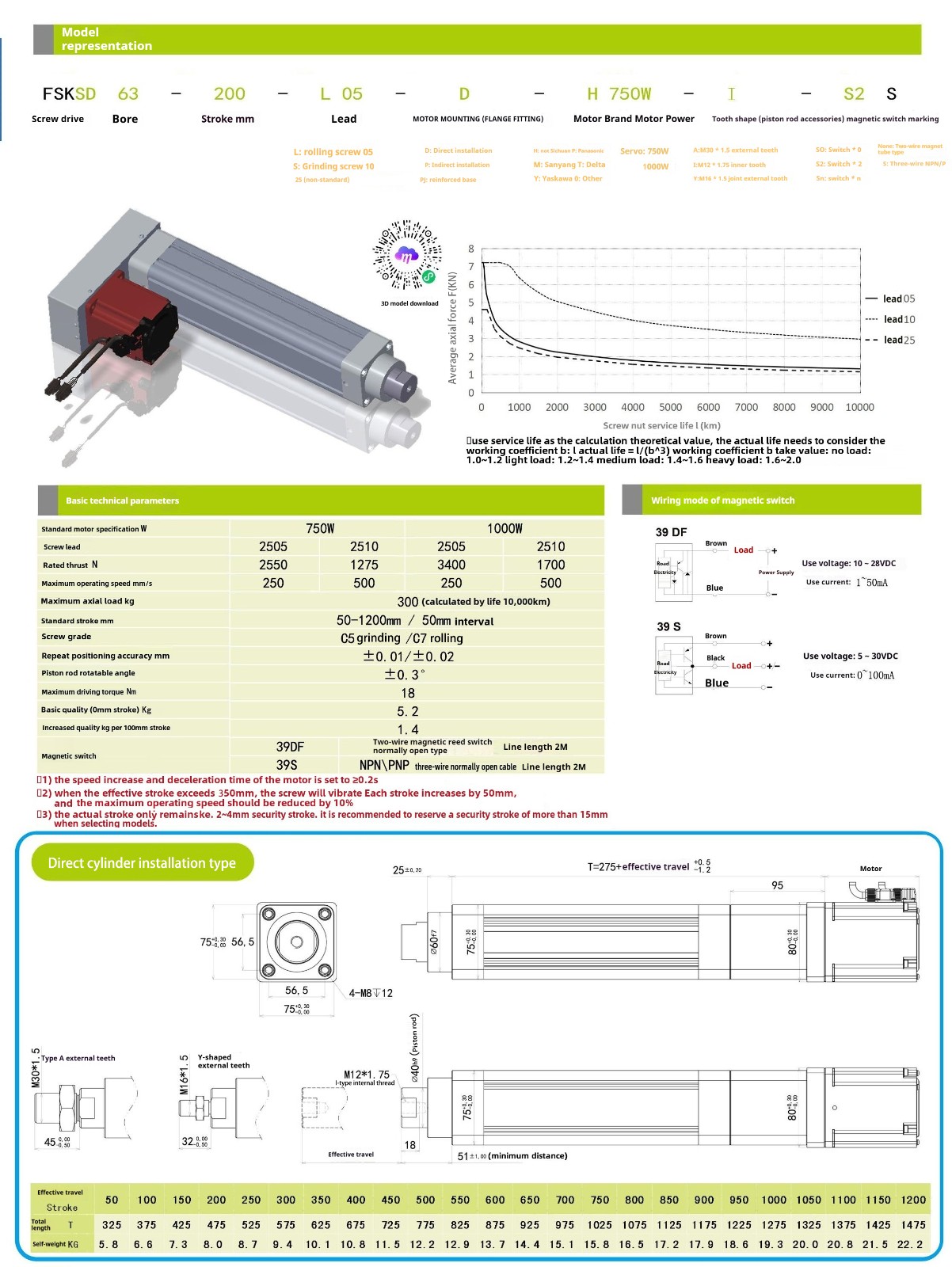

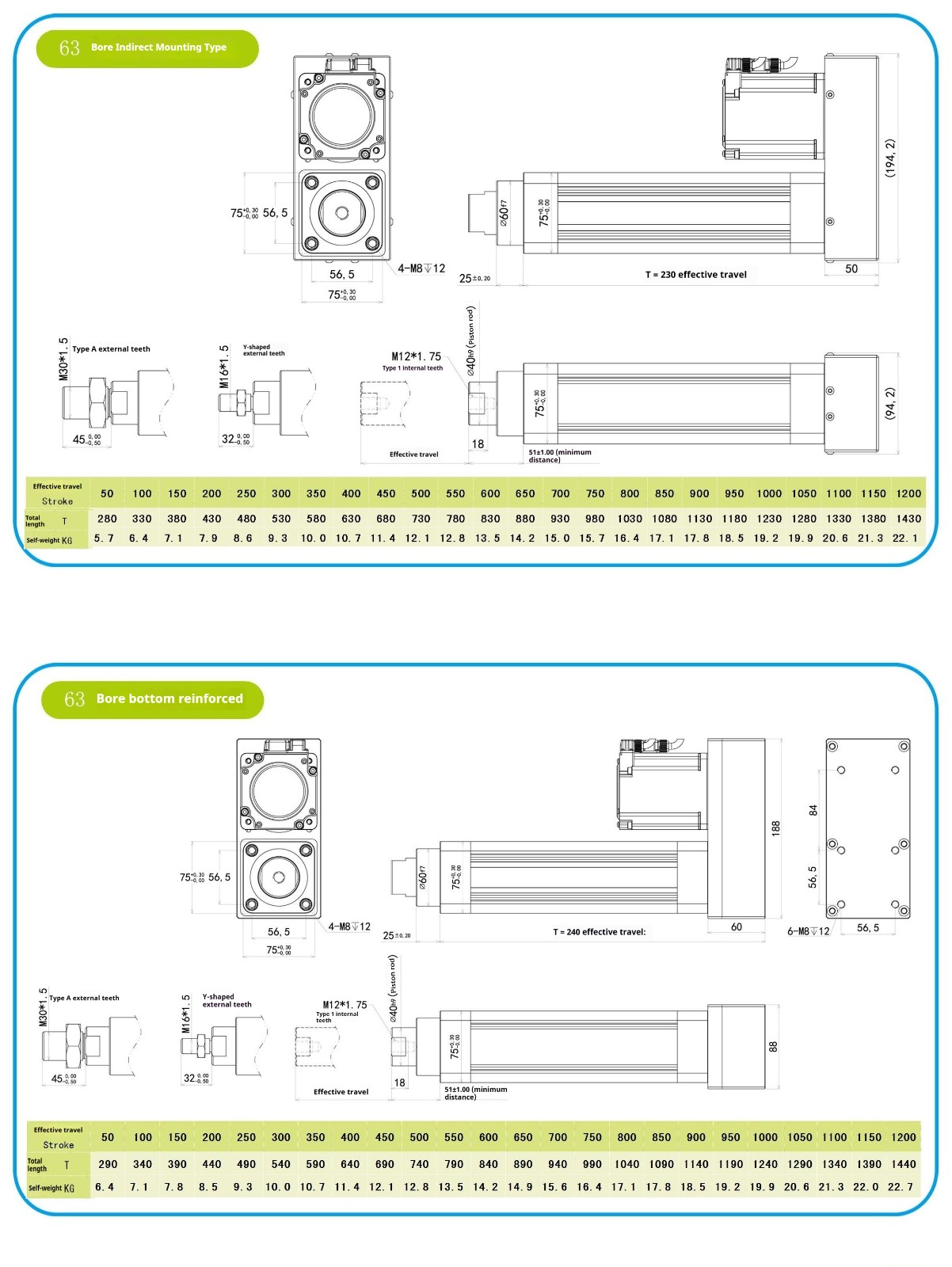

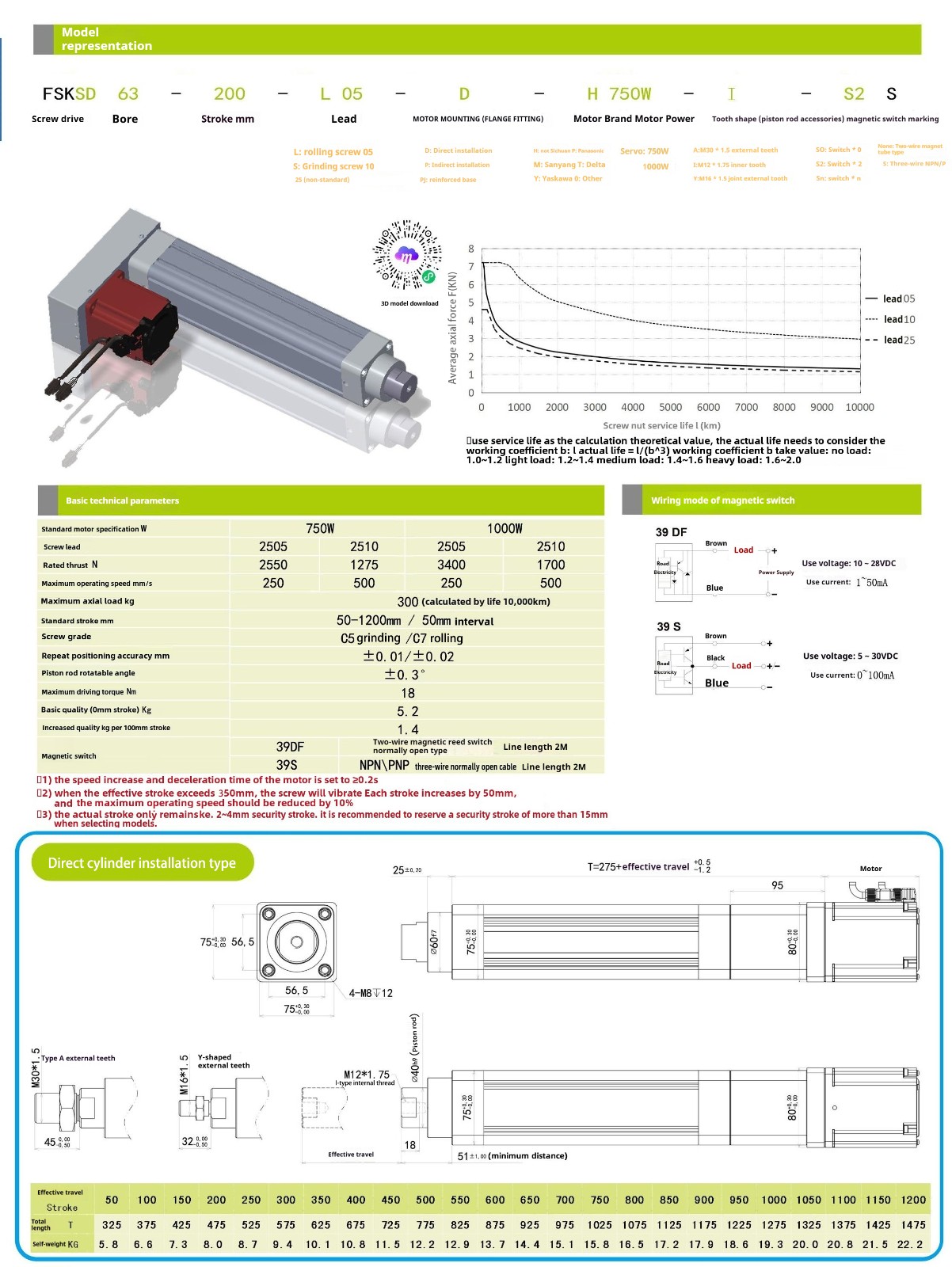

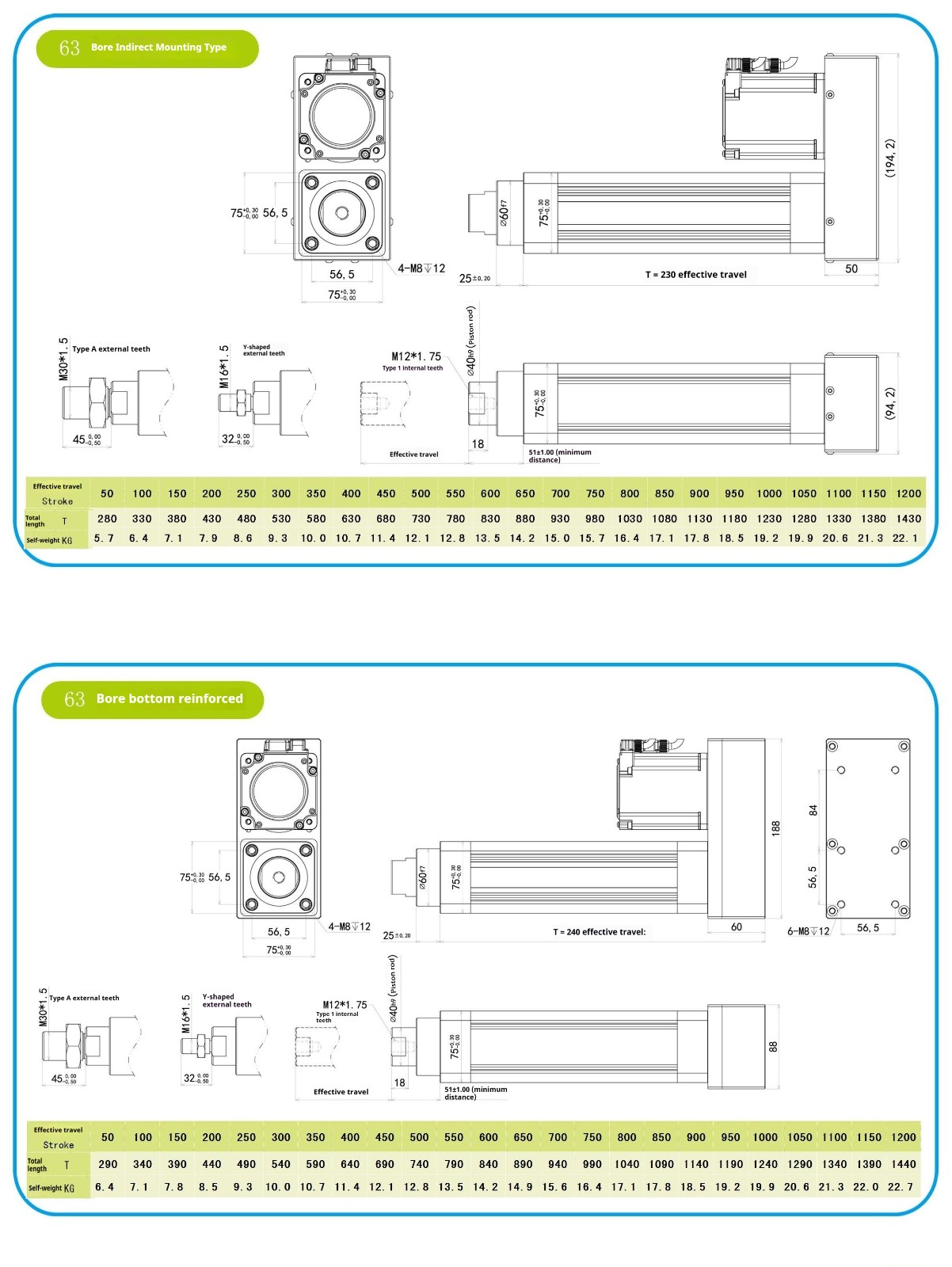

FSKSD-63 electric cylinder

Thrust 300 KG

Repeat positioning accuracy: ±0.01/±0.02MM

Possible stroke: 50-1200MM

Screw outer diameter: φ25MM

Lead: 05/10MM

Maximum speed: 250/500 MM/S

Motor power: 750W

Multile brands of motors available/customizable

The electric cylinder is a modular product that integrates the servo motor and the screw. It converts the rotational motion of the servo motor into linear motion. At the same time, it converts the best advantages of the servo motor - precise speed control, precise revolution control, and precise torque control - into precise speed control, precise position control, and precise force control, realizing a new revolutionary product in the high-precision linear motion series.

Electric cylinders are versatile linear actuators widely used in industrial automation. Their main applications include:

Factory automation – precise positioning in assembly lines, welding robots, and material handling systems.

Packaging – adjusting conveyor height and product clamping mechanisms.

Medical applications – adjusting hospital beds and operating table positioning.

