The linear module is a kind of electric cylinder equipment commonly used in the industry. It consists of a linear slider and a drive motor. The linear module manufacturer can make the company's production line perform automatic linear motion, thereby greatly improving the company's production efficiency. Therefore, in order to obtain better linear motion effects, it is very important to choose modular slide rails.

1. Choose products with light weight and high rigidity

Since the linear module material used by the industry-leading linear module is aluminum alloy profile, it has the advantages of light weight but high rigidity, but due to the different composition of aluminum alloy, its rigidity performance will also be different. At the same time, it should be relatively rigid, and the greater the rigidity under the same weight, the better.

2. Choose wear-resistant and corrosion-resistant products

Linear modules are used in production lines in many fields, and there are many corrosion production and processing companies. Therefore, in order to make the modular slide rail more durable, products with strong corrosion resistance and high wear resistance should be selected. The characteristics of the sliding module can be seen on the surface when purchasing. If the surface is treated with aluminum alloy for corrosion protection and passivation, the resistance of both types will be stronger.

3. Choose standardized products for each component

Enterprises should try to choose modular slides with standardized components when purchasing. Linear module manufacturing

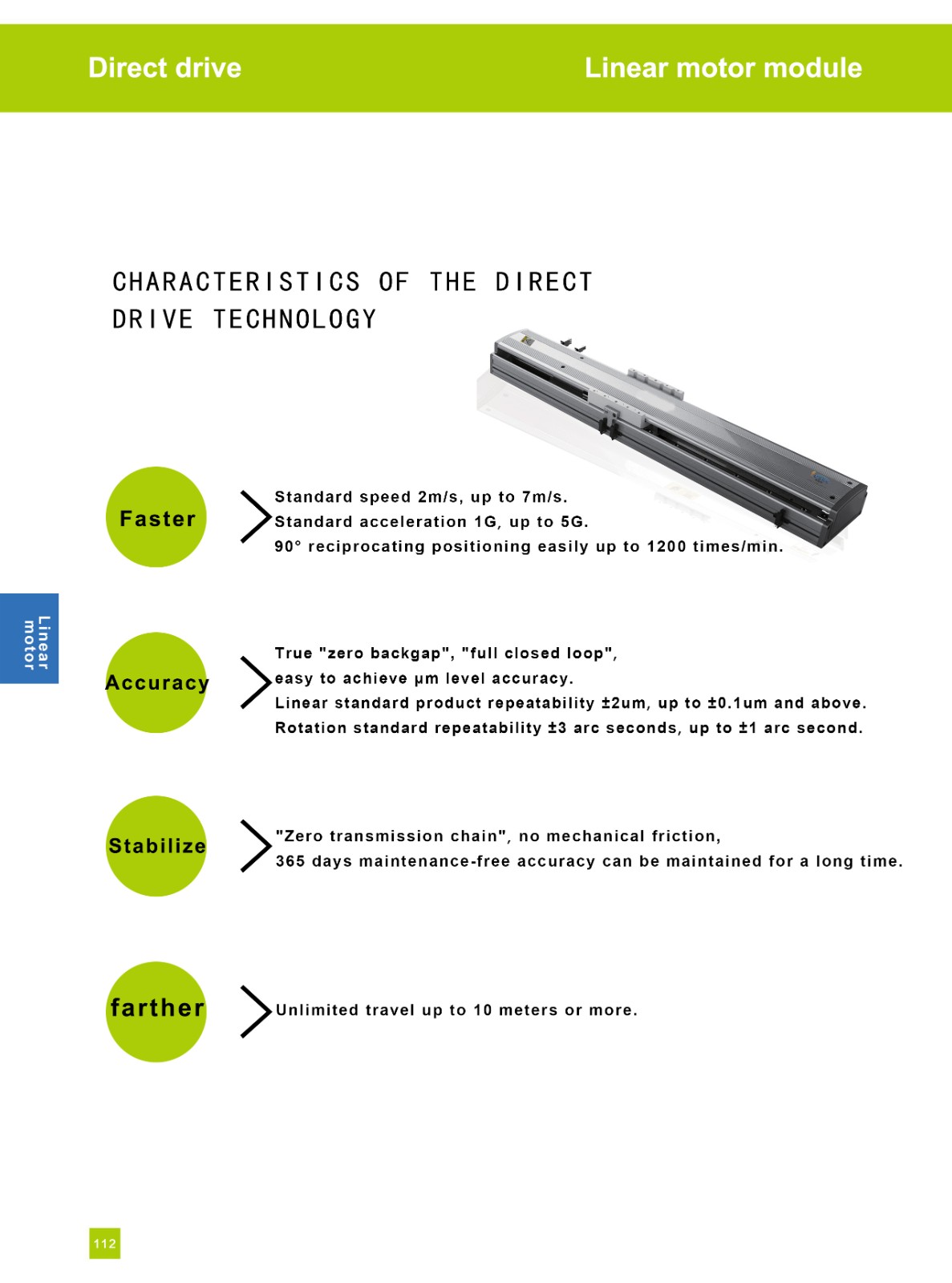

