CHARACTERISTICS OFTHEDIRECTDRIVE TECHNOLOGY

Faster: Standard speed 2m/s, up to 7m/s. Standard acceleration 1G, up to 5G90-degree reciprocating positioning can easily reach 1200 times/min

More accurate: True "zero backlash" and "full closed loop", easily reach μm-level accuracy Linear standard repeatability ±2μm, up to ±0.1μm and above Rotating standard repeatability ±3 arc seconds, up to ±1 arc second

More stable: "zero transmission chain", no mechanical friction, 365 days maintenance-free, long-term accuracy

Farther: unlimited travel, up to 10 meters or more

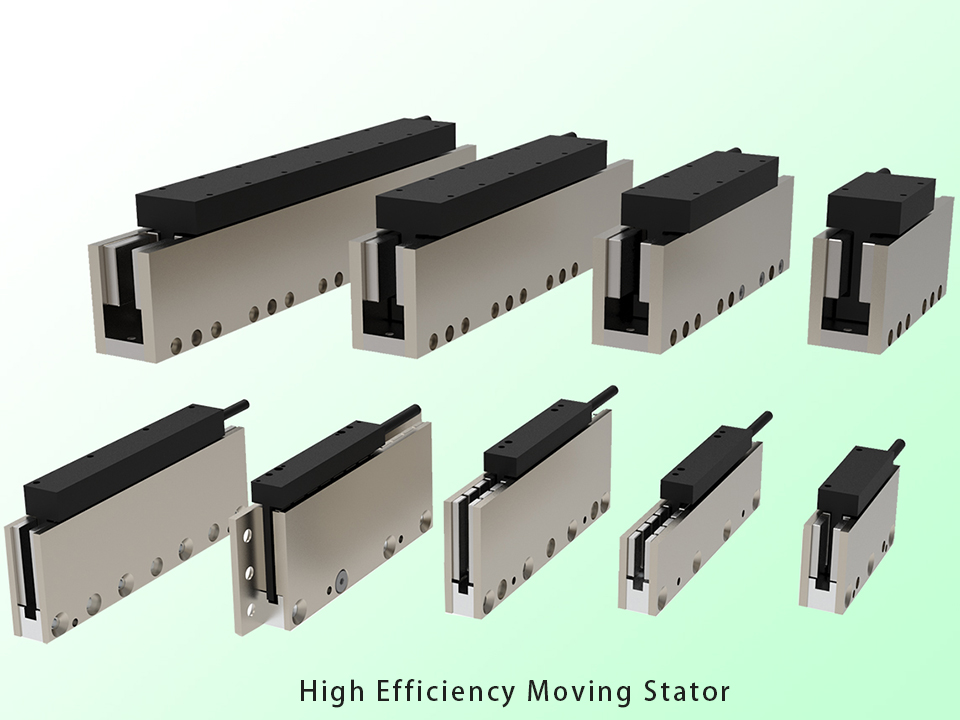

Linear motor performance

Repeatability: ±0.5-±1μm.

Module absolute accuracy: ≤10μm/500mm (original factory accuracy).

Maximum length 6M, accept customization of special module length customization.

Single-axis multi-motor motion.

High-speed motion: rated speed 3m/s; peak speed 5m/s.

High acceleration: Depending on the actual application load, it is easy to reach high acceleration of 2G and above.

