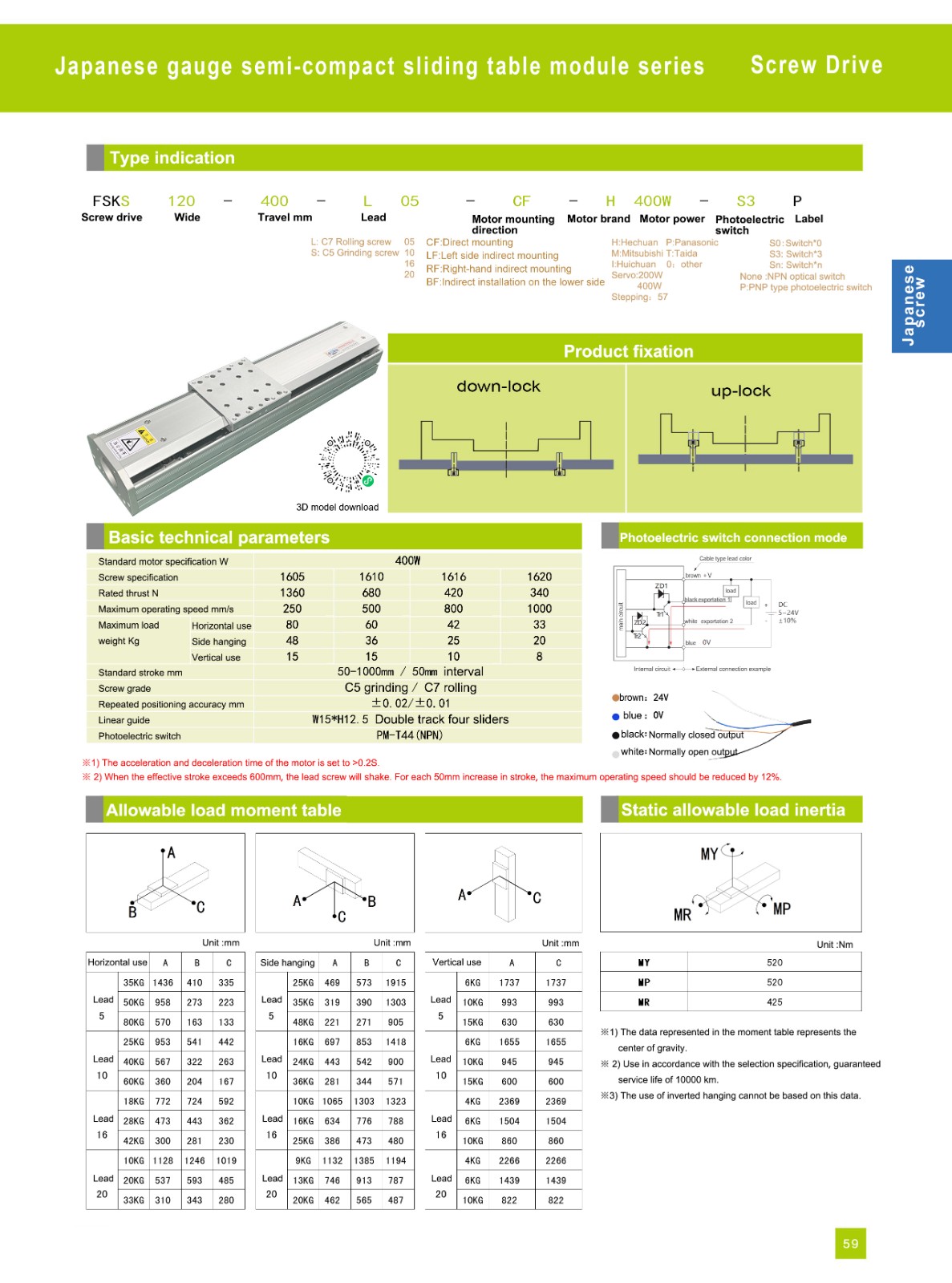

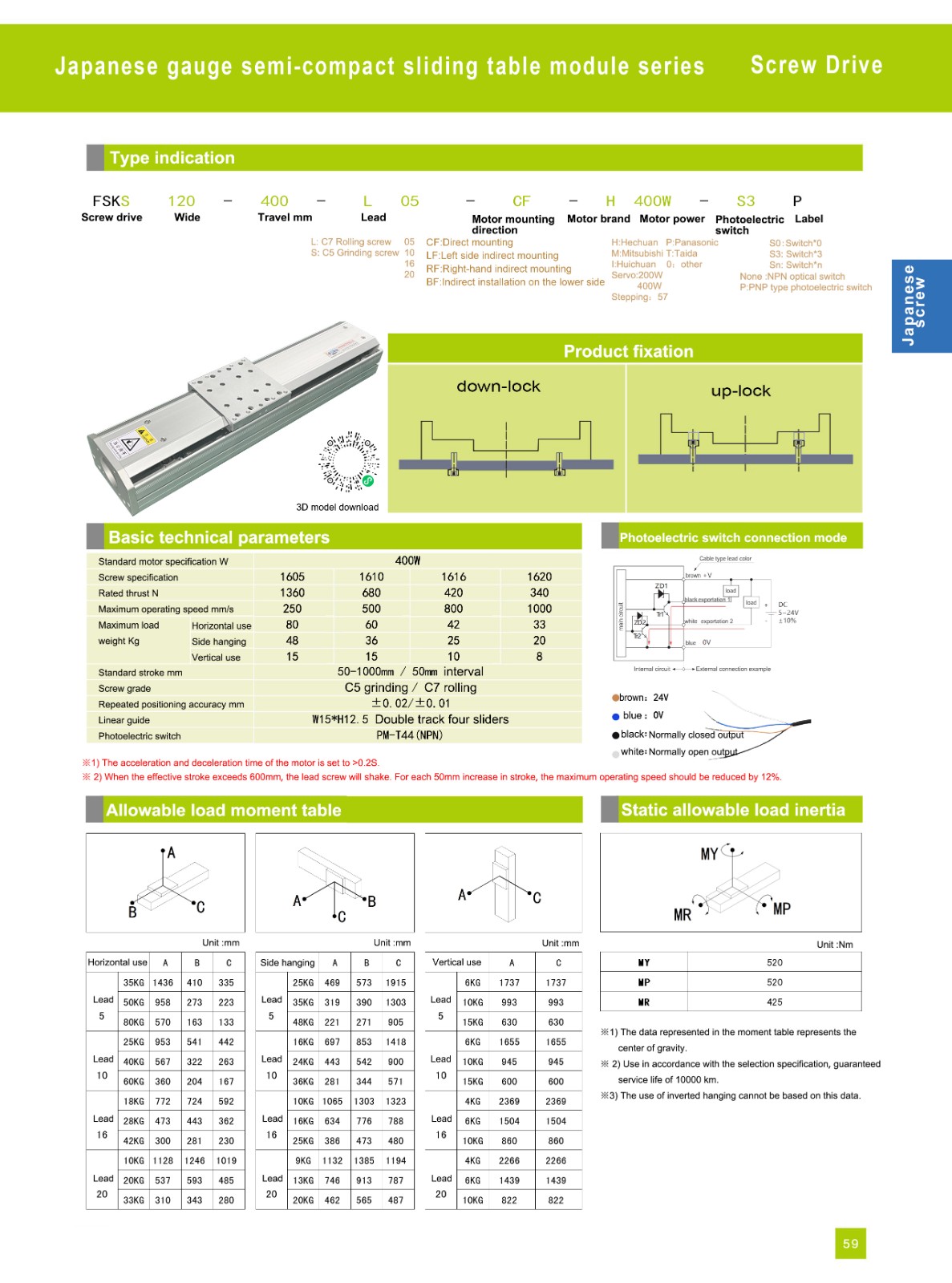

Maximum horizontal load: 60KG

Repeat positioning accuracy: ±0.02/0.01mm

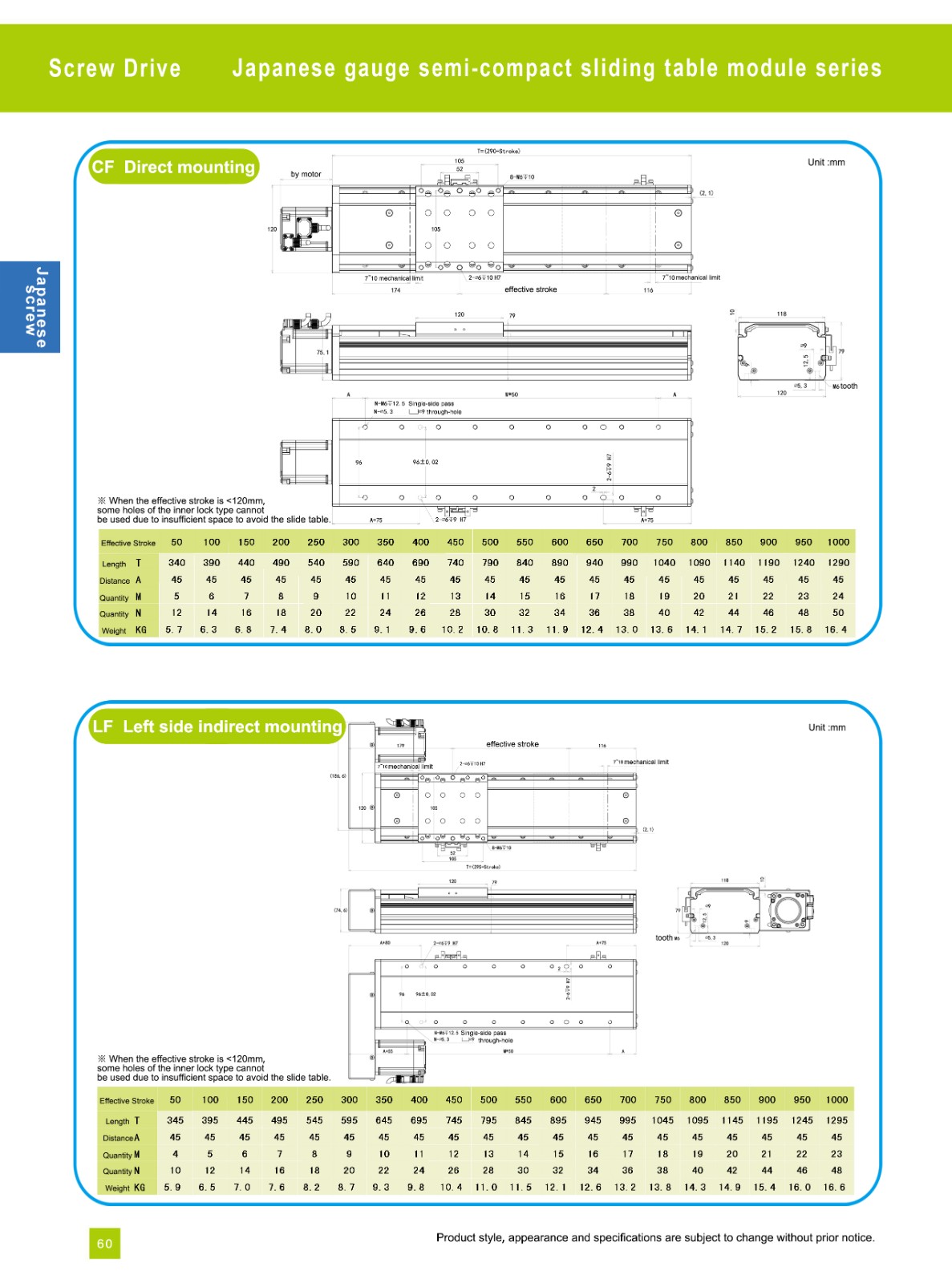

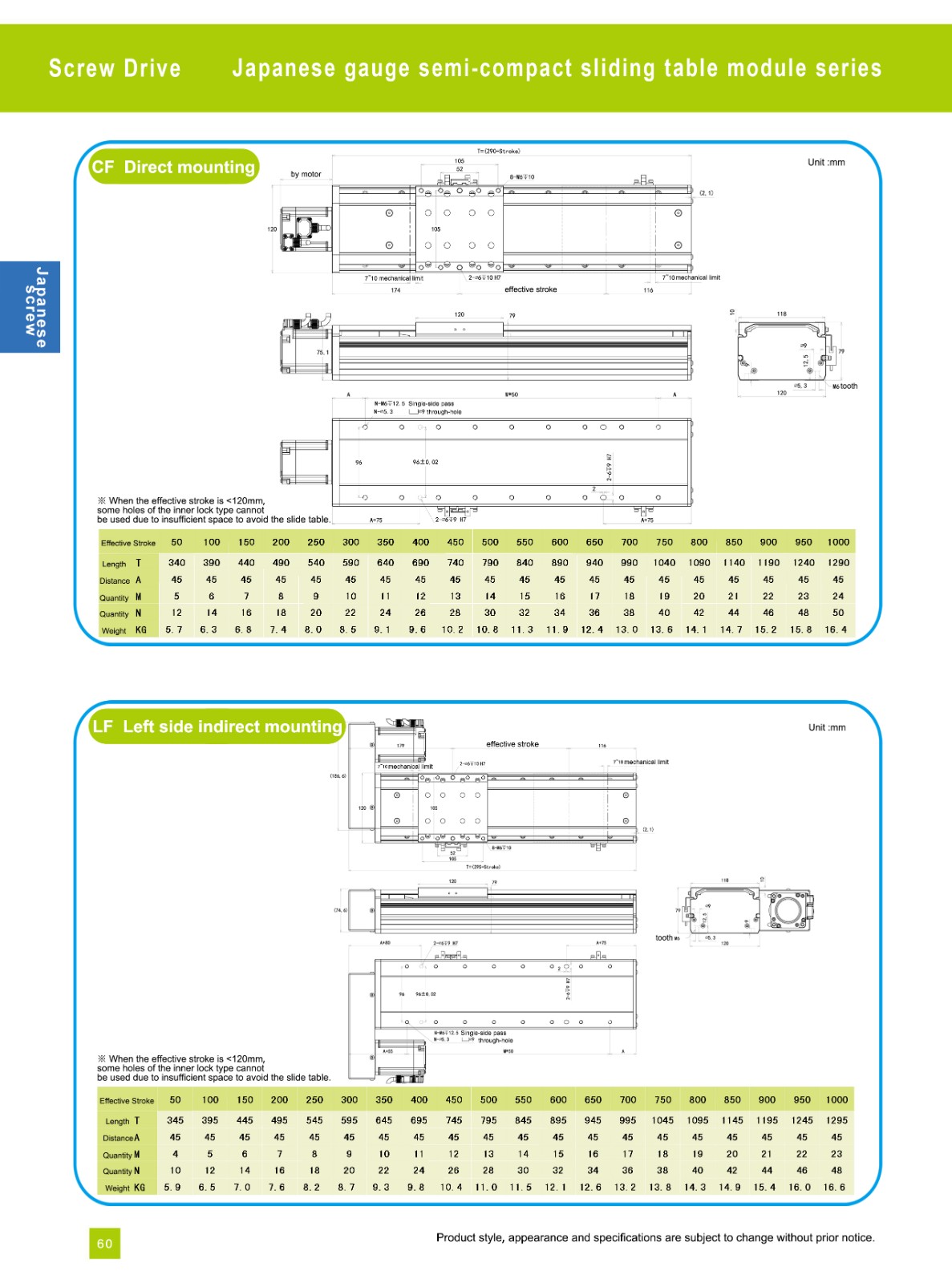

Available stroke: 50-1000mm

Screw outer diameter: Ф16MM

Motor power: 400W

Multi-directional installation: (CF/LF/RF/BF)

Technical characteristics of FSKS-120 high-precision and high-speed ball screw slide module

Core performance parameters

