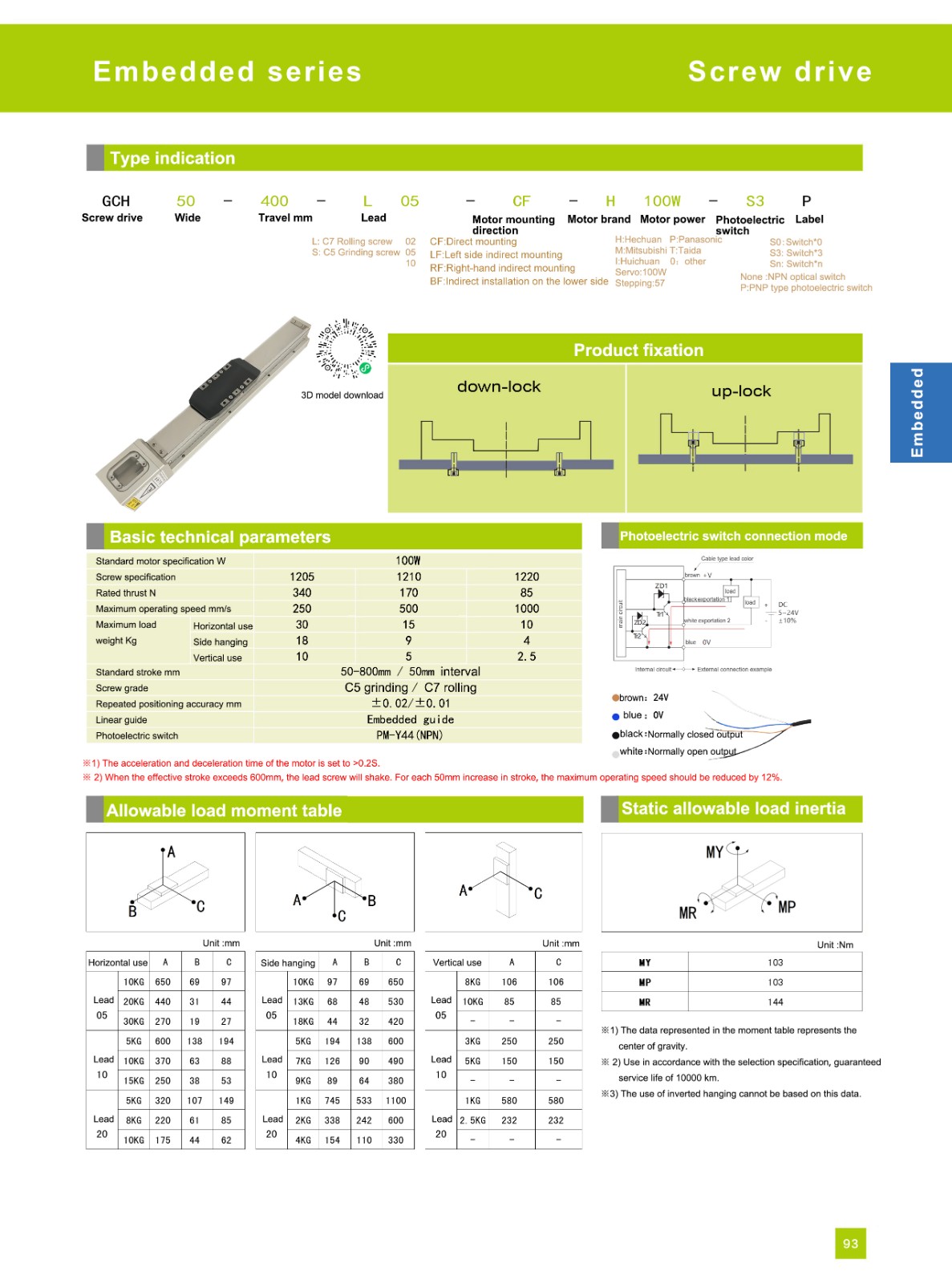

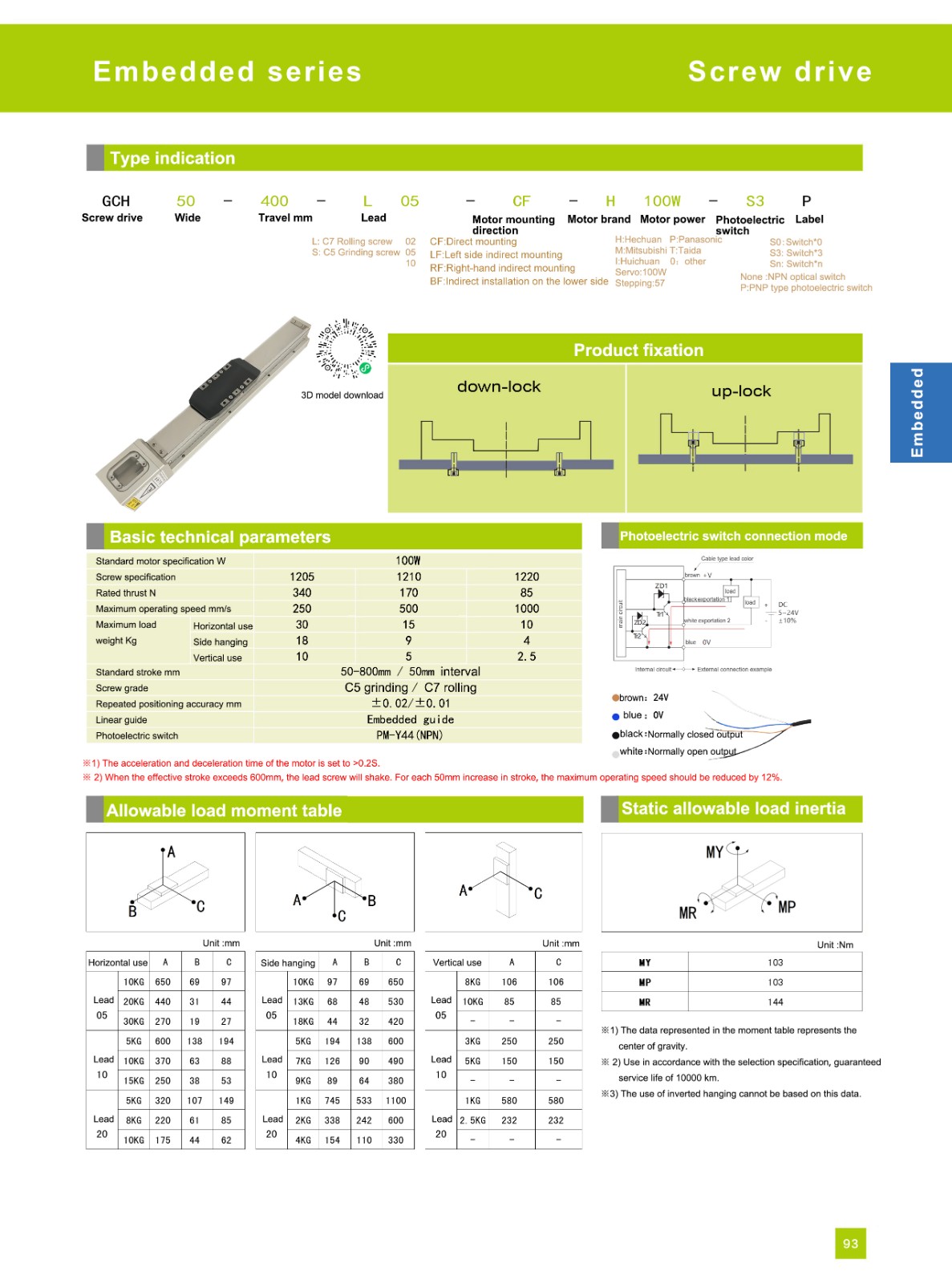

The embedded module adopts U-shaped high-strength aluminum alloy and steel guide rail to ensure the good movement performance of the module and avoid the assembly error of the guide rail pair; the steel guide rail groove adopts a 2-row Gothic structure and a 45-degree contact angle design, providing equal load capacity in four directions, and adjusting the preload of the steel ball to achieve high rigidity and high precision; the flexible stainless steel belt seal is adopted, and the overall sealing and dustproof performance of the module is good: the unique lubrication circuit and convenient external oil supply method are adopted to achieve internal lubrication without disassembly.

The High-Precision Oil-Proof Stainless Steel Cover Inner Slide Module GCH-50 offers the following key

advantages:

High Precision and Oil-Proof Design

Stainless steel construction and a sealed structure effectively prevent oil intrusion, ensuring long-term

stable operation in harsh industrial environments and achieving positioning accuracy of ±0.01mm.

Corrosion Resistance and Long Life

Stainless steel construction and an oil-proof coating significantly enhance corrosion resistance, making

it suitable for use in humid or oily environments such as chemical and food processing, extending its

service life by over 30% compared to conventional slides.

Modularity and Easy Integration

The standardized design enables quick installation and integration with other automated equipment

(such as robotic arms and testing instruments), making it ideal for high-precision assembly lines or test

ing equipment.

Low Maintenance and High Reliability

The lubrication-free design reduces maintenance requirements, while the sealed structure prevents dust

and oil intrusion, reducing failure rates.

High Load Capacity

The optimized guide rail structure can withstand large radial and axial loads, making it suitable for heav

y machinery or precision processing equipment.