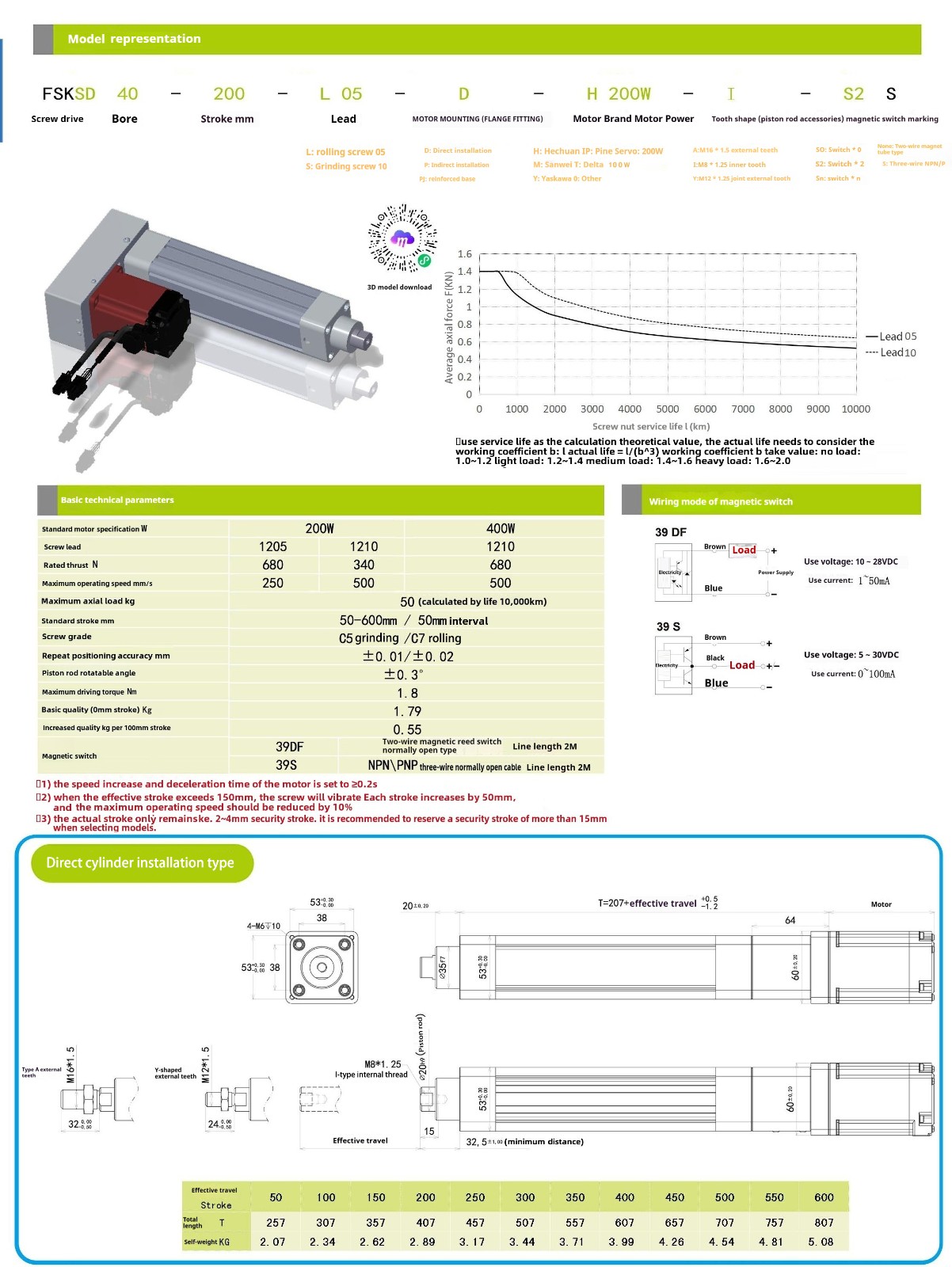

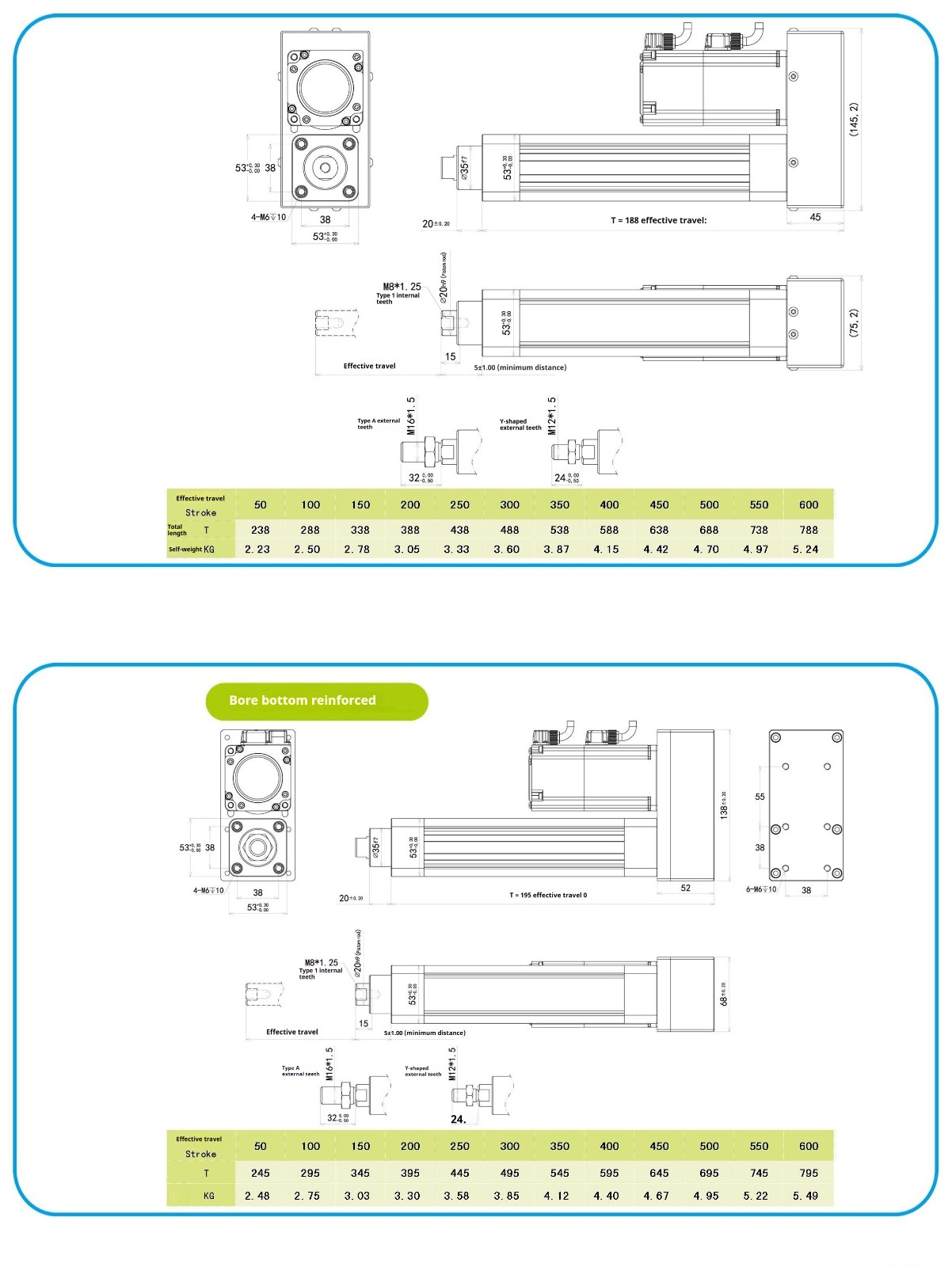

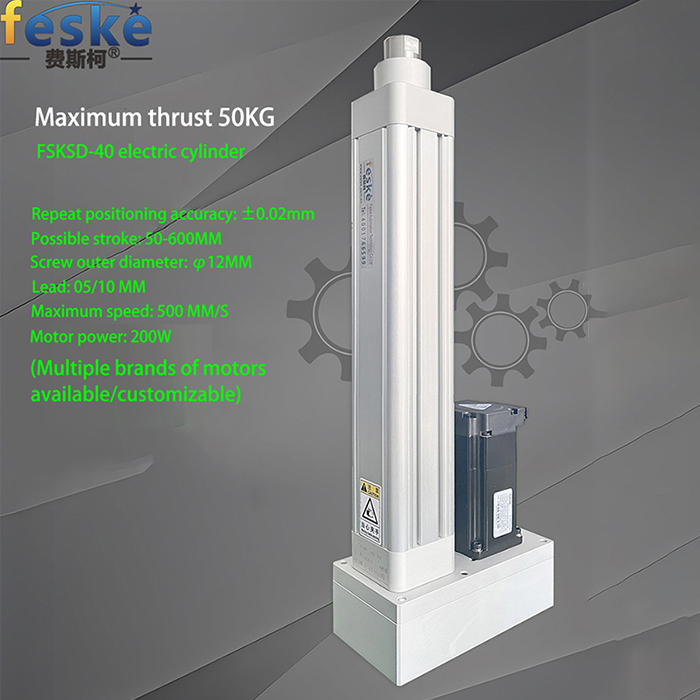

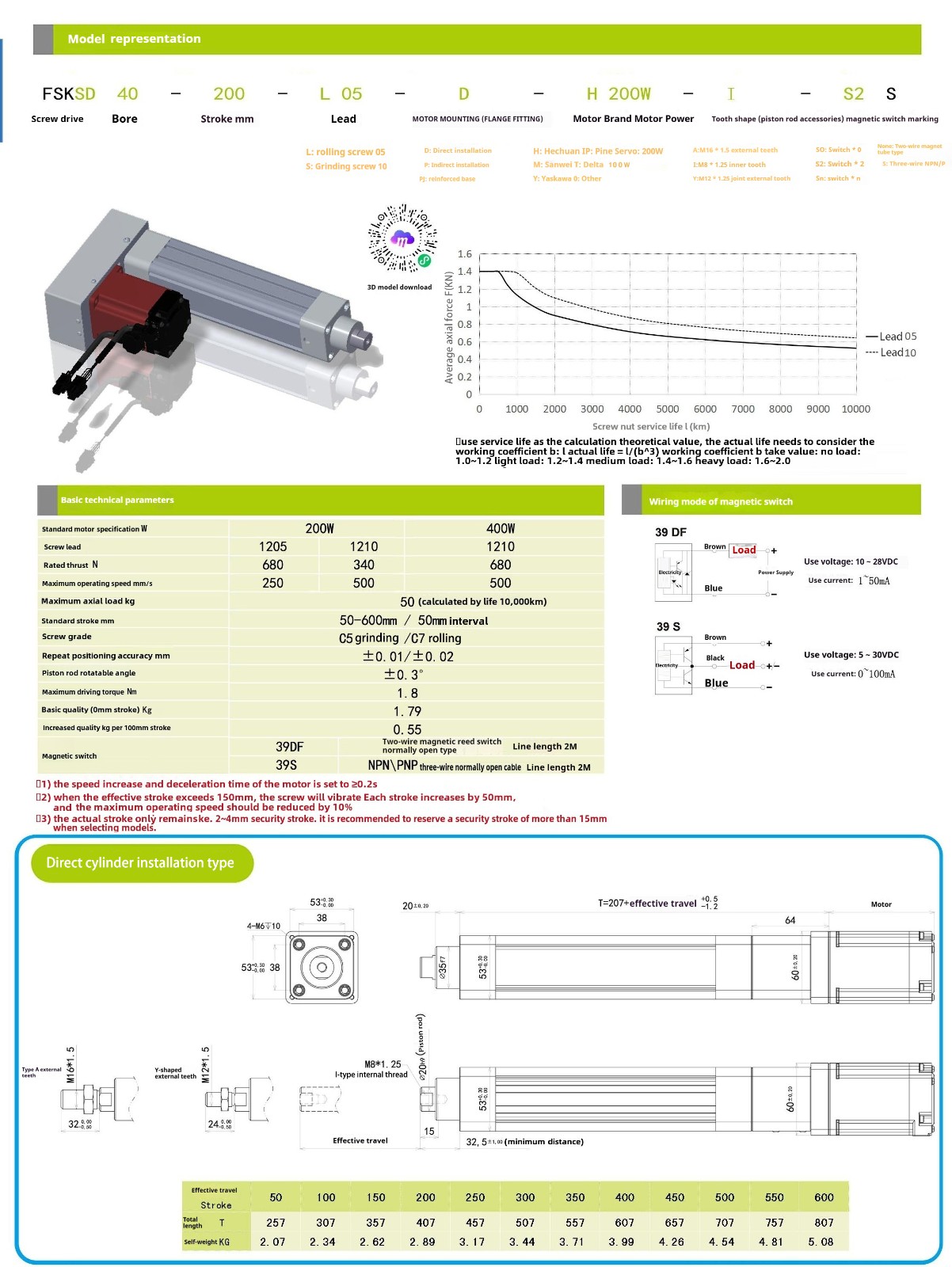

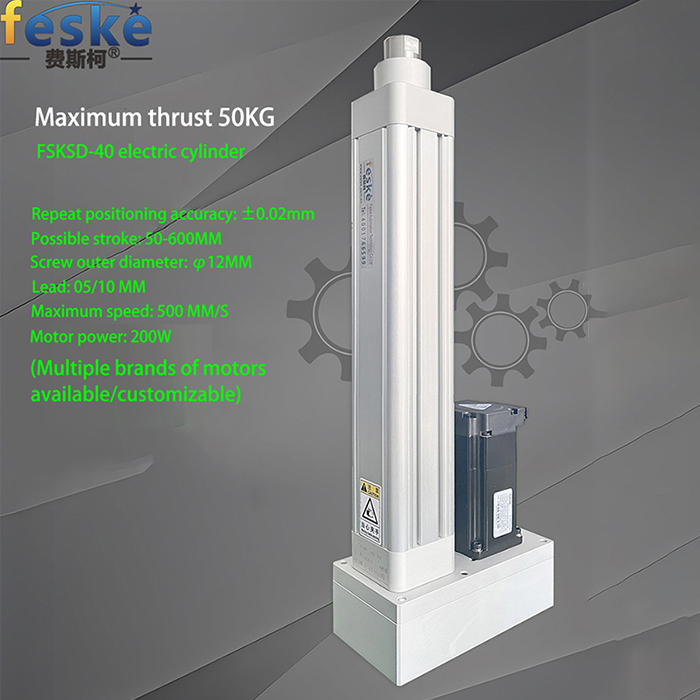

FSKSD-40 electric cylinder

Maximum thrust 50KG

Repeat positioning accuracy: ±0.02mm

Possible stroke: 50-600MM

Screw outer diameter: φ12MM

Lead: 05/10 MM

Maximum speed: 500 MM/S

Motor power: 200W

(Multiple brands of motors available/customizable)

The electric cylinder is a modular product that integrates the servo motor and the lead screw. It converts the rotational motion of the servo motor into linear motion, and at the same time converts the best advantages of the servo motor - precise speed control, precise rotation number control, and