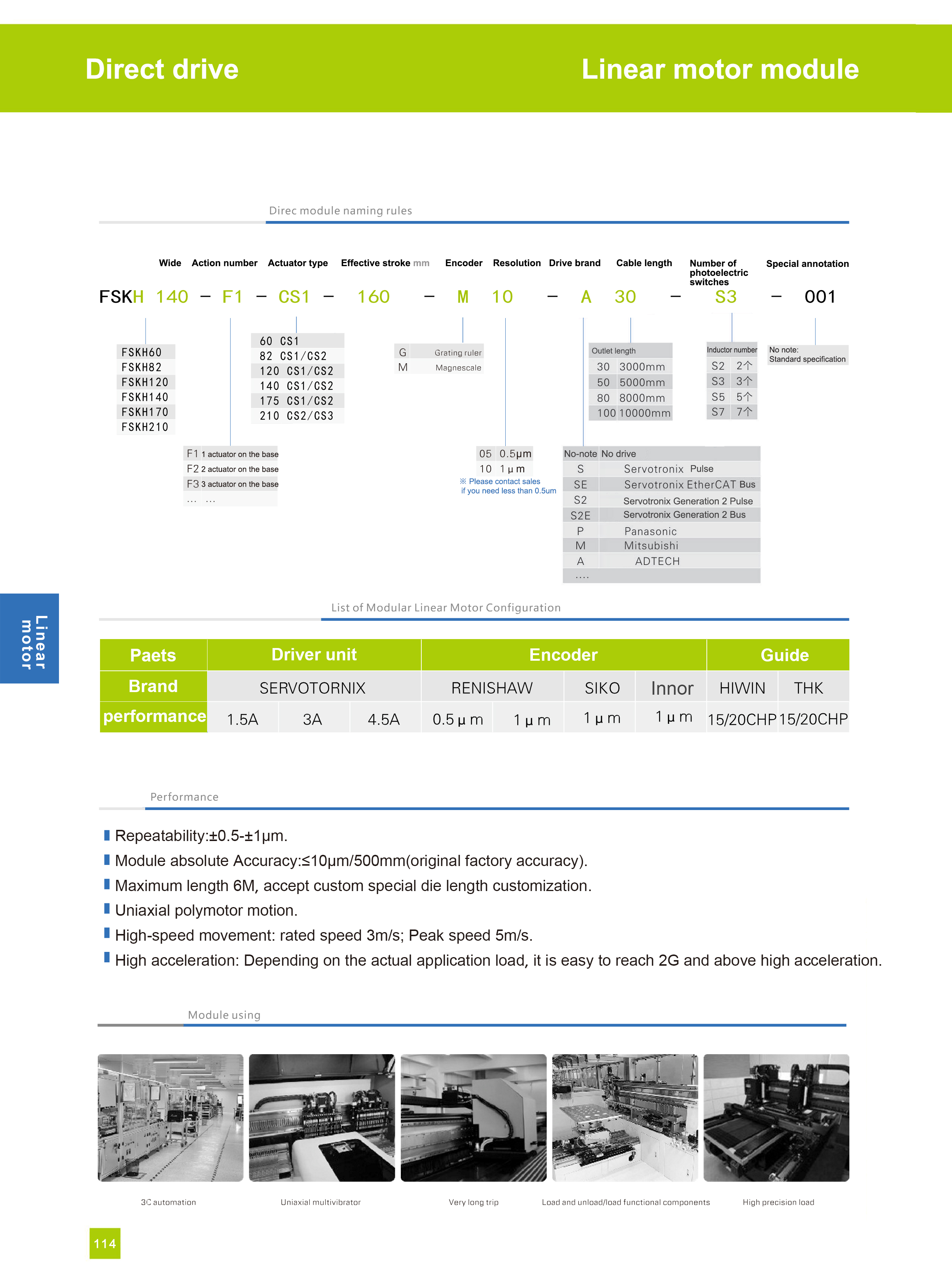

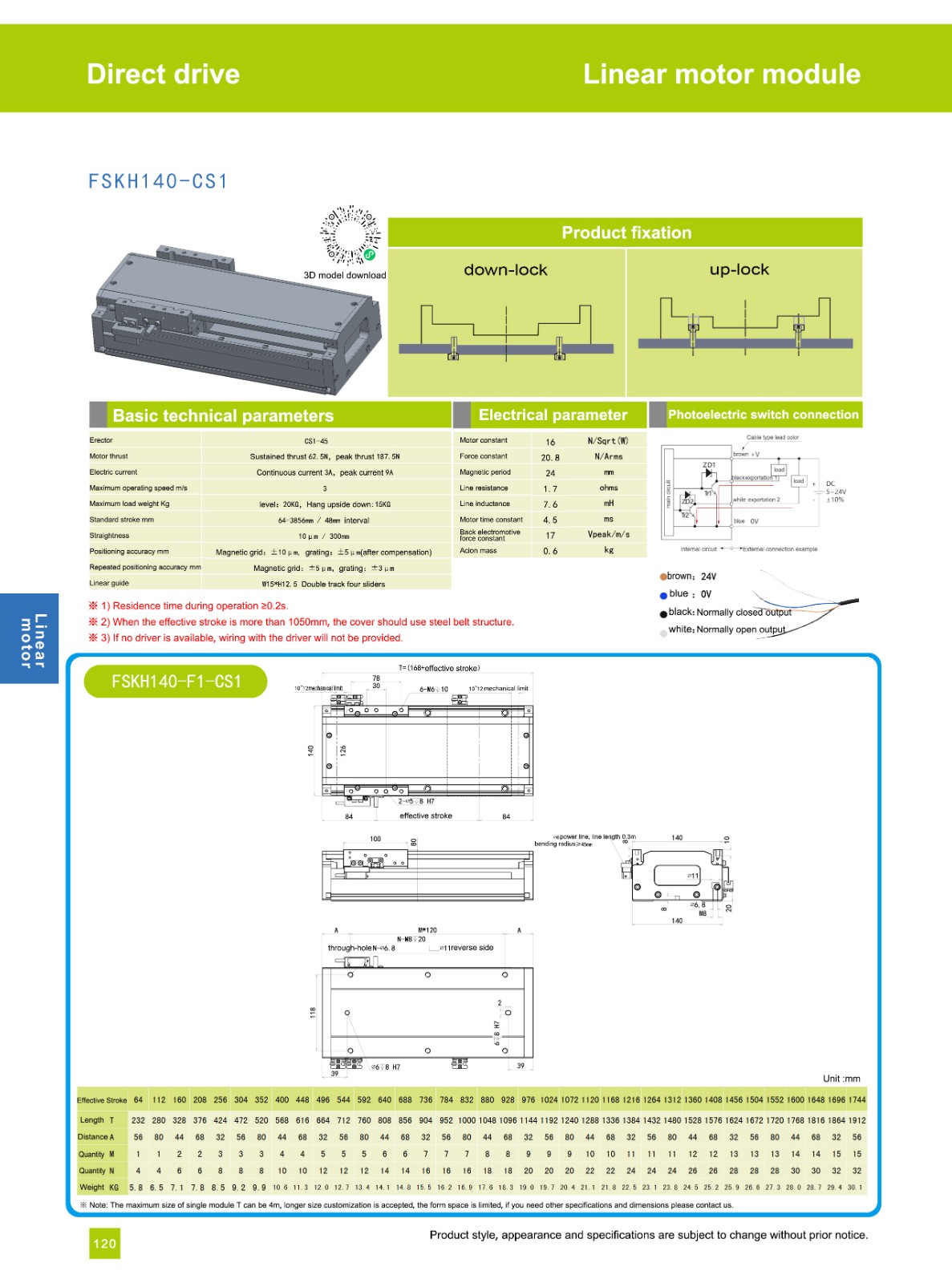

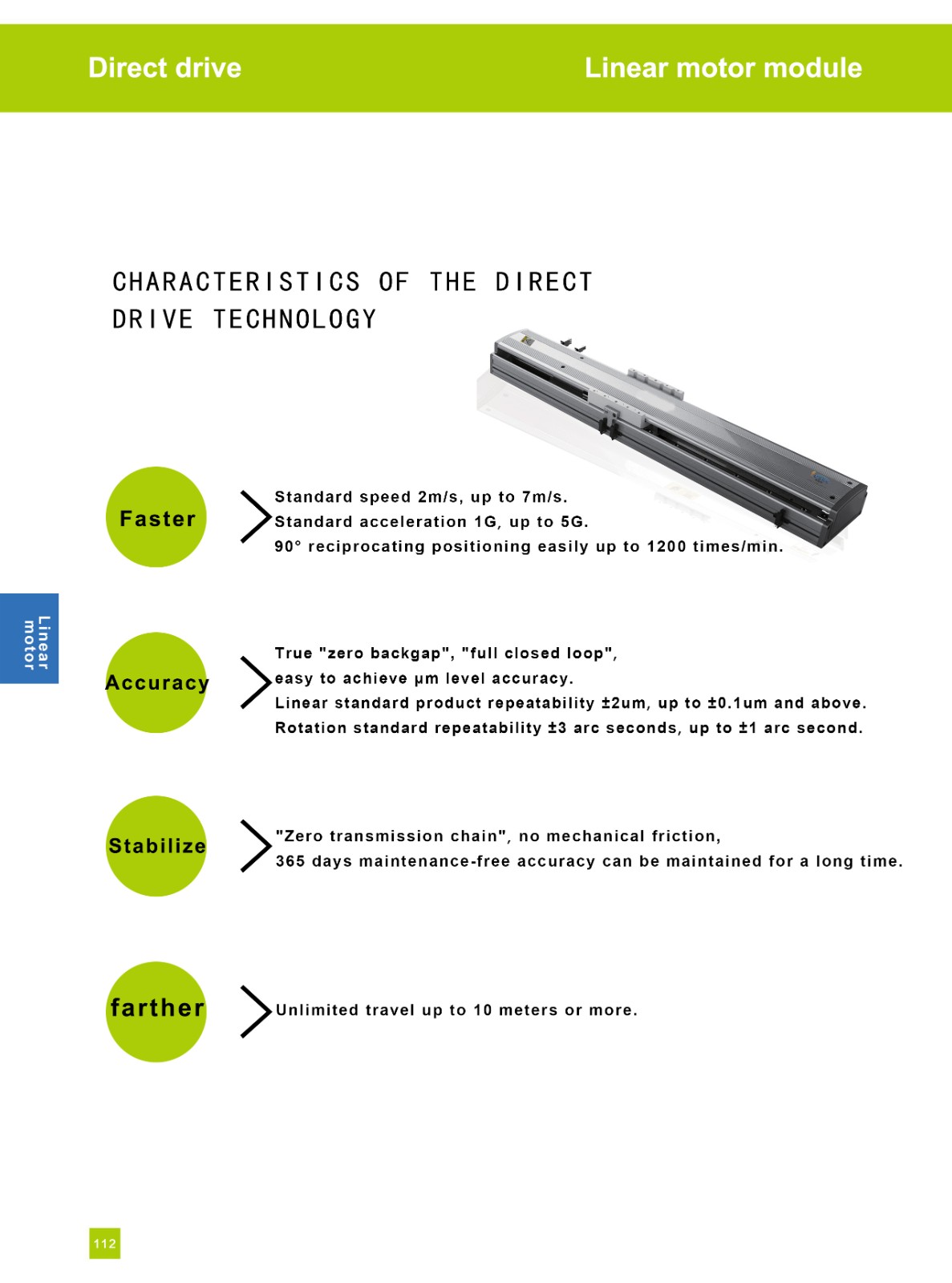

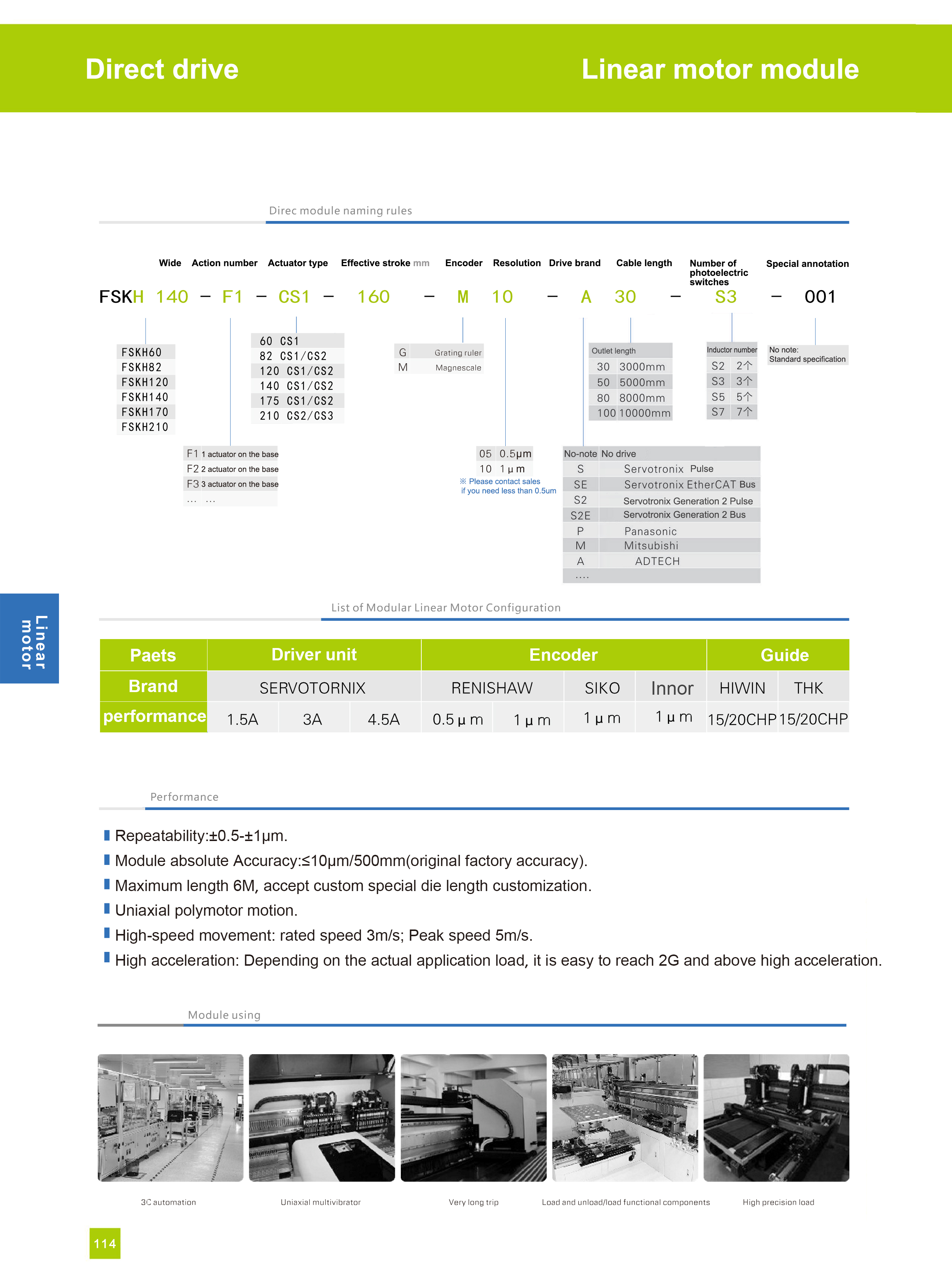

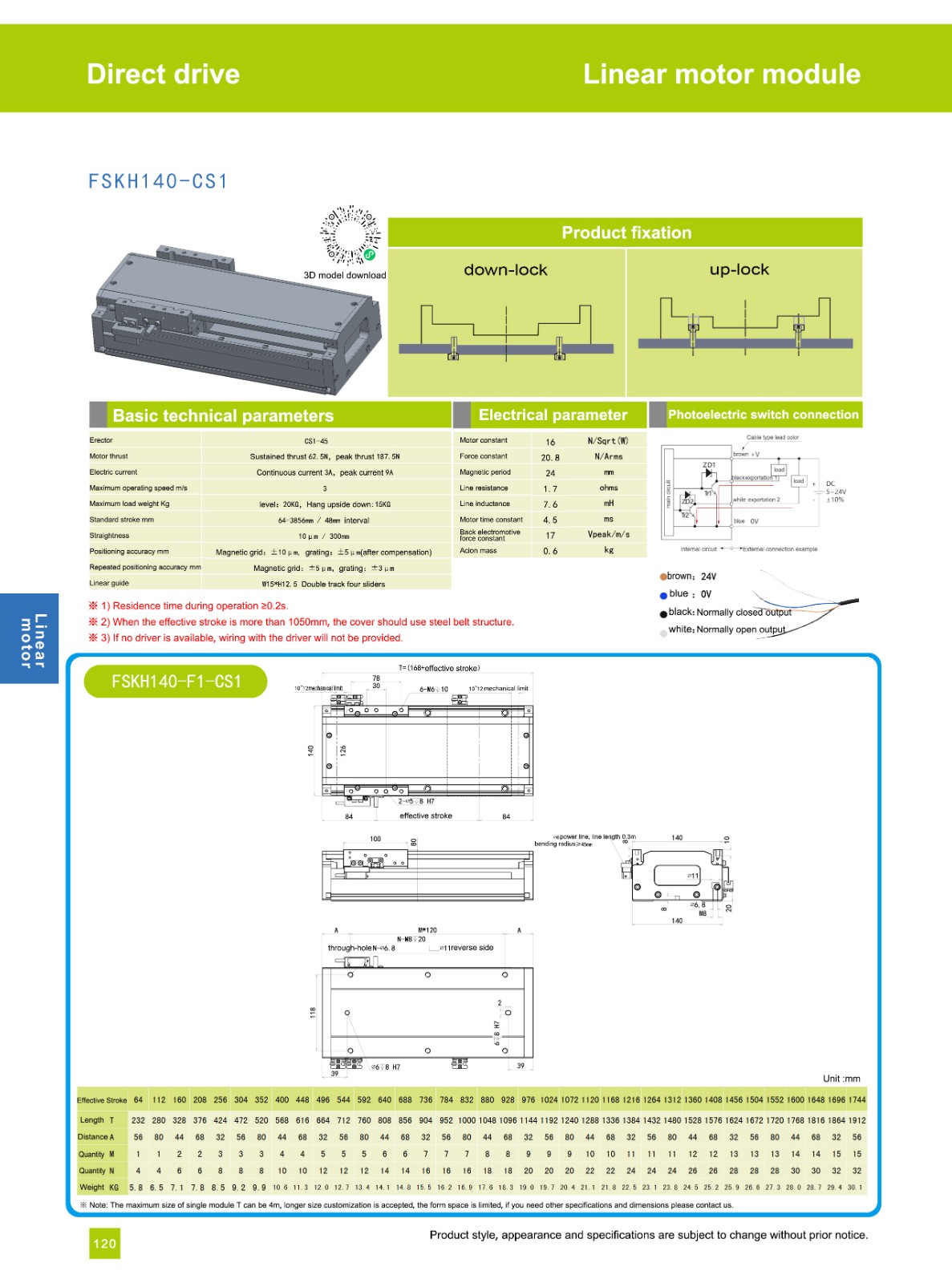

Introducing the FSKH 140 motorized linear slide module – a cutting-edge, low-noise linear motors drive system designed to revolutionize your automation applications. This advanced motorized linear slide is engineered for superior performance, offering a suite of core advantages that set it apart in demanding industrial environments.

Key Advantages of the FSKH 140 Motorized Linear Slide:

High-Precision Positioning for Critical Applications:

Leveraging advanced direct drive technology, our motorized linear slide eliminates the inherent mechanical transmission errors associated with traditional ball screws. This innovation ensures