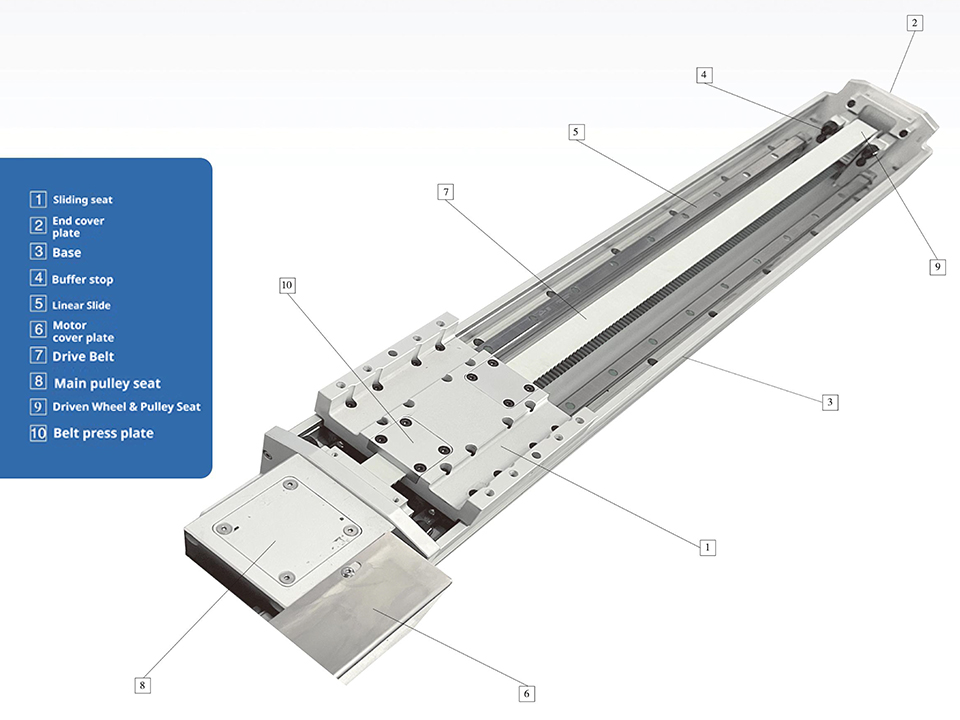

The fully dense belt module is usually composed of belts, transmission parts, guide rails, sliders and other parts. It has a compact structure and reasonable design, and is suitable for various automation equipment and production lines. In the fields of 3D printing, packaging machines, handling mechanisms, lithium battery equipment and 3C industry, the fully dense belt module is widely used.

The dense belt module has the characteristics of high precision, high speed, high stability and strong carrying capacity, and is widely used in various automation equipment and production lines. When selecting and using the fully dense belt module, it is necessary to fully consider factors such as application requirements, load capacity, stroke length and precision requirements, and perform regular maintenance and maintenance to ensure the stability and service life of the module.

In the demanding world of industrial automation, superior performance and reliability are paramount. Our FSKTW-175 synchronous belt module redefines what's possible, offering an unmatched combination of ultra-long stroke, high speed, and robust protection. This isn't just an electric cylinder actuator; it's a game-changer for complex, high-throughput systems. Engineered to outperform, our electric actuator cylinder provides precision and durability where it matters most, setting a new standard for the electric cylinder linear actuator.