precise torque control - into precise speed control, precise position control, and precise force control; it realizes a new revolutionary product in the high-precision linear motion series.

This product is an industrial-grade high-precision electric actuator designed for heavy loads and precision control scenarios. Core features include:

Structural design: High-strength alloy steel pull rod structure, rated load up to 40kN, suitable for linear displacement scenarios with high rigidity requirements7

Drive system: Integrated servo motor and planetary reducer, positioning accuracy ±0.01mm, repeat positioning error less than ±0.005mm67

Protection level: IP67 protection standard, built-in temperature sensor and overload protection module, suitable for -20℃~80℃ working environment11

Control interface: Support Modbus RTU/CANopen protocol, optional absolute encoder for closed-loop control6

Typical applications include:

Automobile production line welding fixture positioning

Injection molding machine mold precision adjustment

Aerospace component assembly platform711

The product is equipped with HSK-A63 flange interface as standard, the stroke can be customized

(100-1000mm), the response time is <50ms, and the life cycle is up to 2 million times

The Heavy Duty Precision Electric Tie Rod Cylinder FSKSD-40, a high-precision electric actuator, offers

the following key advantages:

Heavy-Duty Structural Design

Industrial-grade materials and a reinforced mechanical structure ensure stability and durability under

high-pressure, high-frequency operating conditions. Its load-bearing design, similar to that of heavy

equipment (such as a 40-foot flatbed semi-trailer), demonstrates its load capacity.

Precision Control Performance

The synchronized four-cylinder hydraulic system and Siemens electrical components (referred to from

similar precision lift technology) achieve millimeter-level motion accuracy, making it suitable for indust

rial applications requiring critical positioning.

Modular Adaptability

Supporting voltage customization (220/380V) and interface expansion, it is compatible with integration

into various automation systems. A standardized 40mm back-to-back distance, similar to that used in

door lock components, demonstrates its flexible adaptability.