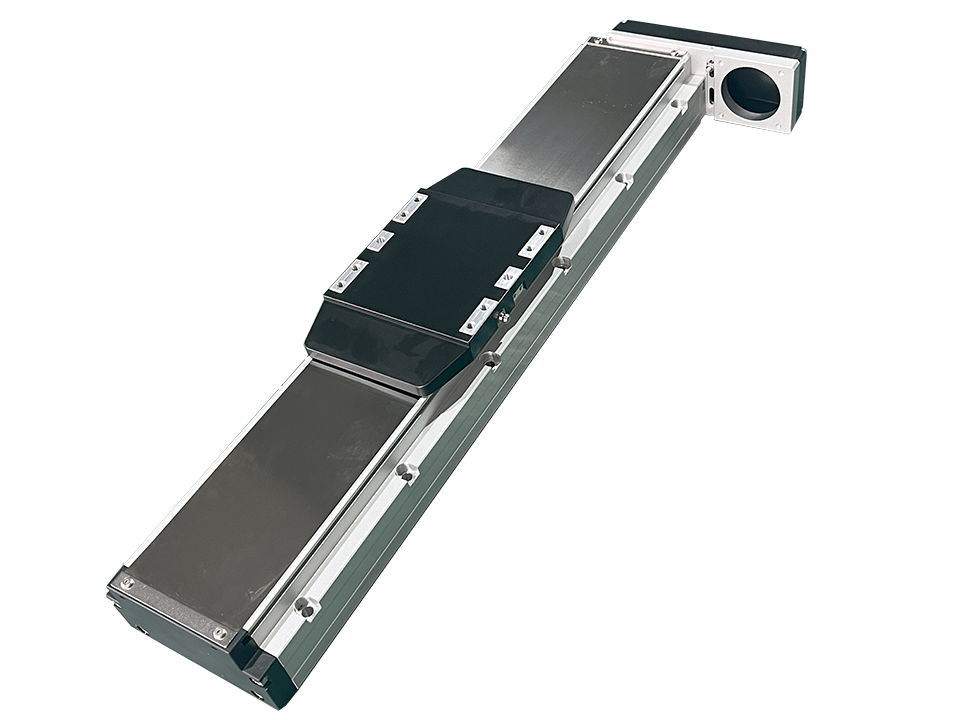

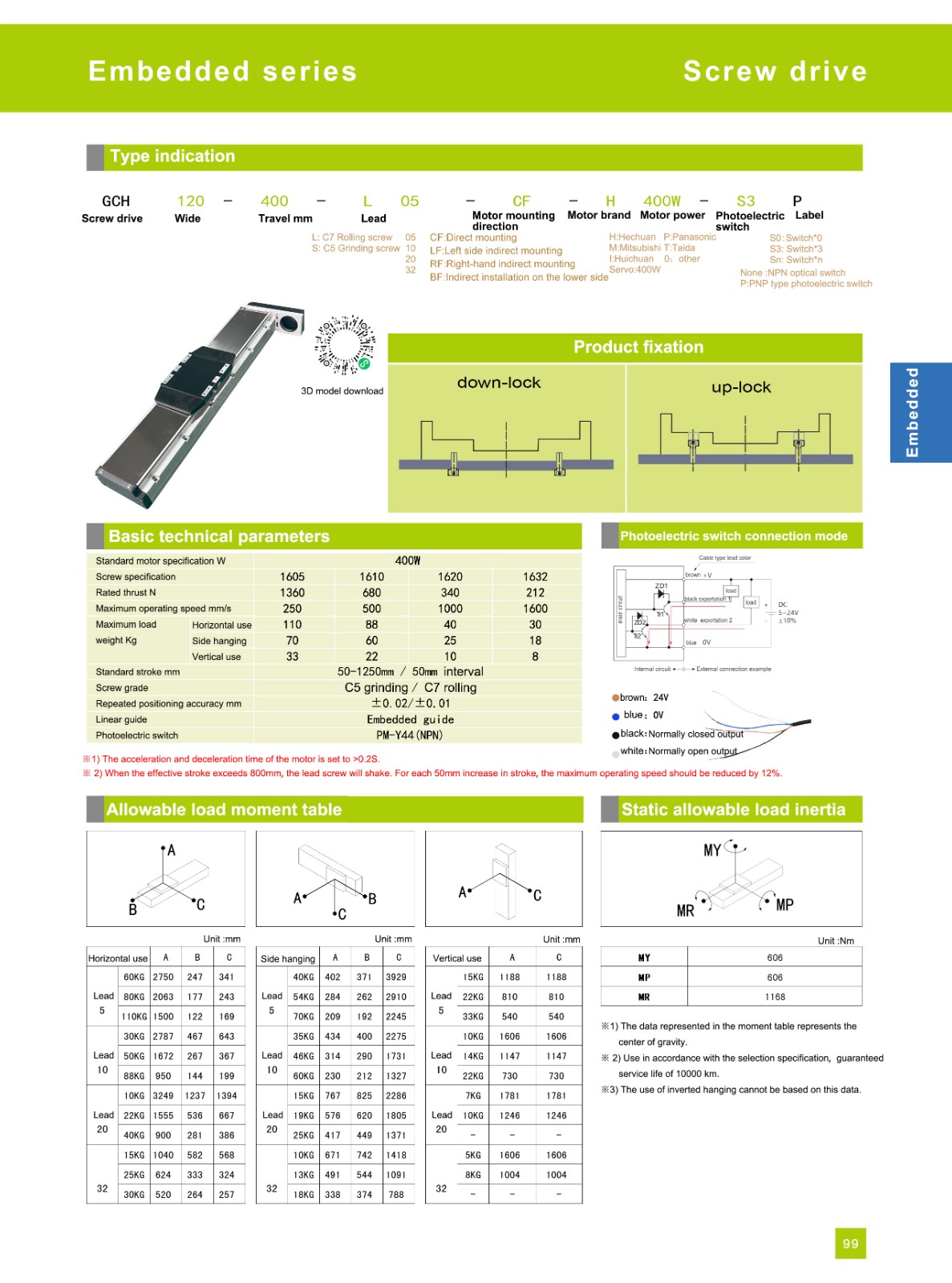

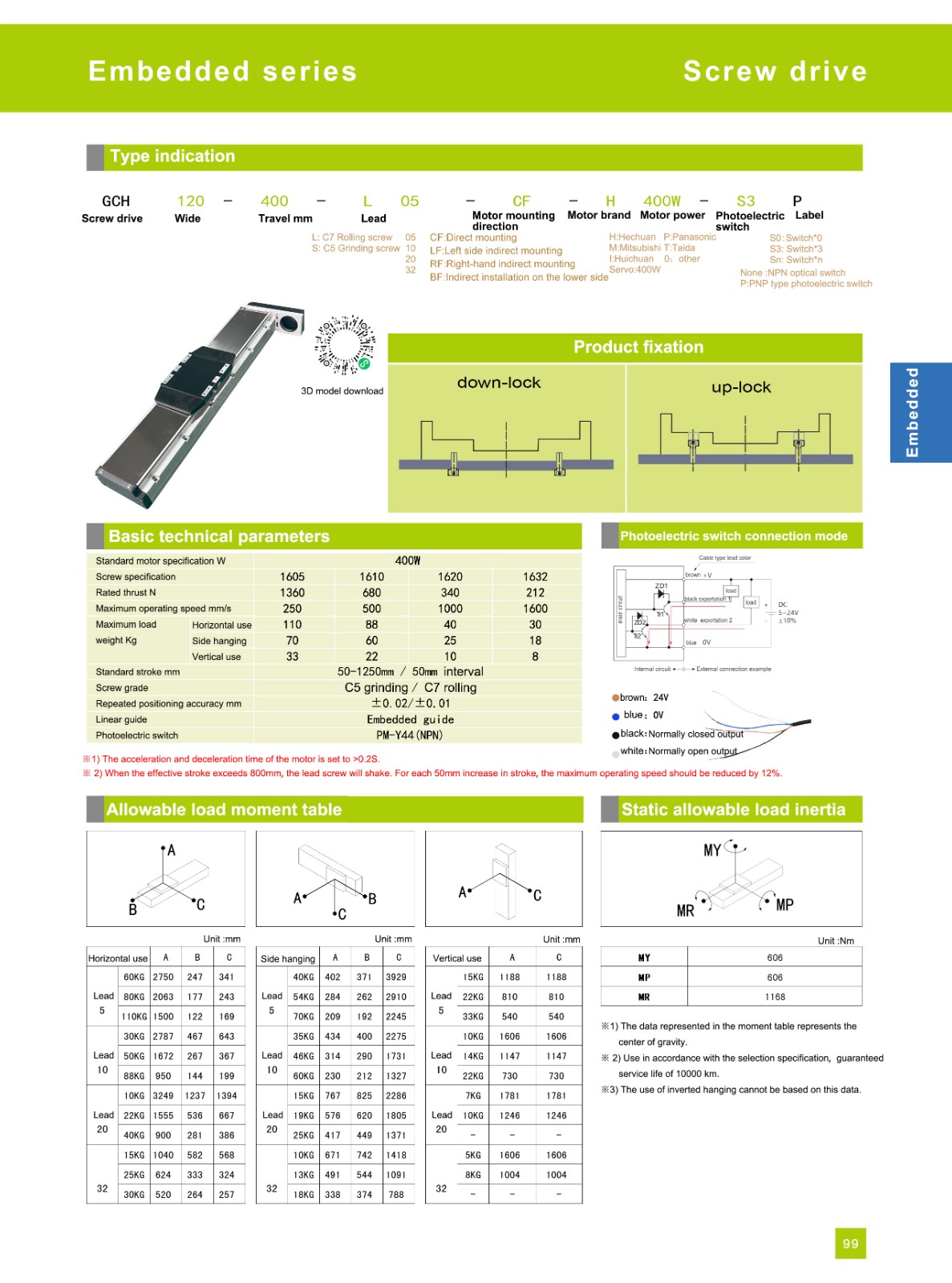

Model: GCH-120

Embedded fully dense module

Repeat positioning accuracy: ±0.01/±0.02 mm

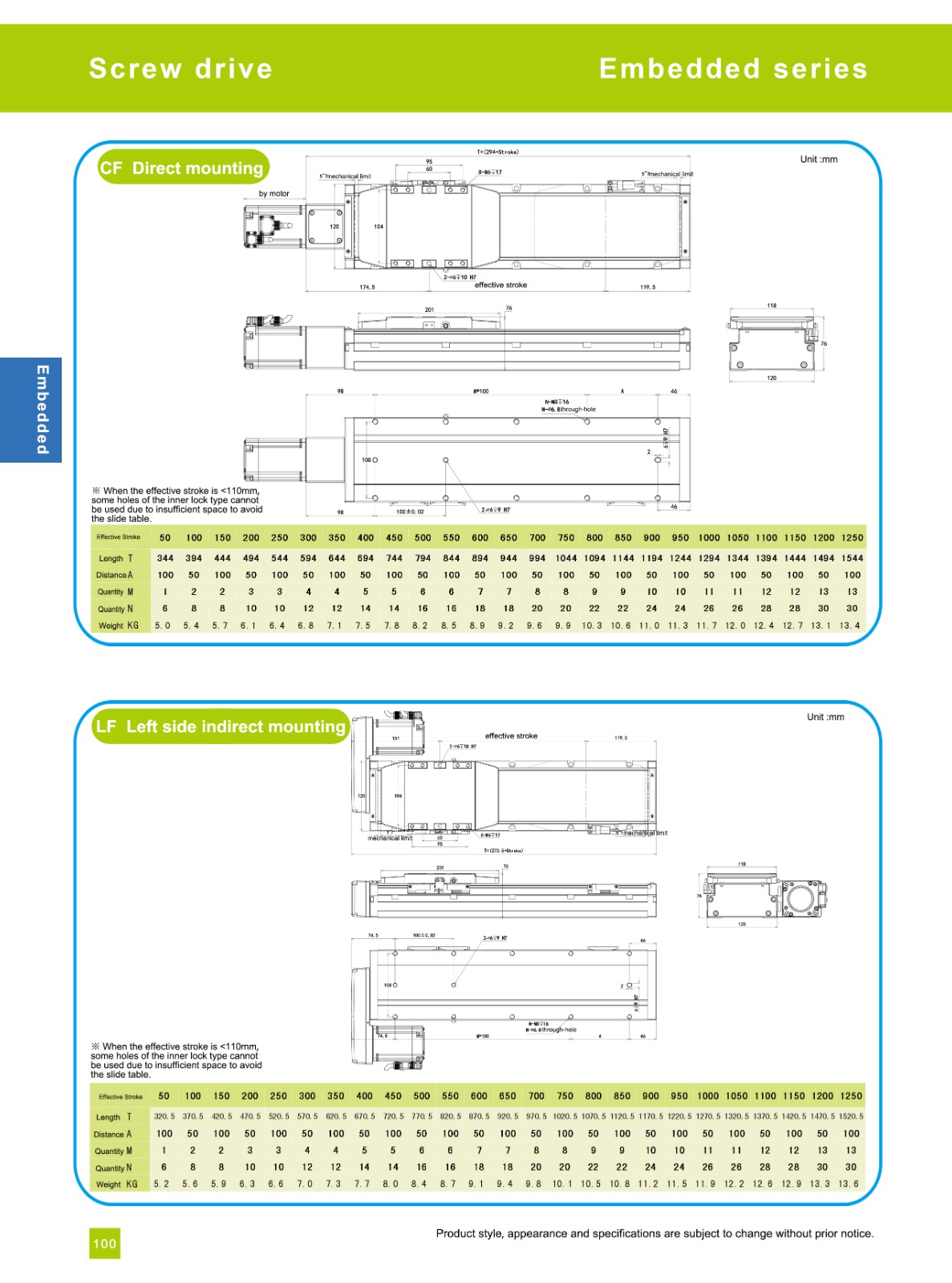

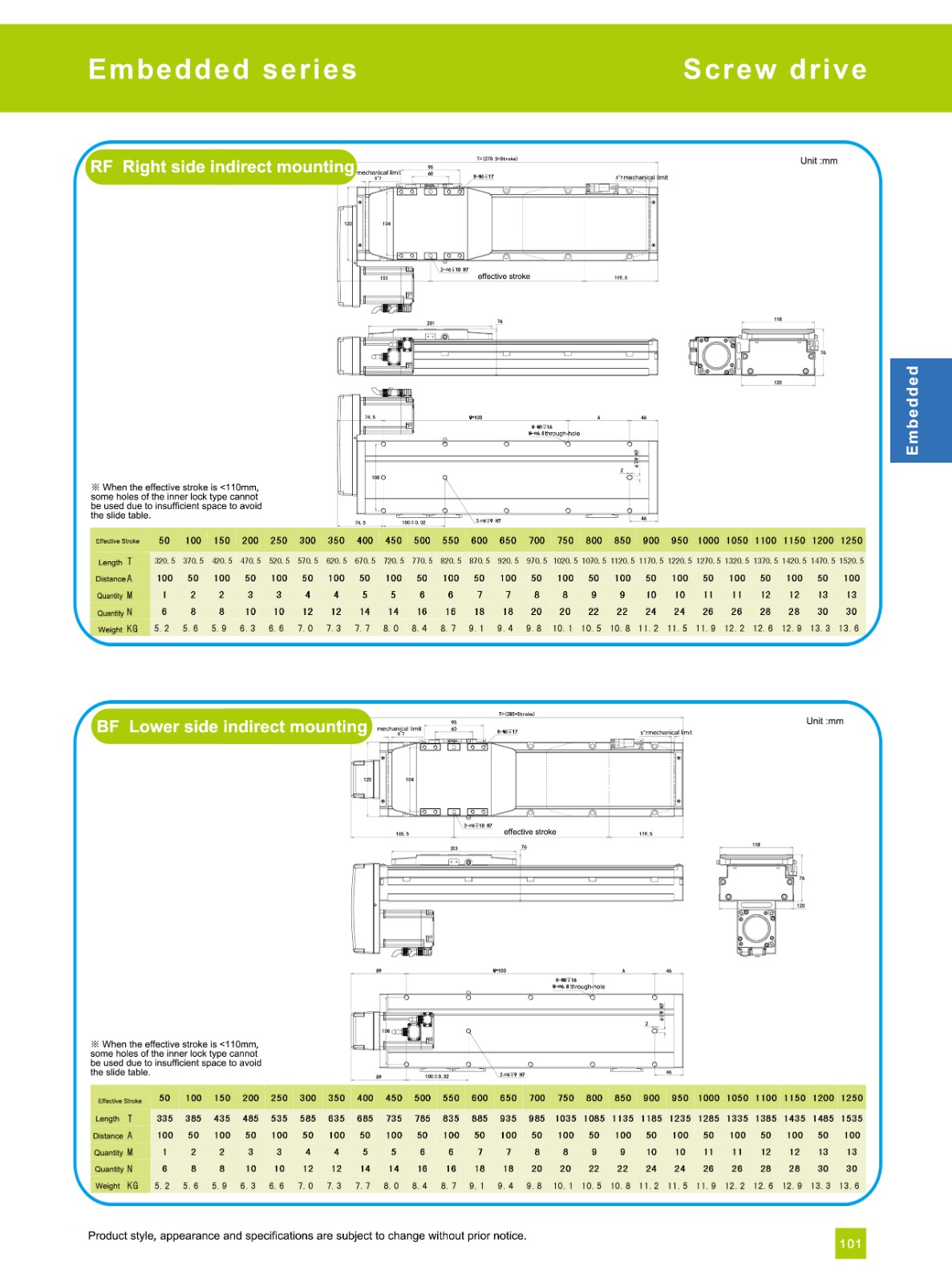

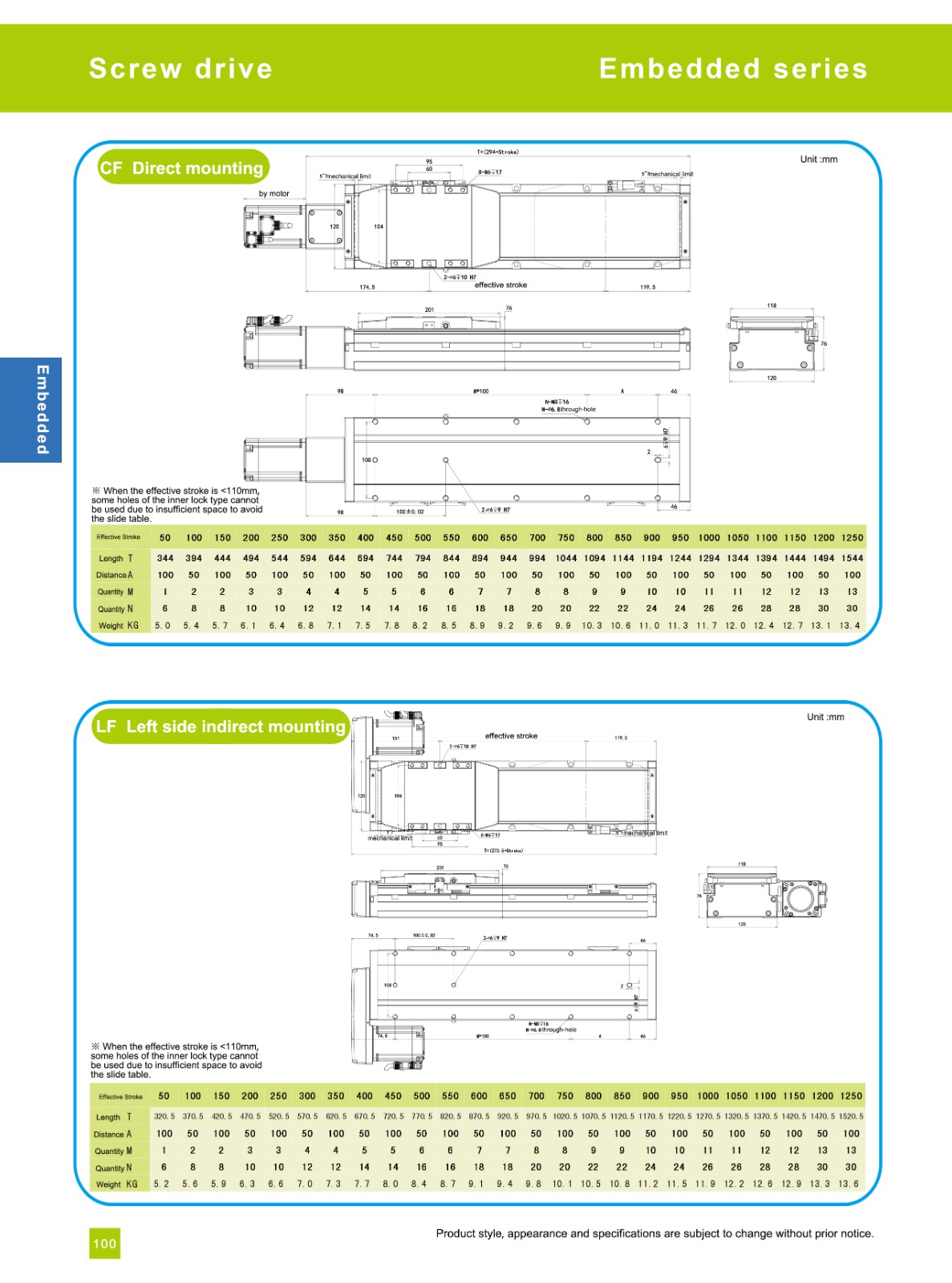

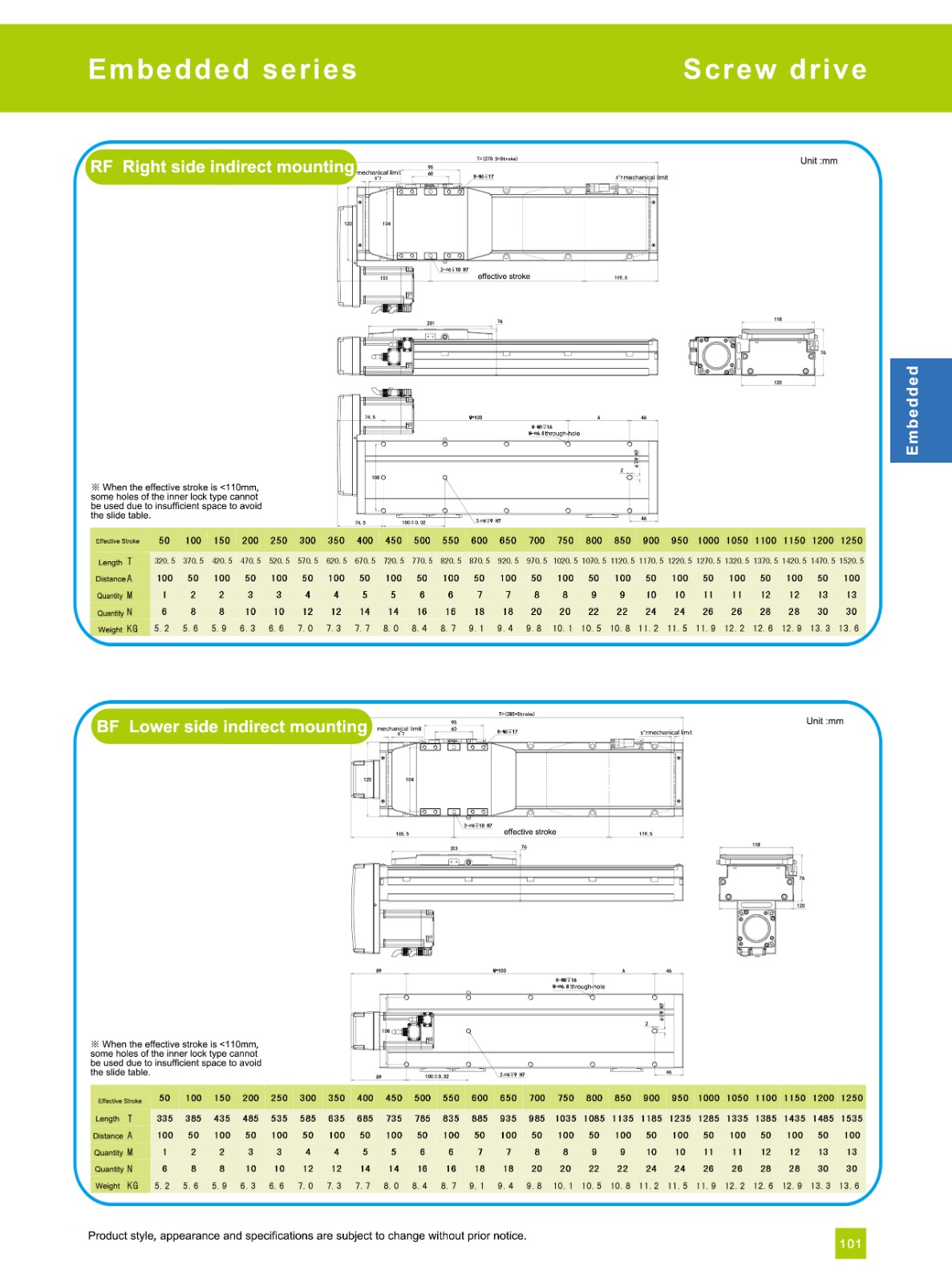

Customizable stroke: 50-1200mm

Screw outer diameter: t16 mm

