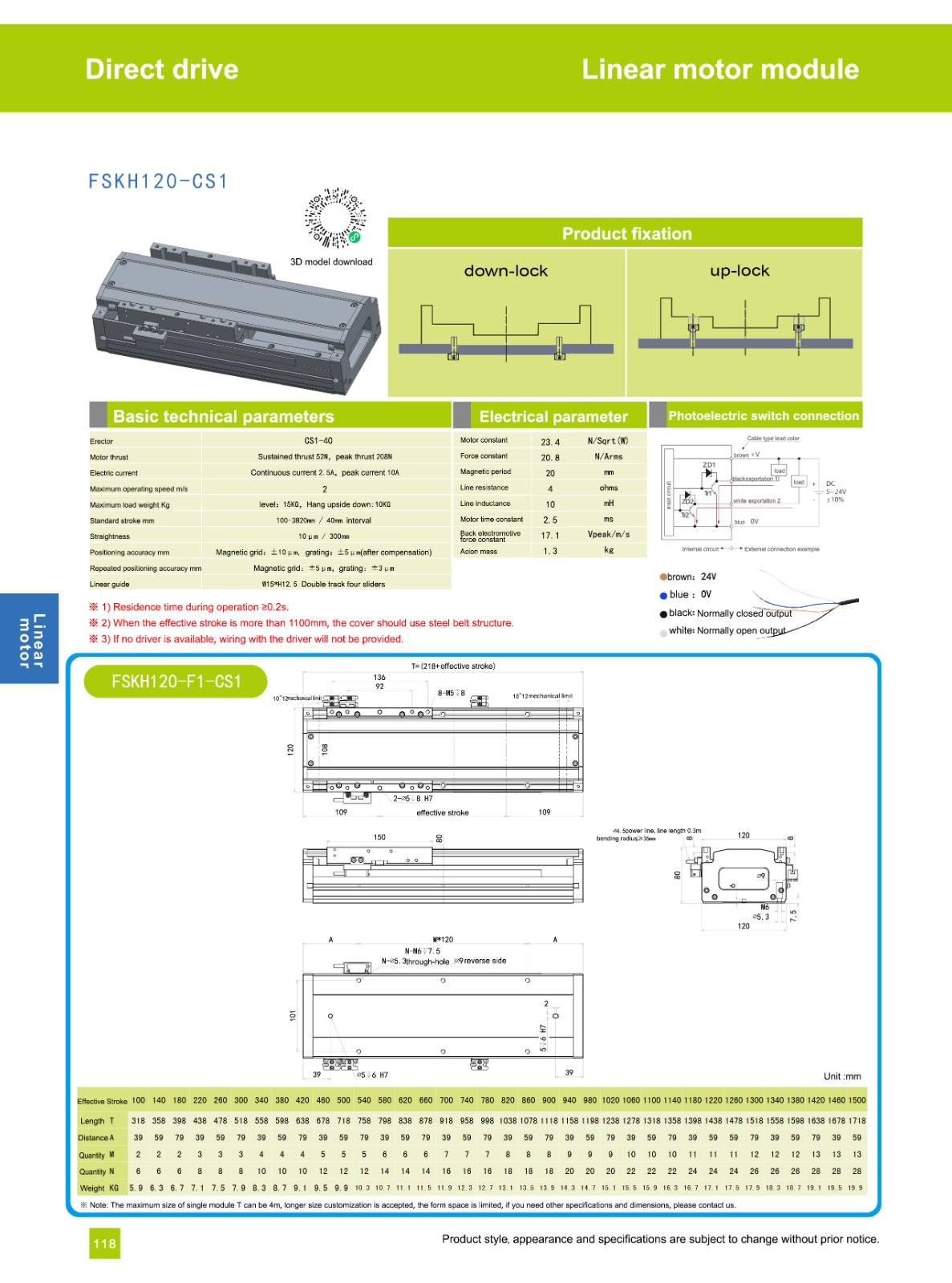

Linear motor module

Horizontal load ≤70KG

Standard stroke: <3.7 meters

Non-standard customized stroke: more than 10 meters

Excellent material, not easy to wear, steady and steady material, increase the service life of the product. Strong bearing capacity, quality, considerate service, rich industry experience, the company has a strong after-sales team to solve your problems.

