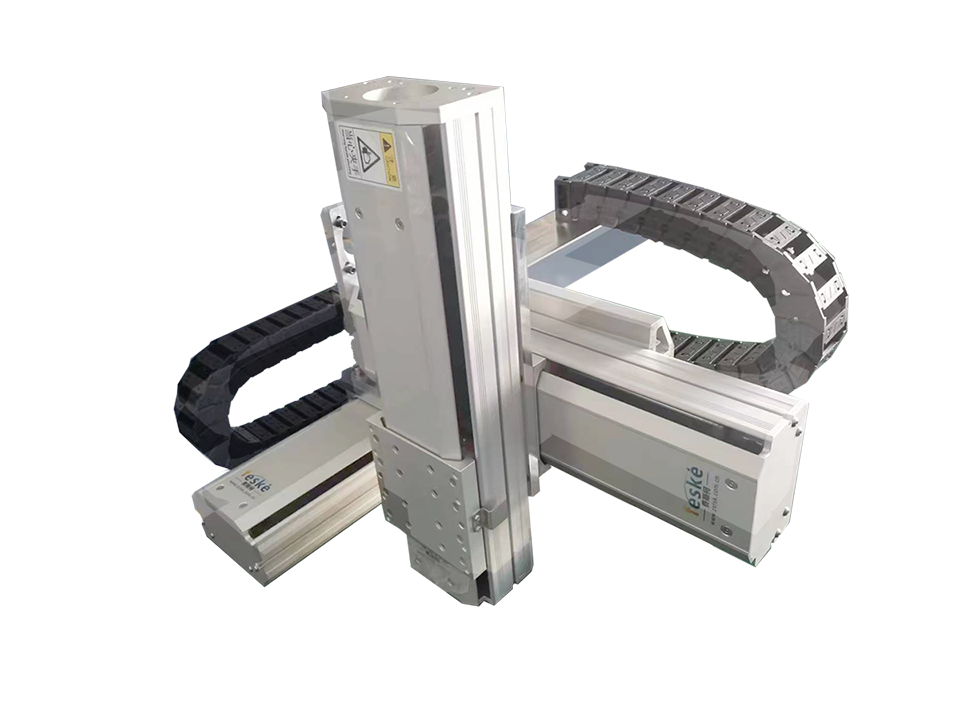

The robot is composed of multiple single-axis robots that can be combined in different styles to achieve multi-axis combination to achieve applications such as rectangular coordinate robots, XYZ multi-axis robotic arms, etc. From light loads to heavy loads, from short strokes to long strokes, we have a wide range of product sizes to choose the most suitable combination according to the application.

Can be spliced with multi-axis manipulator cantilever type, polar coordinate system, gantry type Repeat positioning accuracy ±0.02mm

