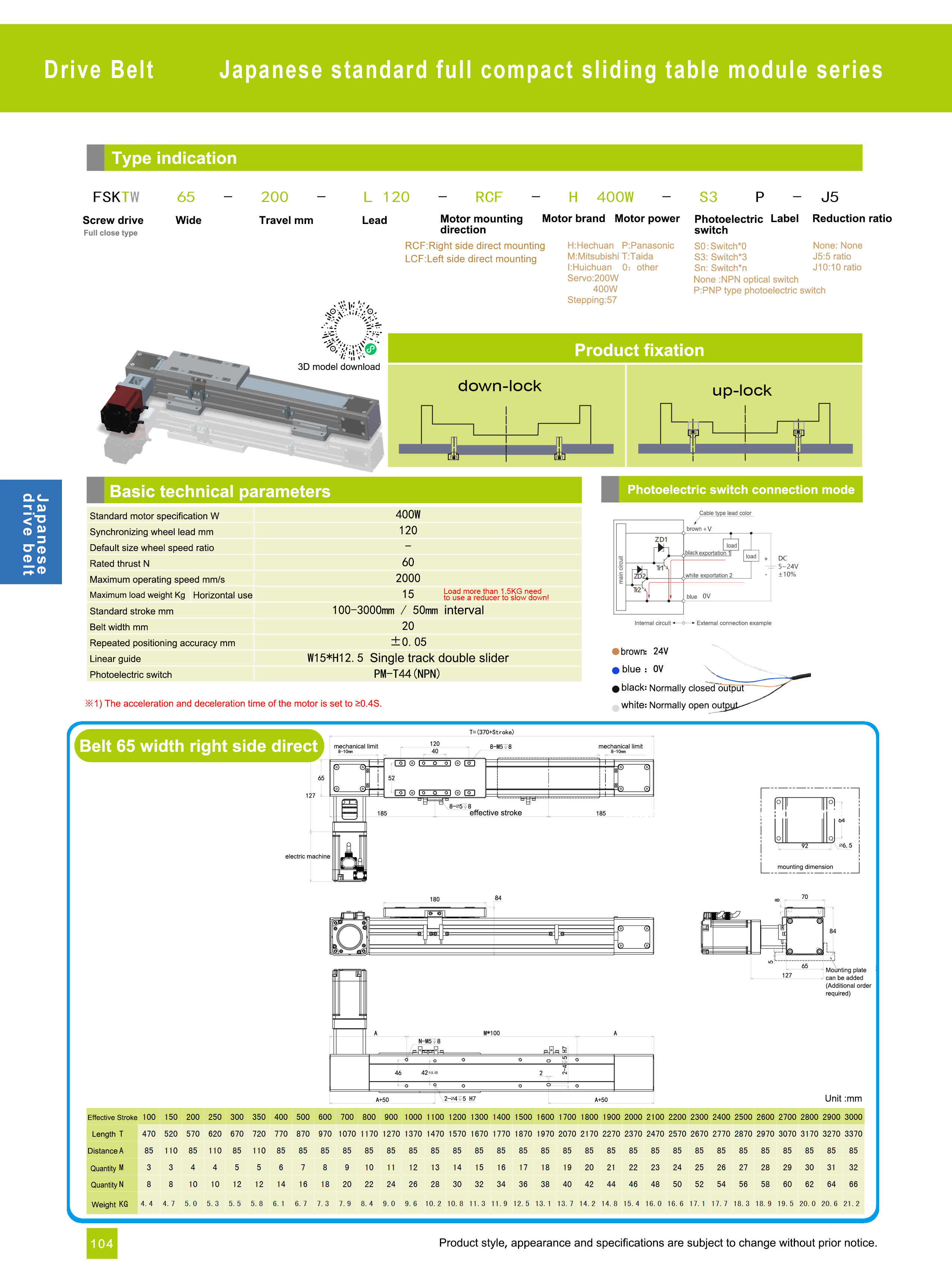

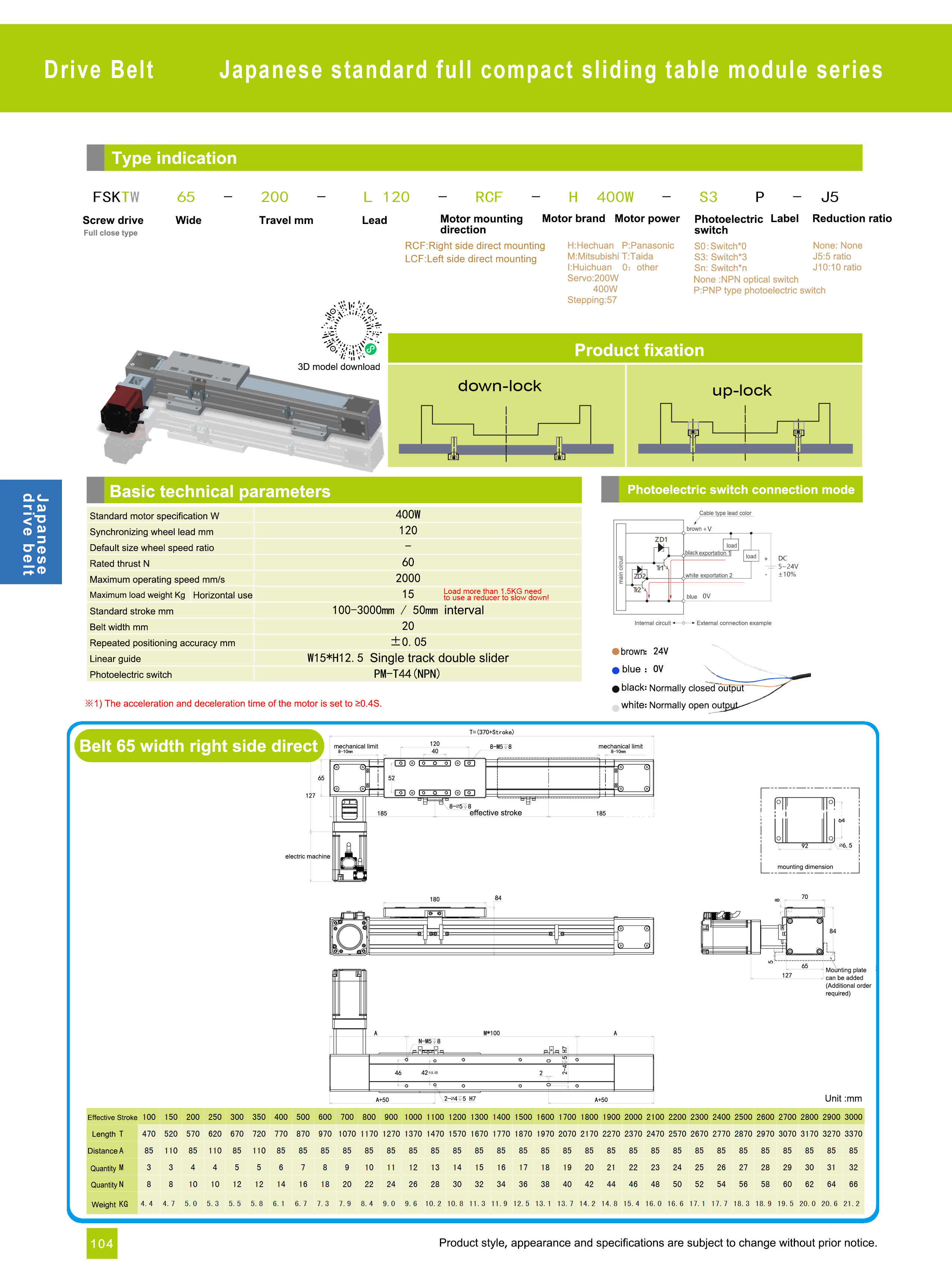

Maximum horizontal load 15KG

Model: FSKTW-65 full-dense belt module

Repeat positioning accuracy: ±0.05 mm

Customizable stroke: 50-3000mm

Timing belt specifications: S3M-20

Timing belt lead: 120 mm

Maximum speed: 2000 MM/S

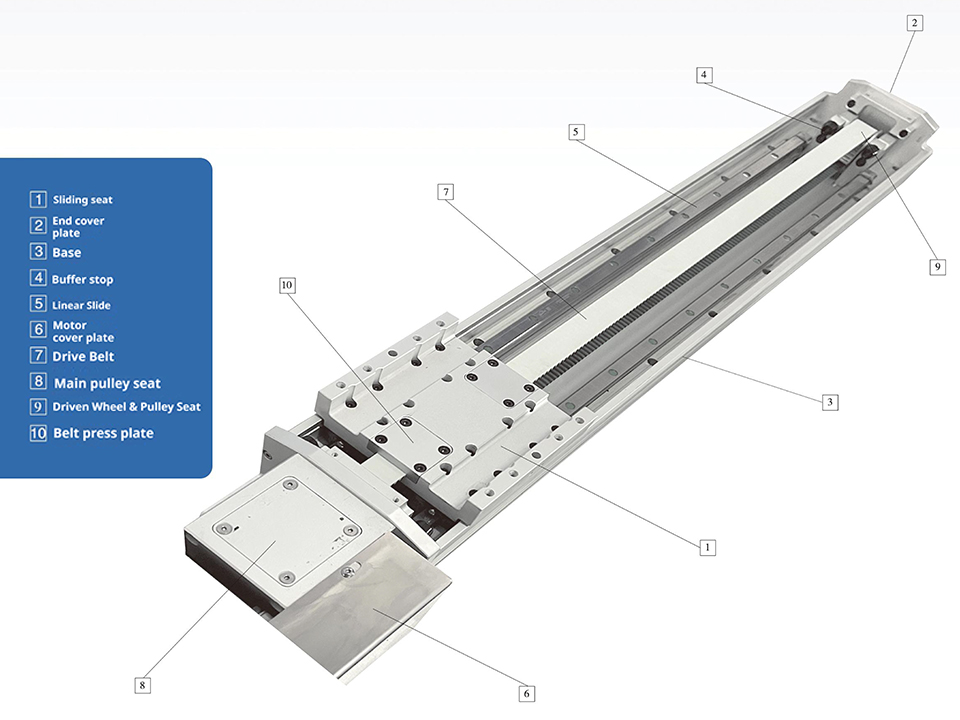

Structure:

Sliding seat

End cover plate

Base

Buffer stop

Linear slide

Motor cover plate

Drive Belt

Main pulley seat

Driven Wheel & Pulley Seat

Belt press plate

The advantages of the Automatic Synchronous Belt Slide for Lathe Drive FSKTW-65 are primarily reflec

ted in the following aspects:

High Rigidity and High Feed Force

A double-sided ball bearing ring guide design, protected by a permanent magnetic stainless steel cover

belt, significantly improves the system's rigidity and torque absorption capacity, making it suitable for

high-precision machining scenarios.

Long-Life Guide System

Optimized guide rail materials and structural design ensure a long service life, reducing maintenance

frequency and costs.

Modularity and Compatibility

As part of a modular mechanical system, its highly versatile interface design allows for seamless integra

tion into various automation environments, supporting linear or rotary motion requirements.

Various Specifications

A variety of standard and wide models are available (widths from 30mm to 220mm), with a maximum

travel of 8.5 meters (toothed belt type), to meet diverse machining requirements.

Dynamic Performance and Stability

The combination of synchronous belt drive technology and a servo control system achieves high dyna

mic response and process stability, making it particularly suitable for continuous automated production.