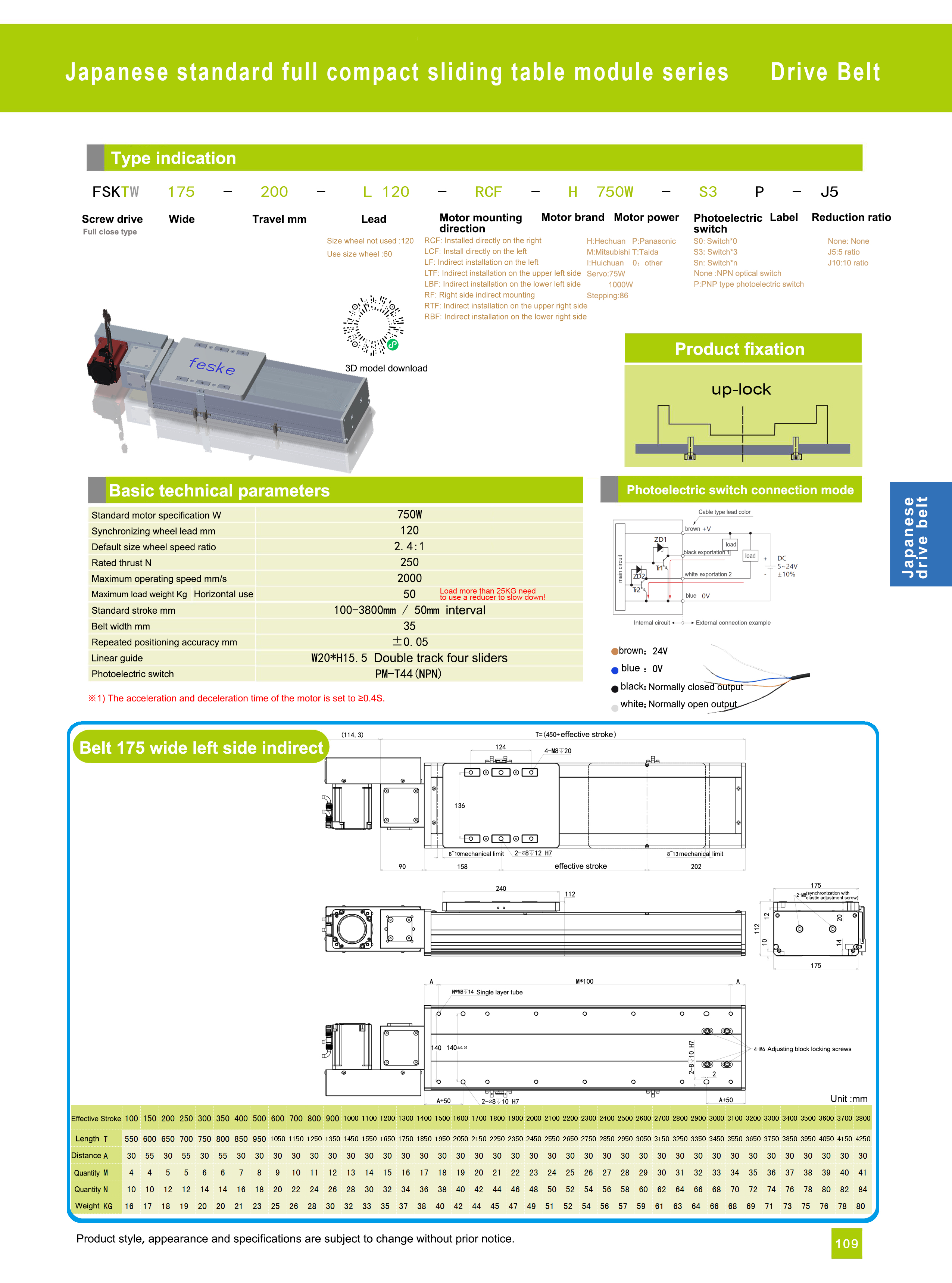

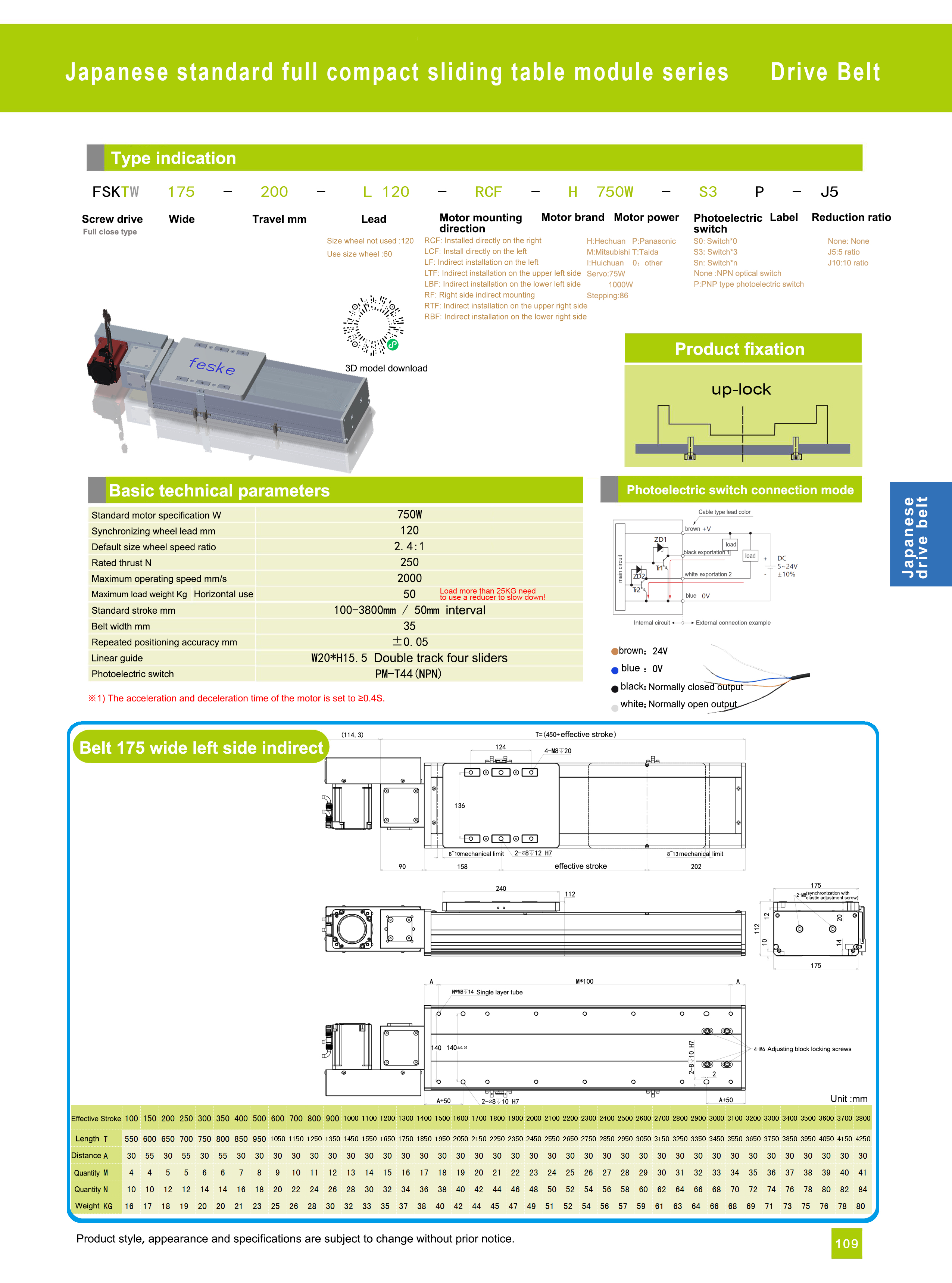

The Fully Sealed Ultra-long Stroke Waterproof Synchronous Belt Module FSKTW-175, a core transmission component in the industrial automation field, offers the following technical advantages:

Extremely Long Stroke and High-Speed Performance

Utilizing synchronous belt drive technology, it achieves effective strokes exceeding 6000mm, far exceeding the 1500mm limit of traditional ball screw modules. With a maximum speed of 5000mm/s, it is suitable for long-distance, high-speed transmission applications such as LCD panel inspection and automotive welding, reducing cycle times by 40%.

Fully Sealed and Waterproof Design

The stainless steel belt dustproof structure combined with NSK waterproof bearings achieves IP65 protection, effectively blocking dust and liquid intrusion and making it suitable for use in dust-free environments or humid working conditions in electronics workshops. A special sealing design reduces noise levels by over 15dB compared to gear transmissions.

Balance of Lightweight and High Rigidity

The 64×64mm anodized aluminum barrel design ensures structural rigidity while reducing weight and significantly improving corrosion resistance. The synchronous belt module costs only 60% of a lead screw solution, yet increases throughput to 1500kg/hour.

Multi-Scenario Adaptability

Applicable to production lines ranging from consumer electronics to new energy vehicles, it supports continuous conveying across workstations (such as welding automotive doors), avoiding precision loss during multi-stage connections. Its modular design facilitates integration with servo motors and is compatible with mainstream control systems.

This synchronous belt module offers an unparalleled advantage for applications demanding a truly robust electric cylinder actuator. Its innovative design sets it apart as a leading electric actuator cylinder in the market, providing the high-speed, long-stroke capabilities that an electric cylinder linear actuator needs for success.