CHARACTERISTICS OFTHEDIRECTDRIVE TECHNOLOGY

Faster: Standard speed 2m/s, up to 7m/s. Standard acceleration 1G, up to 5G90-degree reciprocating positioning can easily reach 1200 times/min

More accurate: True "zero backlash" and "full closed loop", easily reach μm-level accuracy Linear standard repeatability ±2μm, up to ±0.1μm and above Rotating standard repeatability ±3 arc seconds, up to ±1 arc second

More stable: "zero transmission chain", no mechanical friction, 365 days maintenance-free, long-term accuracy

Farther: unlimited travel, up to 10 meters or more

Linear motor performance

Repeatability: ±0.5-±1μm.

Module absolute accuracy: ≤10μm/500mm (original factory accuracy).

Maximum length 6M, accept customization of special module length customization.

Single-axis multi-motor motion.

High-speed motion: rated speed 3m/s; peak speed 5m/s.

High acceleration: Depending on the actual application load, it is easy to reach high acceleration of 2G and above.

Module using

3C Automation

Single-axis multi-motor

Extra-long stroke

Loading and unloading/carrying functional components

High-precision loading

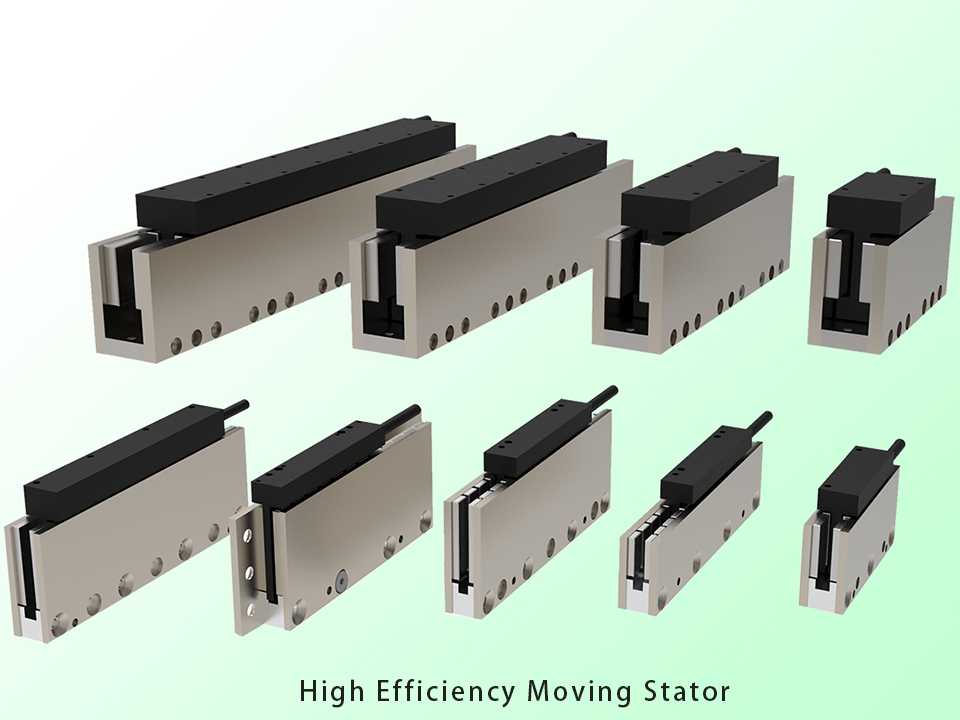

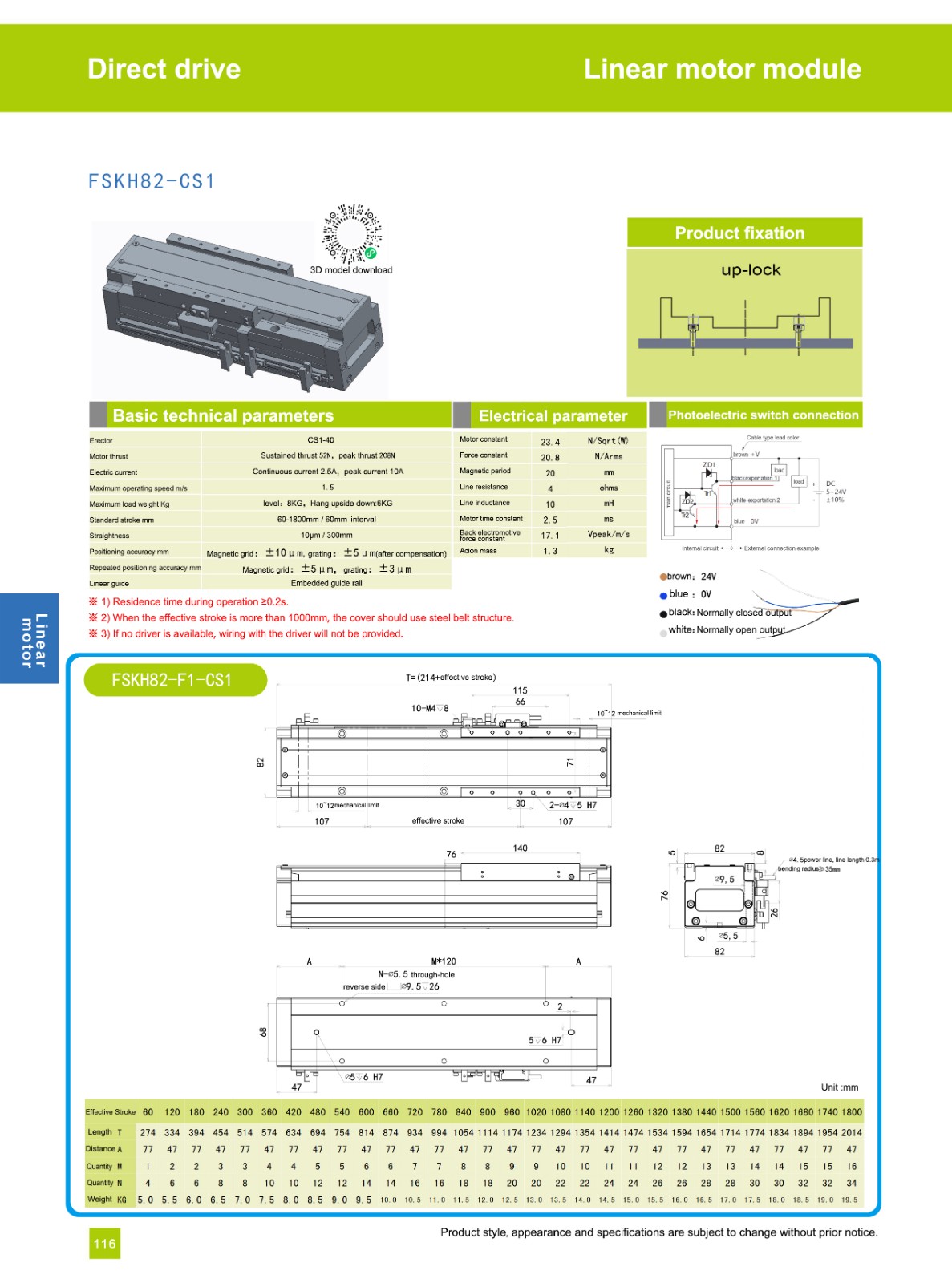

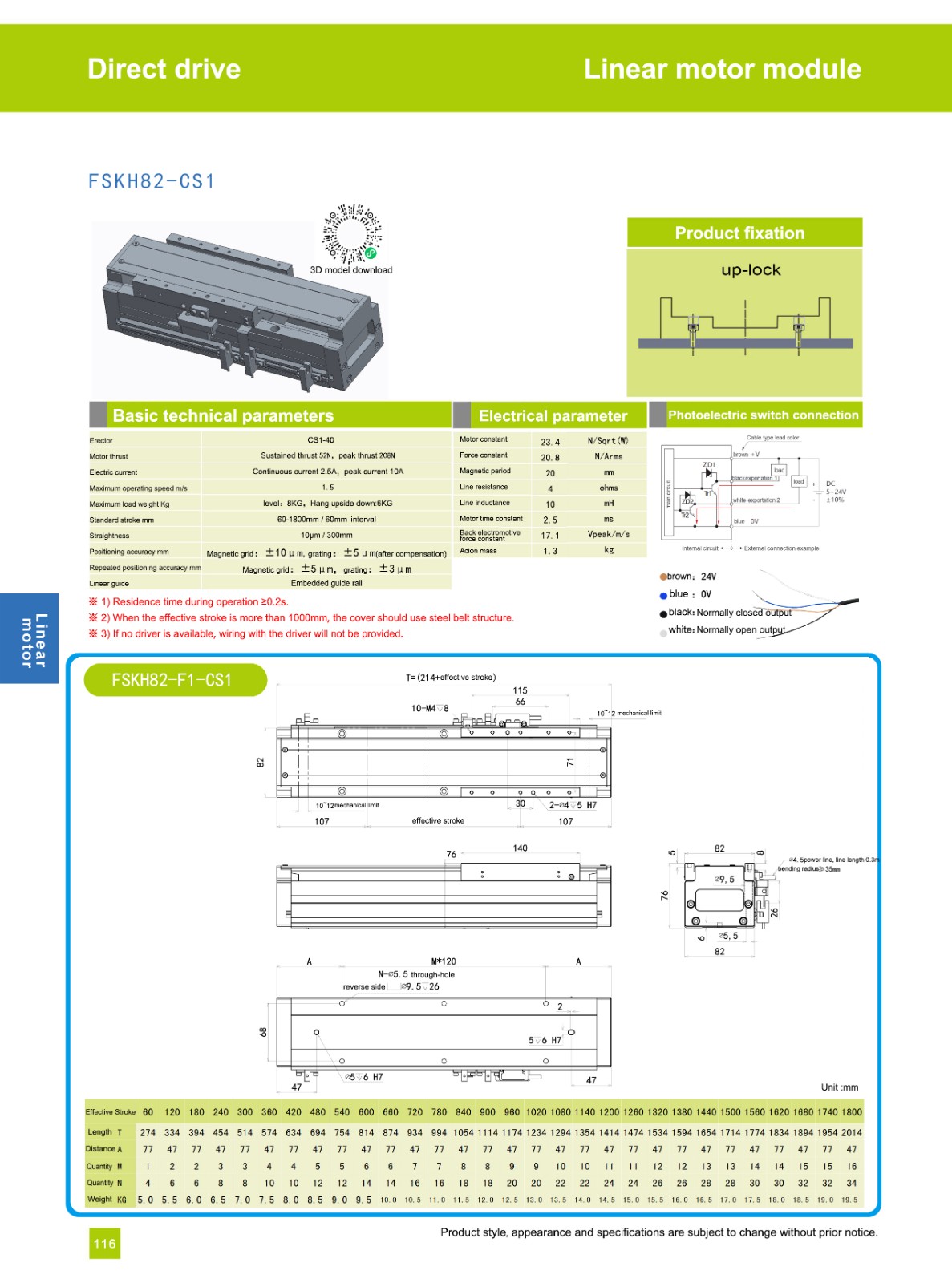

The FSKH 82 is a linear motor slide module focused on ultra-high positioning accuracy, designed for

precision applications requiring micron-level repeatability and high-speed response. Its key features and

advantages include:

[Ultra-High Positioning Accuracy and Stability]

Utilizing fully closed-loop control technology, the linear encoder directly detects the slide position,

achieving repeatability of ±1μm and minimizing accuracy degradation over long-term operation. The

ironless linear motor design eliminates cogging and significantly reduces velocity fluctuation (controll

able to within ±1%), ensuring smooth motion.