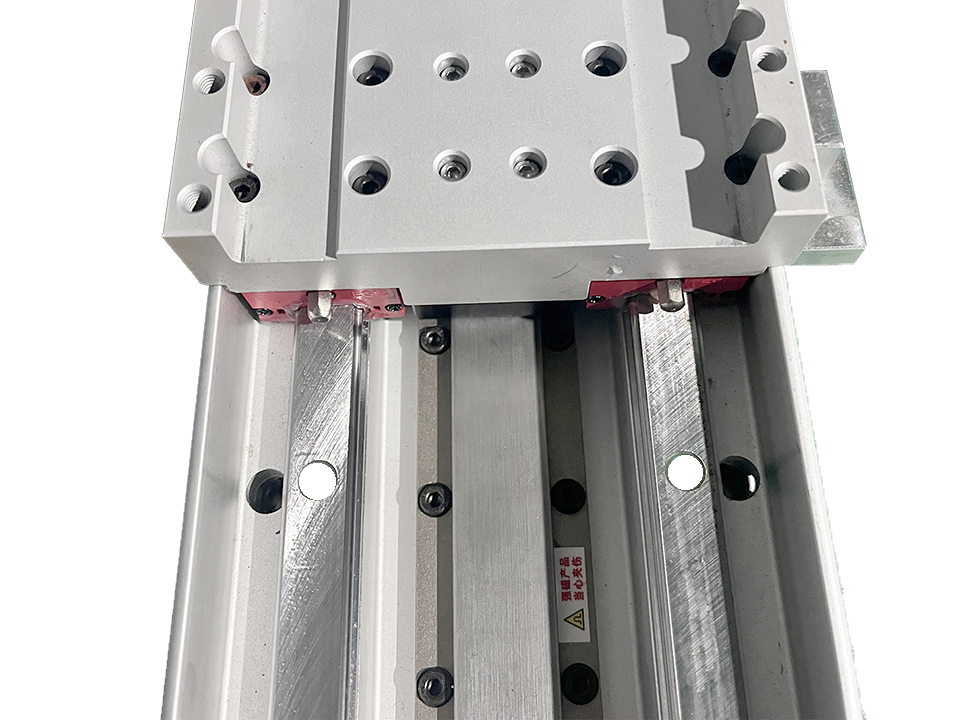

01. Real materials, qualified inspection, exquisite materials, layer-by-layer screening

02. Careful production, excellent craftsmanship, excellent quality

03. Not easy to wear, vacuum quenching process to enhance toughness

Linear actuator is a mechatronic device that converts rotary motion into linear reciprocating motion. Electric linear actuator realizes precise displacement control of load through the coordinated work of motor, transmission mechanism (such as screw, gear rack, synchronous belt) and control system. Electric linear actuator is widely used in industries, medical, home, agriculture and other fields that require linear drive. Electric linear actuator is one of the core components of automation system.

Features of electric linear actuator

High efficiency and energy saving: linear actuator manufacturer adopts permanent magnet synchronous motor, which improves energy efficiency by 40% compared with traditional stepper motor.

Quiet and low noise: linear actuator manufacturer optimizes transmission structure, operating noise ≤45dB (A), suitable for noise-sensitive environments (such as medical and laboratory).

Long life and maintenance-free: key components (such as ball screw and linear guide) are made of wear-resistant materials, with a life of ≥50,000 cycles, reducing downtime maintenance costs. Linear actuator manufacturer is intelligent and programmable; integrated PLC or single-chip microcomputer realizes complex control logic.

Flexible installation: linear actuator manufacturer provides multiple installation methods such as flange, tripod, side installation, etc., suitable for different equipment structures.

