Maximum horizontal load 130 KG

Model: FSKSM-175 screw full-closed module-steel belt

Repeat positioning accuracy: 0.01/±0.02 mm

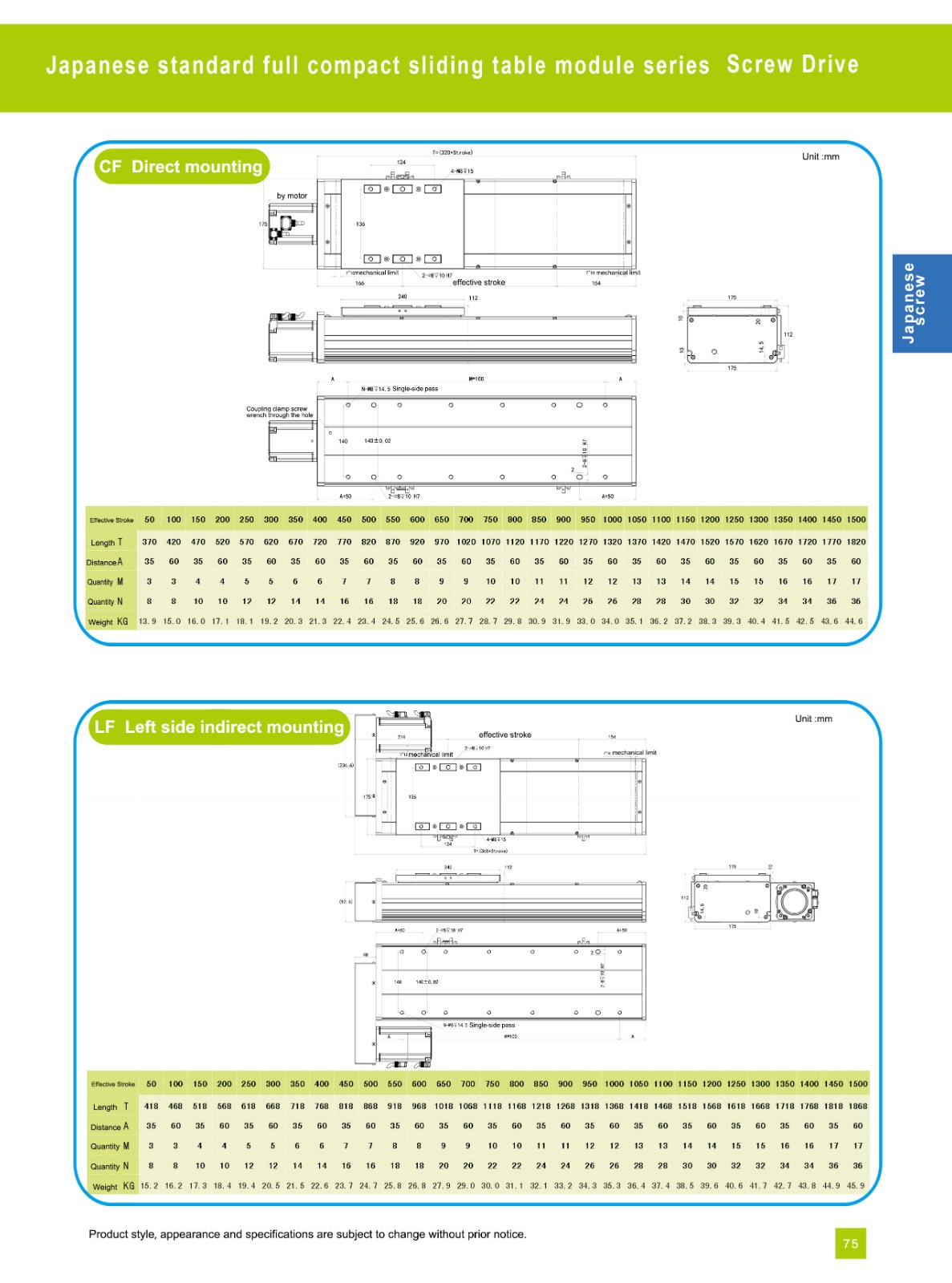

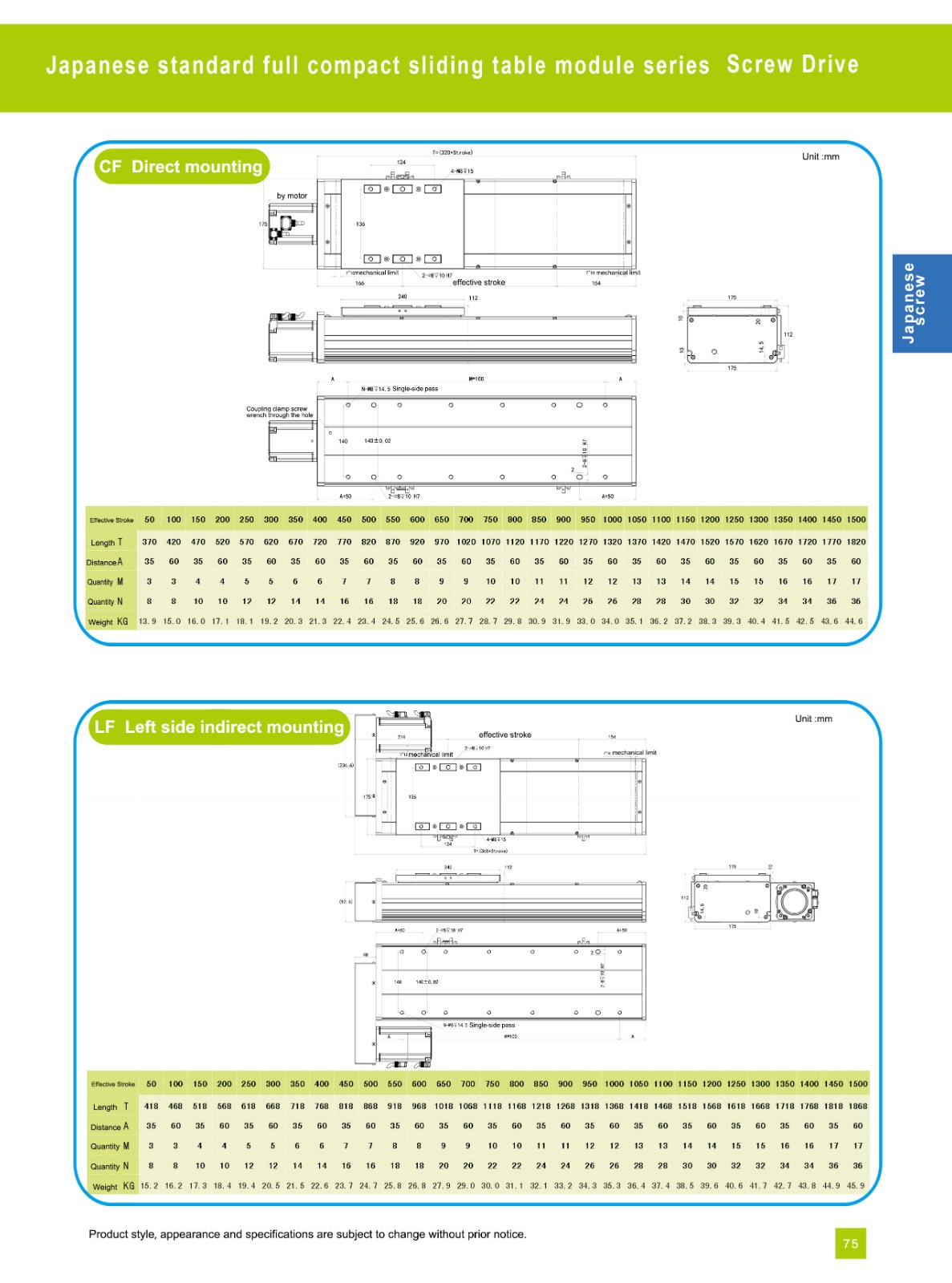

Customizable stroke: 50-1500 mm

Screw outer diameter: φ25 mm

Lead: 05/10/25 mm

Motor power: 750W (motor can be customized)

Maximum speed: 250/500/1250 MM/S

Introducing the Fully Enclosed Waterproof Oil-proof And Splash Proof Screw Slide FSKSW-175, a revolutionary ball screw linear slide engineered for the harshest industrial conditions. This high-protection ball screw actuator redefines reliability, seamlessly integrating a fully enclosed structure with specialized sealing technology. It's the ideal ball screw linear actuator for precision motion where liquid splash, oil, or dust pollution are constant threats. When your application demands an actuator ball screw that performs flawlessly under pressure, or a robust linear screw actuator that simply won't quit, the FSKSW-175 is your ultimate solution.

Fully Enclosed Waterproof Oil-proof And Splash Proof Screw Slide FSKSW-175 is a high-protection linear drive module designed for harsh industrial environments. It integrates a fully enclosed structure, special sealing technology and high-performance transmission components. It is suitable for precision motion scenes with liquid splash, oil or dust pollution. Its core features include:

Sealed protection design

Fully enclosed stainless steel shell: It adopts a modular sealed cabin structure, combined with double-lip rubber sealing strips and metal dust covers to effectively block the intrusion of water, oil and particles, and the protection level reaches IP65 (dustproof and waterproof) and IP54 (oil-proof and splash-proof) standards. This robust sealing is critical for any ball screw linear slide operating in challenging conditions.

Corrosion-resistant material: The main frame and key components are made of SUS304/SUS430 stainless steel, which can withstand acid and alkali environments and long-term humid working conditions. This ensures the longevity of your ball screw actuator.