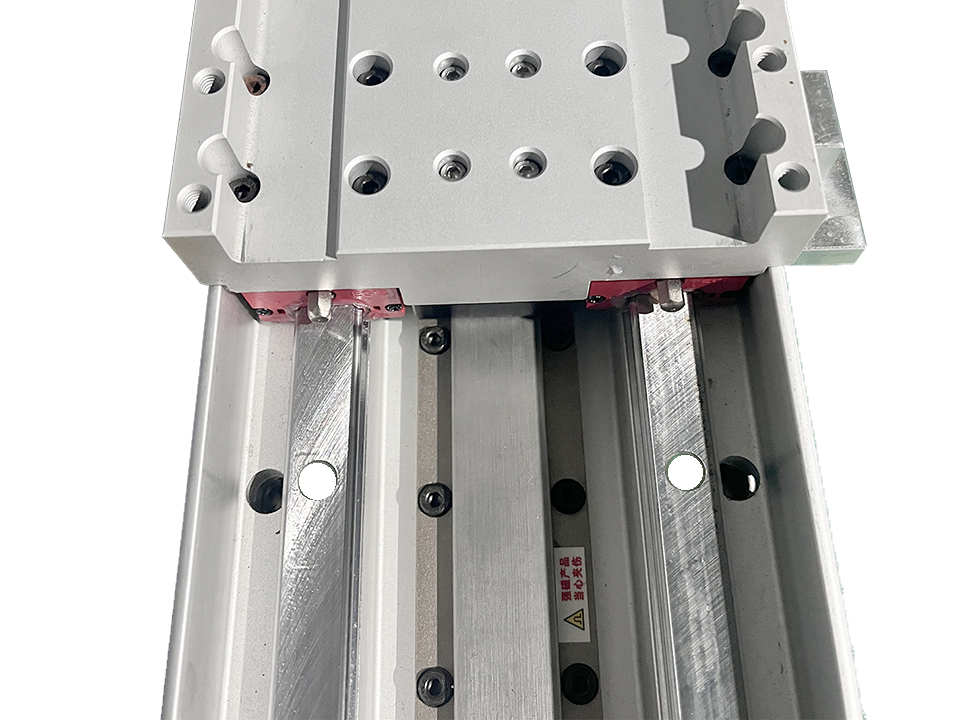

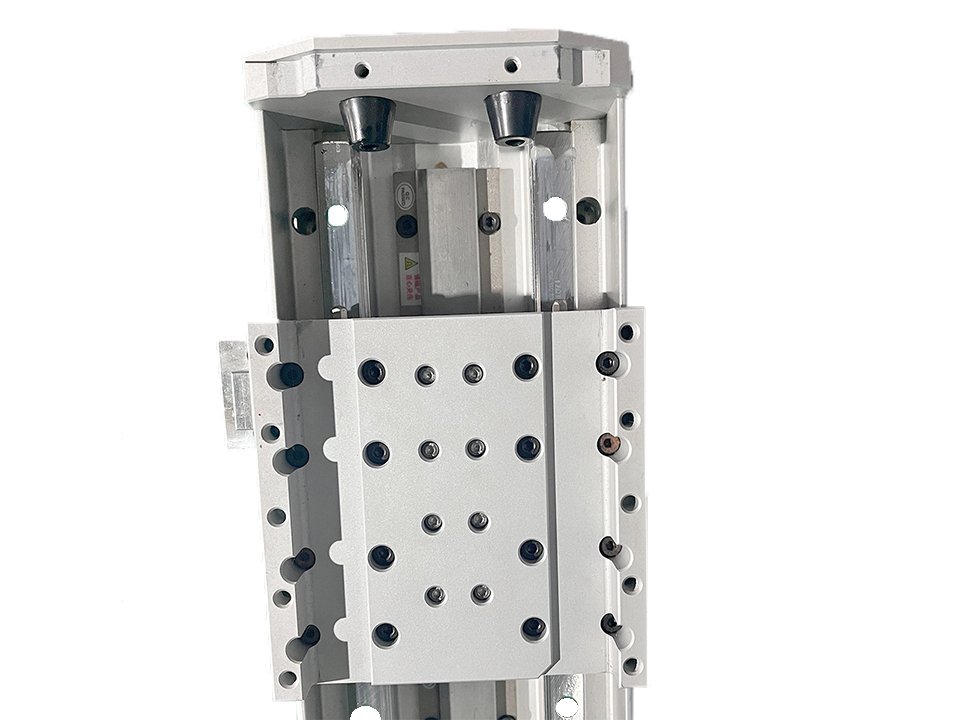

[Compact Structure and High-Rigidity Support]

Integrated with high-performance HDR-type four-row angular contact ball bearing LM guides, the LM

guide utilizes a four-way equal-load DB structure, maintaining excellent rigidity even under high torque

loads. The compact design supports single-axis installation, facilitating equipment miniaturization and

lightweight upgrades.

[High-Speed Response and Dynamic Performance]

The linear motor's direct drive mechanism achieves millisecond response, a maximum operating speed

of 3m/s, and a maximum acceleration of 5G, significantly improving production efficiency. Its high speed

and acceleration/deceleration capabilities are particularly suitable for short-stroke precision operations,

such as semiconductor inspection and precision assembly.

Flexible adaptability and long-stroke expansion

The modular design supports independent control of multiple slides, allowing multiple actuators to be

configured on the same axis. By connecting the bases, it can easily be expanded to ultra-long strokes

exceeding 4 meters, breaking the length limitations of traditional ball screw drives.

2. Compatibility with mainstream drive communication protocols (such as Mitsubishi SSCNET III/H and

Panasonic EtherCAT) facilitates system integration.

This module is widely used in high-value-added manufacturing scenarios such as precision machine

tool spindle positioning, high-speed electronic component sorting, and high-precision measuring

equipment. Its excellent technical specifications provide a reliable motion control solution for industrial

automation.

The FSKH 82 is a high-performance linear motor slide module with the following core features:

Ultra-High Positioning Accuracy: The ironless linear motor design eliminates cogging effects. Combined

with fully closed-loop control using a linear encoder, it achieves exceptional repeatability, reaching

±1μm.