Transportation applications – train door operation and aircraft cargo loading systems.

Energy applications – solar panel tracking and wind turbine blade adjustment.

Electric cylinders replace hydraulic/pneumatic systems with cleaner, programmable electric motion, providing millimeter-level precision and IoT connectivity, enabling smart manufacturing.

Typical Applications of Electric Actuators

1. Electric Cylinder Actuator for Automotive Parts Assembly

Engine valve seat press-fit, 63 kN thrust achieves interference fit, force control accuracy is ±1%, avoiding workpiece damage.

2. Electric Cylinder Actuator for Precision Injection Molding Removal

800 mm/s high-speed conveying, combined with 0.2 second cycle time, improves production line efficiency.

3. Electric Cylinder Actuator for Environmental Protection Equipment Drive

Sewage valve control system, IP66 protection rating, resistant to acid and alkali environments, no risk of oil leakage.

4. Electric Cylinder Actuator for Intelligent Motion Control

Equipped with a high-precision servo drive system, positioning accuracy reaches 0.01mm level.

CANopen/EtherCAT industrial bus protocol ensures real-time control response, perfectly meeting the requirements of Industry 4.0 smart manufacturing.

5. Electric Actuator Sustainable Design

Innovative oil-free lubrication technology eliminates the risk of hydraulic oil leakage.

Energy efficiency is 60% higher than traditional electric actuator systems, and it is ISO 14001 environmental management system certified.

Modular aluminum alloy structure, material recyclability reaches 85%.

Cylinder Actuator Engineering-Grade Performance

| Performance Specifications | Technical Parameters |

| Maximum Thrust | 6.3kN |

| Effective Stroke | 50-800mm (Customization Available) |

| Repeatability | ±0.02mm |

| Environmental Protection | IP67 Dust and Water Resistance Rating |

Typical Industrial Applications of Cylinder Actuator

Precision Assembly of New Energy Power Battery Packs

Non-destructive Transfer System for Semiconductor Wafers

Automated Aseptic Food Packaging Production Line

Key Advantages of the FSKSD-63 Intelligent and Environmentally Friendly Servo Electric Cylinder

Including:

High-Precision Control: Closed-loop servo control accuracy reaches 0.01mm; when used with a pressure sensor, thrust control accuracy can reach 0.5%. Supports seamless integration with PLC and other systems.

Strong Environmental Adaptability: The cylinder actuator has an IP66 protection rating, enabling stable operation in harsh environments, including low temperatures, high temperatures, rain, and snow, without contaminating hydraulic or pneumatic systems.

Cylinder actuators are energy-efficient and highly effective: Utilizing precision ball screws or planetary roller screws, they offer high transmission efficiency, making them more energy-efficient and environmentally friendly than traditional hydraulic or pneumatic systems.

Cylinder actuators have low maintenance costs: Only periodic grease application is required; no replacement of wearing parts is necessary, significantly reducing after-sales service costs.

Cylinder actuators are highly reliable: They operate smoothly, with low noise, long service life, fast response, and good synchronization.

Intelligent and environmentally friendly servo electric cylinders, with their high precision, low energy

consumption, and intelligent features, have enabled efficient and green automated production in mult

iple fields.

Industrial automation is their core application scenario, widely used in precision assembly, laser cutting,

and heavy machinery, improving production efficiency through high-precision positioning and closed

-loop control. In 3C electronics manufacturing, approximately 70% of precision movements are perform

ed by various electric actuators; intelligent electric cylinders, due to their compact and integrated design,

have become key components for achieving efficient and precise assembly. In the logistics and warehou

sing sector, intelligent electric cylinder-driven autonomous mobile robots (such as AIVs) can optimize

space utilization, reduce energy consumption, and achieve green logistics. Furthermore, in packaging

systems and intelligent manufacturing equipment, they can also perform complex pushing, transferring,

and trajectory movement tasks.

The intelligent trend of these electric cylinders is reflected in their compact structure, intelligent debug

ging, and simple programming. Their high energy density and compact design (such as the MCEA series)

allow them to maintain excellent performance within limited spaces, making them ideal for modern

industrial environments with stringent space and energy efficiency requirements.