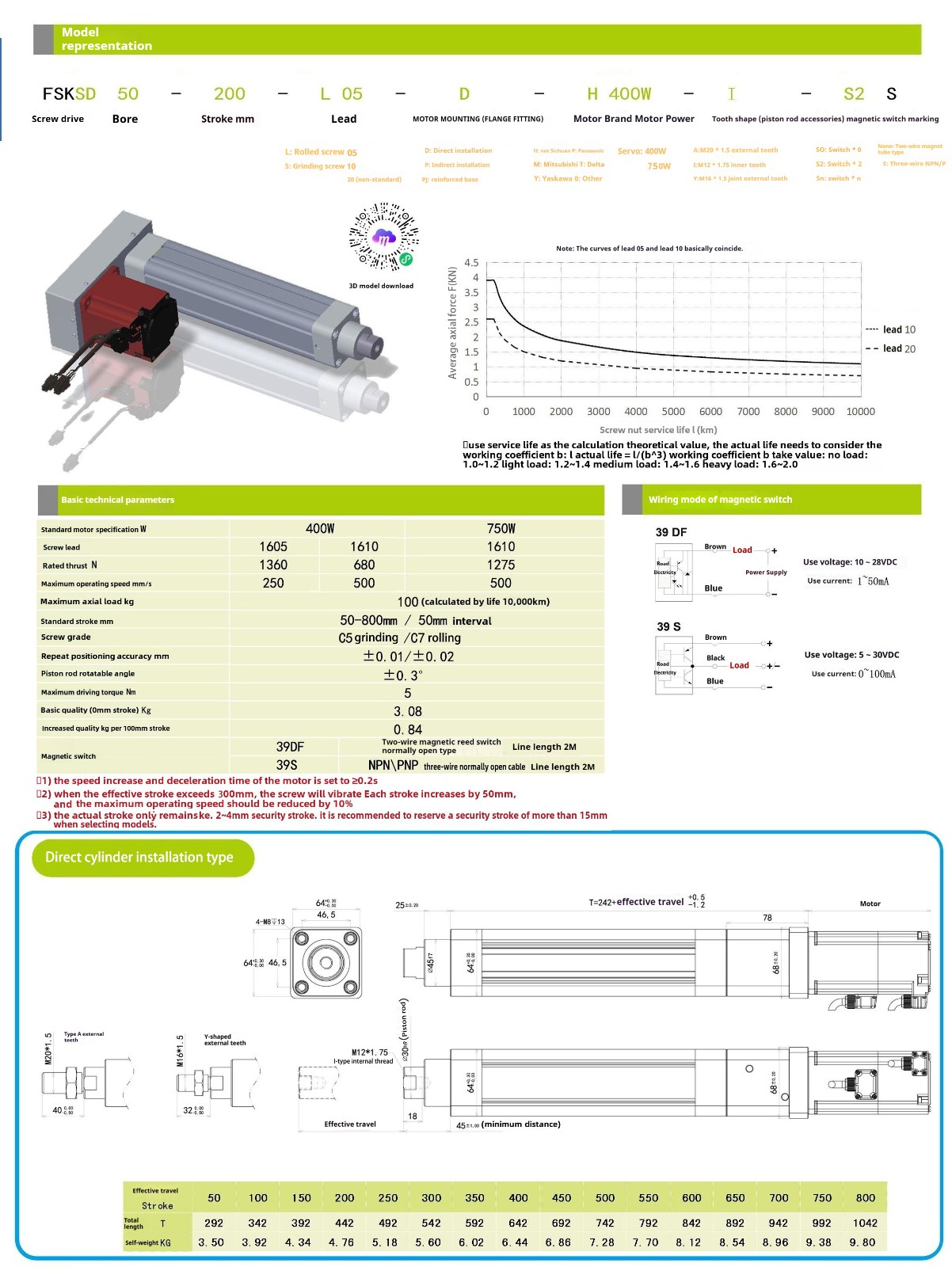

FSKSD-50 electric cylinder

Maximum thrust 100KG

Repeat positioning accuracy: ±0.01/±0.02mm

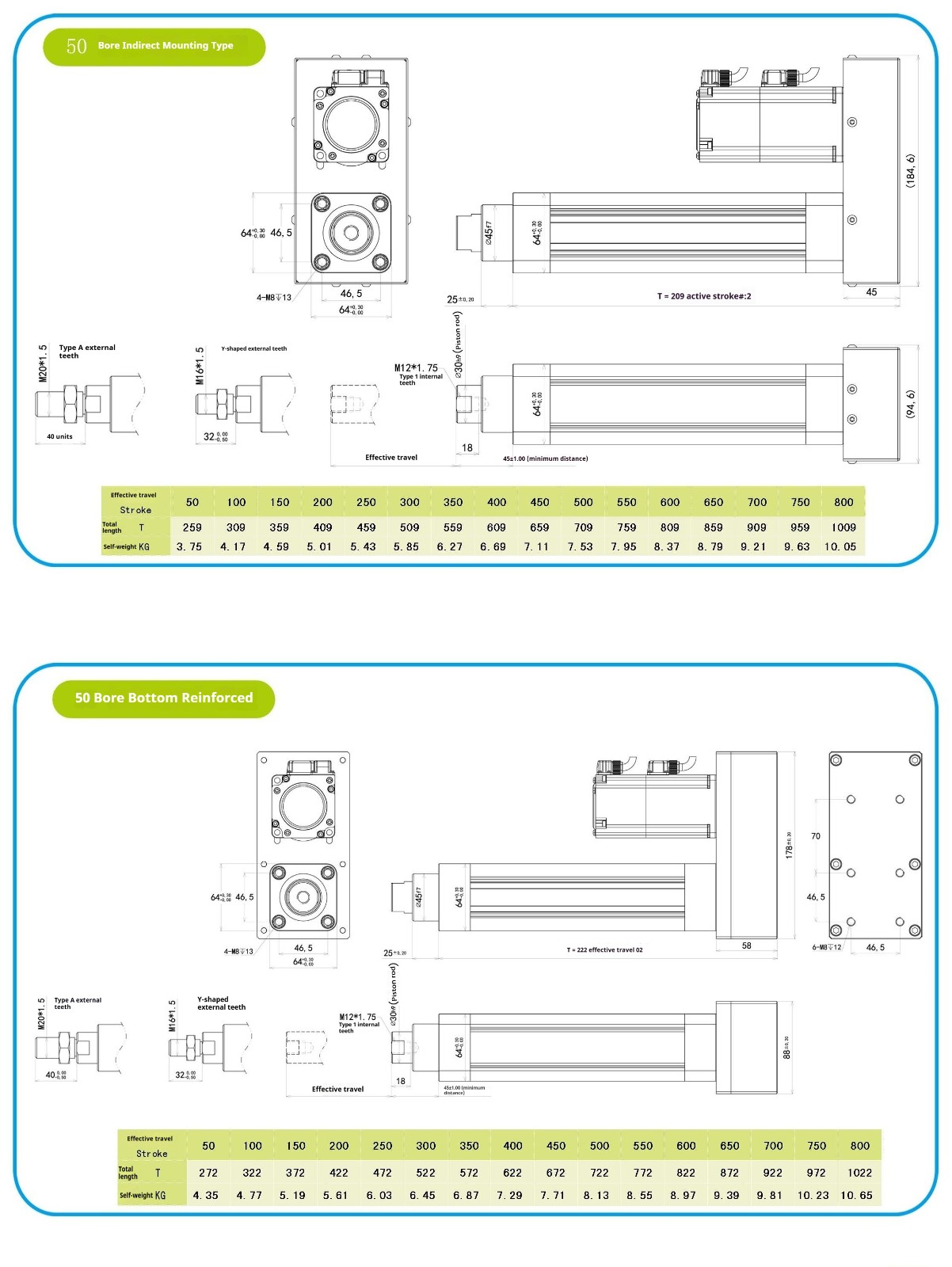

