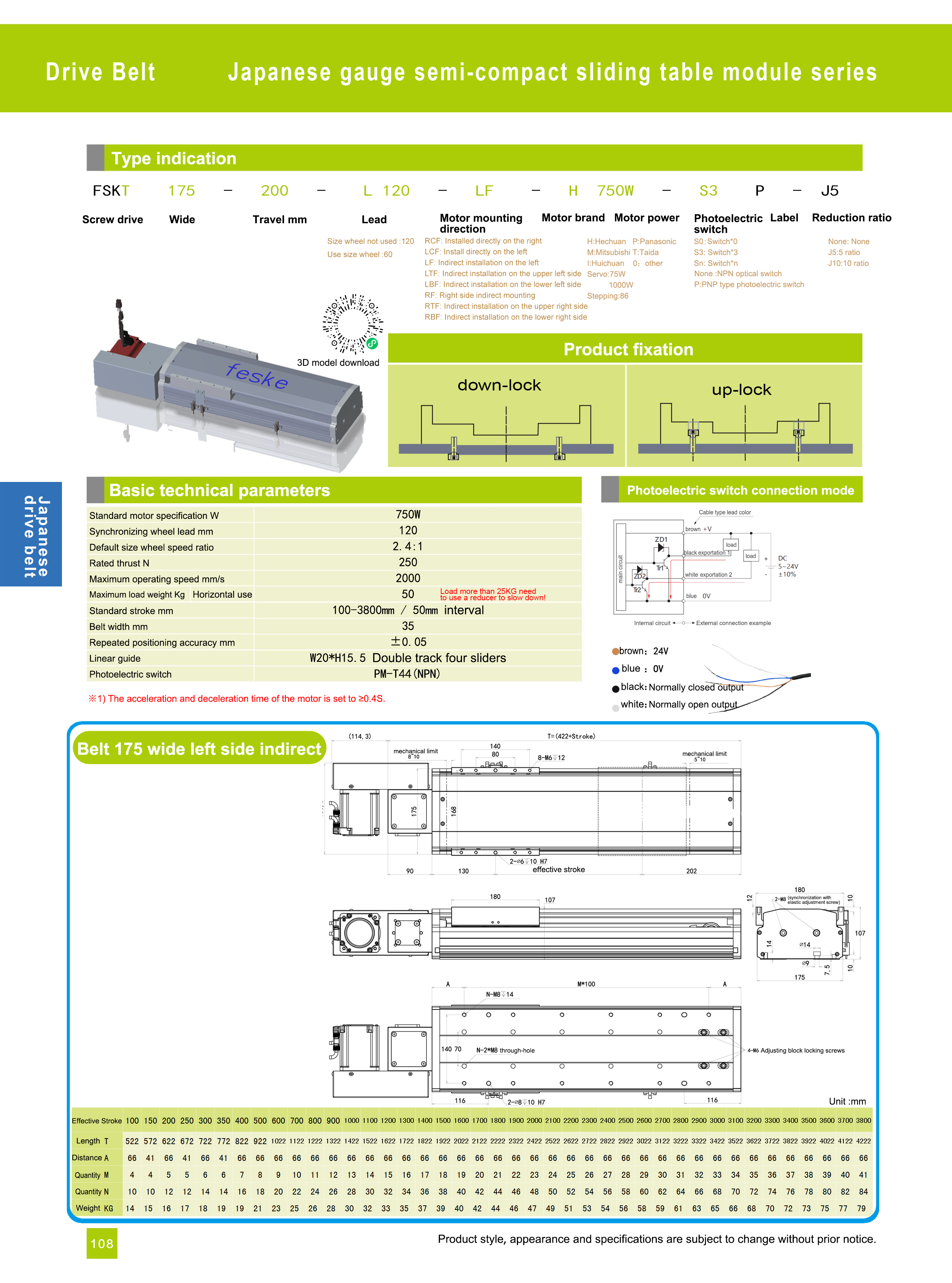

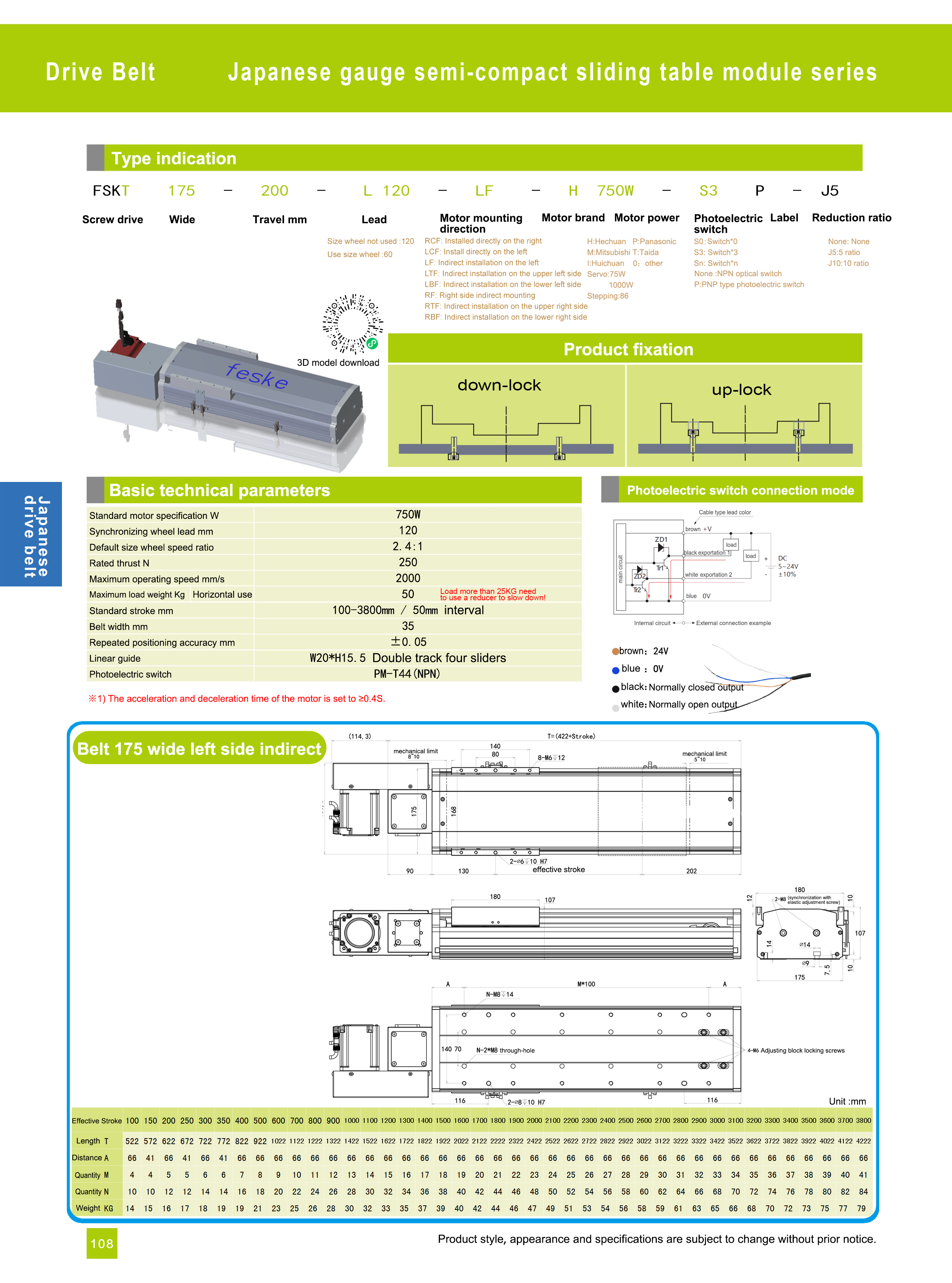

Maximum horizontal load 20KG

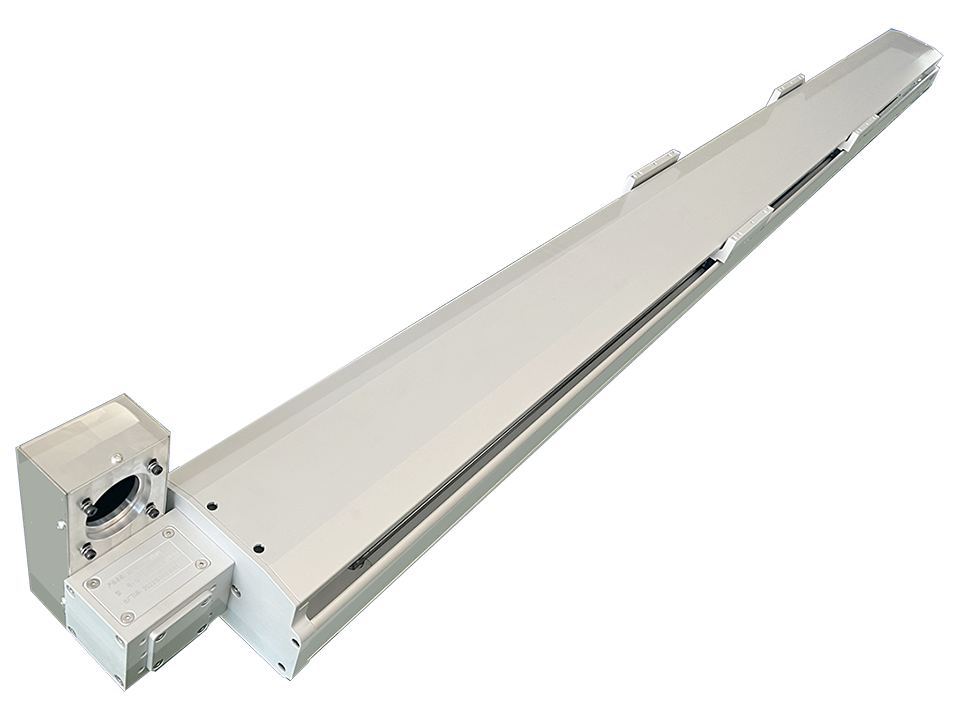

Model: FSKT-175

Semi-dense belt module

Repeat positioning accuracy: ±0.05 mm

Customizable stroke: 50-3900mm

Synchronous belt stroke: 5M-35

Synchronous belt lead: 120 mm

Maximum speed: 2000 mm/s

The working principle of the semi-dense belt module mainly relies on the motor driving the driving wheel of the synchronous belt to rotate, thereby driving the slider on the synchronous belt guide to move linearly. In this process, the material is placed on the belt and transported to the destination as the belt moves. The rollers and guide devices play a key role in this process. The rollers can support the belt and reduce its force, while the guide devices ensure that the belt always stays on the correct motion trajectory to prevent deviation and slippage.

Elevate your automated production lines with the FSKT-175, a cutting-edge belt module designed for precision and reliability. This advanced belt driven linear actuator offers superior performance, making it the ideal choice for demanding industrial applications. Experience seamless operation and enhanced efficiency with our innovative belt drive linear actuator, specifically engineered to meet the needs of modern manufacturing. When you need powerful and precise motion, our belt driven linear actuators deliver.

The advantages of the FSKT-175 automated machine splicing belt module can be summarized as follows:

High Precision and Stability