Performance parameters

Heavy-duty transmission capacity: supports 900 N radial load, 600 N lateral load, anti-flip torque increased to 30 N·m, suitable for high-torque servo motor (maximum speed 6000 min⁻¹). This makes it a powerful ball screw linear actuator.

Precision motion control: adopts C5-grade ground actuator ball screw, repeatability accuracy ≤±0.005 mm, and friction coefficient as low as 0.002~0.004. This exceptional precision elevates it beyond a standard linear screw actuator.

Low maintenance and long-term operation: four-row ball circulation system with self-lubricating bearings eliminates jamming caused by external contamination and increases service life by 40%. This ensures reliable operation of your ball screw linear slide.

Typical application scenarios

Food processing equipment: filling line valve control, conveyor belt positioning mechanism, resistant to cleaning agent erosion and grease environment.

Chemical machinery: reactor feeding arm, sealed tank opening and closing device, resistant to corrosive gas and liquid splashing.

Outdoor detection equipment: all-weather environmental monitoring probe displacement system, adaptable to rain, snow and high dust conditions.

Operational restrictions

It is prohibited to use in explosive environments or strong electromagnetic interference areas;

Long strokes (>2 m) require auxiliary supports to avoid resonance risks during high-speed operation.

Note: The actual selection needs to be combined with the dynamic characteristics of the load and the requirements of the environmental protection level.

The FSKSW-175 is more than just a ball screw linear slide; it's a testament to engineering excellence, providing a robust and precise ball screw actuator solution for the most demanding applications. This ball screw linear actuator offers unparalleled protection, making it the ideal linear screw actuator with a superior actuator ball screw for sustained performance in any harsh environment.