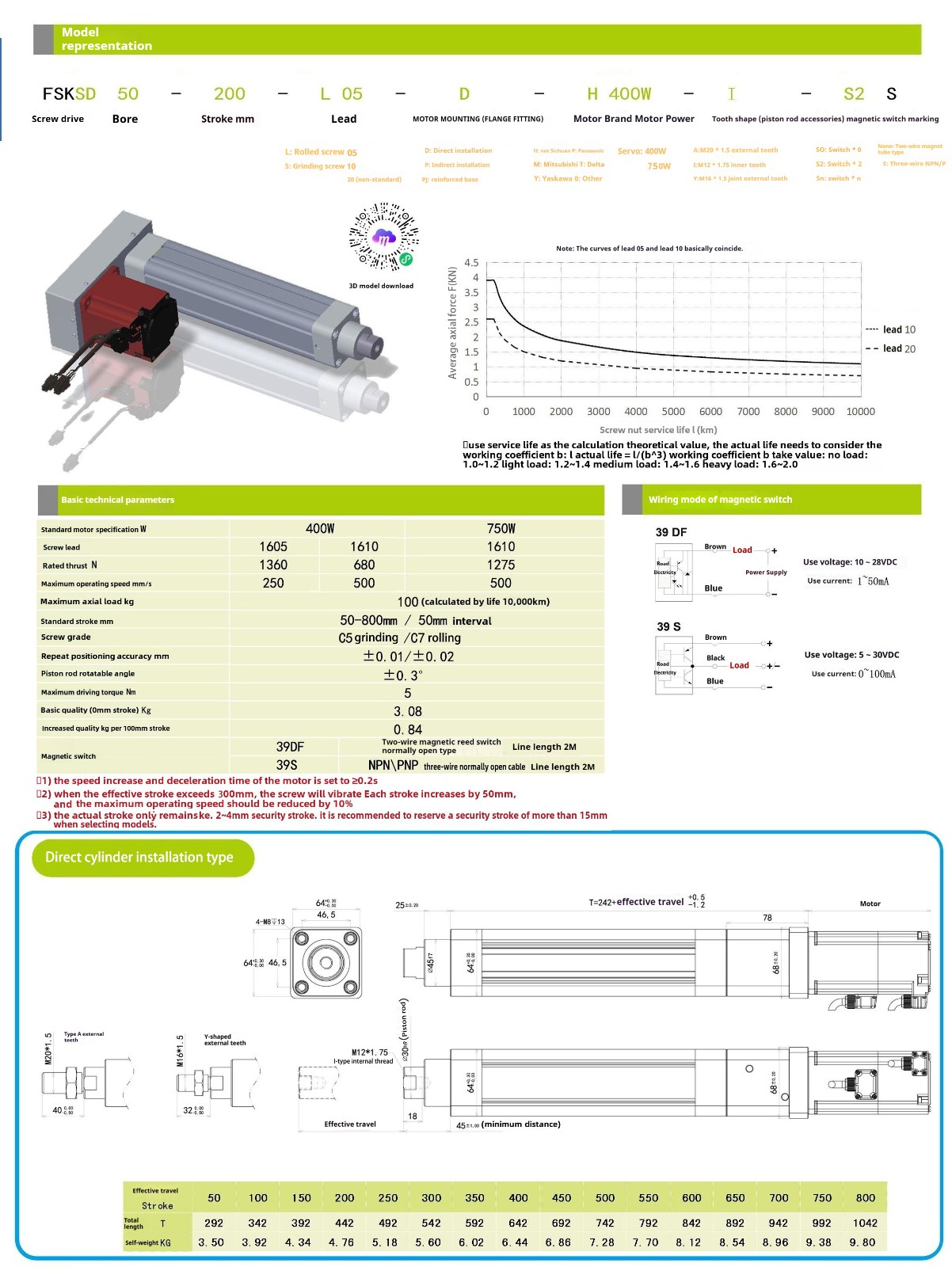

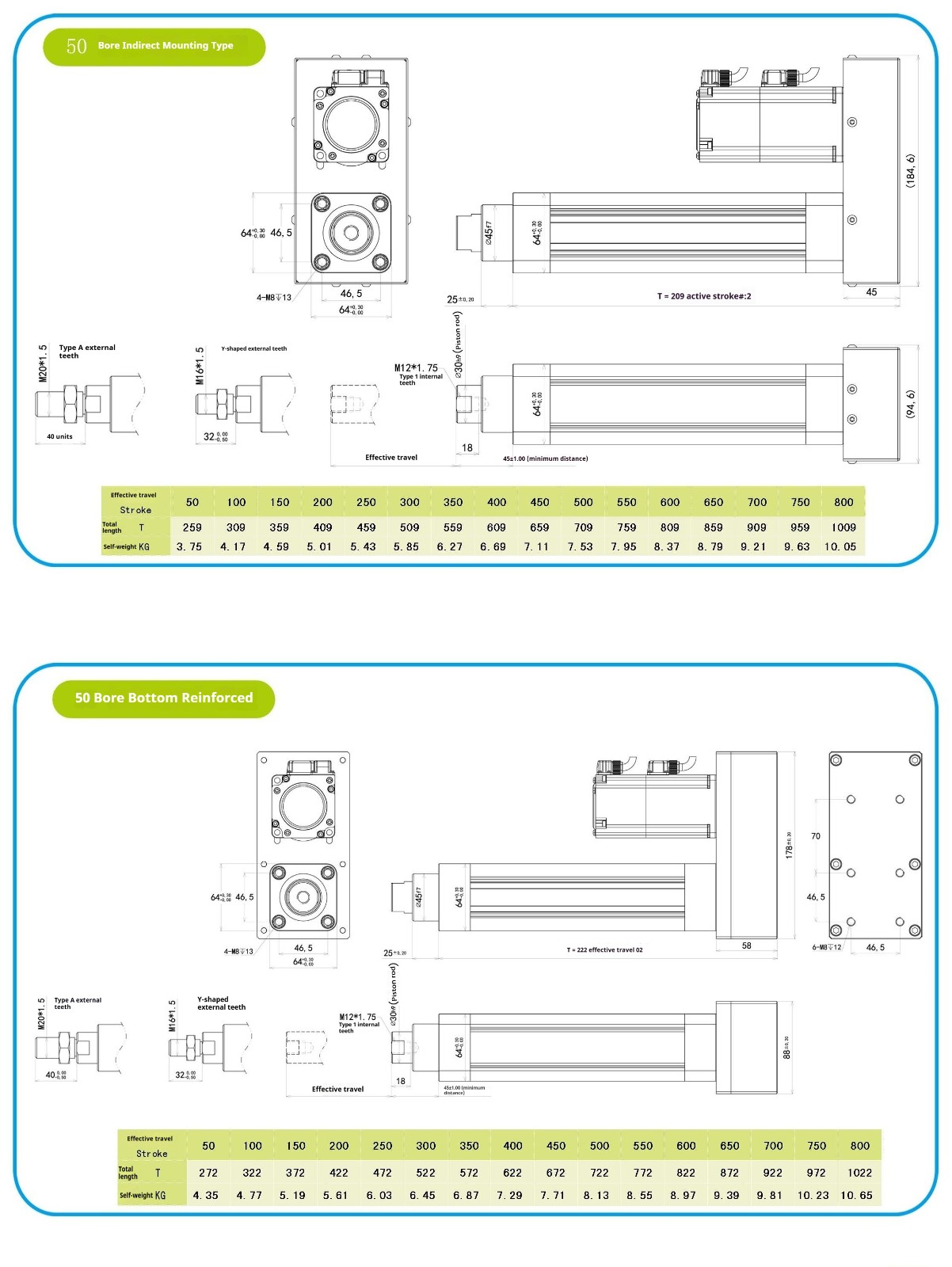

Possible stroke: 50-800MM

Screw outer diameter: φ16MM

Lead: 05/10MM

Maximum speed: 250/500MM/S

Motor power: 400W

(Multiple brands of motors available/customizable)

The servo electric cylinder is a modular product that integrates the servo motor and the lead screw: it can achieve precise speed control, precise position control, precise thrust control, and is environmentally friendly and energy-saving.

