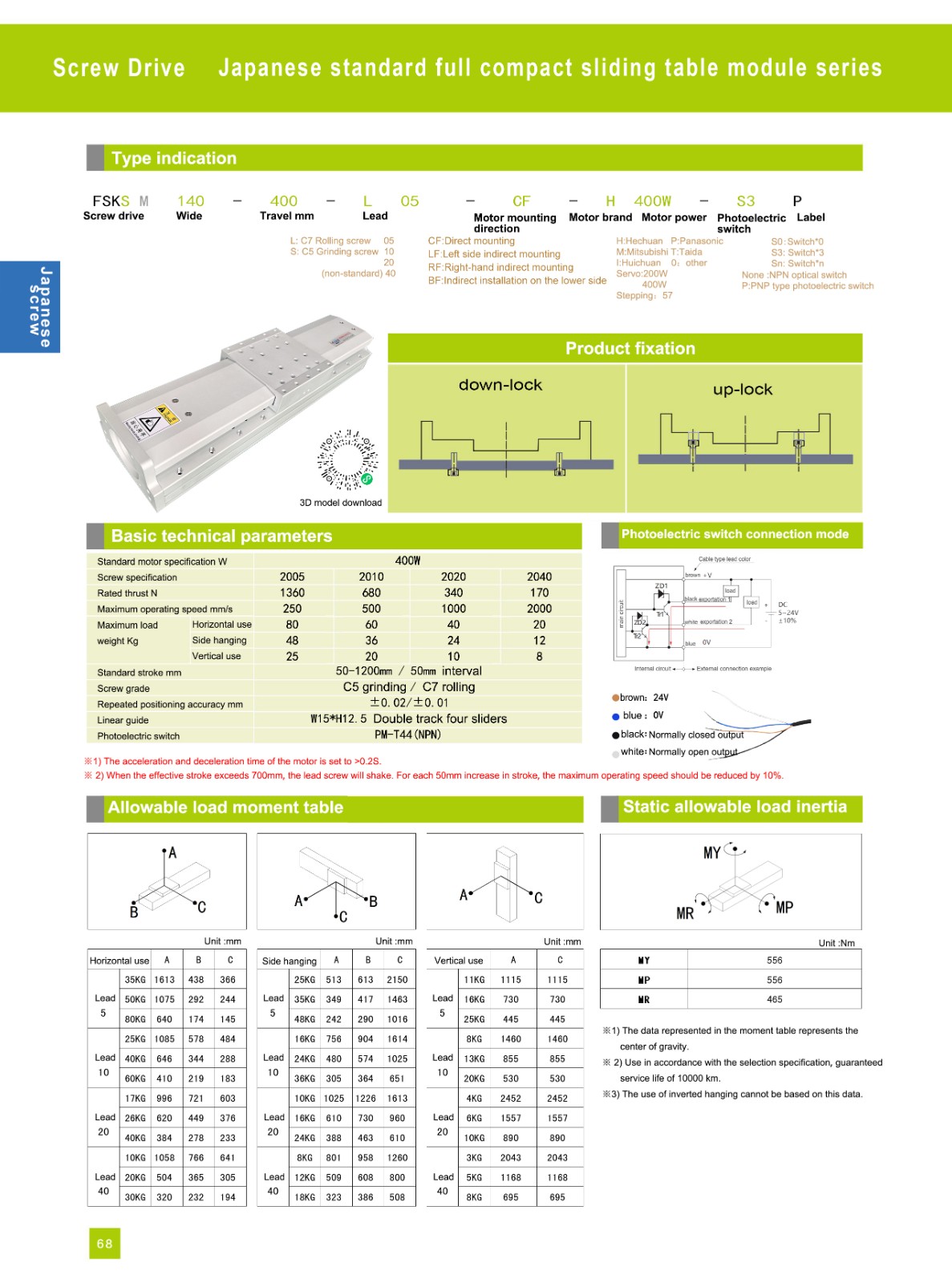

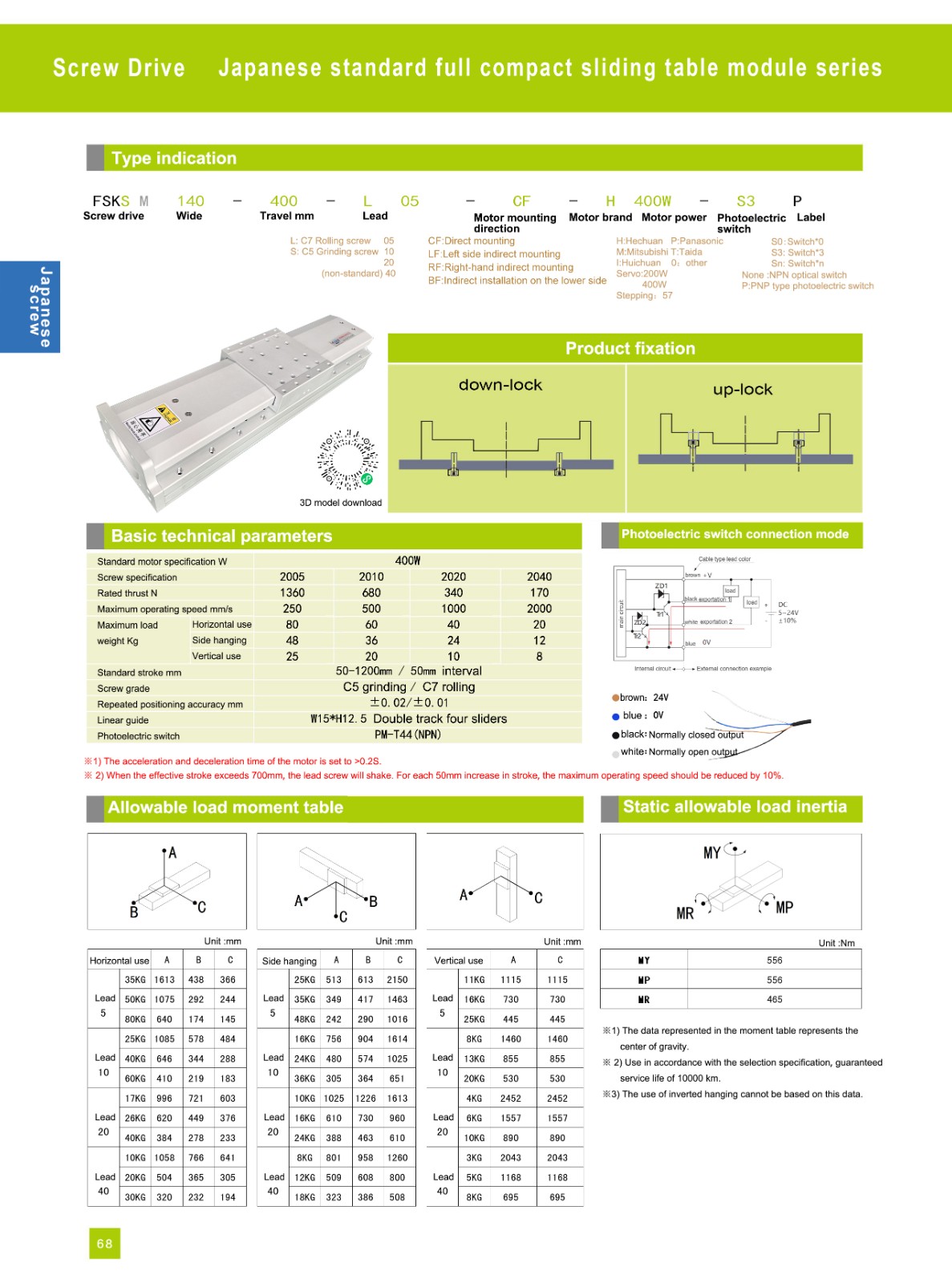

FSKSM-140 Fully Dense Module

Maximum horizontal load weight: 70KG

Available stroke: 50-1500MM

Screw outer diameter: Ф20MM

Motor power: 400W

Repeat positioning accuracy: ±0.02/0.01mm

Introducing the FSKSM-140, a fully enclosed Linear Module expertly crafted for applications demanding high-precision and low-noise operation. This advanced ball screw actuator is designed to seamlessly integrate into sophisticated motion control systems, providing unparalleled accuracy where it matters most. Far surpassing conventional lead screw actuator capabilities, the FSKSM-140 features a superior actuator ball screw system for consistent, reliable performance.

