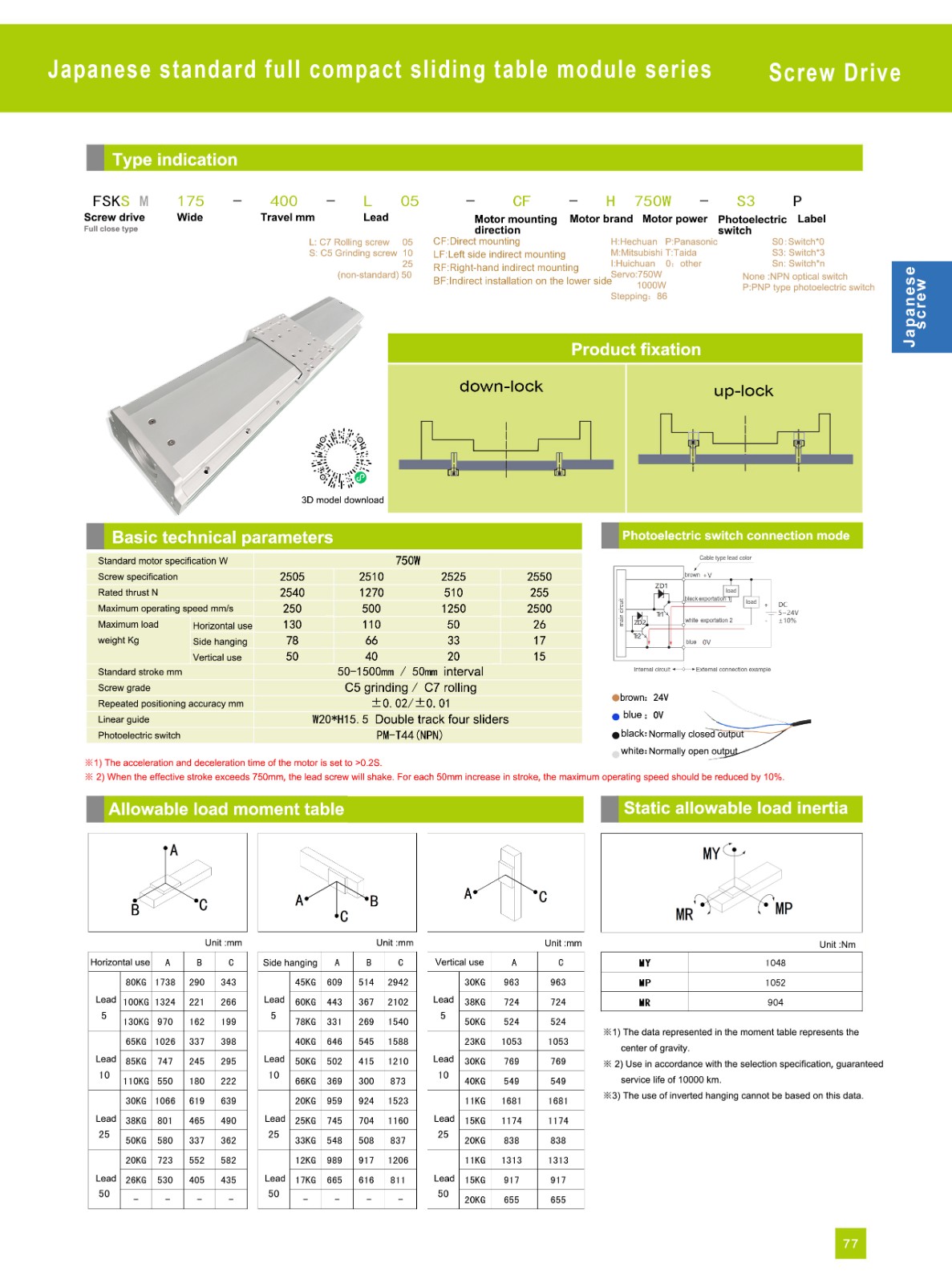

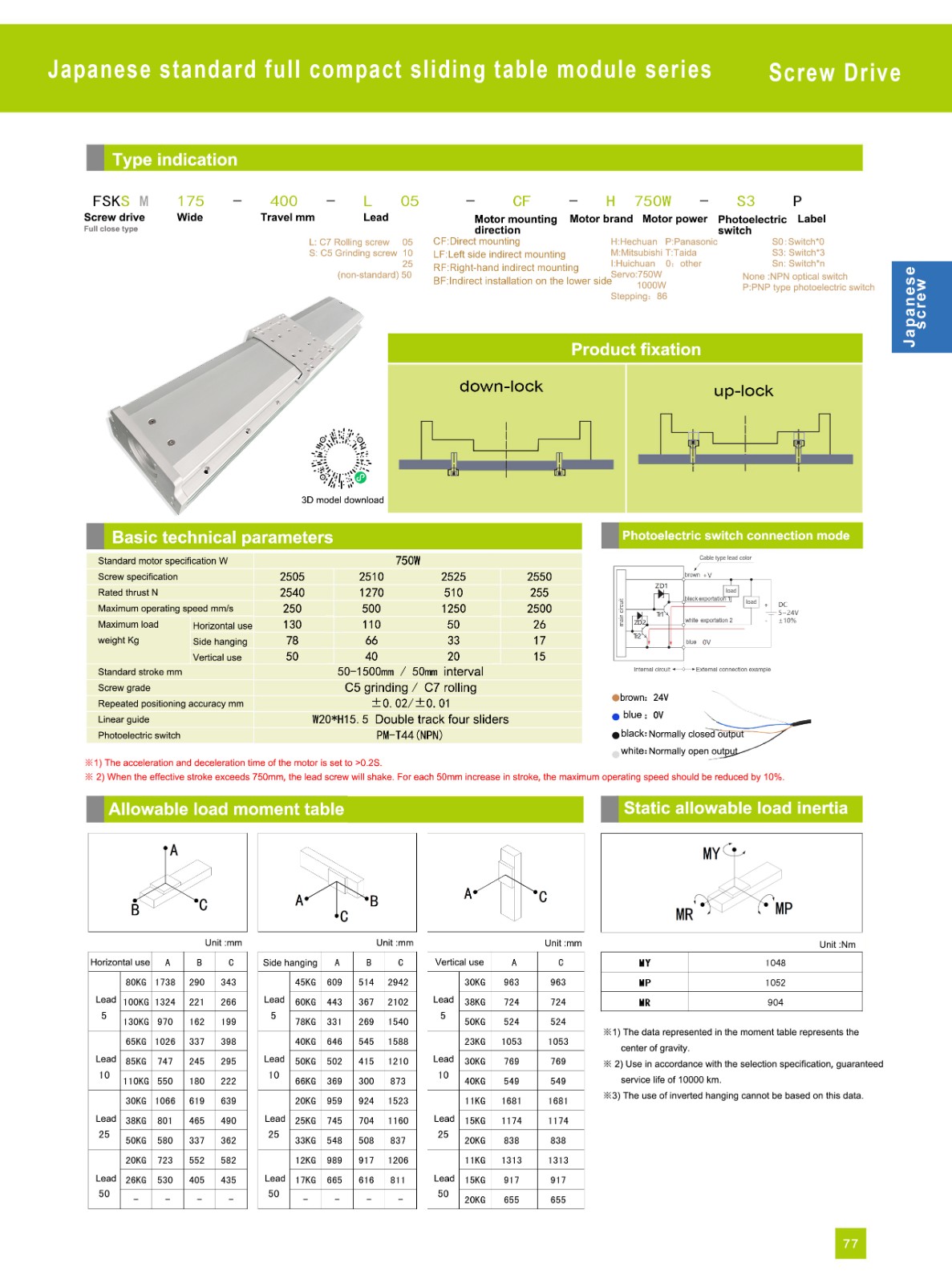

Maximum horizontal load 70 KG

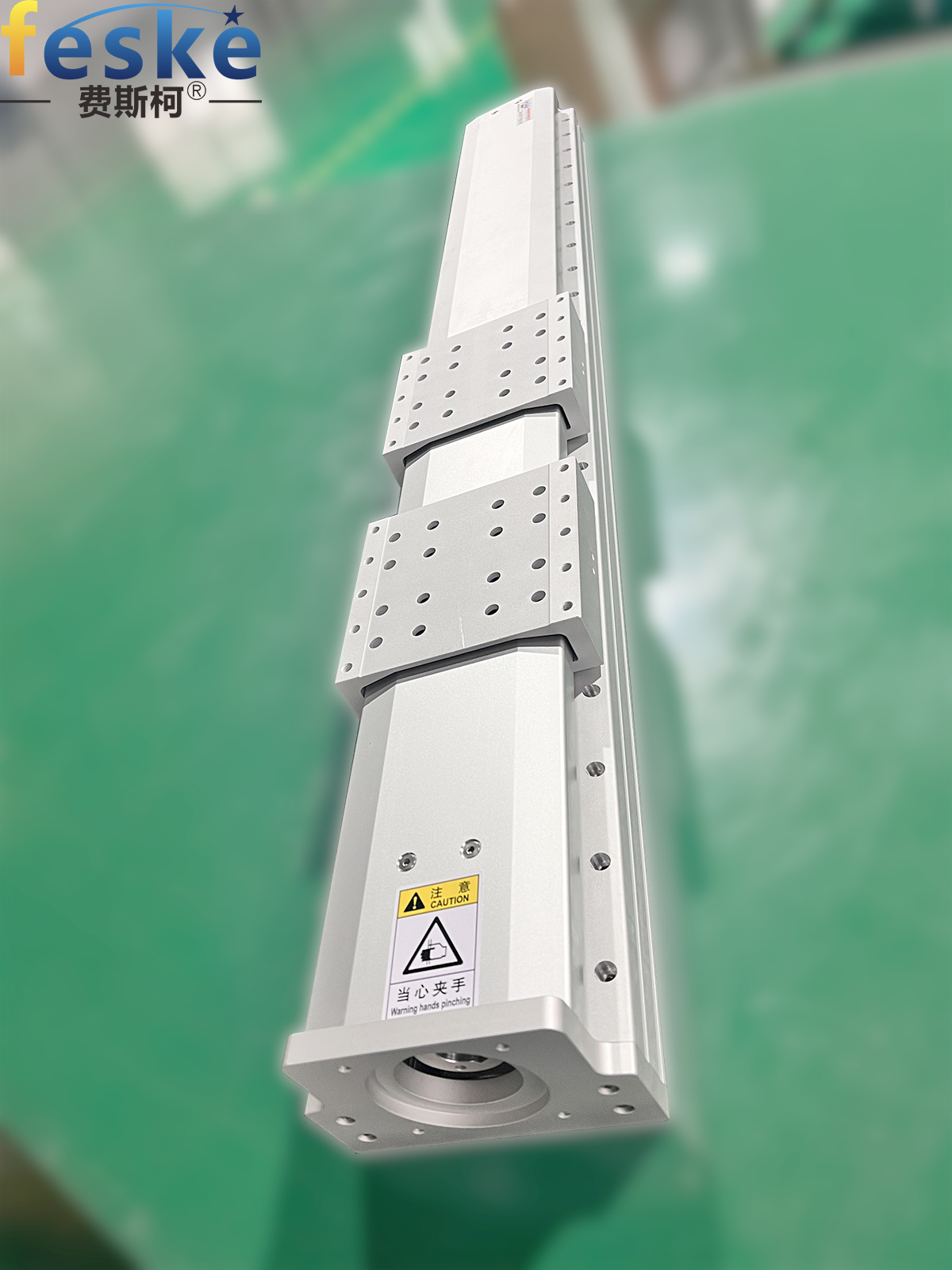

Model: FSKSW-175 screw full-closed module-steel belt

Repeat positioning accuracy: 0.01/±0.02 mm