The modular design ensures positioning accuracy and synchronization during transmission, making it suitable for precision automated assembly scenarios. The contactless signal coupler (Iolink protocol) reduces failure rates and improves signal transmission reliability. This precision is a hallmark of an exceptional belt driven linear actuator.

Efficient Maintenance and Durability

Replacing traditional cam transmission mechanisms reduces the consumption of wearing parts and simplifies maintenance. The optimized structural design ensures a long-life guide rail system, making it suitable for high-intensity, continuous operation. This makes the FSKT-175 a highly dependable belt drive linear actuator.

Flexible Adaptability

Modular replacement allows for quick adjustment of workstation configurations to meet diverse production needs. Compatible with various automation equipment interfaces (such as PLC control), it facilitates integration into existing production lines. The versatility of this belt module is a key advantage.

Energy Saving and Environmental Protection

The electric drive design (such as servo motors) reduces energy consumption, aligning with green manufacturing trends. This makes our belt driven linear actuators an environmentally conscious choice.

Wide Application Range

It is suitable for logistics transportation, precision assembly, test bench automation, and other scenarios. The FSKT-175 truly demonstrates the power of a well-engineered belt linear actuator.

Choosing the FSKT-175 belt module means investing in a high-performance belt driven linear actuator that provides superior accuracy, efficiency, and adaptability. This belt drive linear actuator stands out among other belt driven linear actuators for its robust design and intelligent features, ensuring long-term value for your automation needs.