exceptional positioning accuracy, achieving precision down to the micron level. When integrated with a high-resolution optical scale, the accuracy of this linear actuator motor can be further enhanced to an impressive <5μm, making it ideal for the most sensitive and precise operations.

Whisper-Quiet Operation for Sensitive Environments:

The FSKH 140 motorized linear slide features an optimized magnetic circuit design and a contactless transmission structure. These advancements significantly reduce mechanical friction noise, ensuring remarkably quiet operation. This makes our linear motors an indispensable choice for applications requiring stringent silence, such as medical devices, laboratory automation, and cleanroom environments where noise levels are critical.

Fast Response and High Acceleration for Dynamic Performance:

The direct drive capability of this linear actuator motor enables rapid accelerations of 1-2g, dramatically surpassing the speed limitations of traditional lead screws (which max out at approximately 500m/min). This makes our motorized linear slide perfectly suited for applications demanding high-speed reciprocating motion, improving throughput and efficiency in your production lines.

Simplified Structure and Extended Lifespan:

By eliminating intermediate transmission components, this motorized linear slide significantly reduces potential points of failure and maintenance requirements. The result is near-zero mechanical wear, exceptionally low failure rates, and a remarkably extended operational lifespan for your linear motors, ensuring consistent performance and lower total cost of ownership.

