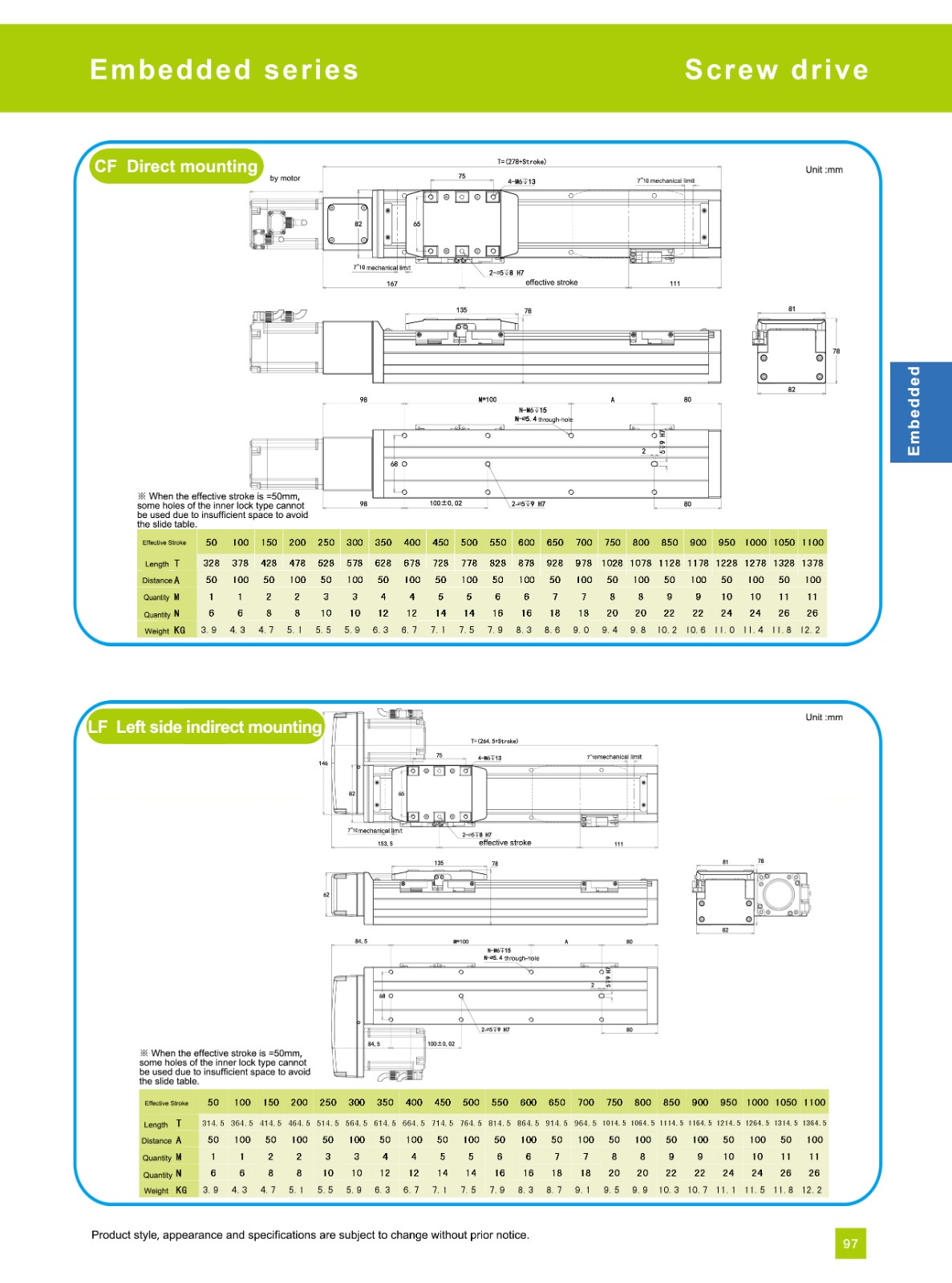

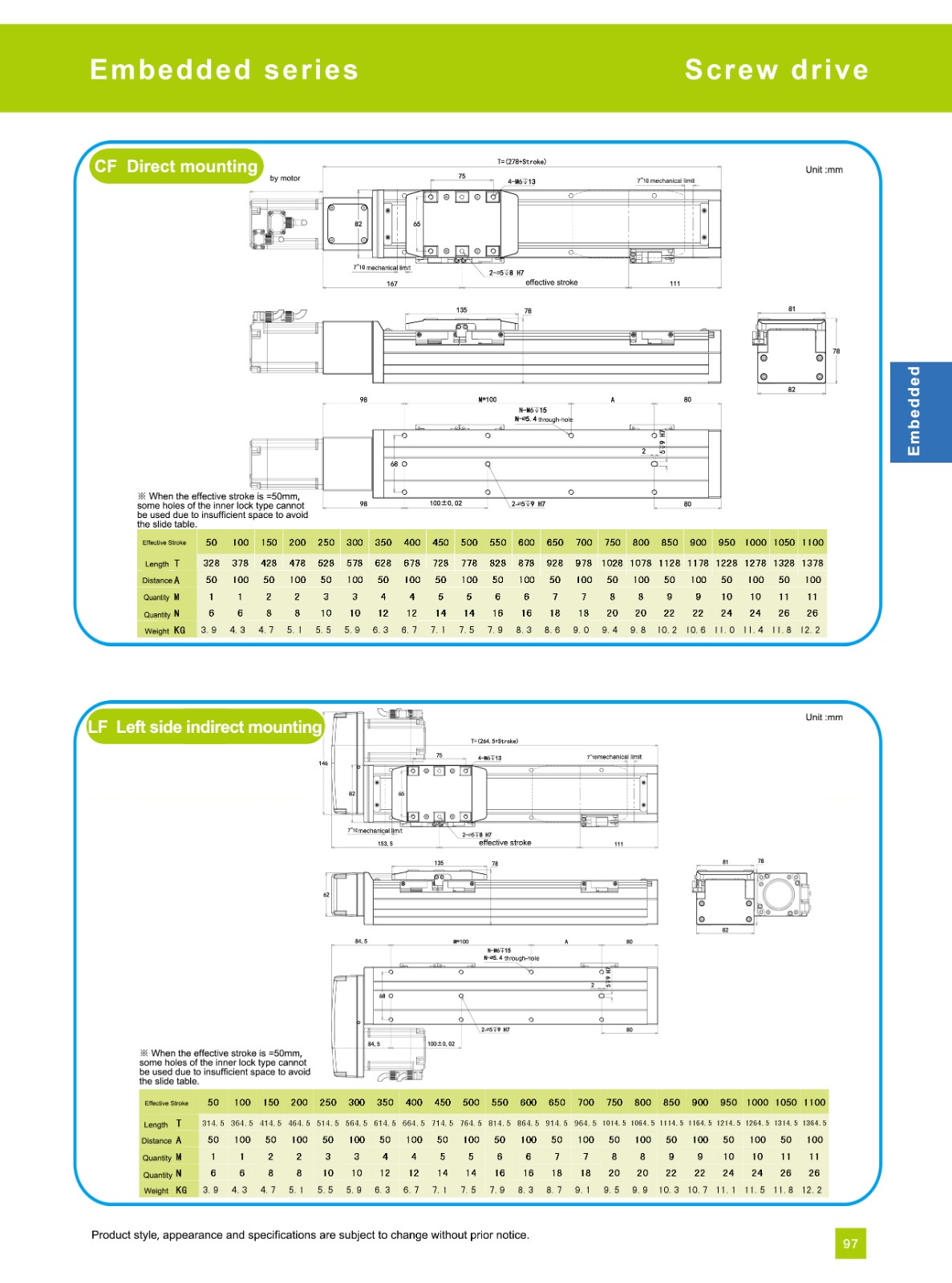

Maximum horizontal load: 50KG

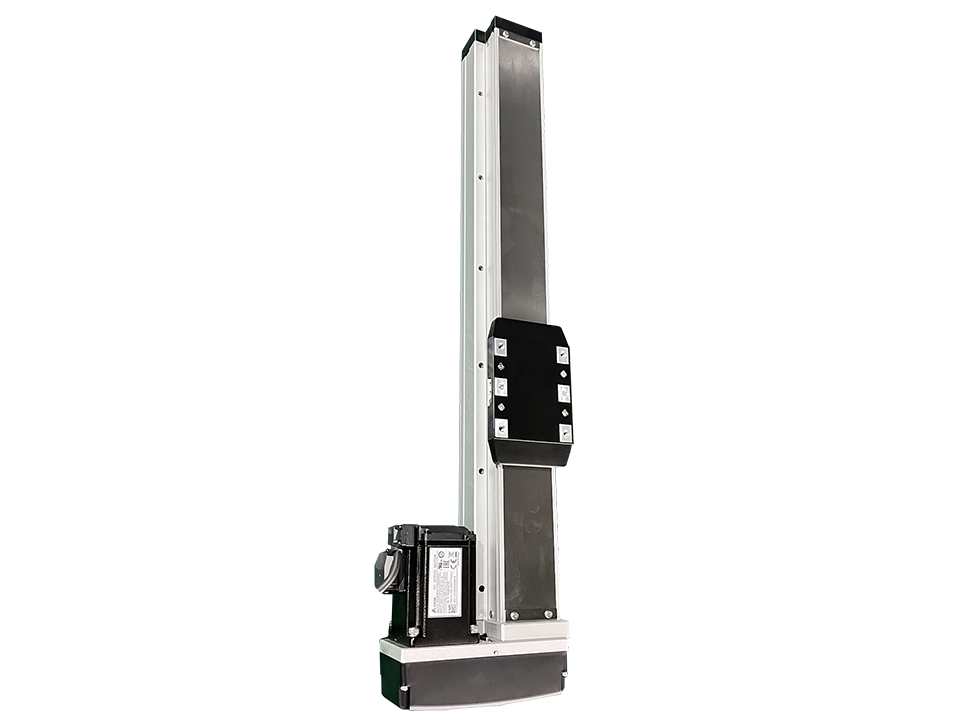

Model: GCH-80 embedded full-closed module

Repeat positioning accuracy: ±0.01/±0.02 mm

Customizable stroke: 50-1000 mm

Screw outer diameter: from 16 mm

Lead: 05/10/20 mm

Motor power: 2200V400W (motor can be self-matched)

Maximum speed: 250V5001000 MM/S

1. Core performance and architecture

Multi-core high-performance computing

Adopts advanced multi-core processor architecture (such as ARM Cortex-M7/M4 combination or Intel

Core i series) to support real-time task processing and complex algorithm operation. The main

frequency covers the range of 75MHz to 500MHz, and some models support up to 8-core processors

to meet the high computing power and low latency requirements in industrial scenarios23.

Industrial-grade interconnection capabilities

Integrated multi-protocol industrial Ethernet interface, supporting mainstream fieldbus protocols such

as EtherCAT, PROFINET, and EtherNet/IP37.

Provides dual Gigabit Ethernet ports, multiple serial interfaces (RS-232/485) and high-speed USB

channels to ensure device-level communication redundancy and scalability12.

2. Industrial reliability and scalability

Harsh environment adaptation

Supports wide temperature operation from -20°C to 60°C, fanless heat dissipation design, and

anti-vibration/shock certification, suitable for scenarios such as smart manufacturing and energy

control2.

Modular expansion interface

Supports PCIe, CAN bus and GPIO expansion, and can flexibly integrate peripherals such as motion

control cards and visual sensors to achieve multi-axis servo control or machine vision collaboration35.

III. Typical application scenarios

Applicable to industrial robot drive, intelligent warehousing and logistics systems, high-precision CNC

machine tools and other fields that require real-time control and edge intelligent analysis