Low Speed Fluctuation: The ironless structure effectively suppresses speed fluctuations, ensuring smooth

and precise motion, with fluctuations controlled to within ±1%.

High Speed and High Response: The linear motor directly converts electromagnetic force into linear

motion, supporting operating speeds up to 3m/s and accelerations up to 5G, significantly improving

production efficiency.

Compact and Rigid Design: The integrated single-axis HDR-type high-rigidity LM rolling guide (four

-point contact ball bearing DB structure) provides excellent torque load resistance in a compact and

lightweight design, making it suitable for high-precision applications in space-constrained environments.

Stability and Reliability: Compared to ball screw drives, linear motors are less susceptible to accuracy

degradation and offer superior long-term operational stability.

Wide compatibility: Supports multiple communication protocols (pulse, SSCNET III/H, EtherCAT) of

mainstream brand drives (such as Mitsubishi, Panasonic, and High-Creation), simplifying system integ

ration.

The FSKH 82 is a high-precision positioning module driven by a linear motor, designed for industrial

applications requiring micron-level repeatability. Its core features include:

Drive Principle: Direct drive using an ironless linear motor eliminates mechanical backlash and keeps

speed fluctuation within ±1%.

Accuracy: Combined with a fully closed-loop optical encoder, it achieves repeatability of ±3μm (±5μm

for a magnetic encoder).

Load Capacity: The dual-guide design supports a horizontal load of 15kg and a continuous thrust of

98N (peak 392N).

Stroke Configuration: Customizable effective strokes range from 60-1800mm, with a maximum speed

of 3m/s.

Environmental Adaptability: The non-contact design between the mover and stator eliminates mechani

cal wear and significantly extends the lifespan of ball screw modules.

This module is suitable for high-end equipment applications such as semiconductor packaging and

precision testing, where smooth motion and positioning accuracy are crucial.

Core Features

High Repeatability

Using ironless linear motor technology to eliminate cogging, this product achieves repeatability of

±1μm. It supports fully closed-loop control and uses a linear encoder to directly detect the slide

position.

High Speed and High Dynamic Response

With a maximum acceleration of 5G and a top speed of 3m/s, it is suitable for precision applications

requiring rapid start and stop (such as 3C automation and semiconductor equipment).

Compact Design

Integrated HDR-type LM rolling guides utilize a four-way equal-load DB structure to achieve high

rigidity and a lightweight structure, making it a viable alternative to traditional ball screw modules.

Drive Compatibility

Compatible with mainstream drive communication protocols from Mitsubishi and Panasonic (such

as EtherCAT and pulse input), it facilitates integration into industrial control systems.

Typical Applications

Precision manufacturing: Semiconductor packaging and PCB inspection equipment (requiring micron

-level positioning).

Automated production lines: Material sorting and high-precision spray coating (relying on high-speed

stability).

Research instruments: Optical stage fine-tuning and biological sample positioning.

Core Features

Nano-level Positioning: Utilizes fully closed-loop linear encoder control, achieving repeatability of

±0.1μm, suitable for high-precision applications such as semiconductor testing equipment.

Magnetic Levitation Drive: An ironless linear motor design eliminates cogging and keeps speed

fluctuation within ±0.5%.

Compound Guide System: Combining HDR-type LM rolling guides with air bearings, the system

achieves axial stiffness of 500N/μm.

Key Technical Parameters

Indicators Performance Parameters Comparison Standard (FSKH 60)

Maximum Acceleration: 5G (with counterweight ≤ 5kg) 2G

Effective Travel: 0.5-3m (supports magnetic track splicing up to 15m 60m (with ±0.01mm accuracy)

Environmental Compatibility: Cleanroom Class 100 / Vacuum 10^-3 Pa IP54 protection

Industry Application Advantages

Wafer Lithography: Combined with a laser interferometer, it achieves submicron synchronization error,

meeting the requirements of 28nm process equipment.

Medical Microscopy: Vibration frequency <0.01Hz (ISO 1940 G0.4 balance standard).

Multi-Axis Collaboration: Controlled via EtherCAT, supports 32-axis synchronization (clock jitter <1μs).

Selection Recommendations

For loads >20kg, the optional CCD real-time deformation compensation system is recommended to

reduce guideway runout error by 30%. The modular design allows for quick replacement of actuator

units, with a mean time to repair (MTTR) of <15 minutes.