Repeat positioning accuracy: ±0.01mm, meeting the stringent positioning requirements of precision

manufacturing scenarios (such as semiconductor testing and medical equipment assembly).

Screw specifications: Adopt C7-grade precision ball screw, outer diameter ø16mm, optional lead 5mm/

10mm/20mm, taking into account high-speed movement and load stability.

Load capacity: Support high-rigidity design, adapt to 400W-750W servo motors, peak acceleration of

5G, maximum speed of 3m/s, suitable for high-speed automated production lines.

Protection level: IPX4 dust and water resistance, can be operated stably for a long time in dust-free

workshops or general industrial environments.

Structural design advantages

Compact and lightweight: Single-axis HDR type guide rail support, through 4-way equal load DB

structure to improve torque resistance, to achieve high-rigidity and lightweight design.

Fully enclosed protection: The slide module adopts a fully enclosed shell to effectively isolate external

dust and liquid erosion and extend its service life.

Drive compatibility: Supports EtherCAT bus communication, can match mainstream servo drives such as

Mitsubishi and Panasonic, and has a response delay of <1ms.

Application scenario expansion Precision electronic manufacturing: Used for PCB board mounting and

chip packaging to achieve micron-level repeated positioning.

New energy equipment: Integrated in photovoltaic string welding machines and lithium battery stacking

equipment to improve production rhythm.