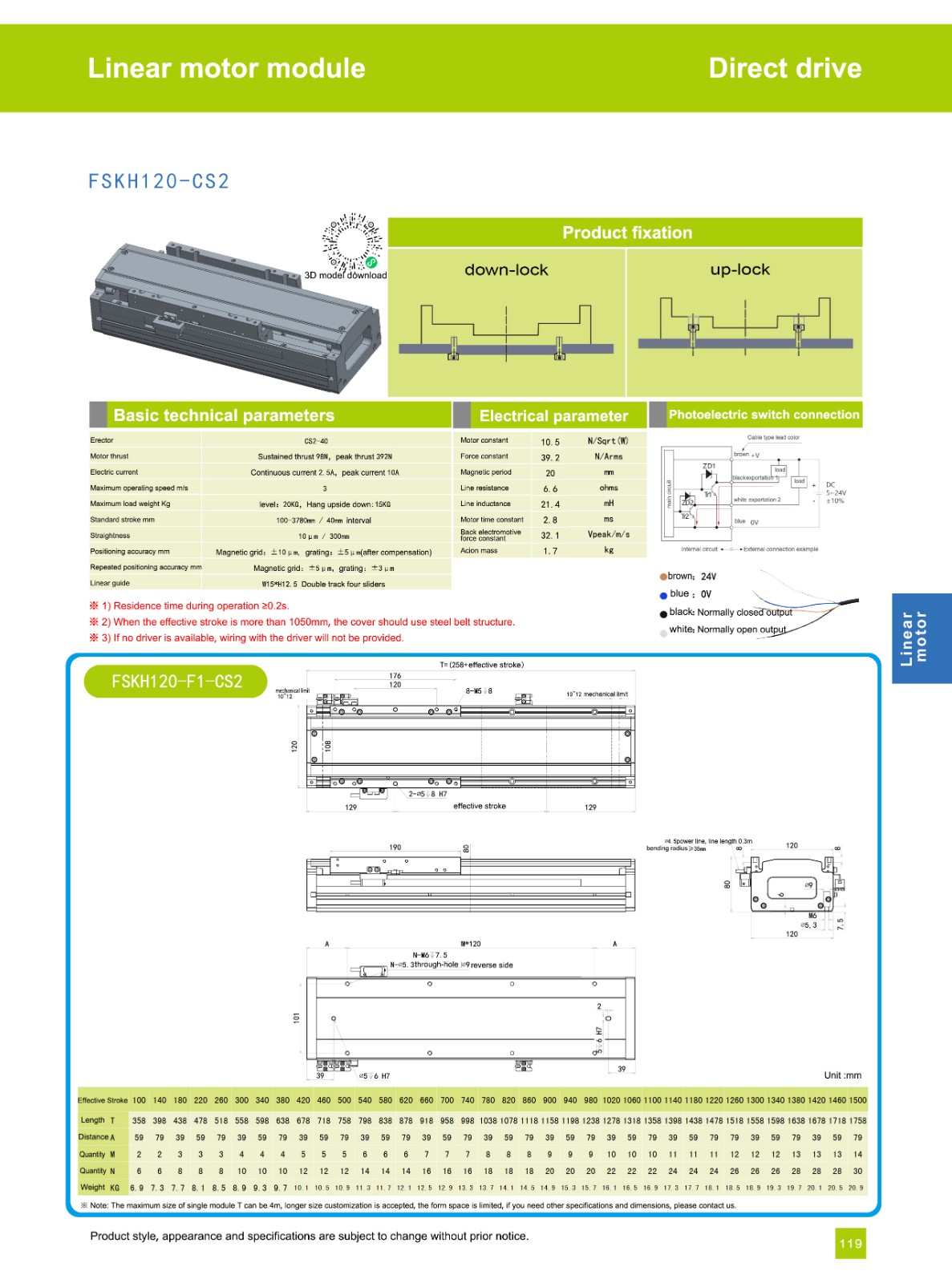

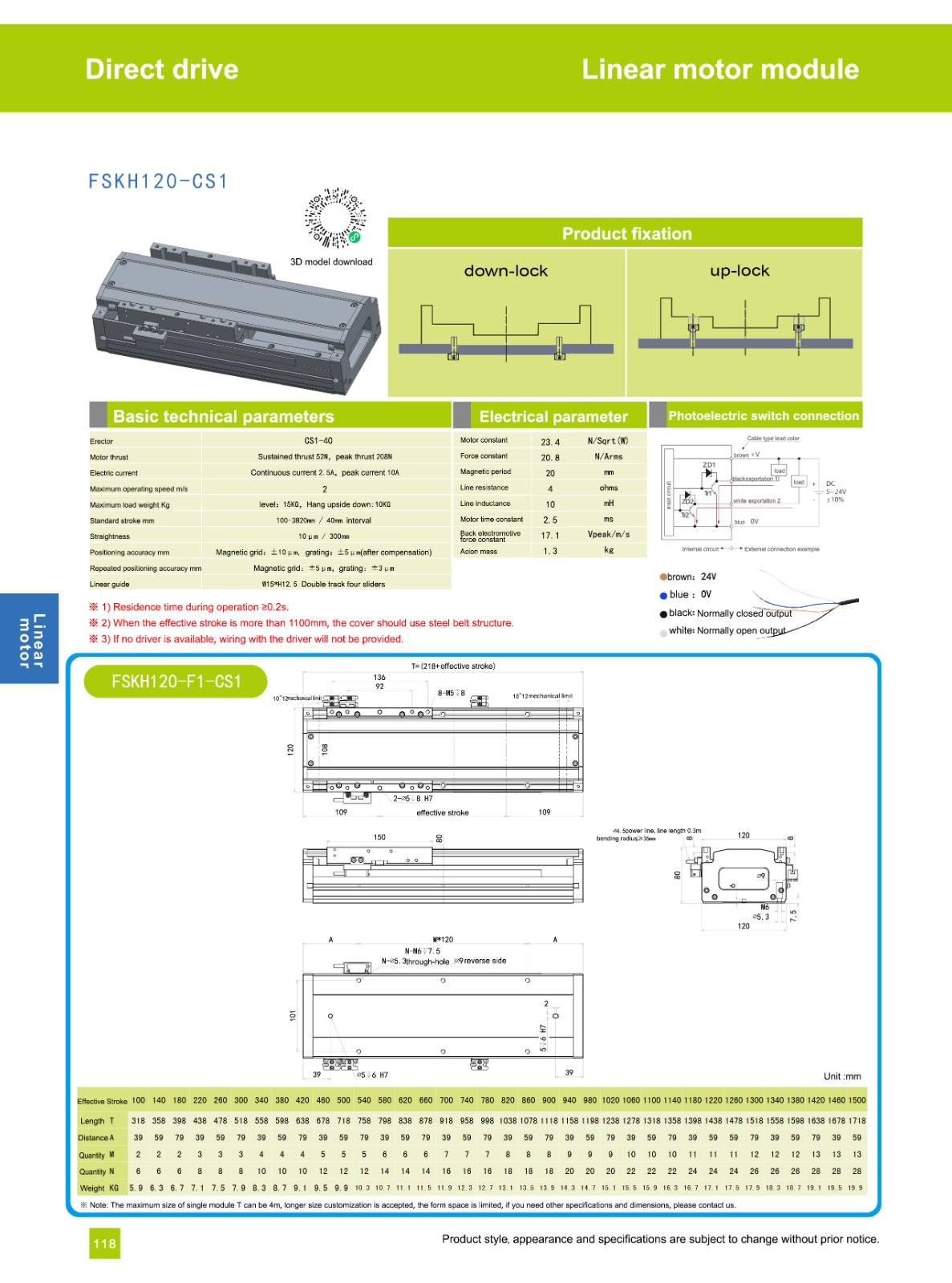

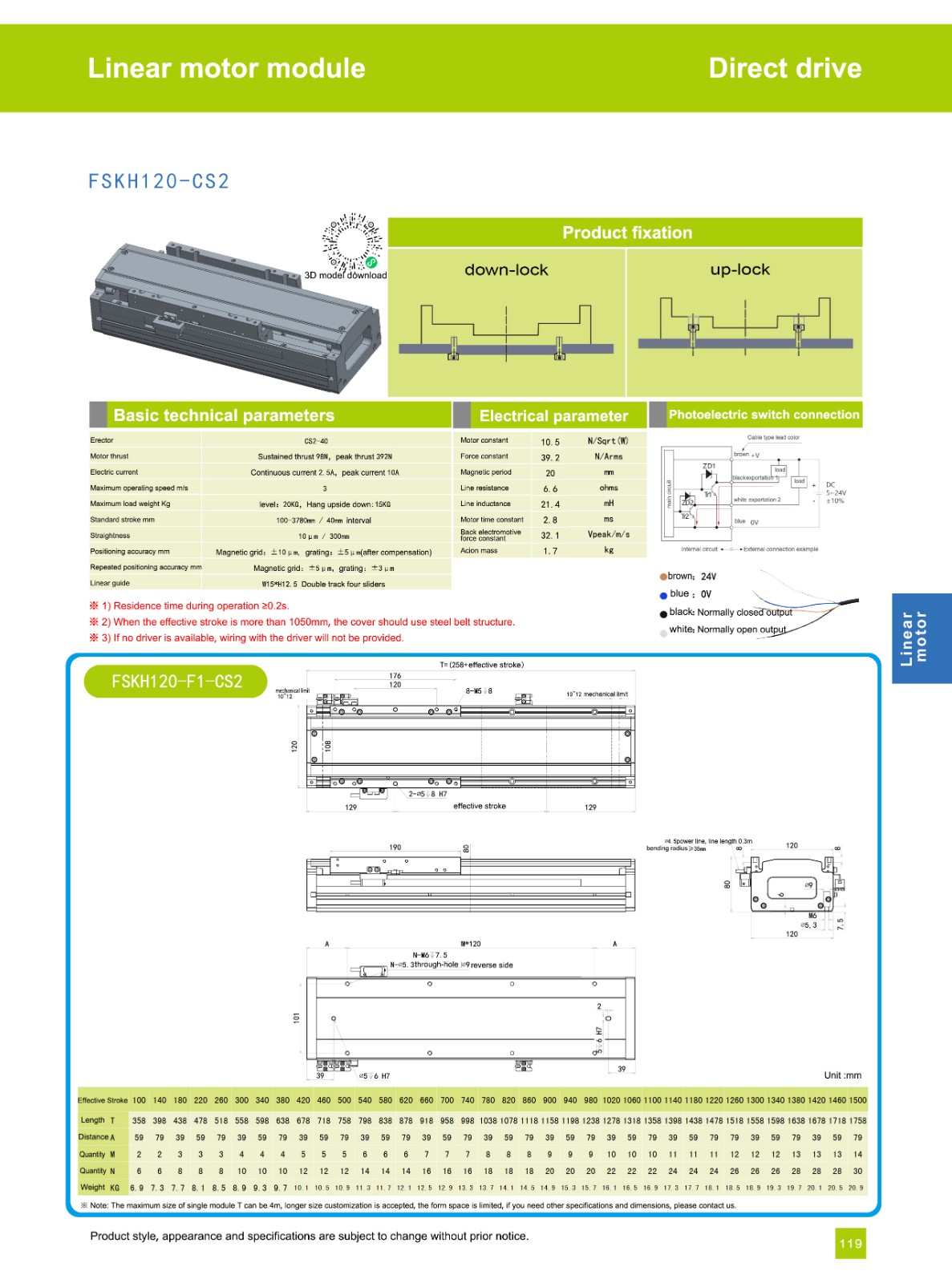

The FSKH 120 high-acceleration moving stator rail linear motor actuator offers the following core advan

tages:

Ultra-High Dynamic Performance

Utilizing direct drive technology, it achieves accelerations up to 10g and speeds exceeding 300m/min,

far exceeding traditional ball screws (1.5g/120m/min).

