The FSKTW-220 is a guide-driven sliding module designed specifically for dust-resistant environments.

It utilizes a fully enclosed structure (e.g., an accordion cover) to prevent dust intrusion. It is suitable for

high-precision, high-load industrial automation applications such as laser cutting and optical inspection.

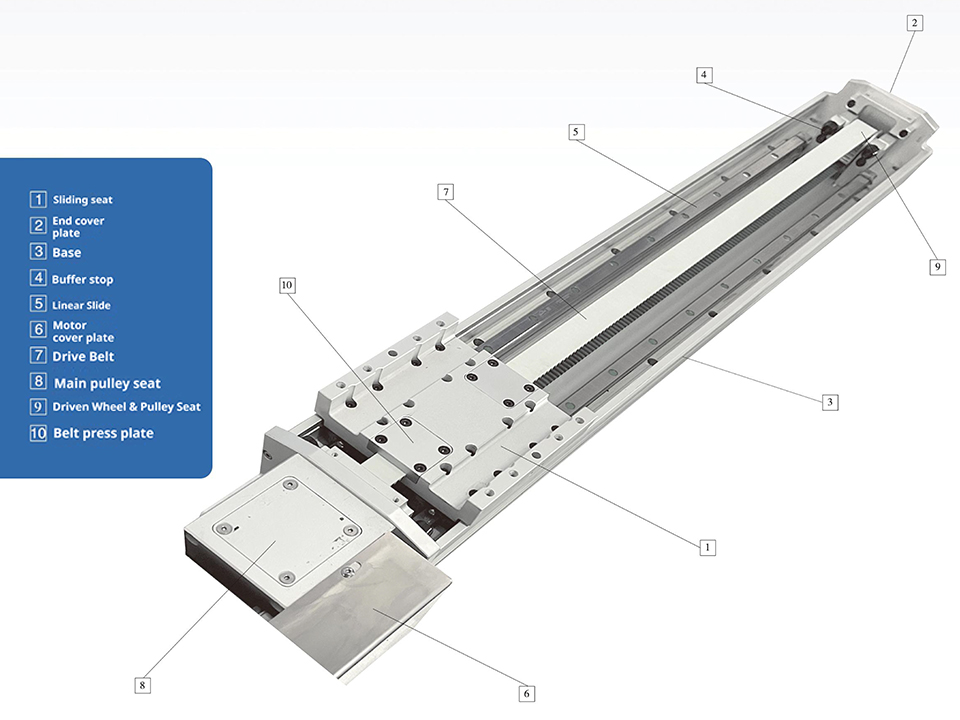

Its core advantages include a dual-guide design for enhanced stability and a ball screw (similar in

specifications to the G1610) for high-precision positioning of ±0.02mm. It boasts an effective travel of

approximately 220mm (based on similar models), a maximum load of 40kg, and a speed of 250mm/s,

enabling long-term reliable operation in harsh conditions. The module offers optional motors (such as

a two-phase 60° stepper motor) and supports customized stacking configurations, such as cross or

gantry, to meet diverse equipment integration needs.