FSKSM-140 is a fully enclosed Linear Module designed for high-precision, low-noise environments. Its core features and applications are as follows:

🛡️ 1. Structure and sealing design

Fully enclosed dustproof system

Adopting double protection of stainless steel dustproof belt and flexible sealing cover, it can effectively isolate dust and liquid intrusion, with a protection level of IP54 or above, suitable for ordinary industrial workshop environments. Internally integrated automatic lubrication unit reduces maintenance frequency and extends service life – a critical feature for any reliable motion control system.

Aluminum alloy integrated frame

High-strength aluminum alloy profile is extruded as a whole, which is lightweight and high rigidity, suppressing vibration deformation during high-speed movement; surface anodizing treatment improves wear resistance and corrosion resistance. This robust frame underpins the precision of this Linear Module.

⚙️ II. Transmission and silent performance

Ball screw transmission

Equipped with C5-level precision ball screw actuator, repeatability accuracy ±0.01mm, suitable for precision assembly and optical calibration scenarios. The lead can be selected as 10mm (high precision) or 20mm (high speed), balancing speed and torque requirements. This makes it a superior choice over a basic lead screw actuator.

Silent optimization technology

Four-row steel ball rolling friction design, the friction coefficient is only 1/50 of the traditional sliding guide, significantly reducing operating noise (suitable for medical and laboratory environments). The low friction characteristics simultaneously reduce heat generation and support high-speed and long-term stable operation, making it ideal for a sensitive motion control system with an actuator ball screw.

📊 III. Core parameters

| Maximum load | 150kg (screw transmission) |

| Stroke | 50-1200mm |

| Protection level | IP54 (basic)/IP65 (splashproof) |

| Repeat positioning accuracy | ±0.01mm (thanks to the advanced actuator ball screw) |

🔧 IV. Application scenarios

Semiconductor manufacturing: wafer handling, chip packaging equipment, relying on high cleanliness sealed environment and micron-level positioning.

Medical equipment: surgical robot joints, imaging equipment detector tracks, requiring silent and dust-free operation.

Precision testing: coordinate measuring machine, optical inspection instrument (AOI) mobile platform.

⚠️ Selection suggestions

High load scenario: ball screw actuator drive is preferred (load ≤ 150kg).

Extreme travel requirements: optional synchronous belt drive version (light load).

Harsh environment: humid/chemical environment requires IP65 protection level.

This Linear Module significantly improves the reliability and environmental adaptability of high-end automation equipment through a fully enclosed structure and silent design. It's an indispensable component for any motion control system that demands the best, outperforming a standard lead screw actuator with its precision actuator ball screw mechanism.

Linear Guide Rail Silent Sealing Sliding Table Linear Module is a high-precision, low-friction linear

motion device that is widely used in the following fields:

1. Industrial automation and machining

CNC machine tools: used for precision guidance of woodworking routers, cutting machines and other

equipment.

Automated production line: such as assembly lines and handling systems to achieve efficient and stable

linear motion.

2. Logistics and lifting equipment

Warehouse crane: Carrying medium weight to ensure the stability of cargo transportation.

Ship crane: adapted to the corrosion resistance requirements of the offshore environment.

3. Medical and scientific research equipment

Medical instruments: such as imaging equipment and surgical robots, which require high precision and

low noise.

Laboratory automation: Such as the OpenWorkstation modular platform for liquid handling, cell culture,

etc..

4. Other fields

Semiconductors and Electronics: Used for precision operations such as chip manufacturing and PCB proc

essing.

Automobile manufacturing: positioning and transmission in welding, spraying and other processes