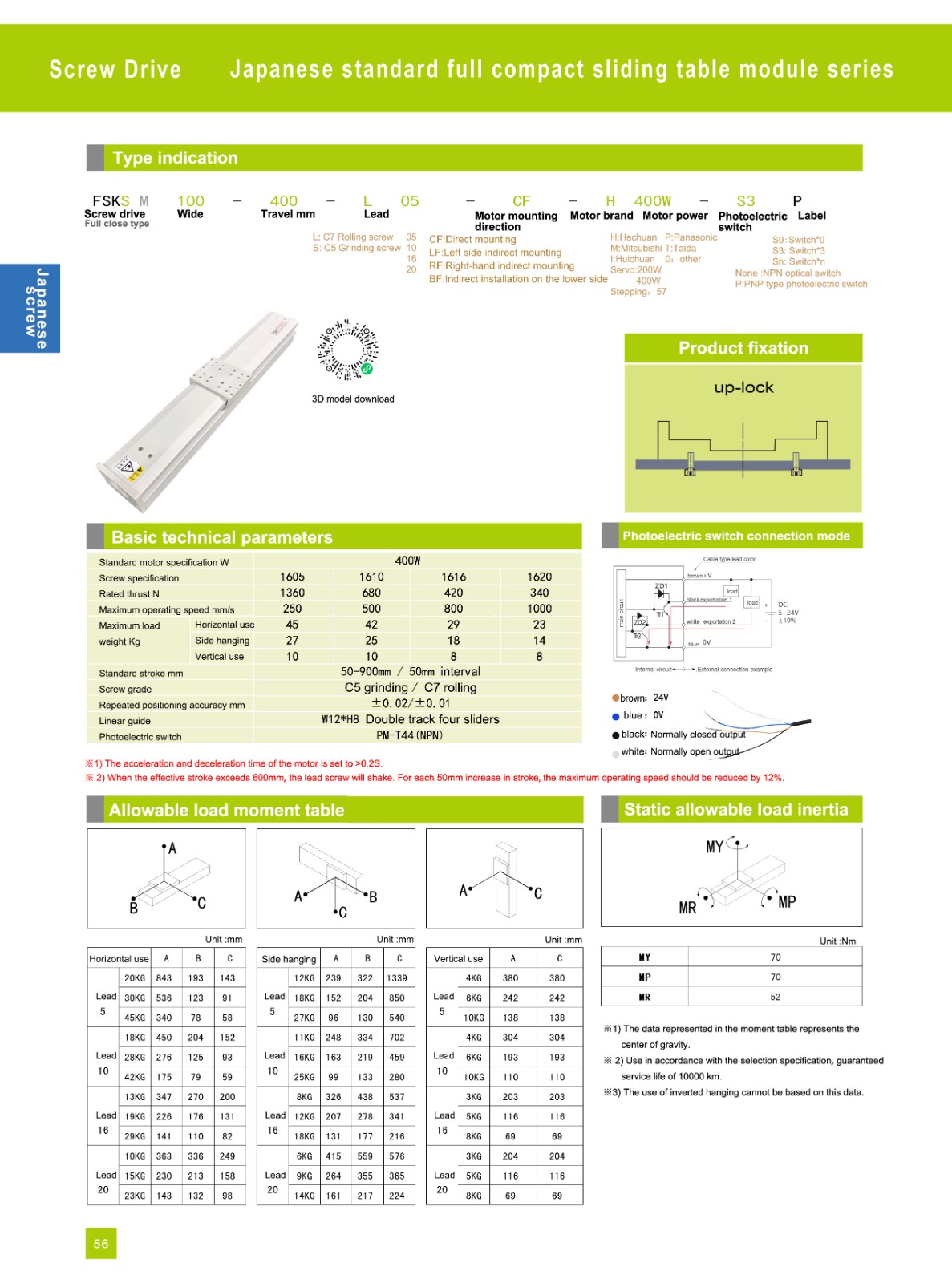

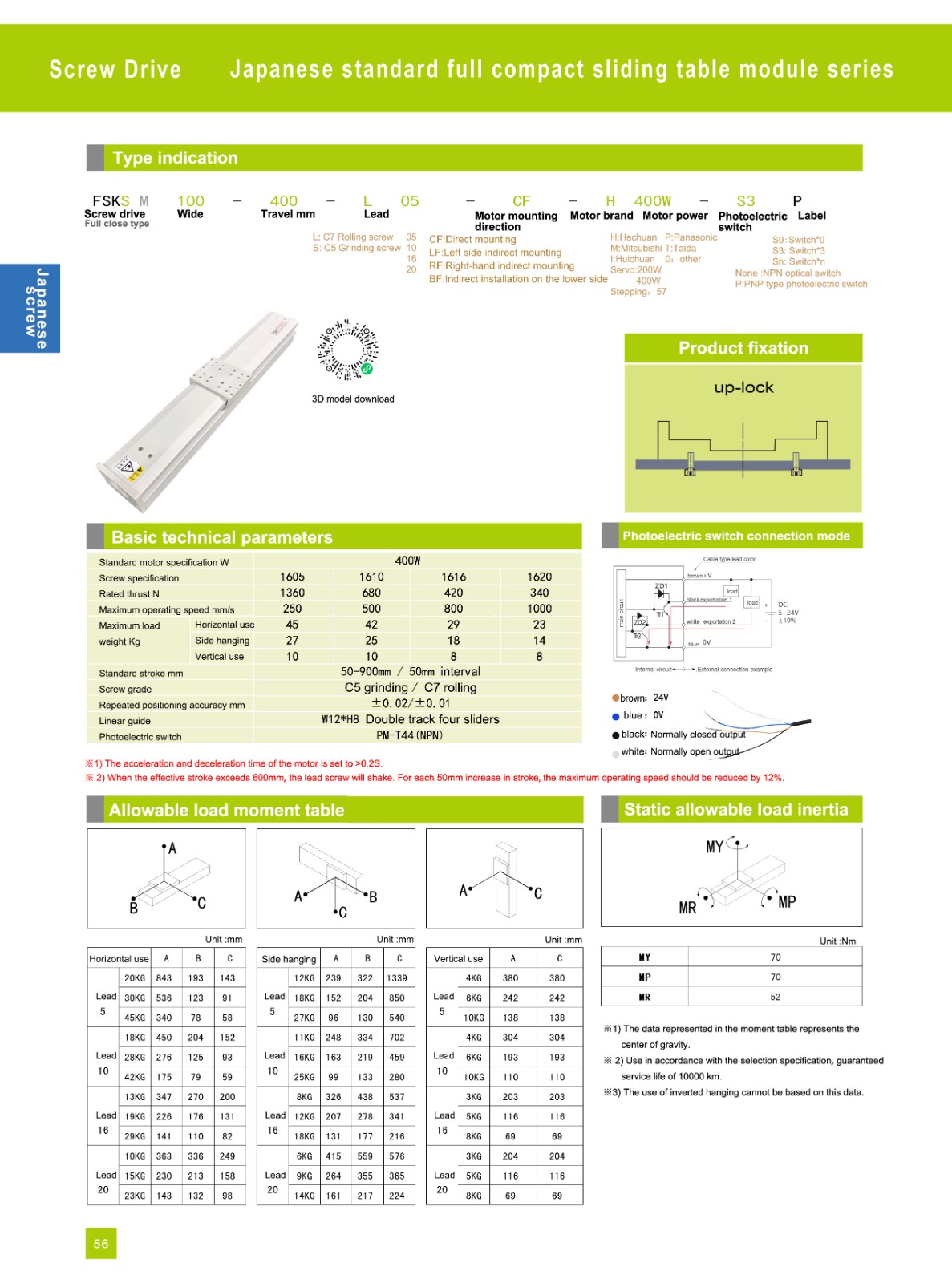

Maximum horizontal load 30 KG