Module using

3C Automation

Single-axis multi-motor

Extra-long stroke

Loading and unloading/carrying functional components

High-precision loading

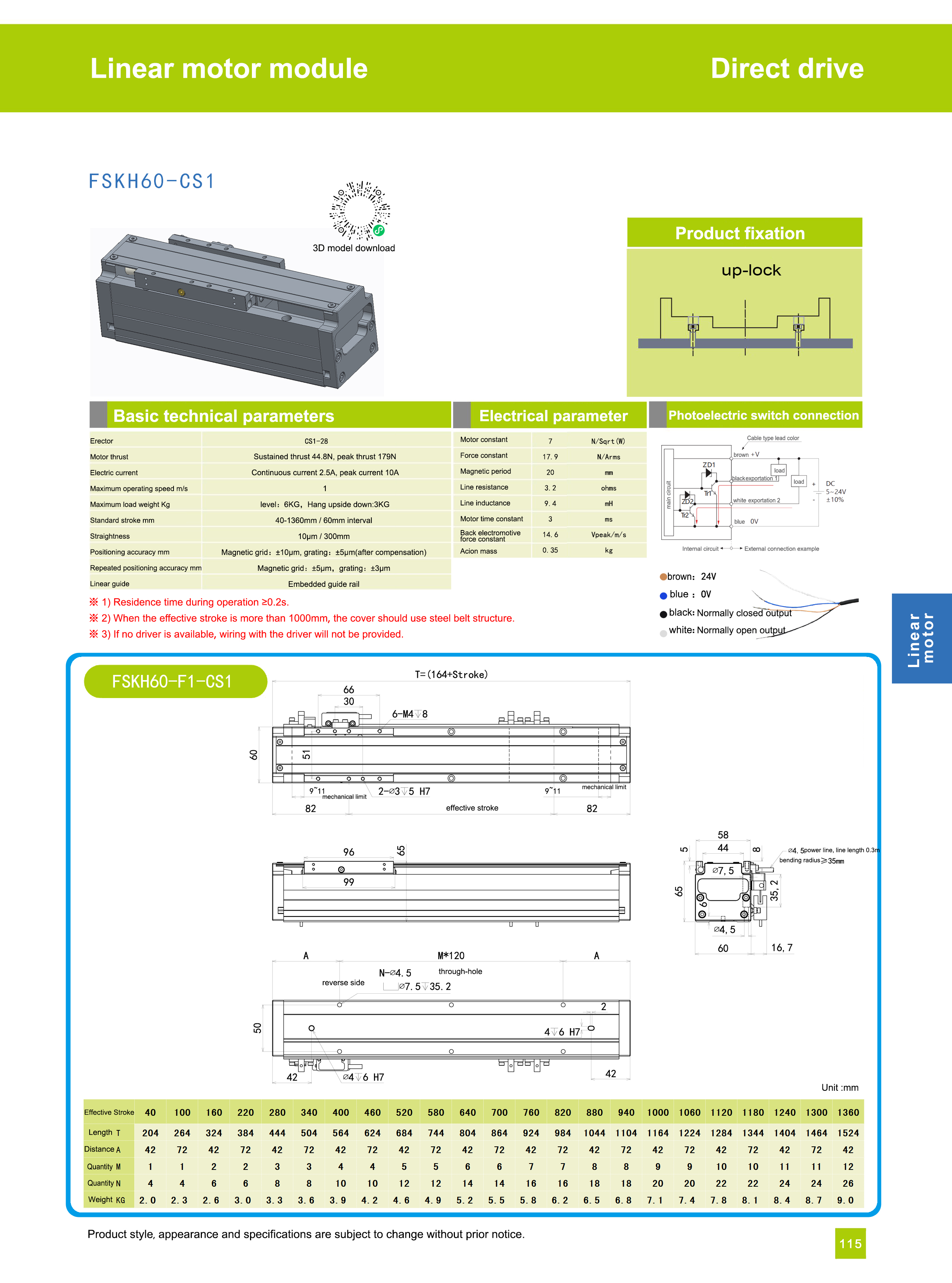

The FSKH 60 linear motor long-stroke actuator module is an efficient and reliable actuator designed

specifically for industrial automation. It utilizes a linear motor drive and is suitable for long-distance,

precision push-pull operations. Its key advantages include a stroke of over 1000mm, a load capacity

ranging from 452N to 11,370N, and a maximum speed of 2m/s, making it ideal for high-precision

applications such as material handling and equipment assembly.

Stroke Characteristics: Supports long-stroke actuator motion with a flexible stroke range (similar

products range from 50 to 1400mm), optimizing space utilization and smooth motion.

Load Capacity: Rugged construction ensures high load capacity, compatibility with various industrial

environments, and reduced maintenance requirements.

Applications: Commonly used in automated testing equipment, production line robotics, or optical

instruments, providing long-term, reliable operation. The module offers optional integrated motor

solutions, such as ball screws or synchronous belt drives, for enhanced versatility. Its fully enclosed

design (including a dust cover) enhances durability and ensures long-term stable output in harsh

operating conditions.

