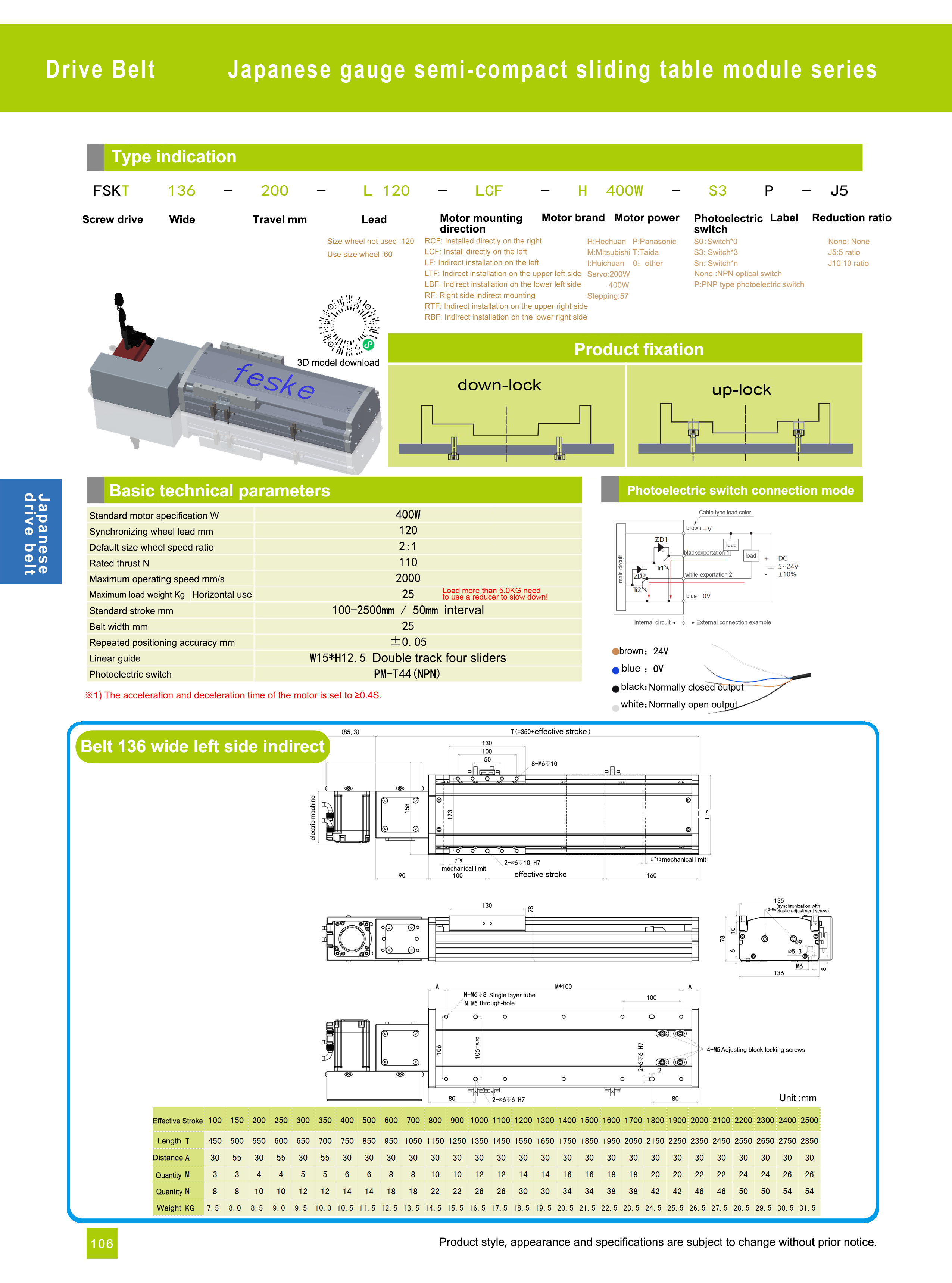

Maximum horizontal load 25KG

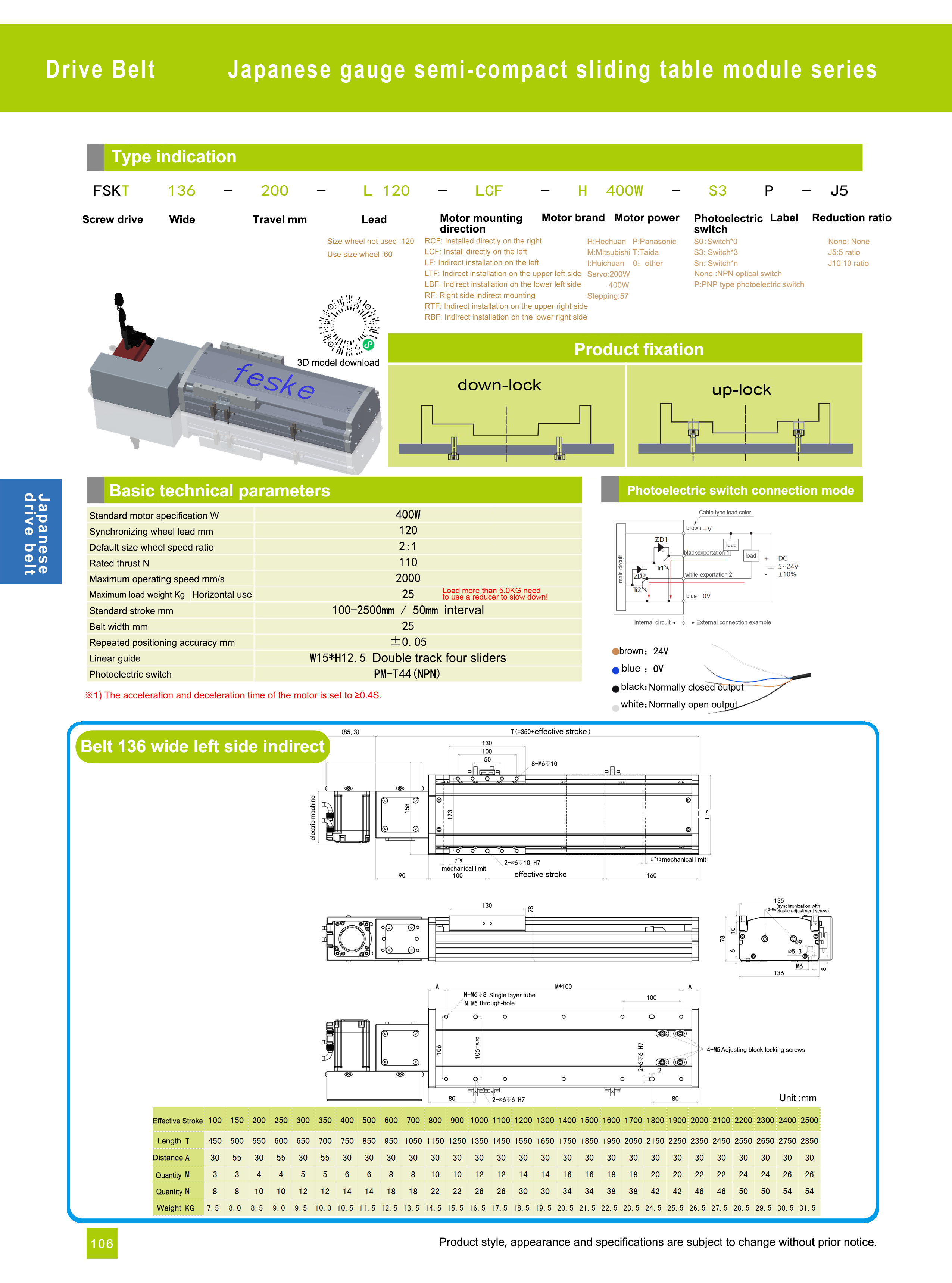

Model: FSKT-136

Semi-dense belt module

Repeat positioning accuracy: ±0.05 mm

Customizable stroke: 50-3000mm

Synchronous belt stroke: S5M-25

Synchronous belt lead: 120 mm

Maximum speed: 2000 mm/s

The semi-dense belt module is a transmission device that uses a belt as a transmission medium, drives the driving wheel of the synchronous belt to rotate through a motor, and then drives the slider on the synchronous belt guide rail to move linearly. Its characteristics are mainly reflected in the following aspects:

Semi-dense dustproof design: The module is made of aluminum profiles and has the characteristics of semi-dense dustproof, which can effectively prevent the intrusion of dust and impurities and ensure the stability and reliability of the equipment.

High efficiency and stability: The motor drive makes the belt module run more stable and efficient, which can meet the high efficiency requirements of the production line for material transportation.

High precision: The high rigidity design ensures the high precision of the module slide, so that the material can reach the specified position accurately during the transportation process.

Strong load capacity: The module can improve its load capacity by changing the profile material and guide rail rigidity to meet the needs of different production lines.

Easy installation and maintenance: The module is exquisitely designed, and each component is strictly produced in accordance with standards, making installation and maintenance relatively simple.