Model: FSKSM-100 screw full-closed module-profile

Repeat positioning accuracy: 0.01/±0.02 mm

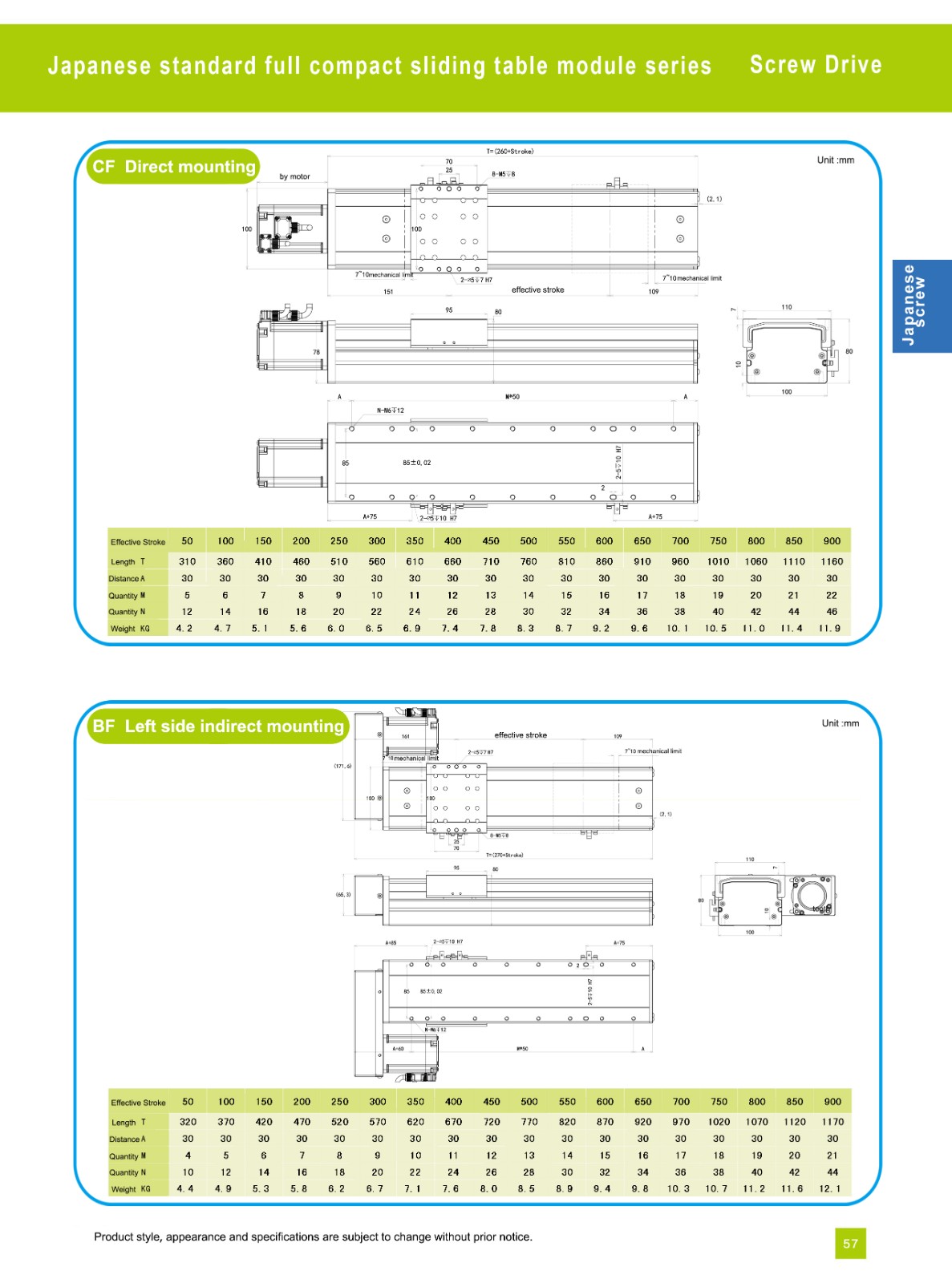

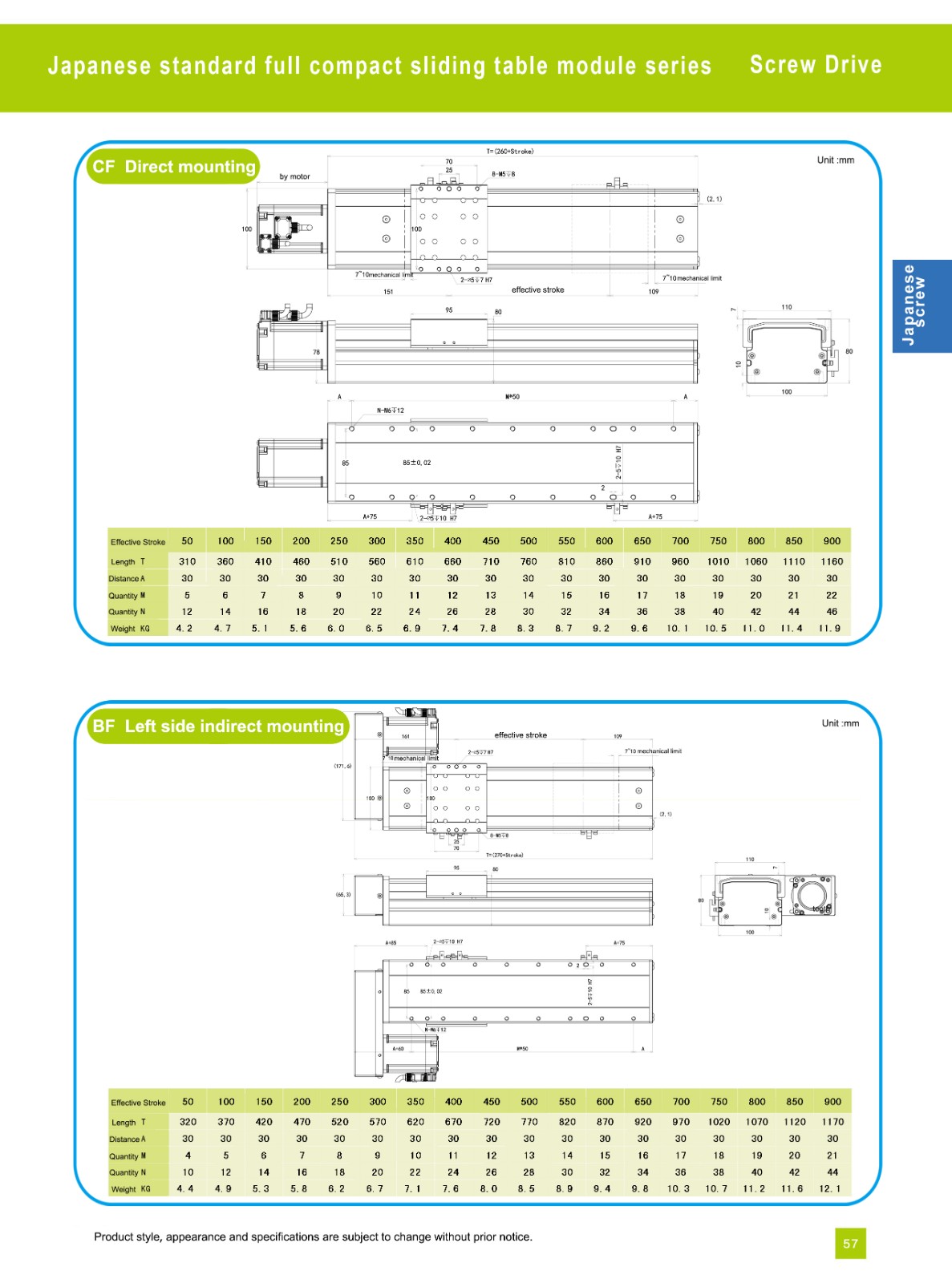

Customizable stroke: 50-1000 mm

Screw outer diameter: φ16 mm

Lead: 05/10/20 mm

Motor power: 200/400W (motor can be customized)