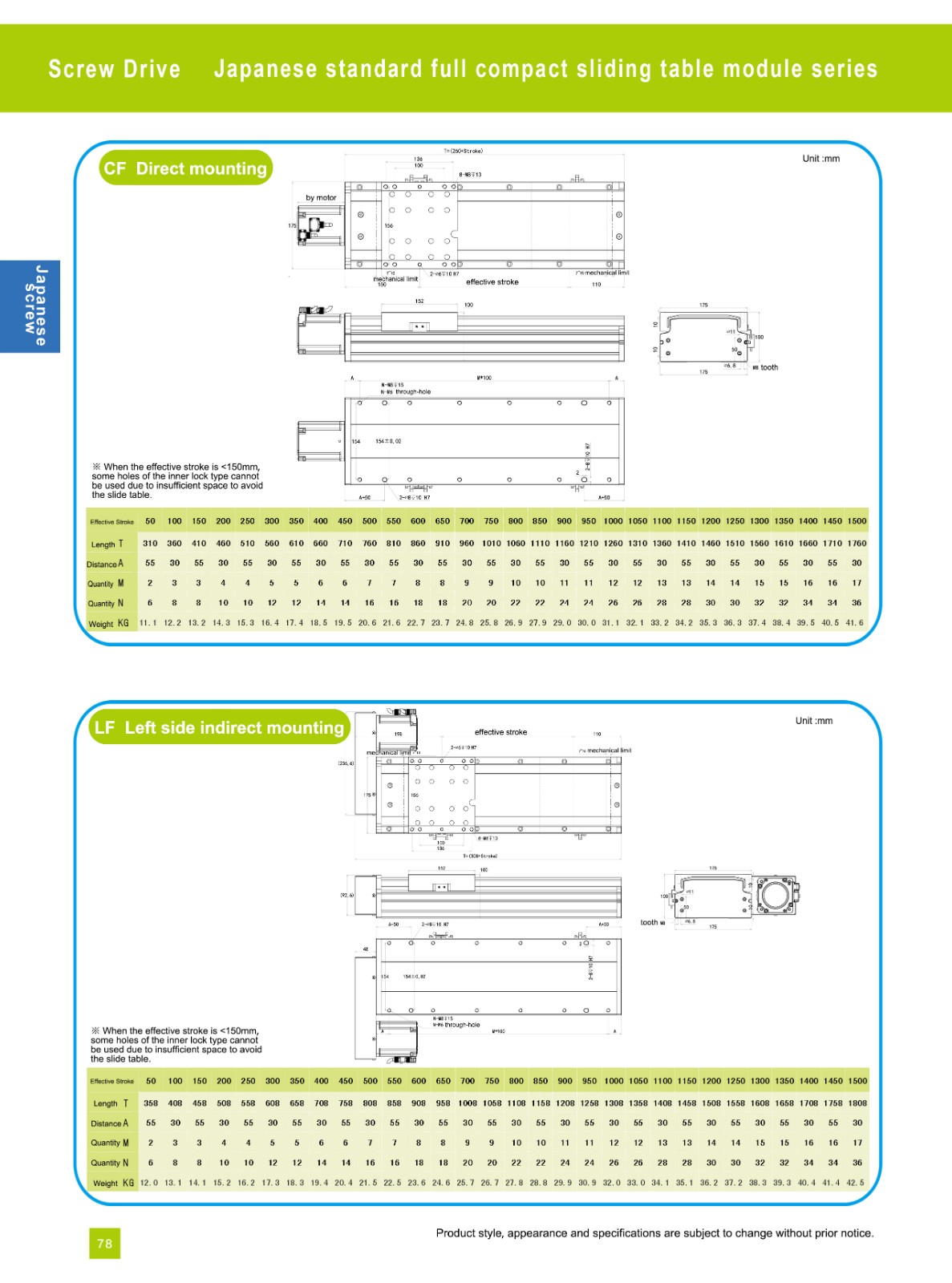

Customizable stroke: 50-1500 mm

Screw outer diameter: φ25 mm

Lead: 05/10/25mm

Motor power: 750W (motor can be customized)

Maximum speed: 250/500/1250 MM/S

Experience the pinnacle of industrial linear motion with the FSKSM-175, a fully enclosed ball screw actuator meticulously engineered for high-load precision positioning. This robust ball screw linear actuator redefines reliability and accuracy in demanding applications. As a leading ball and screw linear actuator, it integrates cutting-edge technology to ensure unwavering performance, making it the preferred choice for those seeking superior ball screws and actuators. When you need an actuator ball screw that delivers consistent, micron-level precision, the FSKSM-175 is your ultimate solution.

