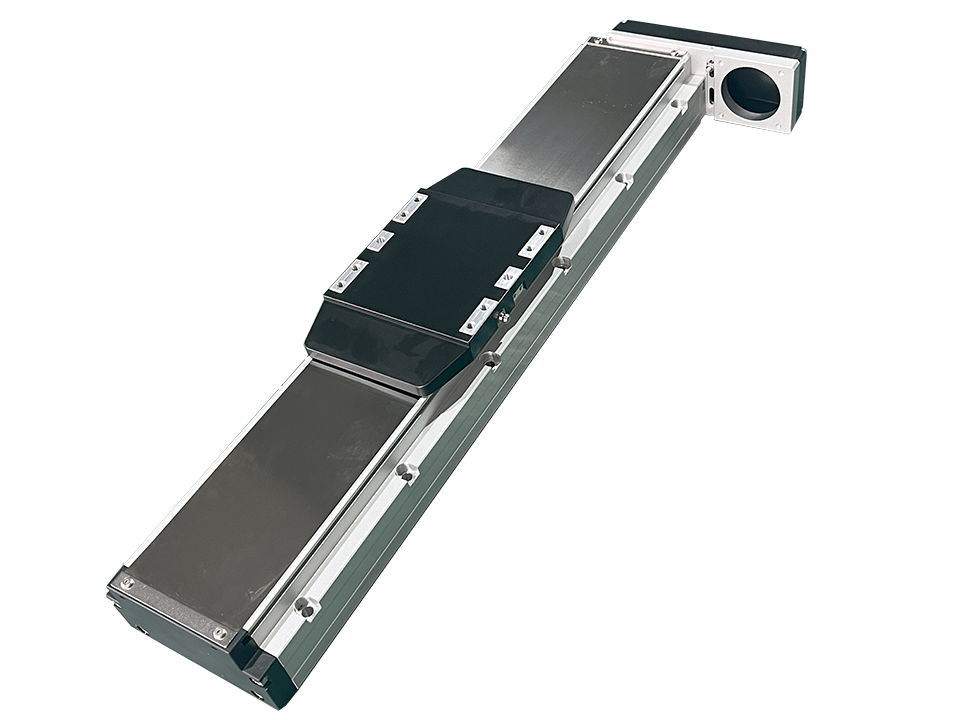

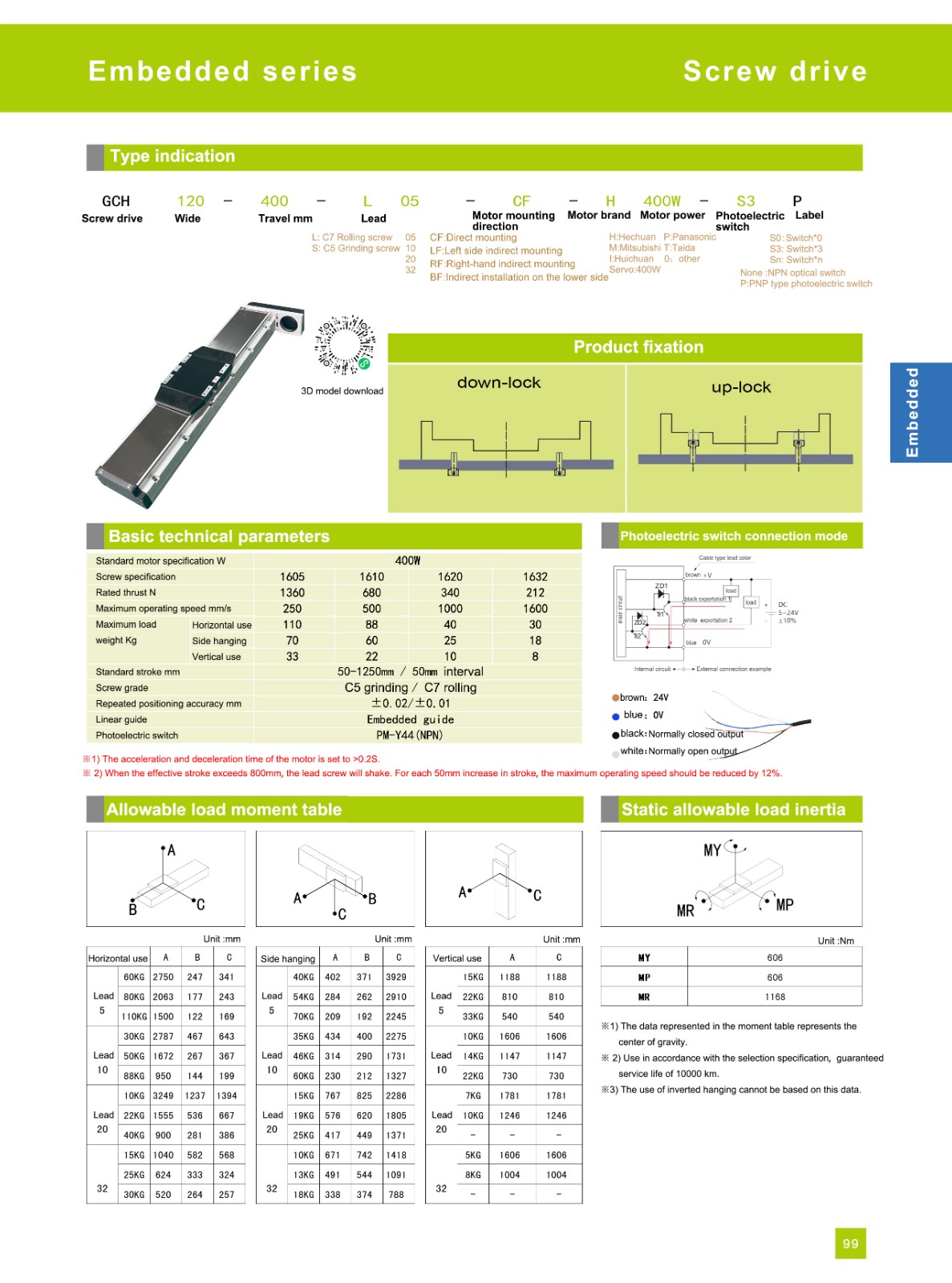

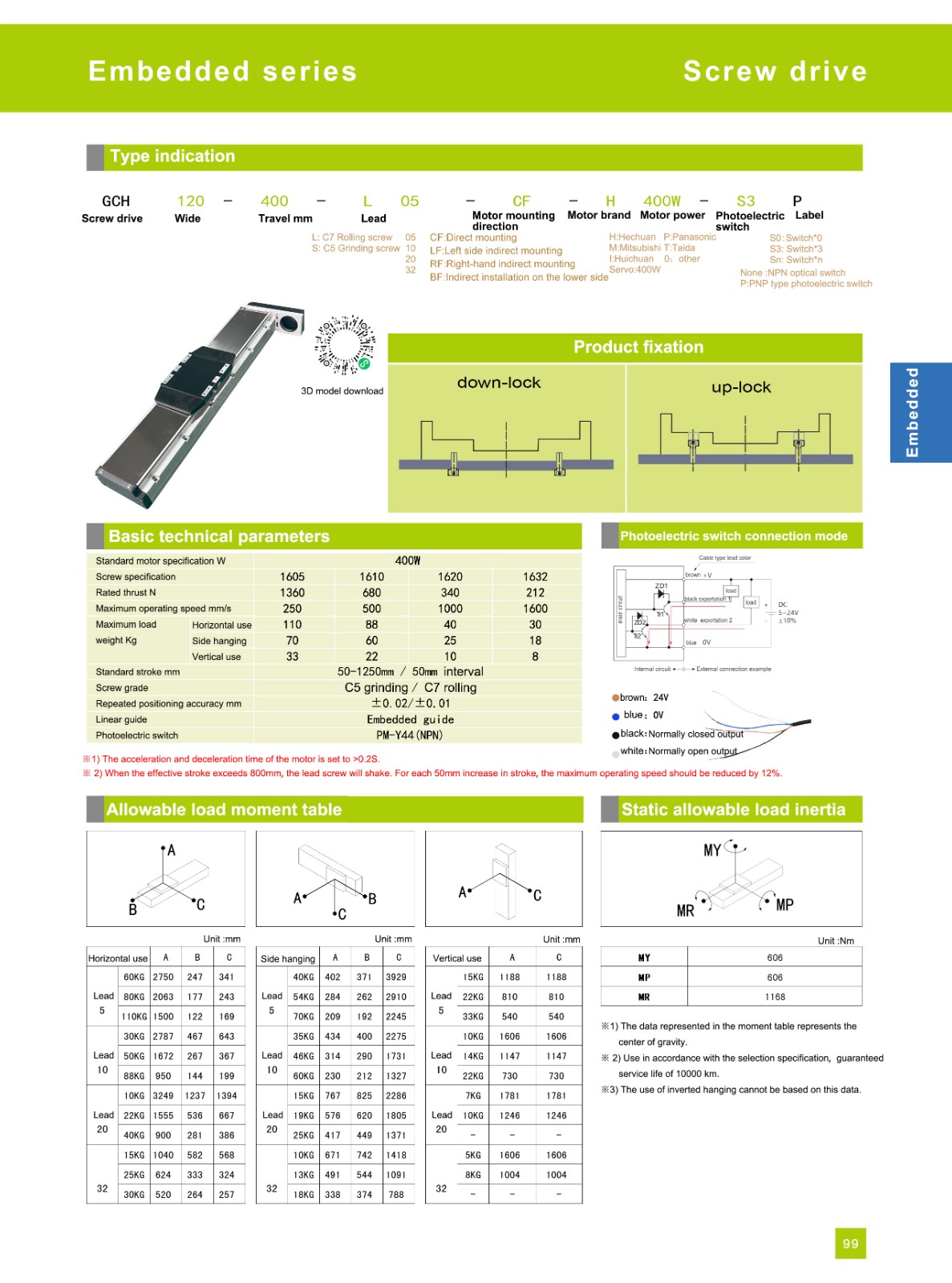

Model: GCH-120

Embedded fully dense module

Repeat positioning accuracy: ±0.01/±0.02 mm

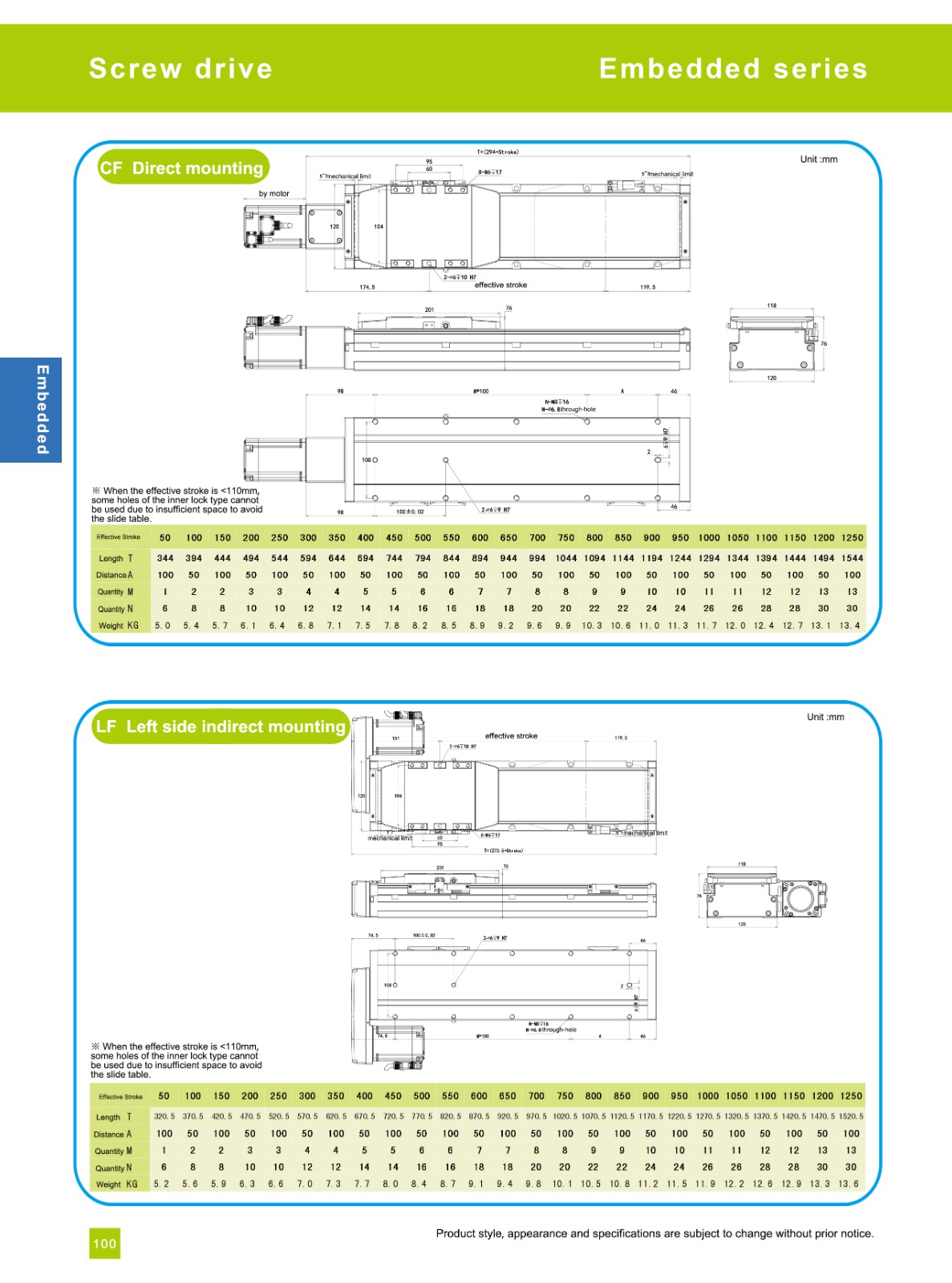

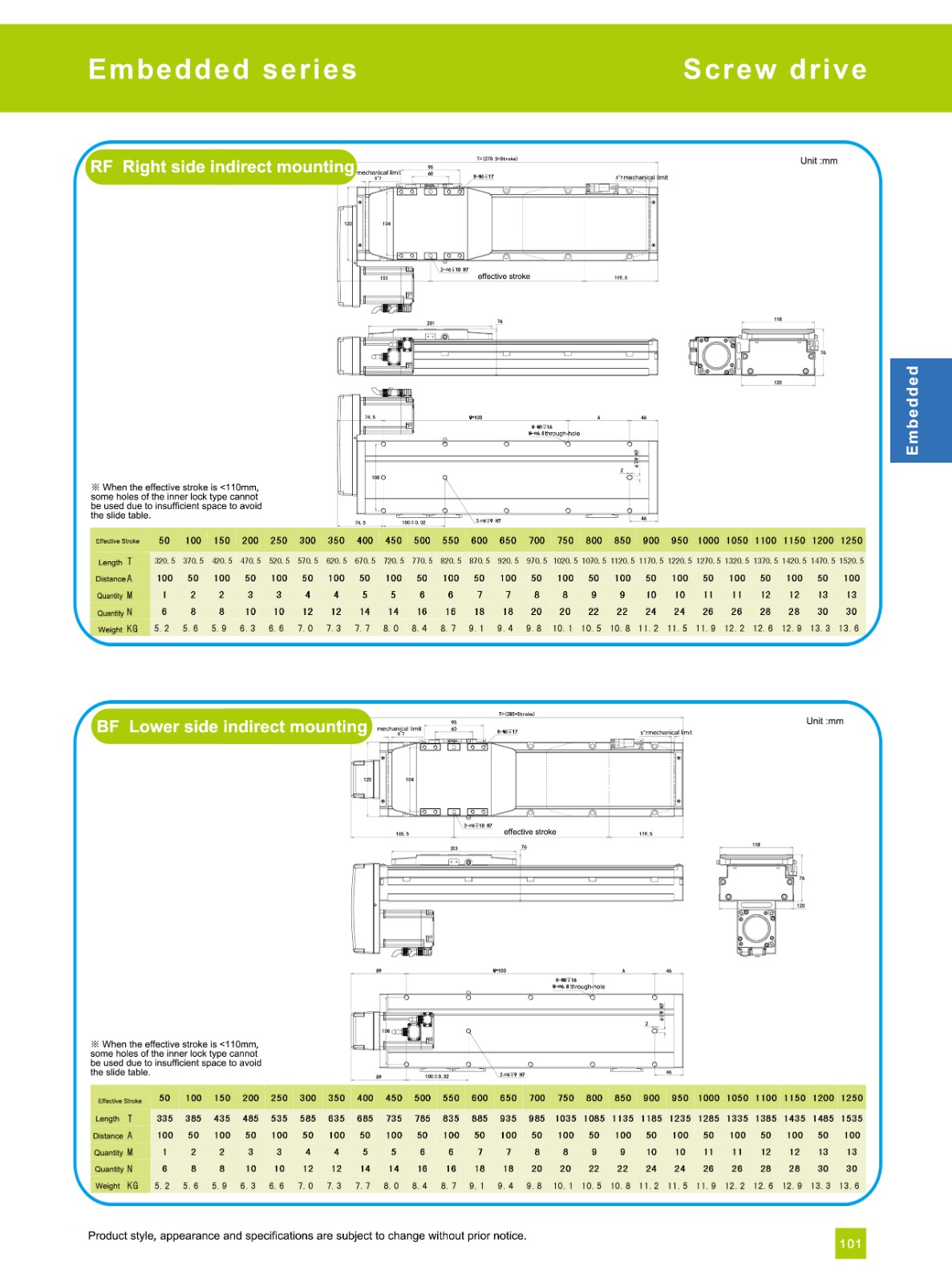

Customizable stroke: 50-1200mm

Screw outer diameter: t16 mm

Lead: 05/1020/32 mm

Motor power: 400W (motor can be customized)

Maximum speed: 250V500/1000/1600 MM/S

Discover the GCH-120, a state-of-the-art electric linear actuator meticulously engineered