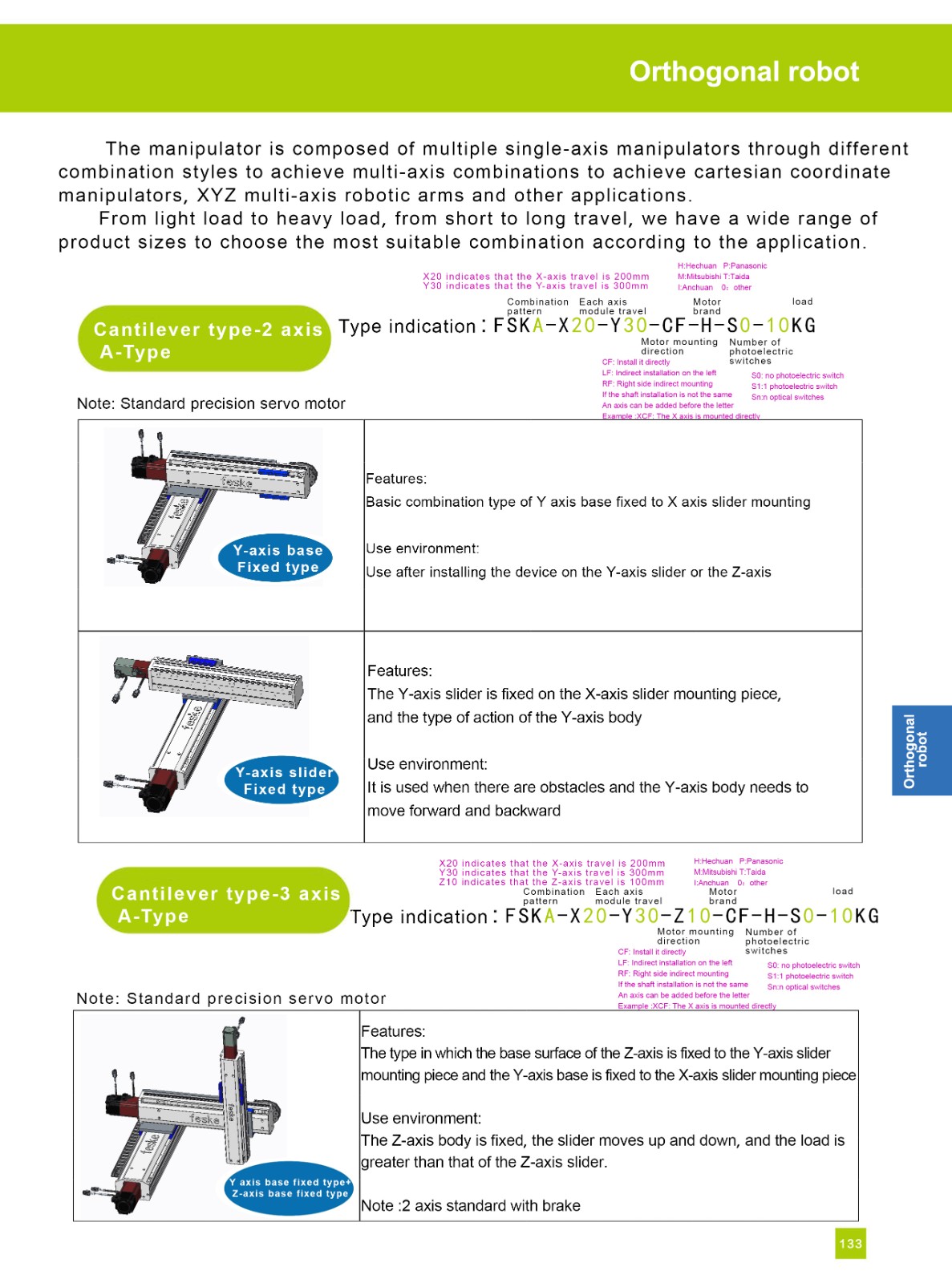

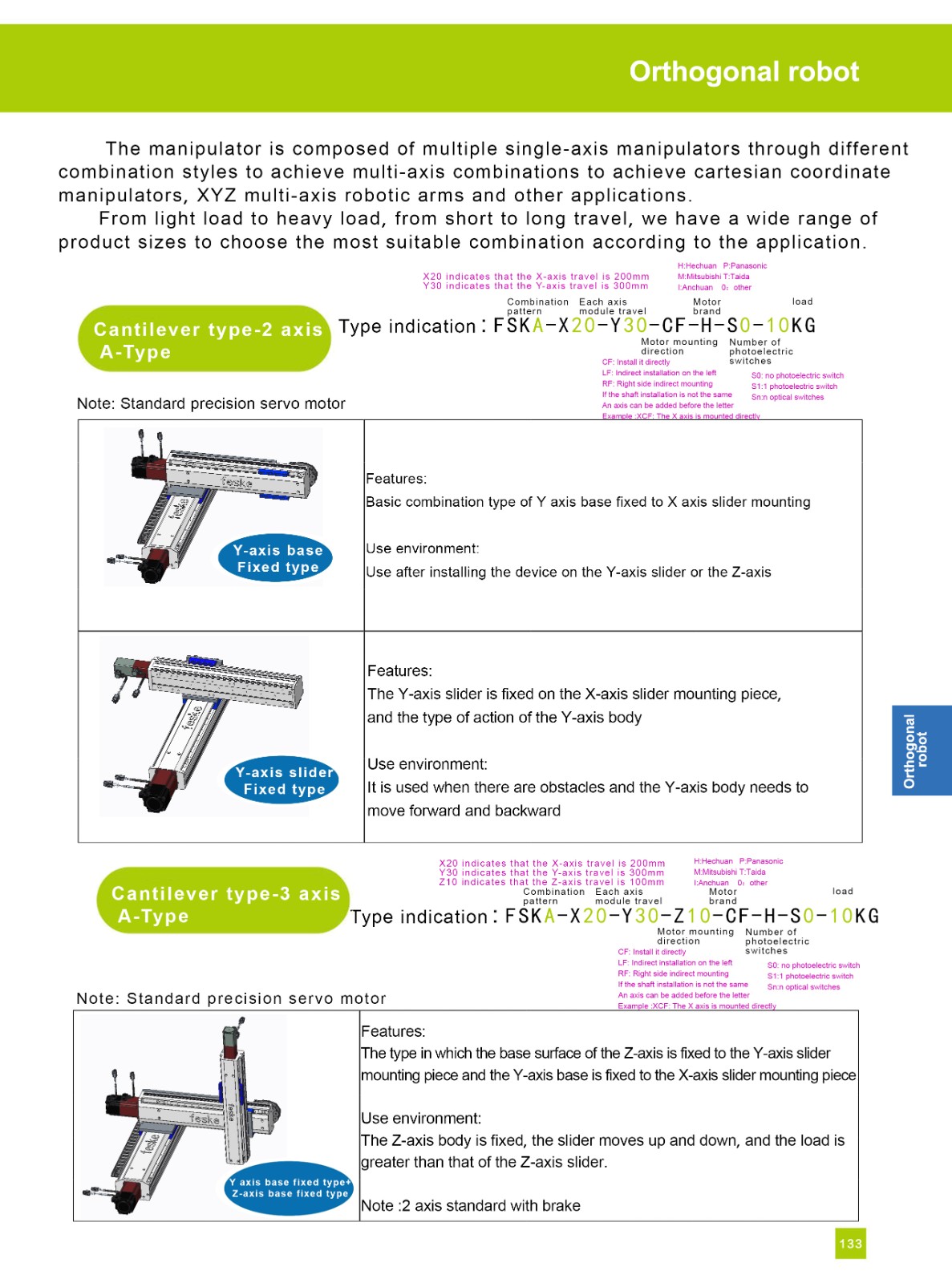

Cantilever Type-2 Axis A-Type

Y-axis base fixed type

Features: Basic combination type where the Y-axis base is fixed on the X-axis slider mounting part.

Usage environment: Use after installing the device or Z-axis on the Y-axis slider

Y-axis slider fixed type

Features: The Y-axis slider is fixed on the X-axis slider mounting part, and the Y-axis body moves

Usage environment: Used when there are obstacles and the Y-axis body needs to move forward and backward