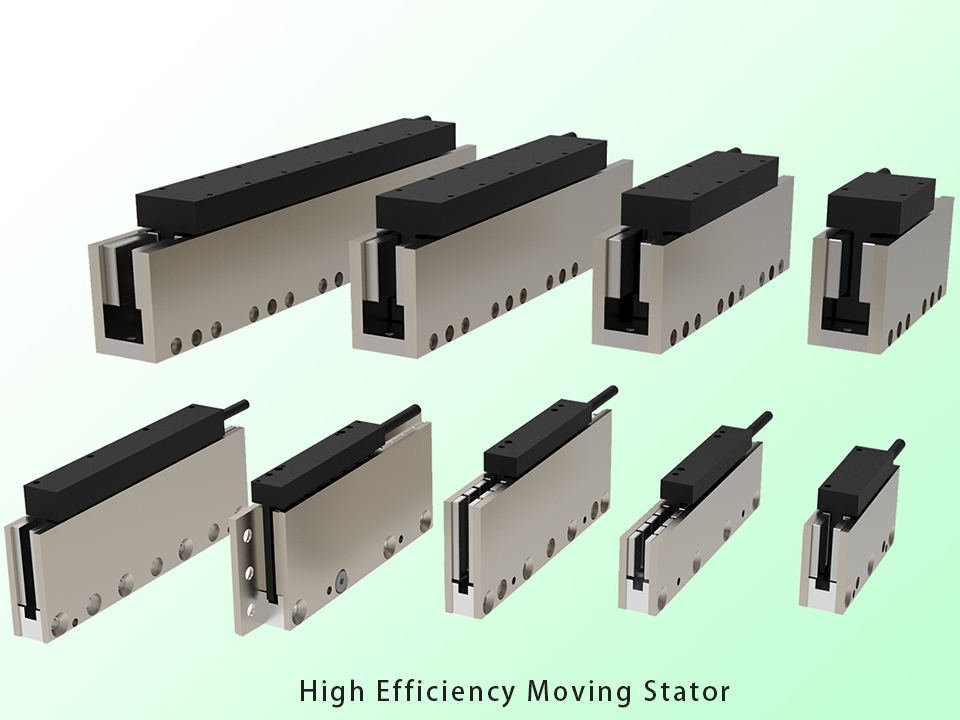

Modular Design for Versatile Integration:

The FSKH 140 motorized linear slide boasts a flexible modular design that supports easy multi-axis configurations. This adaptability facilitates seamless integration into a wide array of automated equipment, including switchgear automatic clamping devices and various other critical industrial applications. Our versatile linear actuator motor solutions streamline your design process and enhance system flexibility.

Elevate Your Automation with Our Advanced Linear Motors

Choose the FSKH 140 motorized linear slide for a powerful combination of precision, speed, and reliability. This high-performance linear actuator motor is designed to meet the rigorous demands of modern industry, providing a robust and efficient solution for your motion control needs. Explore how our advanced linear motors can transform your operations by delivering unparalleled accuracy, quiet performance, and long-term durability.