for applications demanding ultra-precise multi-point positioning with exceptionally low noise. This innovative linear slide actuator integrates advanced screw-embedded technology with superior noise reduction, offering an unparalleled solution for diverse industrial and scientific needs. As a leading electromechanical linear actuator, the GCH-120 stands ready to redefine your automation capabilities.

I. Core Structural Design: Precision Engineered for Excellence

Embedded Ball Screw System: The Heart of Our Linear Actuator

At the core of this sophisticated linear actuator is a preloaded C7-grade precision ball screw system (with C5-grade optional). Available with screw diameters from 16-40mm and leads from 5-20mm, this design ensures a remarkable ±0.01mm repeatability accuracy, even under demanding multi-point positioning scenarios (≥3 points). The integrated alloy base features a built-in screw guide groove, specifically designed to suppress high-speed vibration and significantly reduce the risk of resonance through optimized structural rigidity. This robust construction makes the GCH-120 a highly reliable linear slide actuator.

Low-Noise Operation Technology: A Silent Electric Linear Actuator

Experience tranquility with our advanced noise reduction design for the ball circulation path, complemented by a polymer sealing strip. This innovative combination results in an operational noise level of ≤40dB (under 30% load conditions), making this electric linear actuator perfectly suited for noise-sensitive environments such as medical testing equipment and laboratory precision instruments. The motor direct connection/folding installation compatible design further minimizes transmission chain noise, ensuring the GCH-120 performs as a truly silent electromechanical linear actuator.

Semi-Enclosed Protection: Durability for Your Linear Actuator

The GCH-120 linear actuator features a robust semi-enclosed design, incorporating a top removable dust cover and side labyrinth seals. This configuration provides an IP40 protection level, effectively balancing optimal heat dissipation with superior dust isolation requirements, ensuring the longevity and reliability of your linear slide actuator.