As a professional electric cylinder manufacturer, Feske is committed to providing customers with high-performance and high-reliability servo cylinder solutions. Our servo cylinder integrates advanced motor technology, precision transmission mechanism and intelligent control system. Professional Electric cylinder manufacturers can meet the high-precision, high-speed and high-load requirements of linear motion control in different industries.

This product is a heavy-duty electric linear actuator designed for long-stroke and high-load conditions.

The core features include:

Telescopic structure: Adopting a multi-stage nested design, the maximum stroke can reach 2000mm,

and the height in the compressed state is only 1/32 of the total stroke

Drive system: Equipped with 750W servo motor and planetary reducer, rated thrust 5KN, peak thrust up

to 10KN27

Precision control: Built-in absolute encoder, repeat positioning accuracy ±0.02mm, support Modbus/

CANopen communication protocol 67

Protection performance: IP67 protection level, can work continuously in -20℃~60℃ environment,

aluminum alloy shell is anodized 1113

Typical applications:

Large stamping equipment mold adjustment

Automated storage stacker lifting

Ship deck machinery push rod 712

Standard flange mounting interface, optional anti-rotation mechanism, dynamic response time <100ms,

service life ≥1.5 million cycles

The Industrial Long Stroke Electric Telescopic Cylinder FSKSD-50 offers the following advantages:

High-Precision Control

Utilizing closed-loop servo control, it achieves positioning accuracy of up to 0.01mm and, through a pre

ssure sensor, achieves thrust control accuracy of 0.5%, making it suitable for high-precision motion con

trol applications.

Strong Environmental Adaptability

With an IP66 protection rating, it operates stably in harsh environments (such as high and low tempera

tures, rain and snow), unaffected by temperature.

Efficient and Energy-Saving

Compared to hydraulic and pneumatic cylinders, electric cylinders are more environmentally friendly

and energy-efficient, requiring no compressed air and reducing energy consumption.

Easy Maintenance

Requiring only regular greasing and lubrication, it has no wearing parts, significantly reducing mainten

ance costs and after-sales service requirements.

High Reliability

Using high-quality materials and advanced manufacturing processes, it offers a long lifespan and stable

operation under high-load and high-intensity conditions.

Flexible Integration

Easily connects to control systems such as PLCs, supporting precise control of multiple parameters such

as position, speed, and thrust.

Various Specifications

A wide range of stroke options (e.g., 50mm to 8500mm) and thrust options (e.g., 40N to 6400N) are

available to meet diverse industrial automation needs.

Low-Noise Operation

Smooth motion and low noise make it suitable for applications requiring exceptional quiet operation.

Traditional Drive Replacement

A complete alternative to hydraulic and pneumatic cylinders, offering high precision, controllability, and

cleanliness.

Fast Response

Servo drive technology ensures high dynamic response, making it suitable for high-speed, high-precision

positioning tasks.

Industrial Long Stroke Electric Telescopic Cylinder is mainly used in the following scenarios:

Heavy Machinery and Mining Equipment

For example, the lateral hydraulic cylinders of mining dump trucks and cranes need to withstand extrem

e loads (such as handling 30 tons of aluminum coils) and long strokes (up to 12 meters).

Automated production line

Machining equipment used for high-precision positioning, such as tool drives in fast axis servo systems

(FAS), combine with gas hydrostatic bearings to achieve micron-level motion control.

Intelligent warehousing and logistics

To achieve intensive storage of goods such as aluminum coils in heavy-duty stackers, it is necessary to

adapt to high temperature environments (200°C) and maintain millimeter-level positioning accuracy

Industry 4.0 Equipment

As the driving unit for Industry 4.0 core components such as CNC machine tools and additive manufact

uring (3D printing), it supports efficient and low-energy production