The Industrial Drive Lathe High Precision Semi-sealed Belt Module FSKT-136, a core component of high

-precision industrial drive lathes, offers the following advantages:

1. High Precision and Stability

The semi-sealed belt module design effectively reduces external dust and vibration interference, ensurin

g machining accuracy of up to 0.001mm.

The integrated, efficient drive control system achieves both high-speed operation and high-precision

control, making it suitable for machining complex workpieces.

2. Modularity and Compatibility

The modular design supports multi-axis expansion (such as Y-axis functionality), adapting to complex

machining needs such as turning and milling, and enhancing equipment flexibility.

It is compatible with mainstream CNC systems (such as Siemens SINUMERIK ONE and FANUC FX FANO

VI) and supports digital twin technology for seamless interaction between virtual and real-world environ

ments.

3. Durability and Environmental Adaptability

The industrial-grade sealed structure and wide operating temperature range (-40°C to 85°C) ensure stab

le operation in harsh environments. The belt drive system optimizes noise control while offering high loa

d capacity, making it suitable for long-term continuous operation.

4. Intelligence and Efficiency Improvement

Supports Intelligent Dynamic Control (IDC) and Intelligent Load Control (ILC), optimizing machining path

s and reducing energy consumption.

Integrated multi-channel data acquisition (such as the CAN-FD interface) enables real-time monitoring a

nd fault warnings, improving production safety.