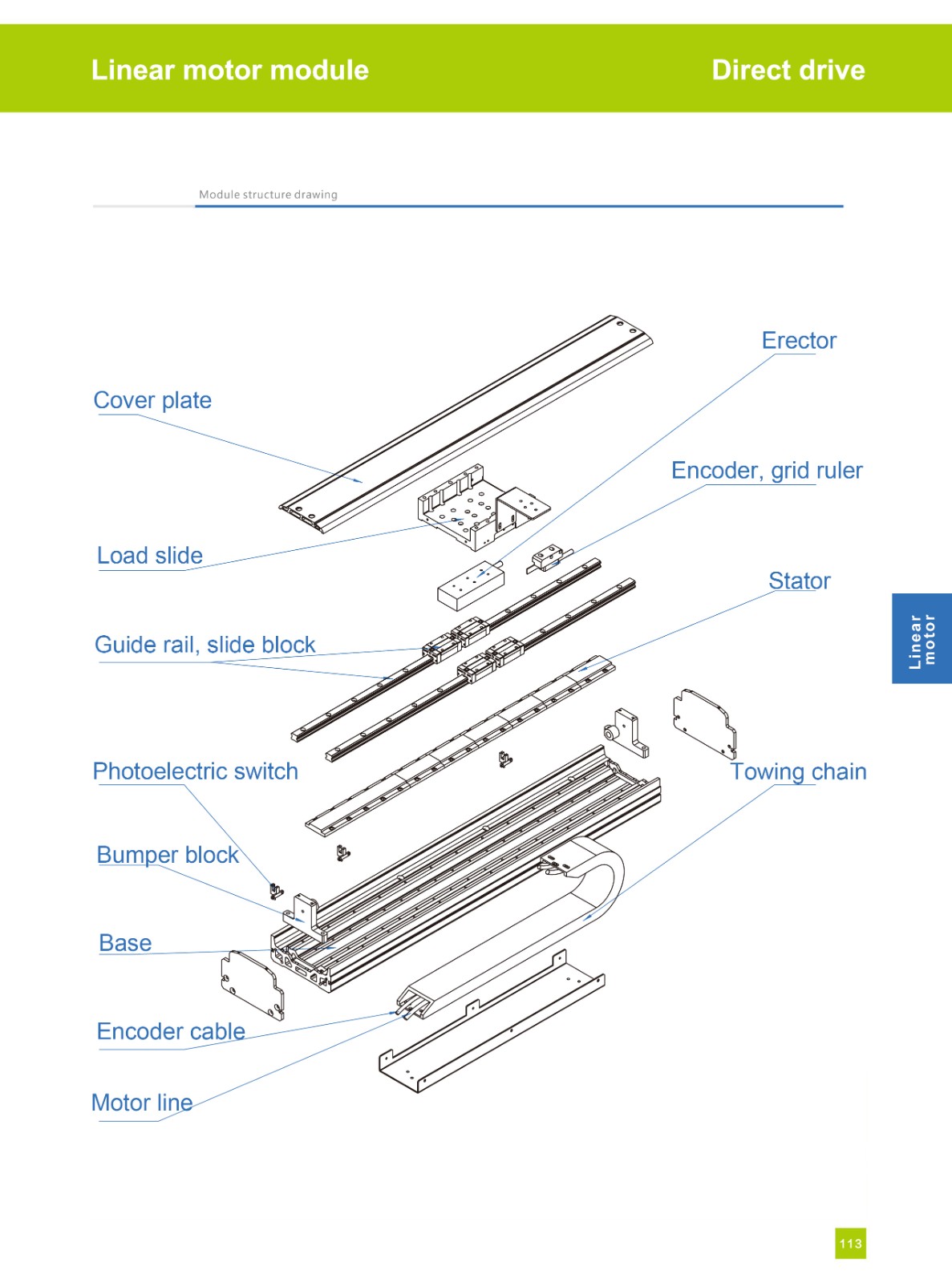

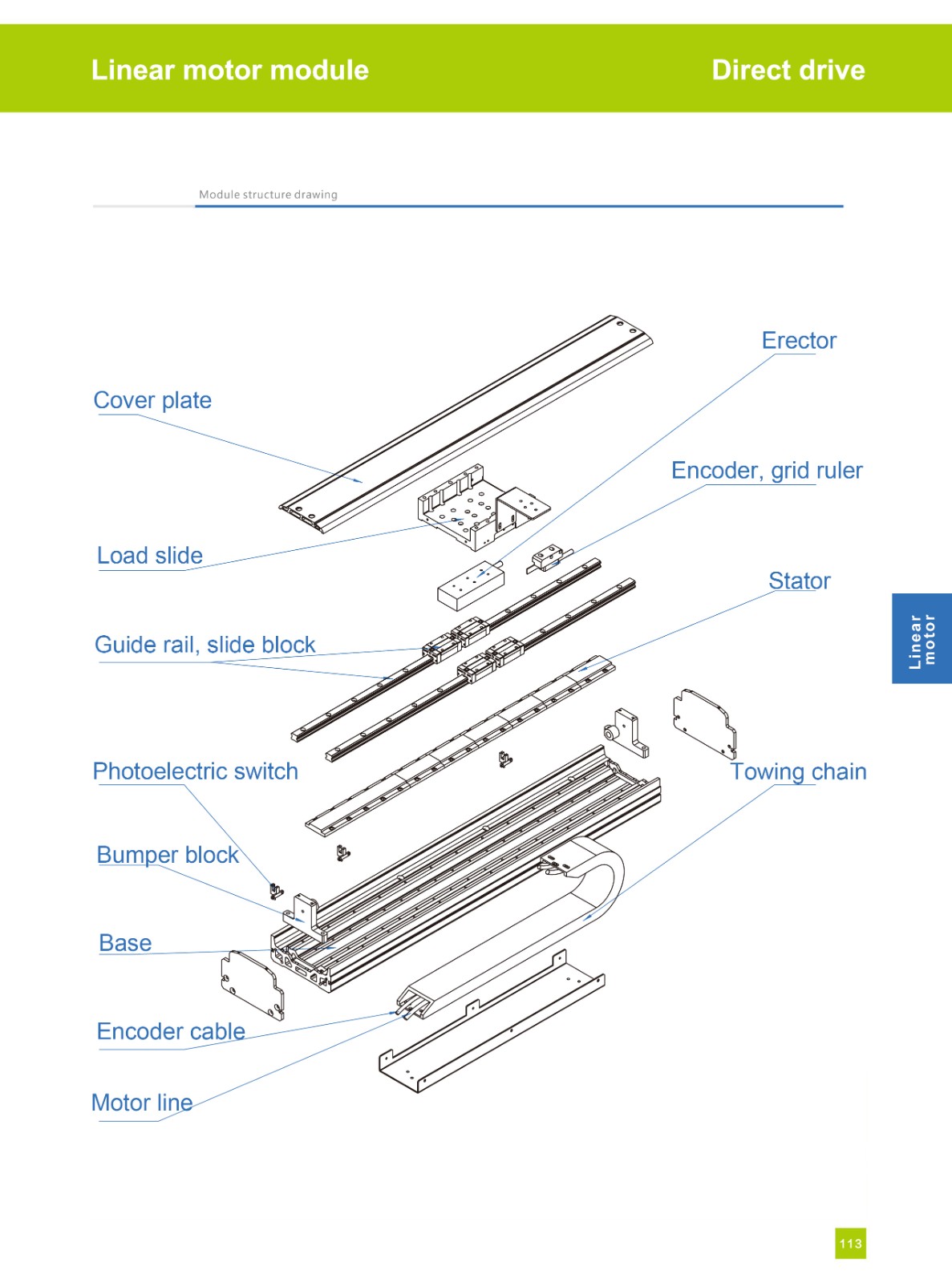

A motor-driven linear slide is a device that converts the rotational motion of a motor into linear motion.