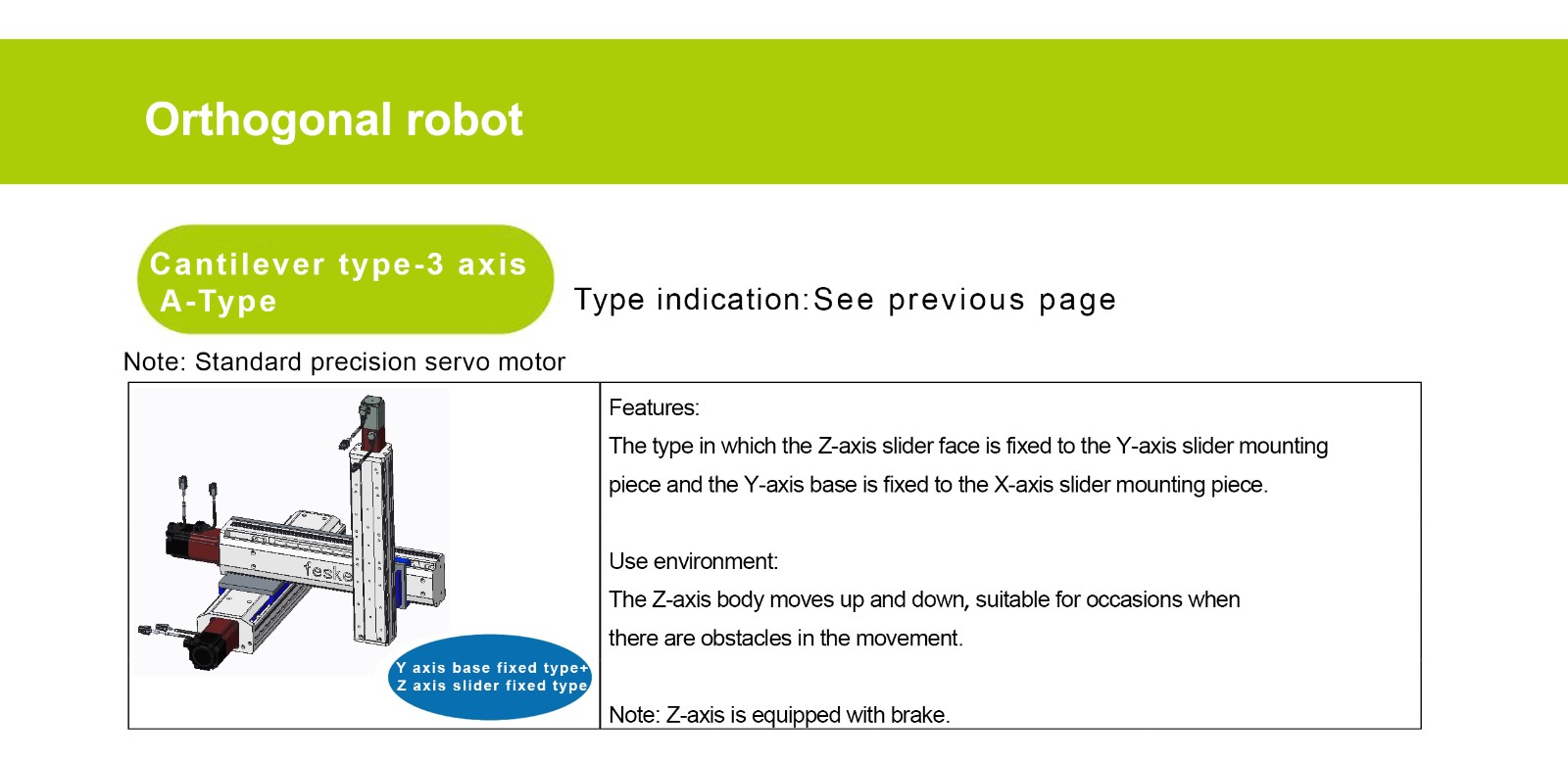

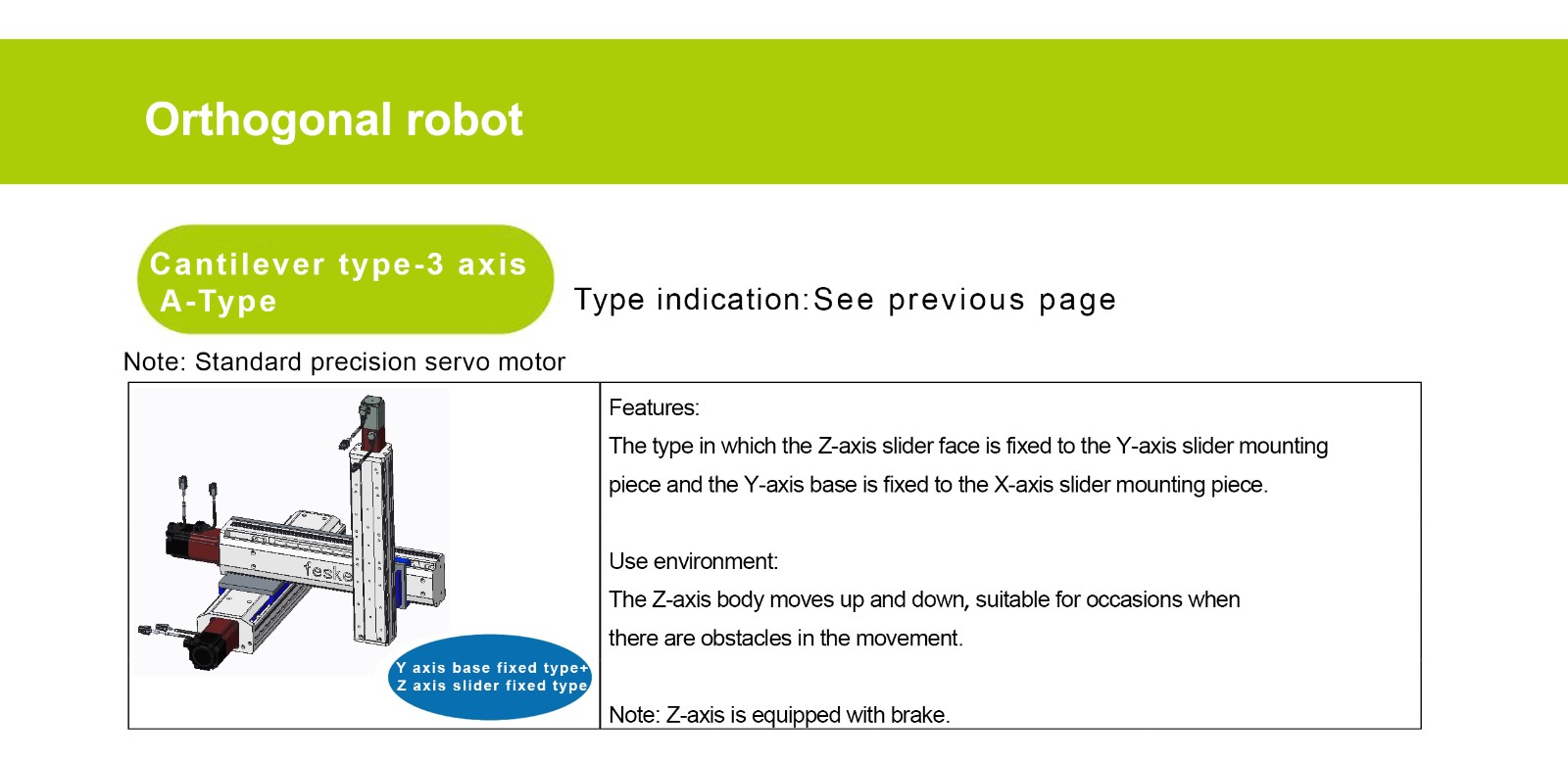

Cantilever Type-3 Axis A-Type

Axis base fixed type + Z-axis base fixed type

Features: The base surface of the Z-axis is fixed on the Y-axis slider mounting part, and the Y-axis base is fixed on the X-axis slider mounting part. Type: Use environment: The Z-axis body is fixed, and the slider moves up and down. Compared with the Z-axis slider fixed type, the load is greater

Note: The Z-axis is equipped with a brake as standard

Y-axis base fixed type + Z-axis slider fixed type

Features: The slider surface of the 2-axis is fixed on the Y-axis slider mounting part, and the Y-axis base is fixed on the X-axis slider mounting part

Usage environment: The 2-axis body moves up and down, suitable for occasions where there are obstacles during movement.

Note: Z-axis comes standard with brake

Discover the transformative power of our Multi-automation Module Industrial Robot Arm FSKA. This intelligent robot arm is engineered to deliver unparalleled flexibility, precision, and safety across a vast spectrum of industrial and commercial applications.

Advantages of the FSKA Multi-automation Module Industrial Robot Smart Arm

1. Modularity and Exceptional Flexibility

Our FSKA industrial robotic arm boasts a modular design, enabling the flexible combination of various functional modules, from six-axis to seven-axis configurations. This allows the robot arm to perfectly adapt to diverse industrial scenarios such as welding, precise palletizing, and complex assembly tasks.

With an open architecture, rapid mechanical adjustments are seamless. You can easily replace the end effector or expand the number of axes, facilitating smooth transitions from a single-axis indexing table to a sophisticated multi-arm collaborative system. This inherent adaptability makes our arm robot industrial solution incredibly versatile for evolving production needs.

2. High Precision and Intelligent Control

The FSKA industrial robot arm integrates advanced servo drives and machine vision systems, achieving a remarkable repeatability of up to 0.05mm. This makes it an ideal industrial robotic arm for precision assembly and delicate micro-manipulation tasks.

Supporting fully integrated control platforms like TwinCAT and compatible with ROS (Robot Operating System), our arm robot industrial solution enables advanced path planning and sophisticated multi-sensor collaboration, ensuring optimal performance and accuracy.

