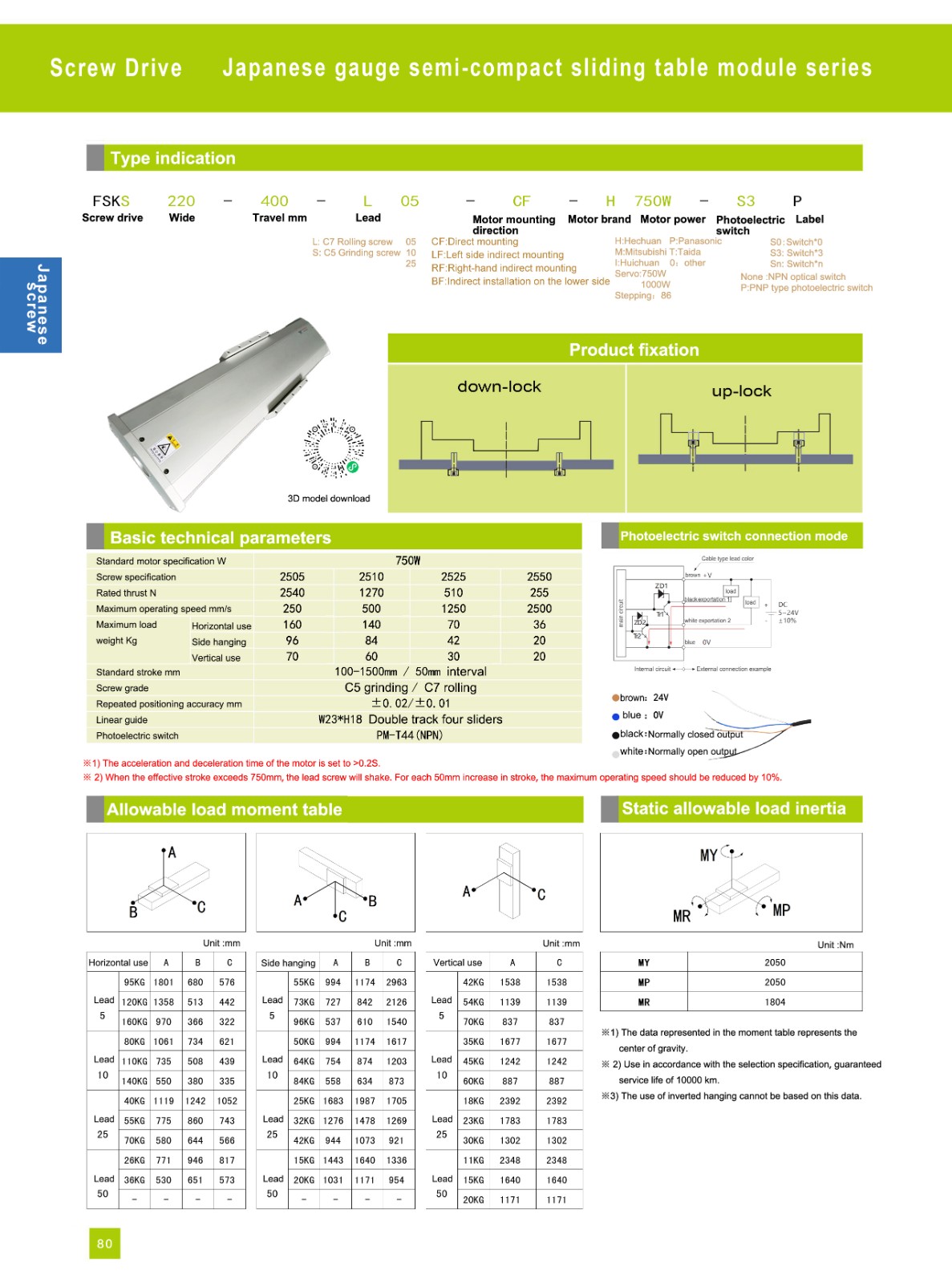

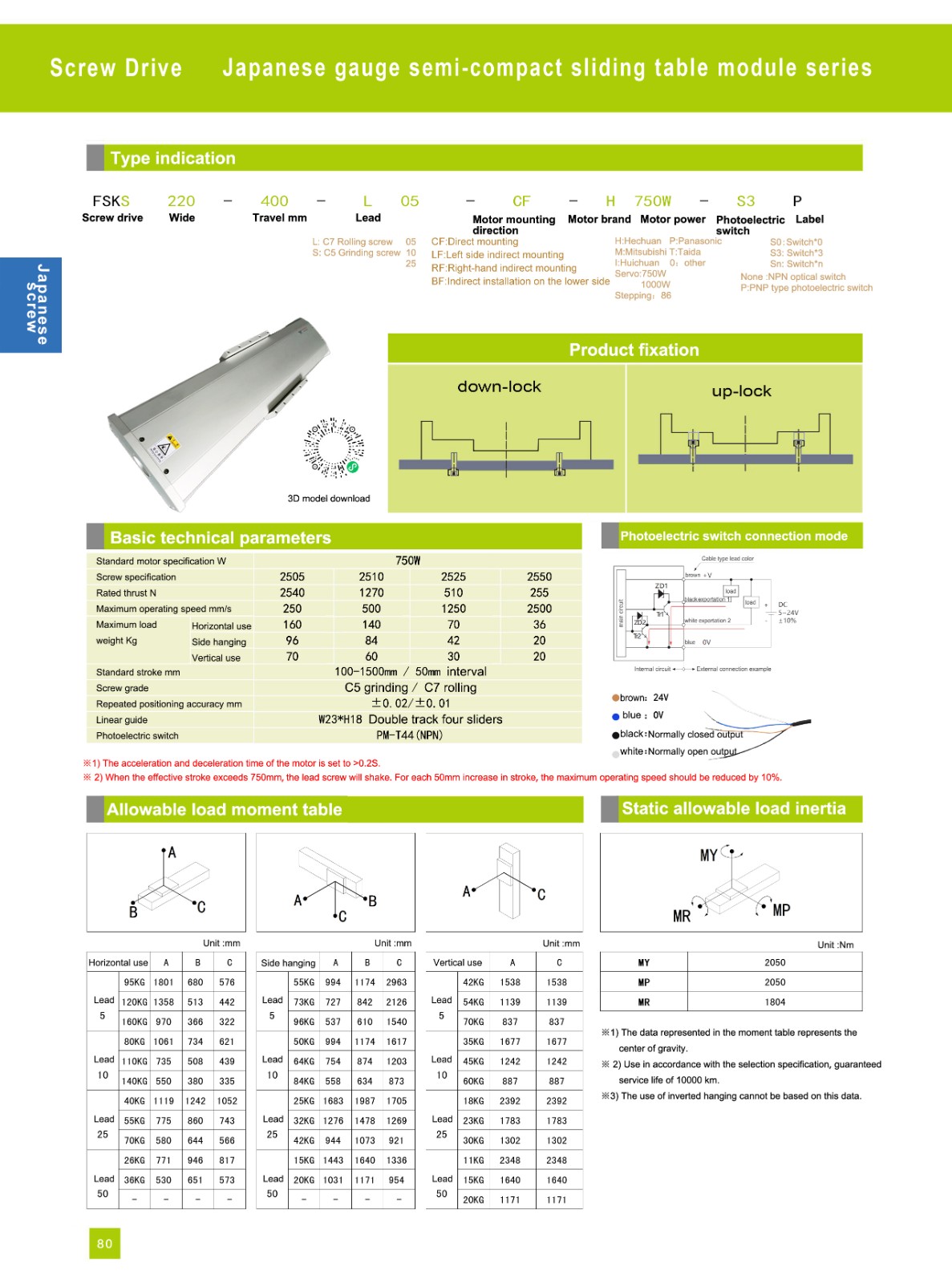

FSKS-220 semi-dense module

Horizontal maximum load: 150KG

Side-mounted maximum load: 105KG

Vertical maximum load: 75KG

Repeat positioning accuracy: ±0.02/0.01mm

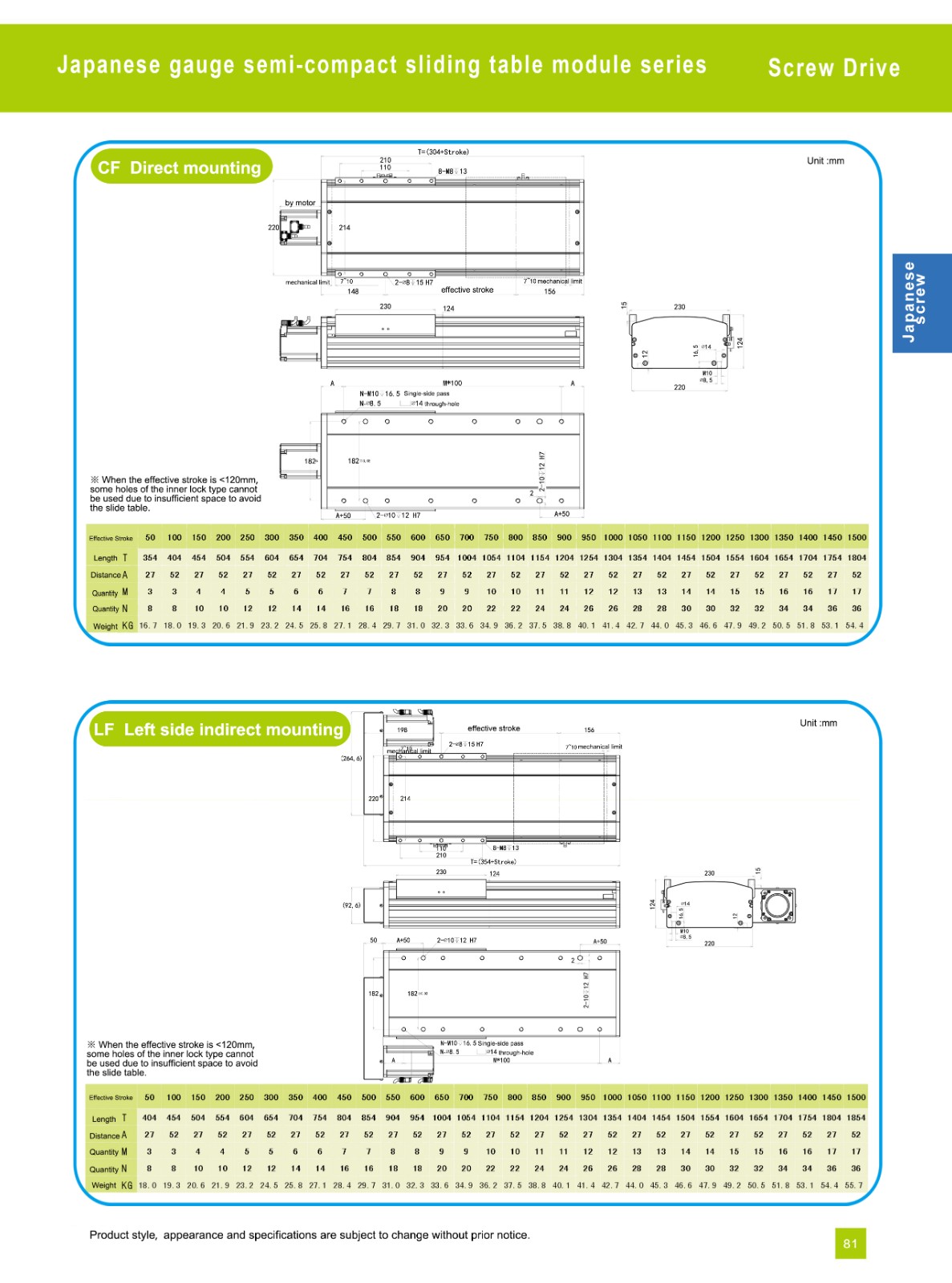

Customizable stroke: 50-1700MM

Screw outer diameter: φ25MM

Lead: 05/10/25 MM

Motor power: 750W

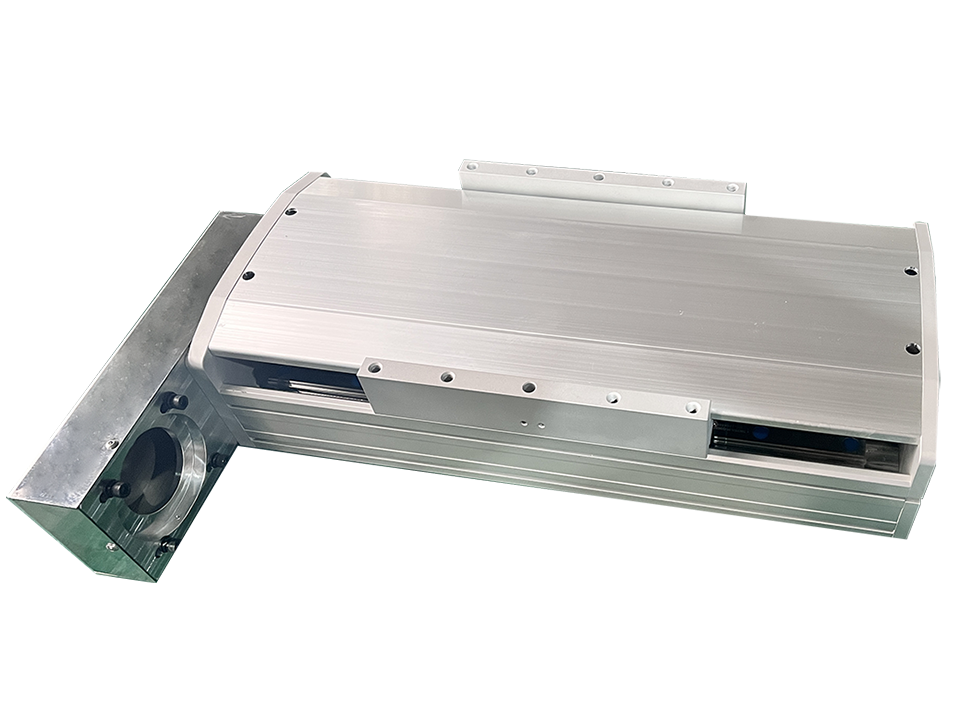

Discover the FSKS-22, a high-performance ball screw linear slide engineered to redefine industrial automation. This integrated aluminum alloy screw slide offers an unparalleled combination of lightweight design and exceptional rigidity, making it the ideal solution for precision load transmission and demanding high-frequency operations. Its innovative semi-enclosed structure provides excellent dust resistance while ensuring optimal heat dissipation, effectively prolonging the service life of this vital ball screw actuator.

Key Features for Superior Performance:

Ultra-Quiet Operation: Experience a significantly quieter working environment thanks to advanced noise reduction technology integrated into this ball screw slide, minimizing friction noise.

Energy-Efficient Design: The optimized ball screw transmission system dramatically reduces energy consumption, aligning with modern energy-saving product standards.

Effortless Maintenance: Featuring a specialized, corrosion-resistant sealing strip, the FSKS-22 linear slide allows for quick reset and convenient cleaning, drastically reducing valuable downtime.

Robust Environmental Adaptability: Engineered to perform reliably across a broad range of climates, from subtemperate to subtropical, this ball screw actuator consistently handles temperature and humidity fluctuations.

Seamless Modular Compatibility: Designed for versatility, this screw slide supports various guide rail accessories, including NK series sliders, making it perfect for integration into logistics sorting systems or advanced CNC equipment.

The FSKS-22 ball screw linear slide is perfectly suited for automated production lines, efficient logistics handling systems, and precision instrument platforms. It expertly balances the need for high-speed translation with micron-level positioning accuracy, making it a critical component for your most demanding applications.

Unmatched Advantages of the FSKS-22 Ball Screw Slide:

The semi-enclosed, integrated aluminum ball screw slide FSKS-22 offers core advantages that set it apart:

High-Rigidity Structural Design: Featuring four rows of steel balls arranged at a 45° contact angle, this ball screw actuator achieves equal load characteristics in all directions. With a rated load of 220 kg and the capacity to withstand instantaneous shock loads of up to 600 N·m, its integrated aluminum alloy housing combines lightweight efficiency with superior strength. This design results in a 30% weight reduction compared to traditional screw slide structures, enhancing overall system performance and ease of installation.

Precision motion control performance

The rolling friction coefficient is only 0.002, with repeatability of ±0.003 mm. Preload technology elimin

ates backlash and supports μm-level dynamic response. The enclosed structure effectively reduces dust

intrusion and maintains long-term operating accuracy.

Efficient heat dissipation and long life

The aluminum alloy housing features a toothed heat dissipation design, which improves heat dissipat

ion efficiency by 40% and supports a wide operating temperature range of -20°C to 80°C. The self-lub

ricating system extends maintenance intervals to 10,000 hours and reduces failure rates by 60%.

Modular Expansion Capability

The 220mm standard width supports multi-axis parallel connection and is compatible with mainstream

servo drive systems. Pre-installed interfaces enable quick installation, and positioning accuracy and rep

atability reach 99.8%.

Enhanced Environmental Adaptability

IP54 protection rating, resistant to salt spray corrosion for over 2000 hours. Non-contact signal transmi

ssion reduces mechanical wear, making it suitable for both cleanroom and outdoor environments.