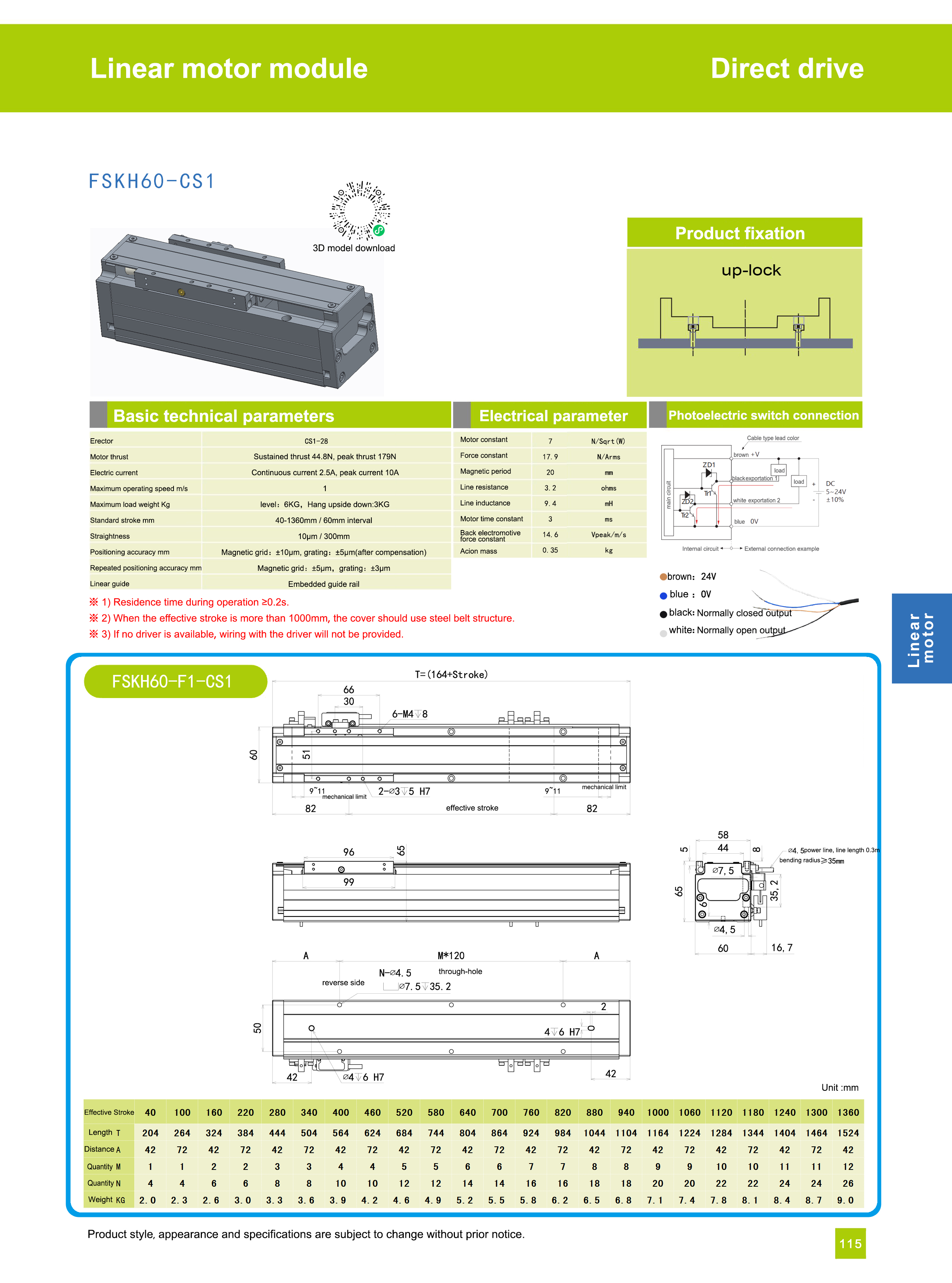

Basic Parameters

Drive Type: X-axis linear motor (transverse linear motor) with a high-voltage driver chip (peak 10V) and

programmable waveform output.

Travel Range: Ultra-long 60m design, with segmented magnetic tracks for stability.

