Menu

- Home

- Products

- Linear Actuator

- Electric Actuator

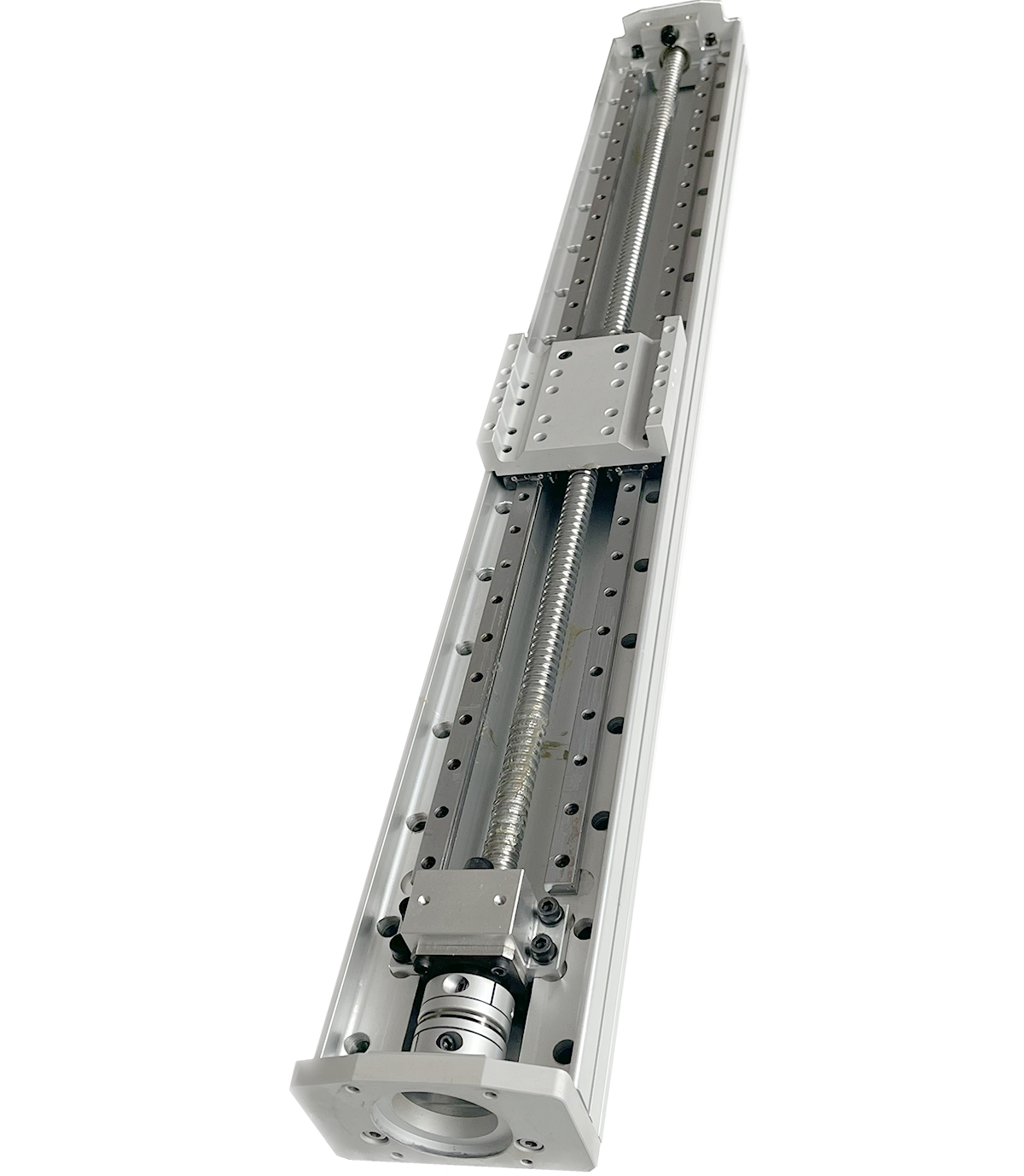

- Ball Screw Actuator

- Belt Driven Linear Actuator

- Linear Motor

- Gear And Rack Linear Module

- Robot Arm

- Servo Press

- 6dof Motion Platform

- News

- 6-Degree-of-Freedom Simulation Platform

- Electric cylinder

- Linear module

- Company News

- Intelligent servo press

- Factory Show

- Industrial Equipment

- Assembly Inspection

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Delivery

- Case

- Servo Electric Cylinder

- module

- Linear Motor

- Online Sizing

- Videos

Search