Lead: 05/1020/32 mm

Motor power: 400W (motor can be customized)

Maximum speed: 250V500/1000/1600 MM/S

The following is a comprehensive introduction to the GCH-120 low-noise multi-point positioning screw

embedded module (based on the integration of technical parameters and application characteristics):

🛠️ I. Core structural design

Embedded ball screw system

Adopting preloaded C7-grade precision ball screw (optional C5-grade), the screw diameter is 16-40mm,

the lead is 5-20mm, and the ±0.01mm repeatability accuracy under multi-point positioning (≥3 points)

is achieved

The integrated alloy base has a built-in screw guide groove, which suppresses high-speed vibration and

reduces the risk of resonance through structural rigidity optimization

Low-noise operation technology

The ball circulation path noise reduction design is combined with a polymer sealing strip, and the

operating noise is ≤40dB (30% load condition), which is suitable for medical testing and laboratory

precision equipment

Motor direct connection/folding installation compatible design reduces transmission chain noise

transmission

Semi-enclosed protection

Top removable dust cover + side labyrinth seal, protection level IP40, balance heat dissipation and dust

isolation requirements

📊 **II. Key performance parameters

Features Parameters

Maximum load 120kg (horizontally installed)

Effective stroke 200–2500mm

Repeat positioning accuracy ±0.01mm (multi-point positioning)

Maximum speed 1.5m/s (long stroke requires speed reduction)

Operation noise ≤40dB (ISO standard test)

Note: When the stroke is greater than 1500mm, the speed must be limited to less than 0.8m/s to avoid

resonance-induced accuracy deviation

3. Application scenarios and advantages

Precision manufacturing: semiconductor wafer multi-point calibration platform, optical lens coating

equipment, relying on ±0.01mm level positioning stability

Medical automation: medical device assembly line, silent inspection bench, meet ≤40dB noise restriction

environment

Long stroke and heavy load: replace the traditional hydraulic positioning mechanism, support 120kg

load precision transfer within 2500mm stroke

⚠️ Fourth, Technical Considerations

Speed-stroke balance

The critical speed is negatively correlated with the screw length. When the stroke is 2500mm, the speed

needs to be controlled below 0.8m/s

Inertial load management

When the acceleration is greater than 0.3G, the handling mass needs to be reduced to avoid positioning

deviation caused by impact

This module provides a high-precision, low-vibration positioning solution for heavy-load and long-stroke

scenarios through the integration of embedded screw structure and noise reduction technology