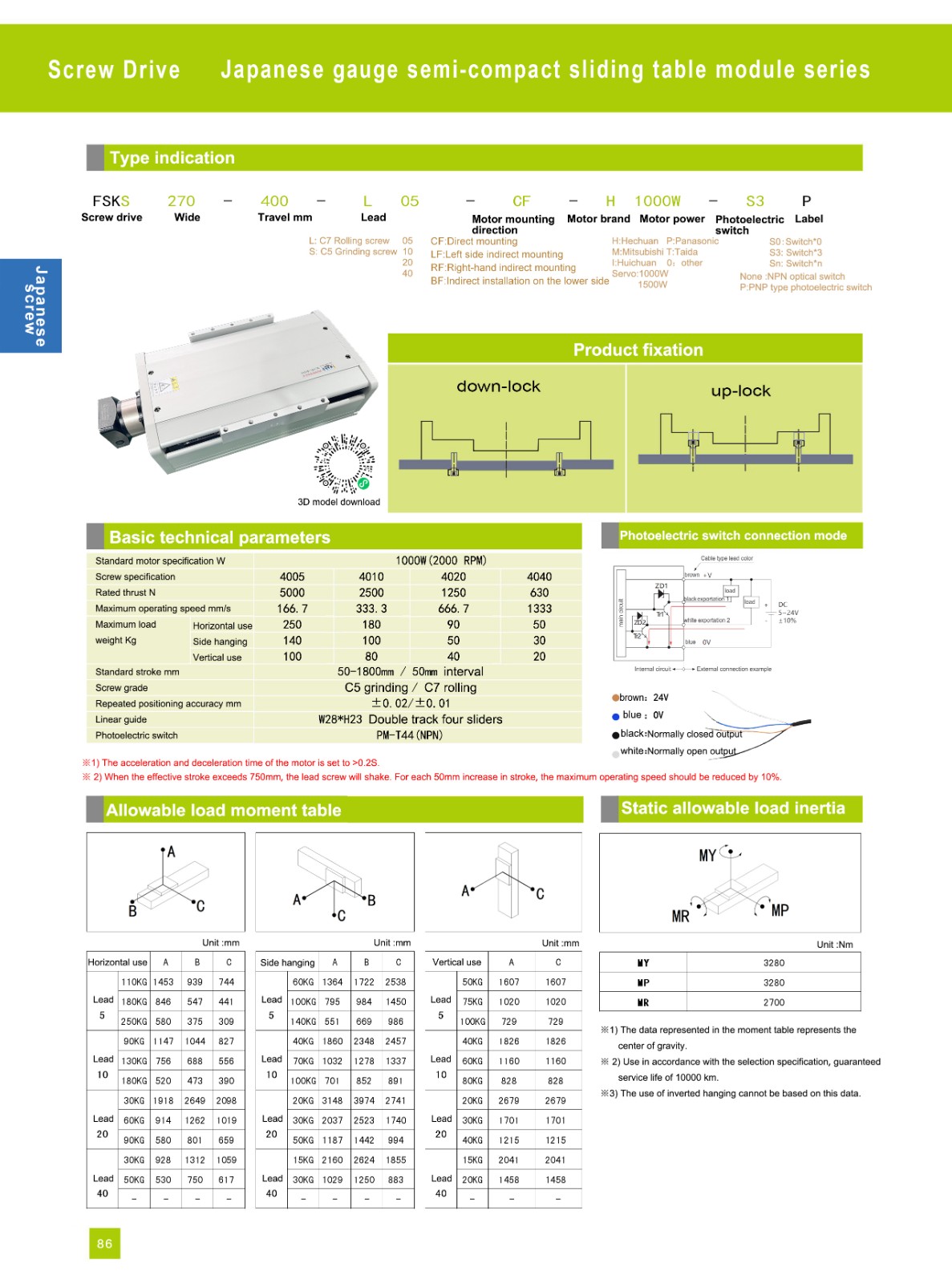

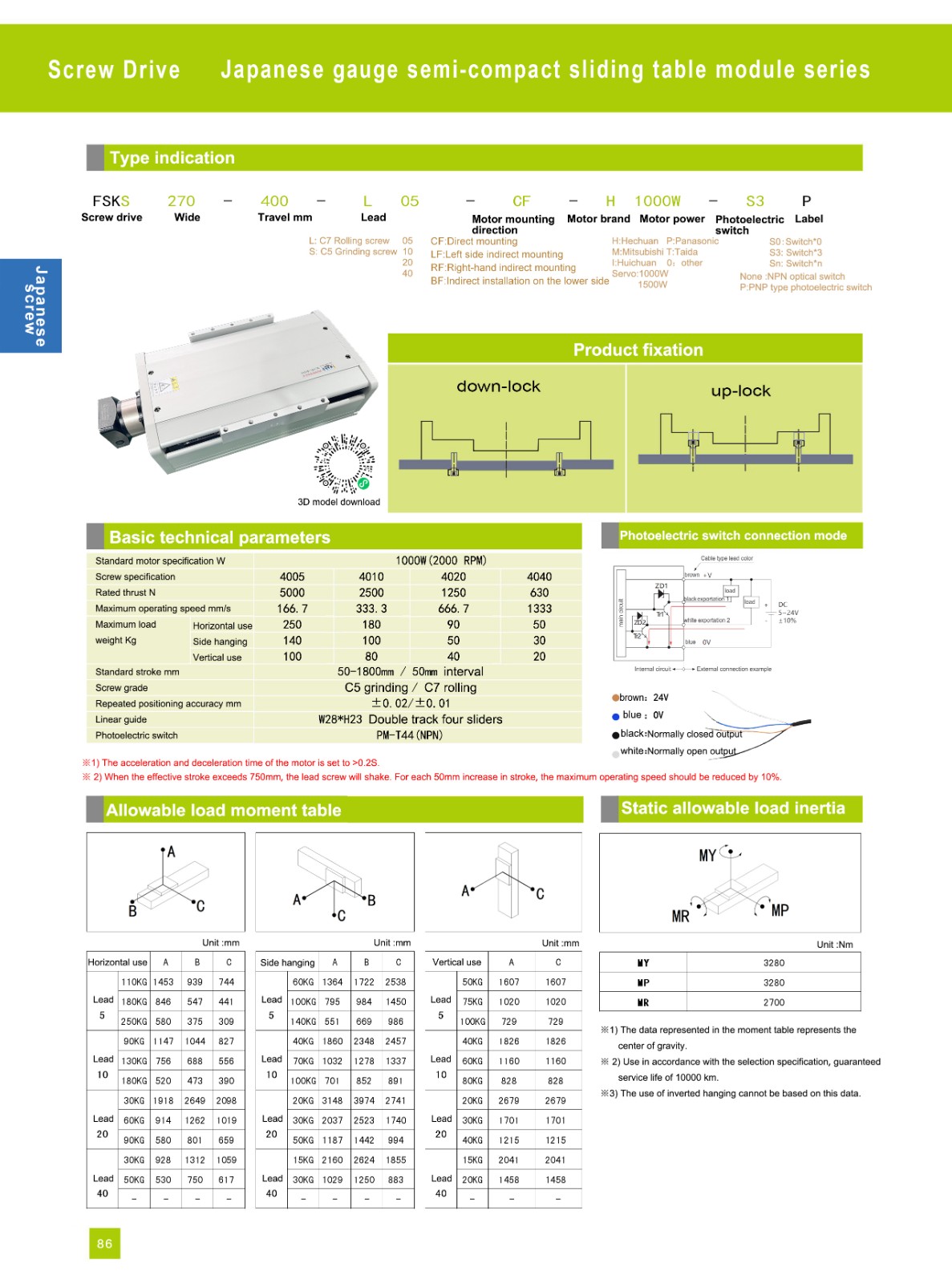

Semi-dense module

Maximum horizontal load: 200KG

Repeat positioning accuracy: ±0.02 mm

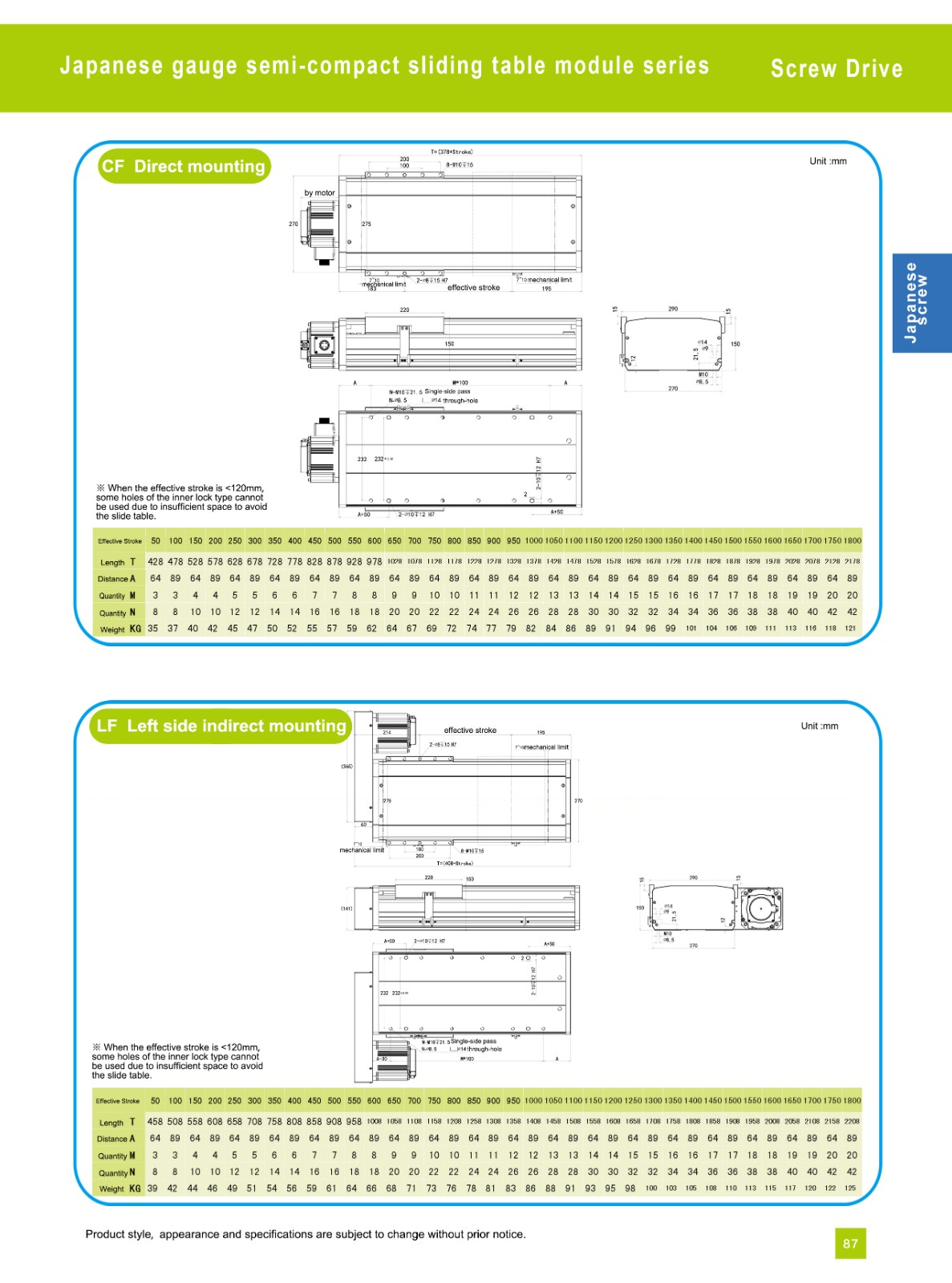

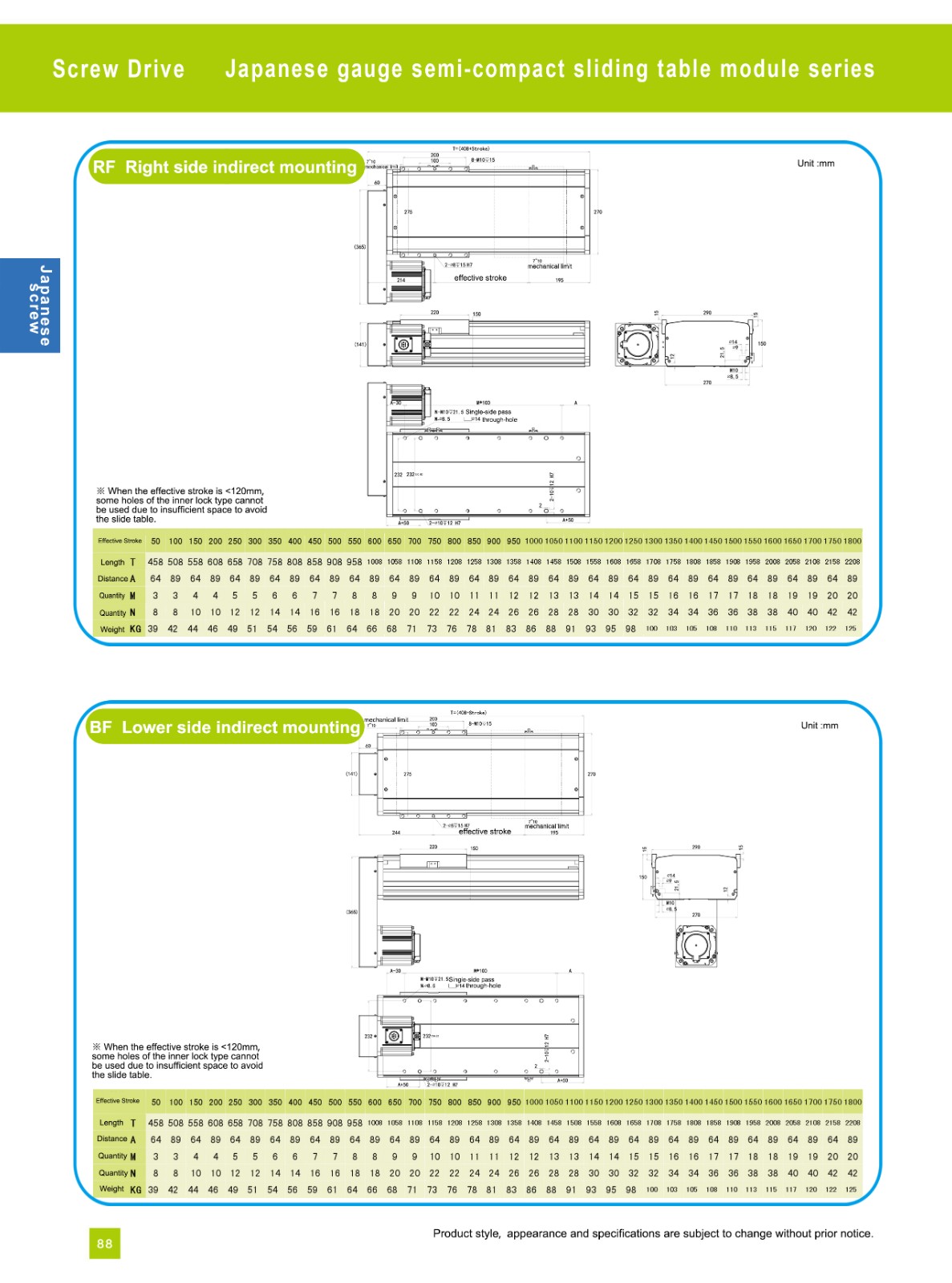

Customizable stroke: 50-2000mm

Contact customer service to confirm parameters and produce drawings

Technical analysis of FSKS-270 semi-enclosed precision fast wear-resistant sliding module

Core performance parameters

Load capacity: radial load ≥ 800 N, lateral load ≥ 500 N, flip torque ≥ 25 N·m, support heavy-load

high-speed motion scenes. Repeat positioning accuracy: ≤ ± 0.01 mm (full stroke), compatible with

closed-loop control to achieve micron-level positioning, adapt to precision machining needs. Running