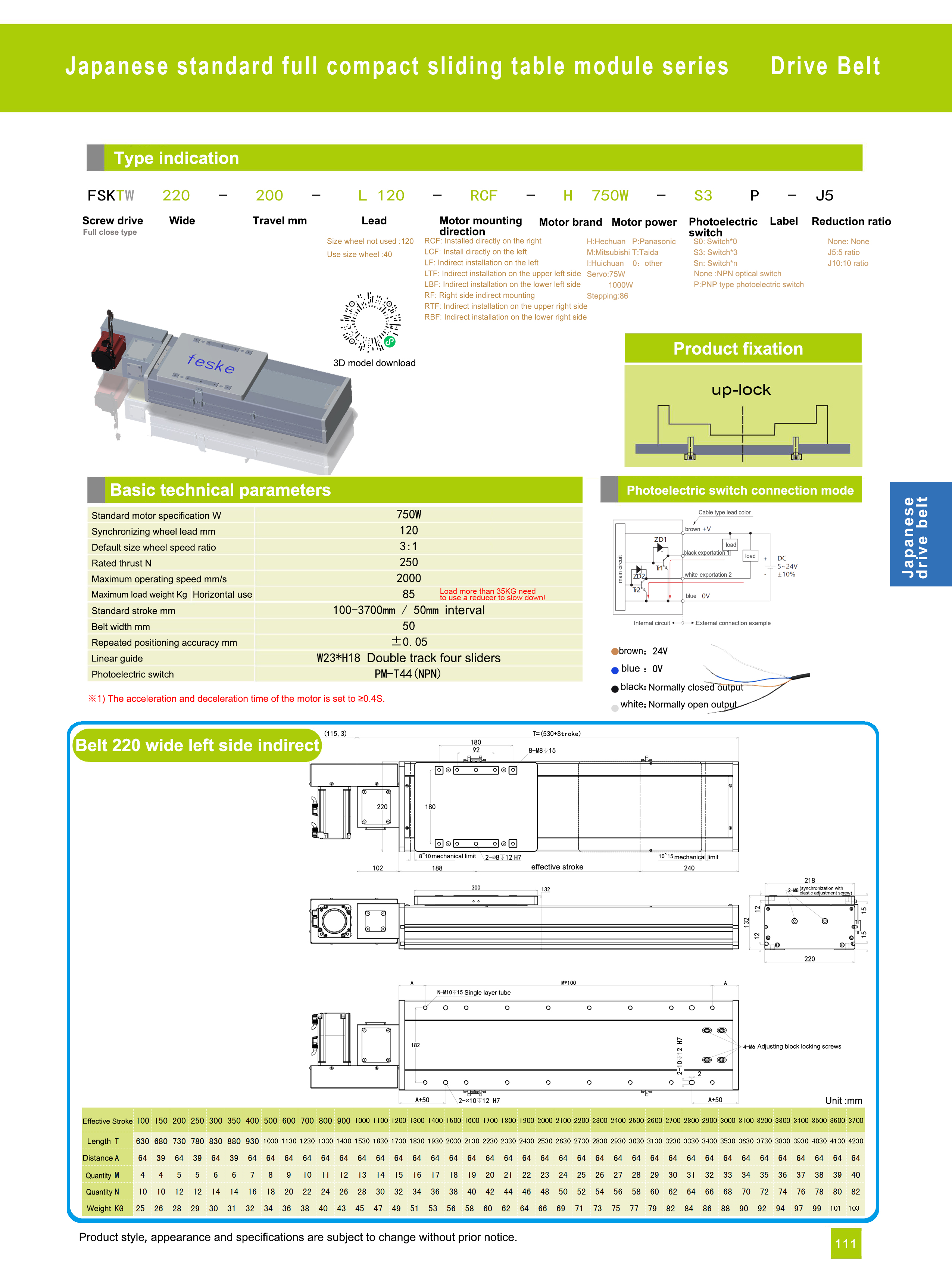

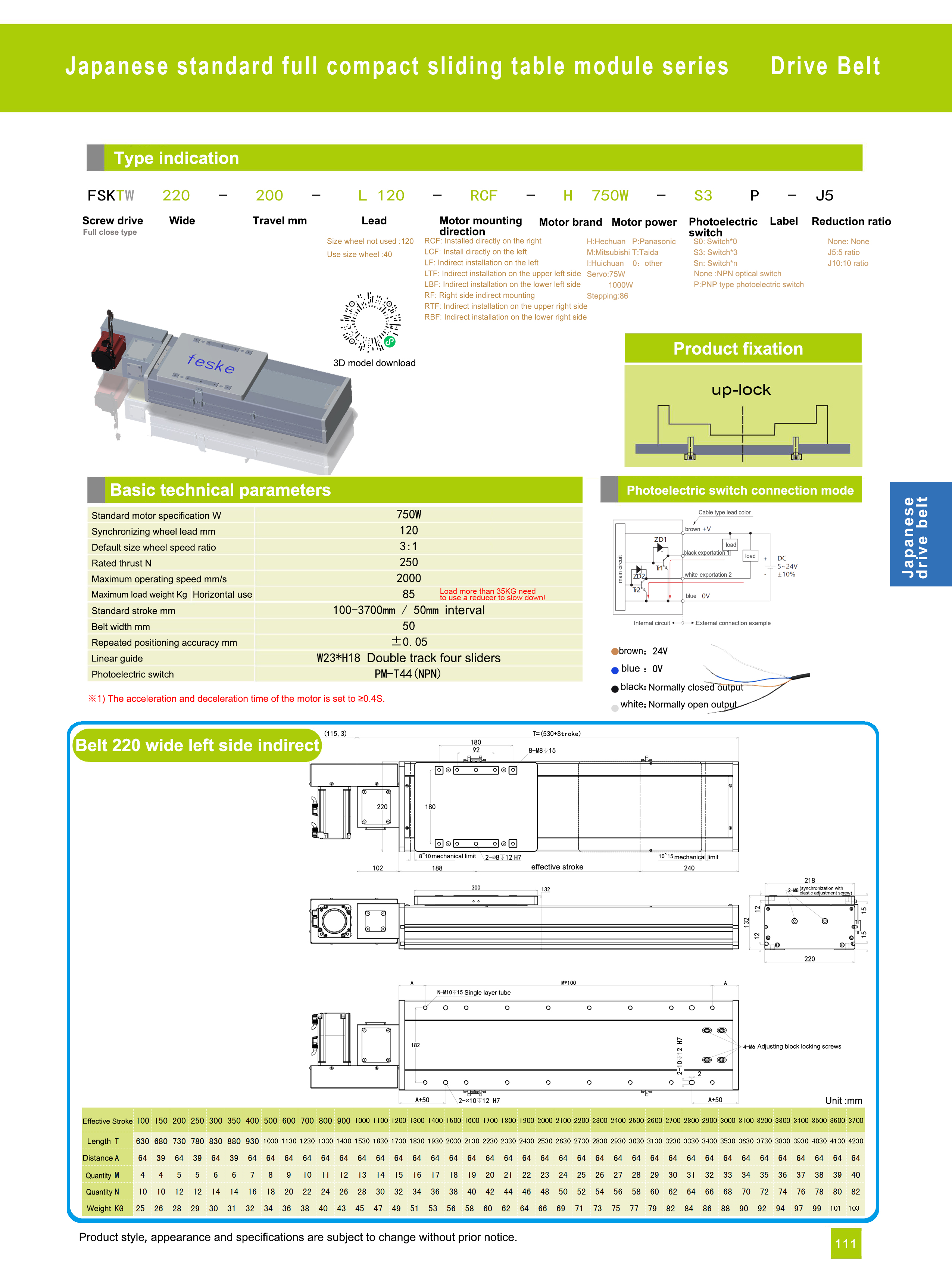

Core Features and Technical Specifications

1. Patented Dust-Proof Guide System

Equipped with a labyrinth seal structure and dual-sided removable dust covers, it achieves ISO

14644-1 Class 5 cleanliness certification.

Dust-Proof Efficiency: Blocks 99.7% of particles ≥ 0.3μm (measured data).

Maintenance Interval: Three Times Longer (Up to 6,000 hours) than Traditional Open Guides.

2. High-Precision Synchronous Belt Drive

Repeatability: ±0.05mm (Tested at a Constant Temperature of 23°C).

Maximum Speed: 2.5m/s (Load ≤ 15kg)

Acceleration: Adjustable from 0-1m/s² (Adaptable to Different Working Conditions).

3. Modular Load Design

Specifications: Standard, Heavy-Duty

Rated Load: 20kg, 35kg

Travel Range: 220mm (Expandable to 500mm)

4. Intelligent diagnostic interface

Integrated RS-485 communication protocol supports real-time feedback:

Temperature monitoring (-10°C to 80°C)

Abnormal belt tension warning

Cumulative mileage statistics

Typical application scenarios:

3C electronics industry: Mobile phone camera module autofocus production line

Photovoltaic equipment: Precision feeding system for solar panel laminators

Medical equipment: In vitro diagnostic instrument test kit transport track

Environmental adaptability: Passed 72-hour salt spray test (ASTM B117 standard) and IP54 protection

rating certification, suitable for:

Non-condensing environments with humidity ≤85% RH

Around machine tool areas with trace oil mist