FSKSM-175 is a fully enclosed ball screw linear actuator designed for high-load precision positioning. Its core features are as follows:

🛠️ 1. Core structure and performance

Heavy-load integrated frame

Adopting high-strength aluminum alloy profiles as a whole, taking into account structural rigidity and lightweight design, effectively suppressing high-speed motion vibration deformation. Surface anodizing treatment enhances wear resistance and corrosion resistance, and adapts to long-term use in industrial environments. This robust frame is fundamental to a reliable ball screw actuator.

Fully enclosed protection system

Stainless steel dustproof belt and flexible sealing cover double protection, isolated from dust and liquid intrusion, basic protection level IP54, optional IP65 (splashproof). Integrated automatic lubrication unit, significantly extending service life and reducing maintenance frequency – a key benefit of advanced ball screws and actuators.

High-precision ball screw transmission

Standard C7 precision actuator ball screw (optional C5), repeat positioning accuracy ±0.01mm, suitable for micron-level positioning scenarios. Screw diameter 16-80mm, lead range 5-50mm, support high torque output and speed balance. This is the heart of our precision ball and screw linear actuator.

📊 II. Key parameters

| Maximum load | 200kg (screw drive mode) |

| Effective stroke | 50-3000mm (customizable) |

| Repeat positioning accuracy | ±0.01mm (achieved by the ball screw linear actuator) |

| Protection level | IP54 (standard)/IP65 (optional) |

| Operation noise | ≤45dB (silent optimization design) |

III. Core advantages

Heavy load and high precision: Maintain ±0.01mm positioning accuracy under 200kg load, meeting the precision assembly requirements of semiconductor equipment and heavy machinery. This makes it an ideal ball screw actuator for critical tasks.

Extreme life: Actuator ball screw preload optimization design, combined with automatic lubrication, service life increased by more than 30%. This extended life is a testament to the quality of our ball screws and actuators.

Multi-scenario adaptation: Support motor direct connection/folding installation, compatible with stepper motor, servo motor and other drive solutions. This flexibility makes it a versatile ball and screw linear actuator.

🔧 Four. Typical applications

Industrial automation: heavy-duty robot arm joints, automobile production line welding positioning platform.

Semiconductor manufacturing: wafer handling robot, chip packaging press.

Precision testing: large three-coordinate measuring machine mobile base, optical lens calibration platform.

The module provides a highly reliable linear motion solution for harsh industrial scenarios through a deep combination of heavy-duty rigid structure and fully enclosed protection, making the FSKSM-175 the definitive ball screw actuator for demanding operations.

High-precision position ball screw linear modules, with their micron-level positioning accuracy and

stable transmission performance, are primarily used in the following scenarios:

1. Precision Machining Equipment

CNC Machine Tools: Achieving backlash-free transmission through the rolling of steel balls in the ball

screw ensures a repeatability of tool feed of ±0.01mm, suitable for metal cutting, mold processing, and

other applications.

Semiconductor Manufacturing: Used for wafer dicing and lithography machine stage positioning, requir

ing a servo system for nanometer-level motion control.

2. Automated Inspection and Assembly

3C Electronics: In processes such as mobile phone screen bonding and chip packaging, their high rigi

dity (e.g., the SFU2505 model) resists vibration interference.

Medical Equipment: CT scanner slip rings and surgical robot joints require C7-level accuracy (±0.05mm

/300mm).

3. Special Environment Applications

Laser Cutting Machine: Single-axis linear modules (such as SFNU2505) with high preload design are suita

ble for high-speed reciprocating motion.

Heavy-duty Handling: Economical modules (such as the Hiwin C7 series) increase load capacity to over

500kg through a 4-row ball bearing structure.

Note: When selecting a model, load, speed, and environmental factors must be considered. For example,

in dusty environments, a dust cover is required.