Maximum speed: 250/500/1000 MM/S

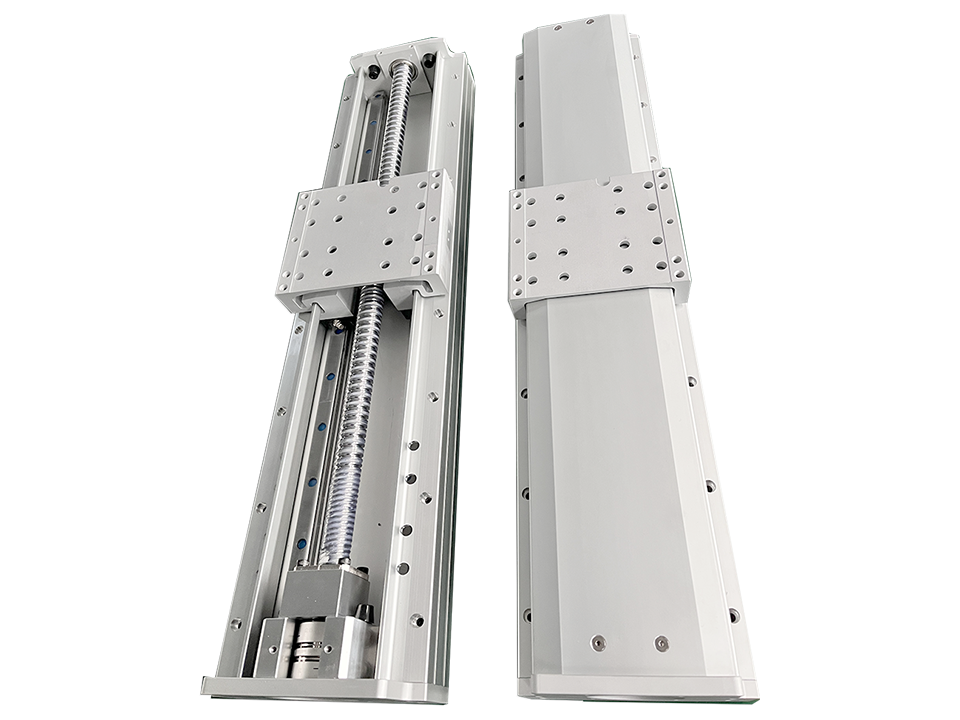

Introducing the FSKSM-100, an aluminum alloy integrated fully enclosed ball screw actuator module. This advanced linear screw actuator combines high protection with structural rigidity, meticulously designed for precision automation scenarios. As a leading ball screw linear actuator, it sets new benchmarks for reliability and accuracy. When your industrial applications demand an actuator ball screw that delivers consistent, micron-level positioning, and you seek top-tier ball screw actuators, the FSKSM-100 is your ultimate solution.

FSKSM-100 aluminum alloy integrated fully enclosed ball screw actuator module is a linear motion unit with integrated high protection and structural rigidity, designed for precision automation scenarios, and its core features are as follows:

1. Core structure and material

Aluminum alloy integrated profile frame

Adopting high-strength aluminum alloy extrusion molding, taking into account lightweight and load-bearing rigidity, effectively suppressing vibration deformation during high-speed movement. The profile surface is anodized to improve wear resistance and corrosion resistance, suitable for long-term use in industrial environments. This robust frame is fundamental to a reliable linear screw actuator.

Fully enclosed protection design

The guide rail and the screw are fully sealed, and the dust and liquid intrusion are isolated by stainless steel dustproof belts or flexible sealing covers, with a protection level of IP54 or above. The internal integrated automatic lubrication system reduces maintenance frequency and extends service life – a key benefit of advanced ball screw actuators.

2. Transmission and performance parameters

Ball screw transmission system

Standard C5 precision actuator ball screw, repeatability ±0.01mm, suitable for precision positioning scenarios (such as semiconductor equipment, optical calibration). Lead range 10-20mm, balance speed and torque requirements, support high-speed and stable operation. This is the heart of our precision ball screw linear actuator.

Load and stroke adaptability

Maximum load 150kg (screw transmission mode), stroke coverage 50-900mm, meet medium and long distance transmission requirements. Optional synchronous belt drive version, expand ultra-long stroke light load application (such as photovoltaic panel transmission line).

3. Typical application scenarios

Electronic manufacturing: PCB board cutting and positioning, chip packaging equipment wafer handling.

Medical equipment: CT scanner detector track, surgical robot arm joint.

Precision detection: three-coordinate measuring machine probe moving platform, automated optical inspection (AOI) equipment.

4. Selection considerations

| Lead | 10mm (high precision) | Precision assembly, optical adjustment |

| 20mm (high speed) | Material transmission, packaging machinery |

| Sealing level | IP54 (basic dustproof) | Ordinary industrial workshop |

| IP65 (splashproof) | Wet/detergent environment |

| Lubrication method | Automatic lubrication unit | Long-term maintenance-free production line |

The module reduces installation complexity through an integrated structure, and the fully enclosed design significantly improves reliability in harsh environments. It is an ideal motion execution unit for high-end automation equipment, especially as a reliable ball screw actuator.