High-speed sorting system: With a visual positioning module, it can complete 120 grabbing actions per

minute on the logistics sorting line.

Technology comparison and iteration direction Compared with linear motors: The cost advantage is

significant in scenarios with loads >50kg, but the maximum speed is lower than that of coreless linear

motors (SCL type can reach 5G acceleration).

Upgrade potential: Some manufacturers reduce the weight of carbon fiber cylinders by 40%, or use

built-in force sensors to achieve closed-loop force control, and may be compatible with ±1μm-level

linear encoders in the future. Industry adaptation suggestions: 5mm lead models are preferred in the

medical/3C field (accuracy is preferred), and 20mm lead models are optional in the logistics/photovolt

aic field (speed is preferred)

Core Features

Precision Drive

Adopts C5-grade ground ball screw with ±0.005mm repeatability.

Integrated THK high-rigidity linear guides with a four-axis equal load design, improving torque

deformation resistance by 30%.

High-Speed Performance

Maximum speed 3m/s, acceleration 5G, compatible with EtherCAT bus control.

Forced cooling hollow screw structure, temperature rise controlled within ±1°C.

Heavy-Duty Design

Module width 120mm, horizontal load 110kg, vertical load 33kg.

Optional planetary roller screw improves shock load resistance by 200%.

Technical Parameters

Item Specifications

Travel 50-1250mm (customizable)

Motor Power 400W servo (supports Mitsubishi/Panasonic drivers)

Protection Rating IP67 (Fully Sealed and Dustproof Design)

Applications

Semiconductor Wafer Slicing Equipment

New Energy Battery Electrode Slitting Machine

Precision Optical Lens Assembly Line

This module combines the efficient transmission of rolling components with the dynamic response of

linear motors, making it suitable for industrial applications requiring both speed and precision.

The core advantages of the FSKS-120 high-precision, high-load ball screw slide module are as follows:

High-Precision Performance

Adopting a rolling friction design, the friction coefficient is reduced to 1/50 of that of a sliding guide,

minimizing the difference between dynamic and static friction, achieving micron-level positioning

accuracy. Repeatability reaches ±0.01mm, meeting the demands of precision machining.

High-Speed Motion

Low friction resistance and heat generation support operating speeds up to 1600mm/s, improving

efficiency by 20%-30% compared to traditional sliding guides. Aviation aluminum alloy material further

enhances high-speed stability.

High-Load Design

The four-row steel ball structure achieves equal loads in four directions, with a maximum load of 110kg

and a rated thrust of 1338N, making it suitable for heavy-duty automation applications. The enclosed

design enhances impact resistance.

Long Life and Low Maintenance

Rolling friction reduces wear, maintaining accuracy over long-term use. The lubrication system supports

automatic oil supply, reducing maintenance frequency. The fully enclosed structure adapts to dust-free

environments.

Modularity and Compatibility

The 120mm standard design supports multi-axis expansion and compatibility with various drive motors

(servo/stepper) and control systems.

The High Precision, High Speed, Load Screw Slide Module FSKS-120 is a high-precision, high-speed ball

screw slide module with the following core advantages:

1. Ultra-High Precision and Stability

Utilizing a linear guide and ball screw drive system, it achieves repeatability of ±0.002mm, making it

suitable for micron-level applications such as semiconductor lithography and precision inspection. Its

zero-backlash design eliminates the elastic deformation associated with traditional lead screws, ensuring

smooth motion.

2. High-Speed Response and Long Life

It boasts a maximum speed of 10m/s and acceleration ≥6G, far exceeding traditional belt or lead screw

modules. Its friction-free design extends maintenance cycles and reduces downtime costs.

3. Heavy-Duty Load and Modular Expansion

With a maximum single-axis load of 500kg and support for independent motion of multiple movers, it is

suitable for heavy-duty applications such as new energy battery sorting and automotive manufacturing. Its modular structure facilitates integration into automated production lines.

4. Environmental Adaptability and Cost-Effectiveness

The sealed, dustproof design (IP67 rating) and aluminum alloy base make it suitable for harsh industrial

environments. Compared to linear motor modules, it offers lower costs and easier maintenance.

5. Wide Application Scenarios

It covers applications such as 3C electronics assembly, experimental equipment, packaging and transport

ation, and is particularly suitable for applications requiring high-frequency reciprocating motion. Its com

pact structure (such as the X-axis design in C-type welders) can save 40% space.