Maximum horizontal load 150 KG

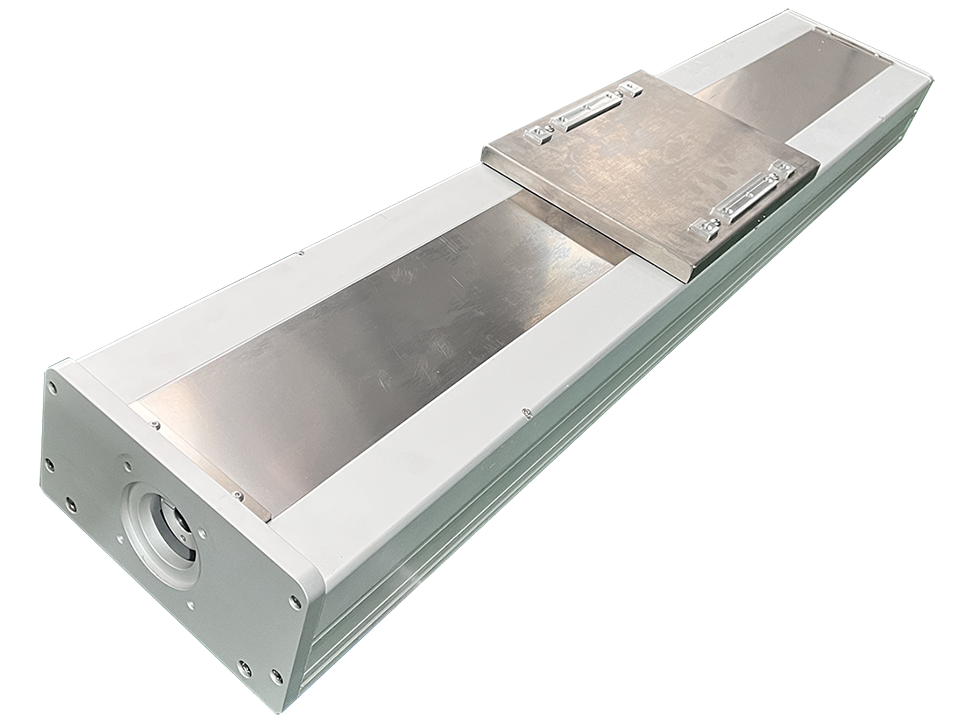

Model: FSKSM-220 screw full-closed module-steel belt

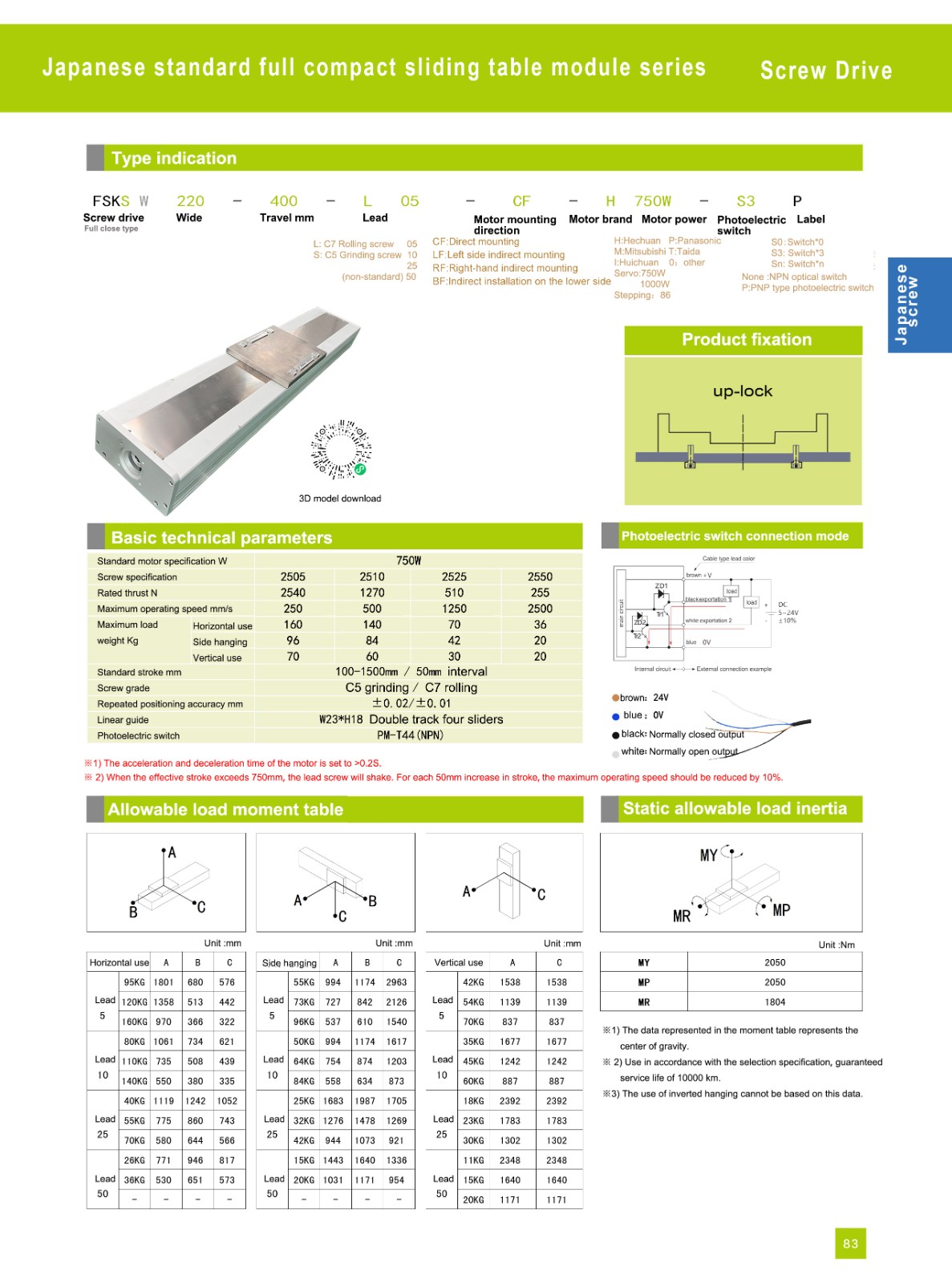

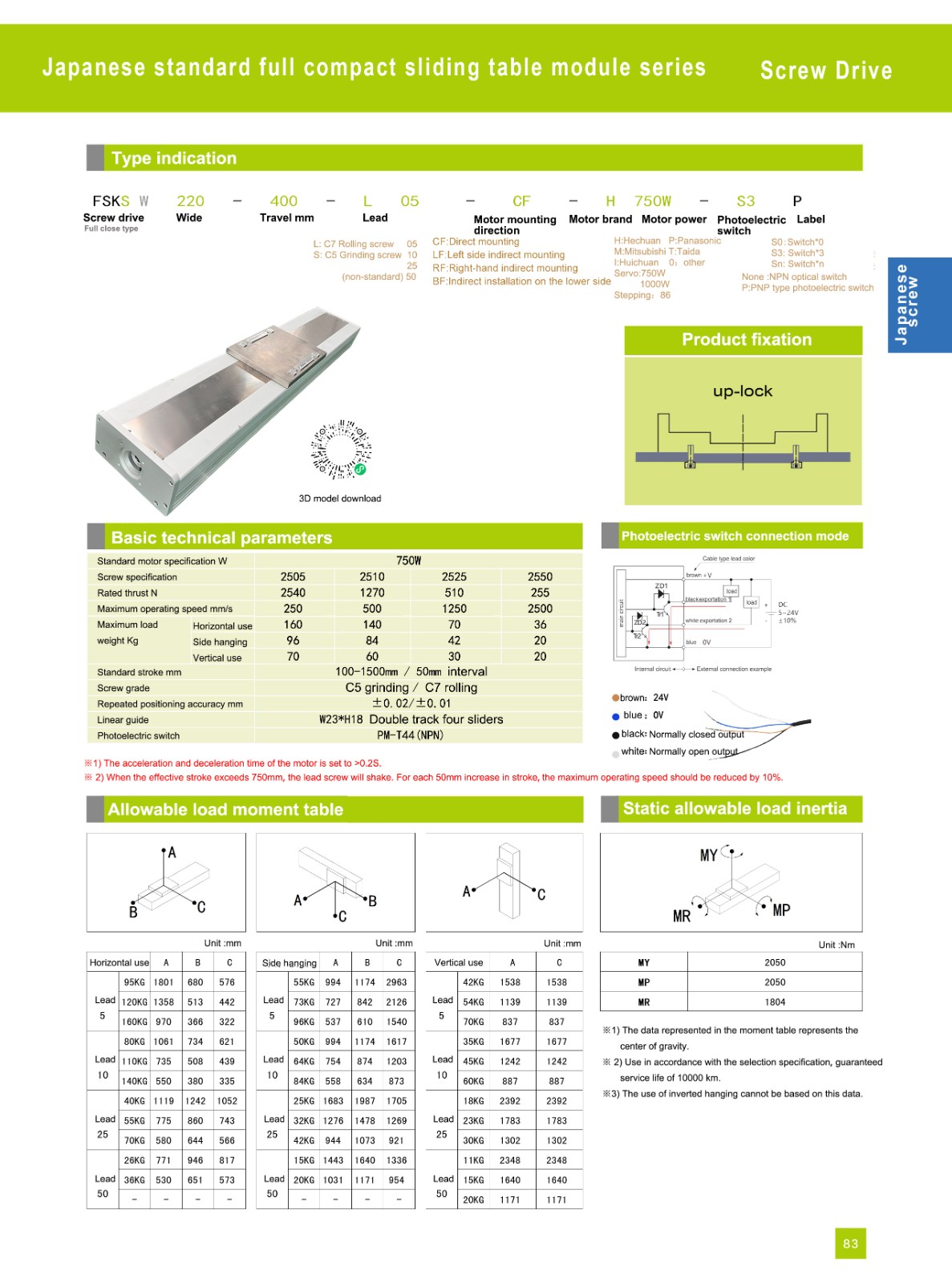

Repeat positioning accuracy: 0.01/±0.02 mm

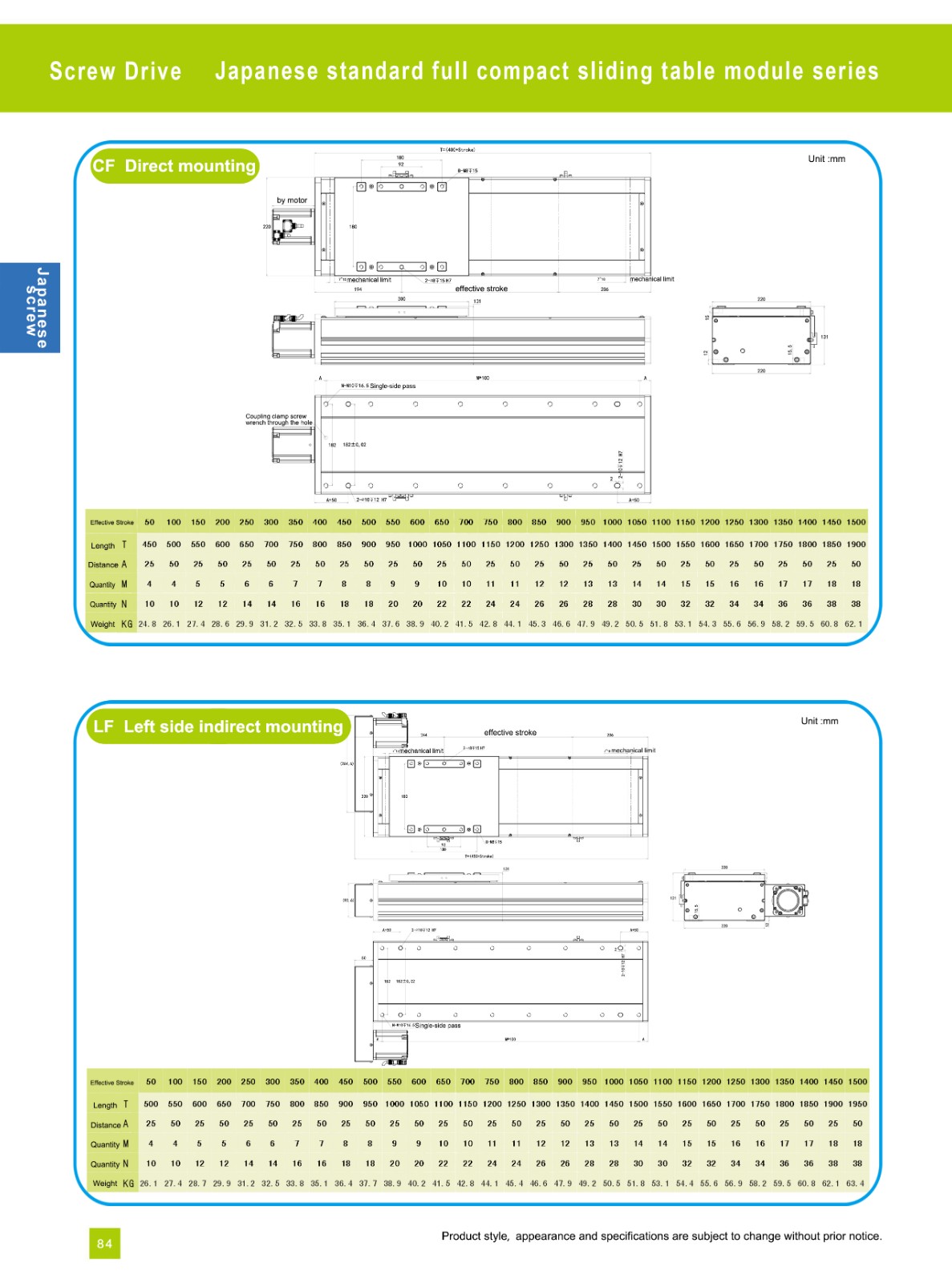

Customizable stroke: 50-1500 mm

Screw outer diameter: φ25 mm

Lead: 05/10/25 mm

Motor power: 750W (motor can be customized)

Maximum speed: 250/500/1250 MM/S

Introducing the Industrial Grade Ball Screw Fully Sealed Dustproof Module FSKSW-220, a premier ball screw actuator engineered for the most challenging industrial environments. This high-load ball screw linear actuator is the definitive solution for precision positioning amidst