Precision Positioning

With no mechanical backlash, positioning accuracy reaches 0.1µm and high repeatability, making it suita

ble for high-precision applications such as semiconductor processing.

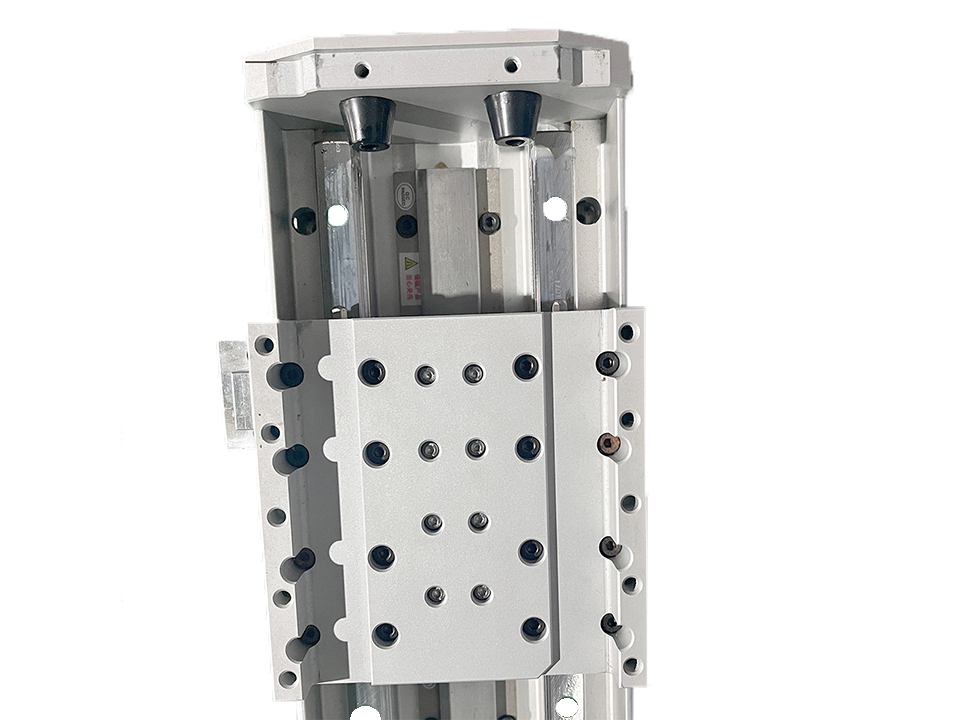

Simplified Structure and Long Life

The elimination of intermediate transmission components reduces maintenance requirements, minimiz

es mechanical wear, and significantly extends life.

Fast Response and Wide Speed Range

With a speed ratio of up to 1:10,000, it can reach maximum speed instantly and stop quickly even at

high speeds.