II. Key Performance Parameters: Powering Your Precision with this High Speed Linear Actuator

The GCH-120 is not just a standard linear actuator; it's a high-performance electric linear actuator with impressive specifications:

| Maximum Load | 120kg (horizontally installed) |

| Effective Stroke | 200–2500mm |

| Repeat Positioning Accuracy | ±0.01mm (multi-point positioning) - Achieving unparalleled precision with this electromechanical linear actuator. |

| Maximum Speed | 1.5m/s (long stroke requires speed reduction) - Positioning it as a high speed linear actuator. |

| Operation Noise | ≤40dB (ISO standard test) - A truly low-noise electric linear actuator. |

| Note | When the stroke exceeds 1500mm, speed must be limited to <0.8m/s to prevent resonance-induced accuracy deviation. |

III. Application Scenarios and Advantages: The Versatility of Our Linear Actuator Solutions

The GCH-120 linear actuator offers significant advantages across a range of critical applications:

Precision Manufacturing: Ideal for semiconductor wafer multi-point calibration platforms and optical lens coating equipment, relying on its exceptional ±0.01mm level positioning stability. This linear slide actuator ensures flawless production.

Medical Automation: A perfect fit for medical device assembly lines and silent inspection benches, meeting stringent ≤40dB noise restrictions. This electric linear actuator enhances patient comfort and diagnostic accuracy.

Long Stroke and Heavy Load Solutions: This robust electromechanical linear actuator can replace traditional hydraulic positioning mechanisms, precisely transferring loads up to 120kg within an impressive 2500mm stroke, offering superior control and efficiency compared to older systems. It truly serves as a reliable high speed linear actuator for demanding tasks.

IV. Technical Considerations: Maximizing Your High Speed Linear Actuator's Performance

Speed-Stroke Balance: The critical speed of this linear actuator is inversely correlated with screw length. For instance, with a 2500mm stroke, the speed must be carefully controlled below 0.8m/s to maintain optimal performance.

Inertial Load Management: When acceleration exceeds 0.3G, the handling mass needs to be adjusted downwards to prevent positioning deviation caused by impact, ensuring the consistent accuracy of your electromechanical linear actuator.

The GCH-120 module provides a high-precision, low-vibration positioning solution for heavy-load and long-stroke scenarios. Through the seamless integration of an embedded screw structure and advanced noise reduction technology, this linear actuator stands out as a superior linear slide actuator, an efficient electric linear actuator, a reliable electromechanical linear actuator, and a capable high speed linear actuator for your most challenging projects.

Low Noise Multi-point Positioning Linear Actuators offer significant advantages in applications requiring

high precision, low noise, and flexible positioning, making them particularly suitable for environments

such as medical, laboratory, and high-end manufacturing. Here are its core advantages:

1. Low Noise Operation

Utilizing advanced drive technologies (such as piezoelectric or electromagnetic drives) and optimized

structural design, these actuators operate with extremely low noise, making them ideal for environments

requiring quiet operation, such as medical equipment or laboratory instruments.

2. High-Precision Multi-point Positioning

Through closed-loop feedback systems (such as encoders or linear scales), they achieve nanometer-level

positioning accuracy and support multiple preset positions, meeting the needs of complex motion

control, such as precision assembly or optical adjustment.

3. Compact Structure and Fast Response

Small size and light weight make them suitable for space-constrained applications; their fast response

speed allows for quick start-up, stopping, and direction changes, improving automation efficiency.

4. No Electromagnetic Interference

Piezoelectric or magnetostrictive driving methods produce no electromagnetic radiation, making them

suitable for electromagnetically sensitive environments, such as medical imaging or electronic testing

equipment.

5. Long Lifespan and Low Maintenance

With no mechanical wear parts, they have a long lifespan and require minimal maintenance, reducing

long-term operating costs.

6. Wide Range of Applications

Medical equipment: such as surgical robots and imaging equipment, requiring high precision and low

noise.

Laboratory instruments: such as microscopes and spectrometers, relying on precise positioning.

High-end manufacturing: such as semiconductor manufacturing and precision assembly, requiring high

reliability and repeatable positioning accuracy.

In short, these actuators, with their low noise, high precision, and compact design, are an ideal choice

for demanding automation scenarios.