dust, moisture, and contamination. As a superior ball and screw actuators system, it seamlessly combines robust protection with pinpoint accuracy. When your operations demand an actuator ball screw that performs flawlessly in extreme conditions, and a reliable screw actuator that consistently delivers, the FSKSW-220 is your answer.

Industrial Grade Ball Screw Fully Sealed Dustproof Module FSKSW-220 is a high-load linear transmission module designed for harsh industrial environments. Its core features integrate precision transmission and fully enclosed protection technology, suitable for precision positioning needs under harsh working conditions such as dust and moisture.

Core Features

Fully enclosed protection structure

The stainless steel sealed cabin integrates double-lip seals to achieve IP54/IP65 protection, effectively blocking the intrusion of dust, liquids and oil. The protection design takes into account long-term corrosion resistance and is suitable for easily polluted scenes such as food processing and chemical industry. This robust protection is crucial for a dependable ball screw actuator.

High-precision transmission system

Equipped with G1605 actuator ball screw (diameter 16mm, lead 5mm), it supports repeated positioning accuracy ≤±0.01 mm to ensure precise linear motion control. Low friction coefficient design (0.003~0.005) reduces energy consumption and improves running smoothness. This high precision sets our screw actuator apart.

Strong load and high adaptability

Supports radial load ≥900 N (inferred value, based on the same series FSKSW-175 parameter enhancement design), and the anti-turnover torque is increased to 30 N·m level. The travel range 100–2000 mm can be customized, compatible with servo motors (maximum speed 6000 min⁻¹), and meets the needs of diversified equipment integration. This capability makes it a versatile ball screw linear actuator.

Modular compatible design

Provides multi-directional motor installation interface (right/left/folding down) to simplify mechanical layout. Adapts to mainstream stepper motors and servo drives to reduce the complexity of system integration. This flexibility is a key advantage of modern ball and screw actuators.