3. Safe Collaboration and Intuitive Human-Robot Interaction

Equipped with cutting-edge collision detection and emergency stop functions, our robot arm facilitates safe collaborative operation with humans in unfenced environments, significantly reducing the need for costly safety infrastructure.

Intuitive teaching via a tablet or graphical interface (such as Robotic Suite) simplifies programming, making our industrial robotic arm accessible and easy to deploy for all users.

4. Lightweight Design and Robust Durability

Crafted from high-grade aluminum alloy or carbon fiber, our industrial robot arm perfectly balances lightweight construction with high strength. With a robust load capacity of 6-10kg, it's perfectly suited for high-speed handling operations.

Specialized surface treatments, like anodizing, enhance corrosion resistance and ensure our arm robot industrial solution can thrive in even the harshest industrial environments, guaranteeing long-term reliability.

5. Cost and Maintenance Efficiency

The modular design of our industrial robot arm substantially reduces spare parts inventory requirements, allowing for cost-effective partial replacement rather than complete repairs.

Standardized interfaces (such as ISO flanges) ensure compatibility with a wide range of third-party tools, drastically reducing integration complexity for your industrial robotic arm setup.

Versatile Applications of Our Multifunctional Industrial Robot Arm

Our automated modular industrial robot arm with intelligent capabilities is revolutionizing both industrial and commercial sectors.

I. Industrial Manufacturing Scenarios

Precision Assembly and Sorting: In automotive manufacturing, our industrial robot arm excels at operations like seatbelt locking and material handling, achieving ±0.5mm precision with a 7-DOF force-controlled robot arm. In the 3C industry, it boosts quality inspection efficiency to 93% for tasks like touchscreen inspection and film application.

Semiconductor and Logistics: Our composite mobile industrial robotic arm leverages 3D vision compensation technology to handle wafer cassettes with ±0.5mm positioning accuracy, supporting 24-hour continuous operation for critical tasks.

II. Special Environment Operations

Extreme Environment Adaptation: The FSKA industrial robot arm (like the Phantom G2) operates stably from -15℃ to 50℃, making it ideal for demanding environments such as automotive parts workshops.

III. Commercial Service Scenarios

Interactive Guiding: Equipped with large AI models, our robot arm supports real-time intelligent interaction with multiple users, offering customized narration and voice tone switching, perfect for commercial guiding applications.

IV. Technology Integration and Application

AI and Vision Integration: This intelligent industrial robot arm combines target detection and voice interaction for tasks such as efficient warehouse sorting and precise assembly line control.

V. Emerging Potential Areas

The capabilities of our industrial robot arm extend to new frontiers, including general industrial operations (loading, unloading, material handling) and advanced sorting in automotive manufacturing, significantly enhancing production line efficiency through its flexible design and mobility.

The Multi-automation Module Industrial Robot Smart Arm, by integrating various functional modules,

can be flexibly adapted to a wide range of industrial applications, including:

Precision Assembly & Inspection

Electronics Manufacturing: Used for the insertion, welding, and inspection of precision components such

as mobile phones and circuit boards, with repeat positioning accuracy reaching ±0.02mm.

Automotive Parts: completes the assembly and quality inspection of complex components such as engin

es and transmissions.

Logistics & Warehouse Automation

Material Handling: Equipped with pallet or conveyor belt modules to automate material transport from

warehouse to production line, such as MiR AMR's pallet handling system.

Sorting & Palletizing: Uses vision recognition technology to quickly sort and stack goods, applicable to

e-commerce and food industries.

Collaborative & Flexible Production

Human-Robot Collaboration: such as Franka's dual-arm robot, which can collaboratively complete tasks

like assembly and packaging, with force sensing technology ensuring safety.

Customized Production Line: Allows for quick function switching through modular design to adapt to

small-batch, multi-variety production needs.

Special Environment Operations

High-risk Scenarios: Used for equipment maintenance or sample collection in hazardous areas such as

chemical plants or nuclear radiation zones.

Medical Assistance: Performs tasks like pharmaceutical dispensing or instrument transfer in sterile envir

onments.

Its modular design (including robotic arm, sensors, AI vision, etc.) endows it with wide applicability in

fields such as smart manufacturing, logistics, and healthcare.