The Aluminum Integrated Profile Fully Enclosed Screw Actuator Module Slide FSKSM-100 offers the following key advantages:

Fully Enclosed Structural Protection

The integrated aluminum alloy design with IP65 protection effectively isolates dust, moisture, and cutting fluids, making it suitable for harsh environments such as CNC machine tools and semiconductor equipment.

High Precision and High Rigidity

Equipped with a precision-ground ball screw, it achieves repeatability of ±0.02mm and increases axial rigidity by over 30%, meeting high-speed and high-load motion requirements. This makes it a formidable ball screw linear actuator.

Modularity and Lightweight

The aluminum alloy body is 40% lighter than traditional steel structures, supporting multi-axis configurations (such as XY gantries), easy installation, and compatible with NEMA 23/34 stepper/servo motors.

Long Life and Low Maintenance

The self-lubricating guide rail design reduces maintenance frequency. Available travel ranges range from 100 to 4000mm, it boasts a lifespan exceeding 5000 hours.

Industrial-grade durability

The anodized surface allows for an operating temperature range of -20°C to 80°C, offering strong corrosion resistance and is suitable for food processing, medical equipment, and other fields.

The Aluminum Integrated Profile Fully Enclosed Screw Actuator Module Slide FSKSM-100 is primarily used in high-precision, high-stability automation equipment. Its core advantage lies in combining the lightweight properties of aluminum alloy profiles with the precise transmission performance of a fully enclosed ball screw actuator module. The following is an analysis of typical application scenarios:

Precision Automation Equipment

3D Printing and CNC Machine Tools: Suitable for linear motion components requiring high repeatability (±0.05mm), such as the Z-axis drive of print heads or tooling.

Semiconductor Equipment: In wafer handling and lithography equipment, the fully enclosed design effectively prevents dust and meets cleanroom environment requirements. This makes it a crucial ball screw linear actuator.

Industrial Robotics

Collaborative Robot Joints: Aluminum alloy profiles reduce overall weight, while screw modules provide high torque output, making them suitable for linear joints in lightweight robotic arms.

Aerospace and Automotive Manufacturing

Lightweight Structural Assembly: Precision slides for aircraft doors or automotive battery packs are made of aluminum alloy, meeting lightweight requirements, and the fully enclosed design withstands harsh working conditions.

Medical Equipment

Imaging Equipment Mobile Platforms: CT scanner bed drives, for example, require low noise and high stability. The screw actuator's smooth speed regulation (0-500 rpm) meets these requirements.

Technical Compatibility

Environmental Adaptability: The fully enclosed structure supports IP65 protection, making it suitable for dusty or humid environments.

Expandability: The modular design facilitates integration of limit switches or encoders for closed-loop control.

By combining the lightweight aluminum alloy profile with the precision of screw actuator drive, this model has become a key transmission component in high-end manufacturing, providing unparalleled performance as an actuator ball screw within a system of sophisticated ball screw actuators.

The core advantages of the Aluminum Integrated Profile Fully Enclosed Screw Module Slide include:

**High Precision and Stability:** Utilizing aluminum alloy profiles and precision machining technology,

straightness error can be controlled within ±0.02mm, and repeatability reaches ±0.01mm, suitable for

high-precision applications such as semiconductors and precision measurement.

**Lightweight and Space-Saving:** The aluminum alloy material (density 2.7g/cm³) reduces module weig

ht, while the embedded design reduces the body width, saving installation space.

**Corrosion Resistance and Low Maintenance:** Anodizing treatment forms an anti-corrosion oxide film,

suitable for cleanrooms or humid environments, and supports external oiling maintenance without rem

oving the cover.

**Modular Design and Easy Installation:** Standard models (such as ATH5/ATH8/ATH12) support flexible

combinations, and the side mounting reference surface and bottom positioning pin holes simplify the

fixing process.

High-efficiency transmission: Maximum speed up to 1000mm/s, stroke up to 1250mm, meeting the needs of high-speed automation.

Its comprehensive performance is outstanding in fields such as 3C electronics, new energy, and logistics

warehousing.