speed: up to 4 m/s (linear motor drive solution), acceleration ≥ 2g, meeting high-speed reciprocating

operation requirements. Wear-resistant design: four-row rolling steel ball structure, friction coefficient

as low as 0.003–0.005, life ≥ 5000 km (L10 standard). Protection level: semi-enclosed dustproof structure

(IP54/IP65 optional), integrated double-lip seal or metal dust cover, balance heat dissipation and

cleanliness. Structural highlights

High-rigidity integrated base

The guide rail adopts a Gothic arched raceway design with a contact angle of 45°, a 30% increase in

lateral rigidity, and suppression of high-speed vibration .

Four-way equal-load slider (HDR structure), automatic centering capability to ensure eccentric load

stability, and support vertical installation .

Modular drive compatibility

Adapt to stepper motors, servo motors or linear motors (such as Feichuang FCL350 series), support

synchronous belt/gear rack transmission .

Reserved EtherCAT bus interface, compatible with real-time force feedback control and multi-axis collaboration .

Typical applications

Laser cutting platform: 4 m/s high-speed translation combined with ±0.01 mm accuracy to achieve

high-precision metal cutting .

Semiconductor testing equipment: Ultra-low friction coefficient ensures the smoothness of wafer

transmission, adapted to Class 10 clean environment .

Heavy-duty handling robot: Single slider bears 800 N, integrated in the high-speed handling system of

the logistics sorting line .

Technological evolution

Lightweight upgrade: Explore the carbon fiber base solution, aiming to reduce weight by 40% to improve

dynamic response .

Intelligent maintenance system: Built-in wear sensor, early warning lubrication cycle (it is recommended

to add special grease every 2000 hours).

Selection suggestion:

High-speed scenario: linear motor drive + metal dust cover (IP65) is preferred;

Heavy-load environment: dual slider parallel configuration is recommended to enhance anti-flipping

ability .

Note: The parameters are inferred based on similar products in the industry, and the specific manufactu

rer's technical documents shall prevail.