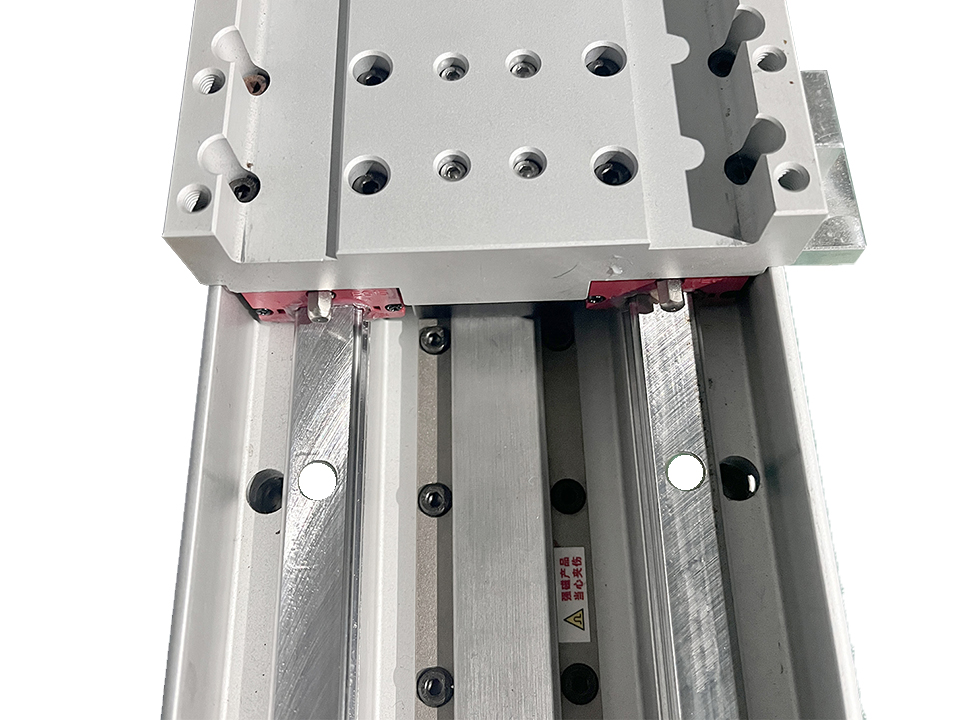

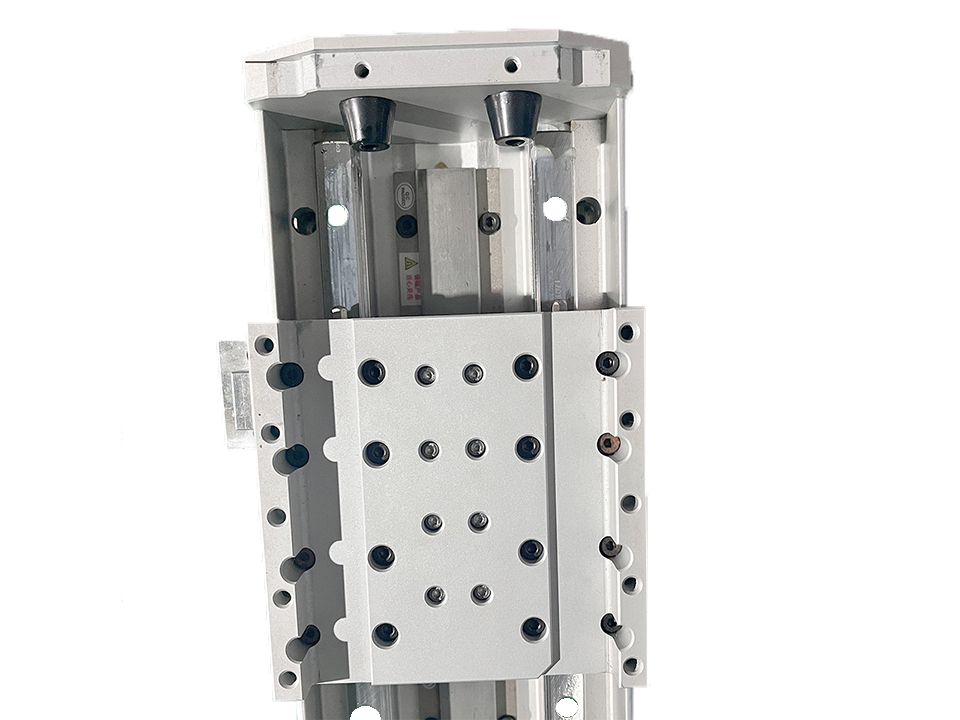

Structure: U-shaped slot linear motor architecture, with a fixed magnetic track as the secondary and a

thrust coil motion assembly as the primary.