Splicing belt modules are primarily used in automated equipment to achieve efficient and reliable

connections between conveyor belts. Their core applications include:

**Logistics Sorting Systems:** In cross-belt sorting machines used in express delivery and e-commerce

warehousing, this module rapidly splices conveyor belts to ensure continuous package transport. For

example, small-item circular sorting machines use splicing belts for high-precision sorting, saving labor

and improving efficiency.

**Industrial Production Lines:**

**Electronics Manufacturing:** In PCB assembly lines, splicing belt modules work in conjunction with

vacuum technology and vision systems to achieve high-precision component placement.

**Automotive Manufacturing:** Splicing belts coordinate material flow between workstations on body

welding lines, improving production cycle time.

**Food Packaging:** In filling lines, splicing belts ensure continuous container transport and work in

conjunction with PLCs to control the filling and capping processes.

**Special Industrial Environments:**

**Battery Production:** In drying chambers, splicing belt modules must meet copper-free and corrosion

-resistant requirements to support automated lithium-ion battery production. High-Temperature Aging

Test: During batch processing of circuit boards, the splicing tape module works in conjunction with the

PLC to achieve stable transmission of the high-temperature aging queue.

Maintenance and Flexibility: The modular design of the splicing tape supports quick assembly and dis

assembly, reducing downtime (e.g., Alibaba's hot-fitting machine can reduce maintenance time by 40%),

making it suitable for flexible production lines requiring frequent adjustments.