Typical application areas

Automated production lines: heavy workpiece handling robot arms, high-precision assembly platforms.

Environmentally sensitive equipment: food packaging machinery valve control, pharmaceutical equipment filling mechanism.

Outdoor industrial instruments: detection probe displacement system in dusty environments, transmission positioning in humid conditions.

Operational restrictions and selection recommendations

Avoid using in explosive environments or areas with strong electromagnetic interference;

Extremely long strokes (>1.5 m) require auxiliary support to suppress high-speed vibration;

When selecting, it is necessary to comprehensively evaluate the dynamic characteristics of the load and the stroke requirements, and give priority to verifying the matching accuracy requirements of the screw grade (C5/C7).

The fully sealed, dust-proof module for industrial-grade ball screw actuator offers the following core advantages:

High-Performance Protection

A dual sealing structure (e.g., O-rings and labyrinth seals) and a protective cover design effectively block the intrusion of dust, particulate matter, and moisture, reducing the increased friction and wear caused by contamination. A protective film formed by a special dust-repellent lubricant further enhances the isolation effect, protecting the crucial actuator ball screw.

Extended Service Life

The sealed design reduces the erosion of contaminants on the internal components of the ball screw actuator. Combined with the use of wear-resistant materials (e.g., stainless steel and fluororubber), maintenance frequency is significantly reduced and the equipment's operating life is extended, making it a reliable screw actuator.

Maintaining Motion Precision

The fully sealed structure prevents motion jamming or deformation caused by dust accumulation, ensuring micron-level or even nanometer-level positioning accuracy even under high loads, a testament to its being a superior ball screw linear actuator.

Adaptable to Complex Environments

The modular design allows customization for diverse industrial environments, including high and low temperatures and humidity, balancing sealing strength with smooth operation without sacrificing transmission efficiency. This adaptability makes it a versatile solution among ball and screw actuators.

Comprehensive Cost Optimization

The fully sealed module reduces equipment downtime and replacement costs by reducing failure rates and maintenance requirements, offering outstanding cost-effectiveness over the long term.

The core advantages of the Industrial Grade Ball Screw Fully Sealed Dustproof Module FSKSW-220 are as follows:

Fully Sealed and Dustproof Design

The fully enclosed structure, with an IP65 protection rating, effectively blocks the intrusion of dust, oil, and cutting fluids, making it suitable for use in highly polluted industrial environments and significantly extending the life of the actuator ball screw and guide rails.

High Precision and High Rigidity

Equipped with a precision-ground ball screw, it achieves repeatability of ±0.01mm and increases axial rigidity by over 30%, meeting the high-precision requirements of CNC machine tools, semiconductor equipment, and other applications.

Low Friction and Long Life

The optimized ball recirculation system design

Industrial Grade Ball Screw Fully Sealed Dustproof Module is mainly used in the following scenarios:

Heavy Industrial Environment

In scenes with high dust concentration such as metallurgy and mining, its fully sealed design can effect

ively prevent the intrusion of metal debris and dust and ensure transmission accuracy. For example, the

conveying equipment in the sintering workshop of a steel plant needs to withstand a dust environment

of ≥50 mg/m³.

Precision Manufacturing

It is used in CNC machine tools, automated production lines and other equipment that require high po

sitioning accuracy. The sealing structure can reduce the wear of the ball screw by oil dirt and particulate

matter and maintain micron-level motion control.

Extreme climate areas

In high-temperature (such as 350°C pipelines in coal chemical industry) or high-humidity (such as 95%

humidity in ports) environments, the module's temperature-resistant materials and anti-rust coating can

maintain stable operation, with operating force fluctuations of ≤30%.

Clean Rooms and Medical Equipment

Combined with a seamless design (such as the item modular system), it is suitable for clean room robot

ic arms or medical instruments that need to be dust-proof to avoid particle contamination.

Through triple sealing (IP65/66 protection level), self-lubricating bearings and impact-resistant structure,

this module achieves long life (such as 100,000 hours of maintenance cycle) and high reliability under

harsh working conditions.