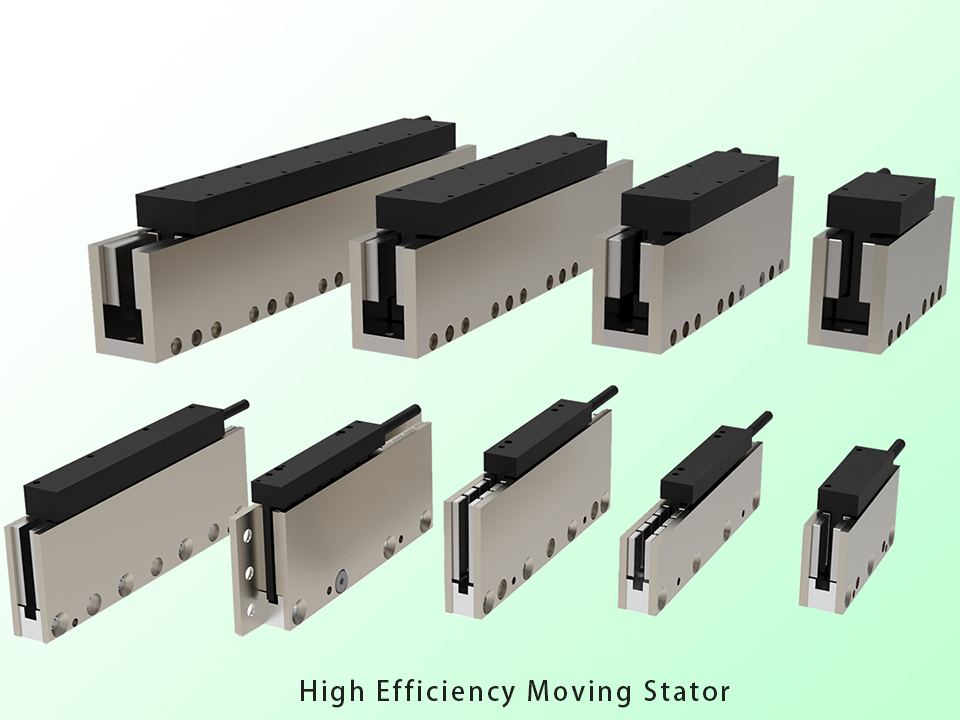

Modular Design

Supports multi-axis configurations, facilitating integration into automation equipment such as high-

speed conveyors and other industrial applications.

The core advantages of high-acceleration moving-stator linear motor actuators with guide rails lie in

the high dynamic response, high precision, and low maintenance offered by direct drive, making them

particularly suitable for applications requiring rapid start-stop and precise positioning.

I. High Dynamic Performance

High acceleration: The moving part has low mass, and the electromagnetic force acts directly, resulting

in acceleration reaching tens of times the acceleration due to gravity (g), far exceeding traditional rotary

motor + ball screw systems.

High speed: The maximum speed is limited only by the control system and bearings, reaching several

meters per second or even higher.

Fast response: With virtually zero transmission stiffness and zero backlash, it responds very quickly to

control signals, resulting in minimal tracking error.

II. High Precision and High Resolution

Direct drive: Without intermediate mechanical transmission links, it eliminates backlash, elastic deforma

tion, and friction, achieving positioning accuracy of micrometers or even nanometers.

High rigidity: There are no elastic elements between the drive unit and the load, resulting in high motion

rigidity, good overall system rigidity, and strong resistance to disturbances.

III. Low Maintenance and Long Lifespan

Maintenance-free: There is no mechanical contact between the primary and secondary parts, avoiding

mechanical wear and significantly reducing maintenance requirements and maintenance costs over the

lifespan.

Long lifespan: Non-contact drive, minimal friction and wear, high reliability, and long lifespan.

IV. Flexibility and Cleanliness

Flexible stroke length: By increasing the stator length, theoretically any stroke length can be achieved,

and the performance does not easily degrade over long strokes.

Quiet and clean operation: No mechanical friction or impact, resulting in low noise; no lubrication is

required, eliminating the possibility of oil contamination, making it suitable for cleanroom environments.

V. Application Scenarios

Semiconductor field: High-precision linear motion, such as photolithography machines and wafer

handling.

CNC machining centers: High dynamic response, such as high-speed milling and laser cutting.

Automation equipment: High-precision positioning, such as robots and assembly lines.

Magnetic levitation trains: High-speed, low-noise operation.

Medical equipment: Clean, low-noise environment, such as surgical robots and imaging equipment.

VI. Conclusion

High-acceleration moving-stator linear motor actuators with guide rails have broad application prospects

in fields such as semiconductors, CNC machining, automation equipment, magnetic levitation trains,

and medical devices, thanks to their high dynamic performance, high precision, low maintenance, and

flexibility.