Performance Features: High dynamic response: Start-stop time <5ms, adjustable acceleration from 0-

2m/s².

Positioning Accuracy: Equipped with closed-loop feedback from a linear encoder, repeatability ±0.01mm.

Load Capacity: Maximum thrust 3000N, compatible with standard hydraulic actuator interfaces (DYZW).

Applications: Long-axis positioning in large CNC machining centers; Linear conveyor modules for

logistics sorting systems; Track drive for photovoltaic panel cleaning robots.

Core Features

Extreme-Long Stroke Design: Utilizing a modular tubular linear motor architecture, a single module

offers an effective stroke of 60 meters, and supports seamless expansion with multiple modules.

Intelligent Drive System: Integrated 10V high-voltage driver IC, delivering ≤5ms dynamic response, and

supporting eight programmable vibration modes, including sinusoidal and trapezoidal.

High-Precision Guidance System: U-shaped dual-track magnetic circuit with composite epoxy actuators,

standard with 0.1μm resolution linear encoder (±0.01mm repeatability).

Technical Parameters Performance Specifications

Thrust Output: 1200N (continuous) / 1500N (peak instantaneous)

Operating Speed: 3m/s (fully closed-loop encoder feedback control)

Environmental Adaptability: IP54 protection rating / -10°C to 50°C wide operating temperature range.

Typical Applications: Vacuum transfer of LCD panels (meets Class 100 cleanliness requirements); Power

battery pole piece winding (thrust ripple controlled within ±1%); Precision Laser Processing (dual-axis

synchronous error compensation <20μm).

Technical Advantage Comparison

Key Specifications Traditional ball screw solution, innovative FSKH 60 solution

Maintenance requirements: Regular lubrication and maintenance; Fully sealed, maintenance-free design

Dynamic performance: 0.5G acceleration limit, 2G rapid acceleration and deceleration capability

System scalability: Mechanical segmented splicing; Unlimited electrification expansion

The FSKH 60 linear motor long-stroke actuator module is a drive device based on linear motor technol

ogy. Its core principle is to convert electrical energy directly into linear motion without the need for

intermediate conversion mechanisms such as leadscrews or gears, resulting in high-precision, high-

speed, and long-stroke control. This module typically integrates an actuator design, providing stable

thrust output and is suitable for applications requiring linear push and pull motions. Key features

include ultra-high load capacity (up to hundreds of kilograms), ultra-high speed (up to 10 m/s), ultra-

long stroke (customizable lengths up to 60 meters), and micron-level repeatability (±0.05 mm), making

it a highly effective solution for industrial automation.

The FSKH 60 module is widely used in various applications:

Automated production lines: For example, in the packaging and handling of FPD liquid crystal panels,

the module's long stroke and high speed (up to 10 m/s) enable efficient transfer of large panels, impro

ving production efficiency and safety.

Glass Manufacturing: Used in glass cutting, grinding, and assembly, its high payload (800 kg) and

precision control (±5 μm) ensure product quality and production stability.

Medical Testing Equipment: The module provides precise linear motion (such as probe positioning) with

a travel range of several meters, ensuring accurate and repeatable test results.

Smart Manufacturing Workshop Inspection: As part of a truss system, the module supports long travel

ranges (over 26 meters) and multi-axis collaboration, making it suitable for material handling, position

ing, and monitoring tasks in automated production lines.

Spraying Machinery: In industries such as automotive manufacturing, the module's high-precision posi

tioning and smooth motion improve spray uniformity, reduce overspray, and enhance efficiency while

reducing maintenance costs.

Furthermore, the module's modular design facilitates integration into complex systems (such as Carte

sian robots), enabling rapid customization and expansion. Its energy-saving and low-maintenance

advantages are further driving its adoption in industries such as electronics, new energy, and automotive

manufacturing.