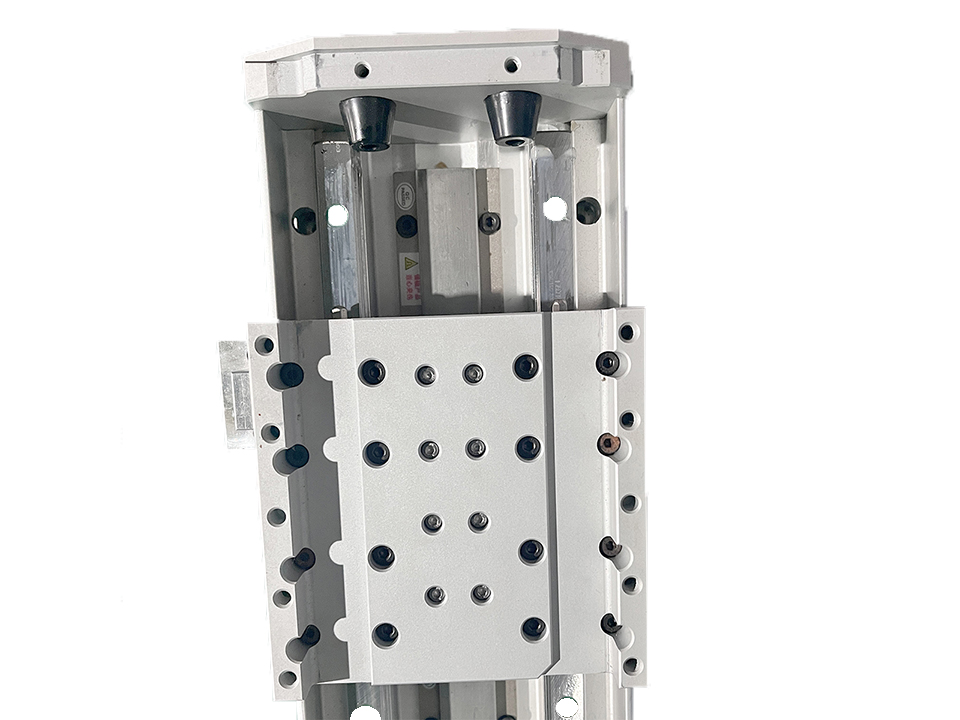

Motor Drive:

A motor-driven linear slide contains a motor, which is the power source for the entire device.

When the motor starts working, it rotates, generating rotational power.

Transmission Mechanism Transforms Motion:

The motor-driven linear slide also has a transmission mechanism, such as a screw, belt, or gears.

This transmission mechanism acts like a "translator," converting the rotational power generated by the

motor into linear motion.

For example, if the transmission mechanism is a screw, the screw will convert the motor's rotational

motion into the linear motion of a nut.

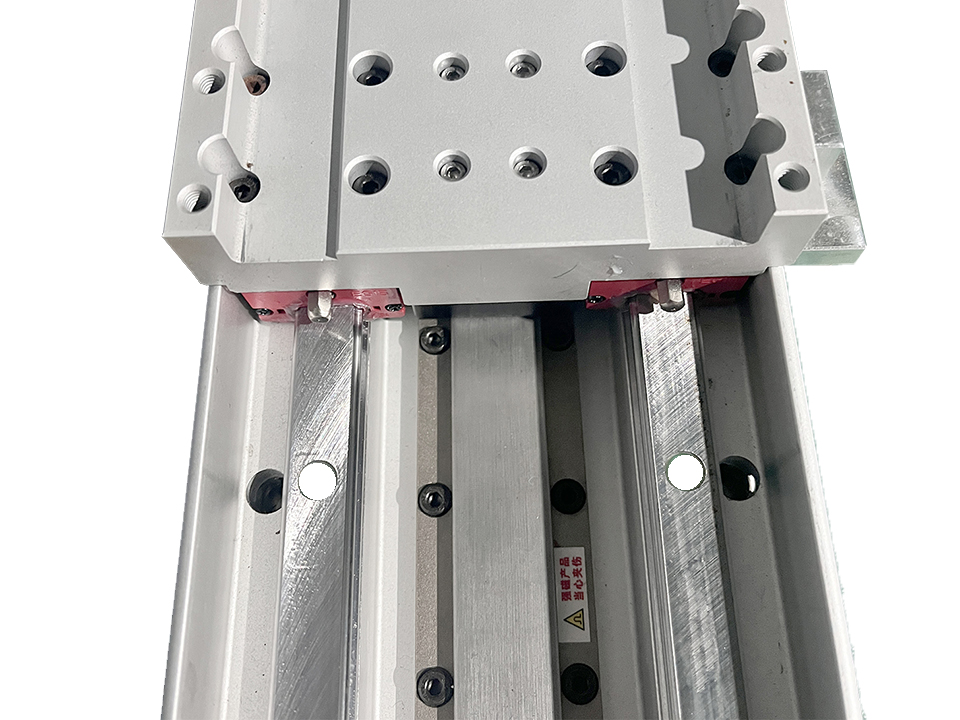

Guiding Mechanism Ensures Linear Accuracy:

In addition to the transmission mechanism, the motor-driven linear slide also has a guiding mechanism,

such as guide rails.

The guiding mechanism plays a crucial role; it ensures that the slide maintains a straight line during

movement and doesn't deviate.

It's like when we walk, our eyes look ahead, and our feet follow a straight line, preventing us from going

off course.

Load Platform Achieves Linear Movement:

Finally, the motor-driven linear slide has a load platform, which is used to place items that need to move

linearly.

When the motor rotates, the transmission mechanism converts the rotational power into linear motion,

the guiding mechanism ensures the correct direction, and the load platform can then carry the items to

achieve linear movement.

In summary, the working principle of a motor-driven linear slide is that the motor provides power, the

transmission mechanism transforms the motion, the guiding mechanism ensures linear accuracy, and

the load platform achieves linear movement. This allows the motor-driven linear slide to convert the

motor's rotational motion into the desired linear motion.