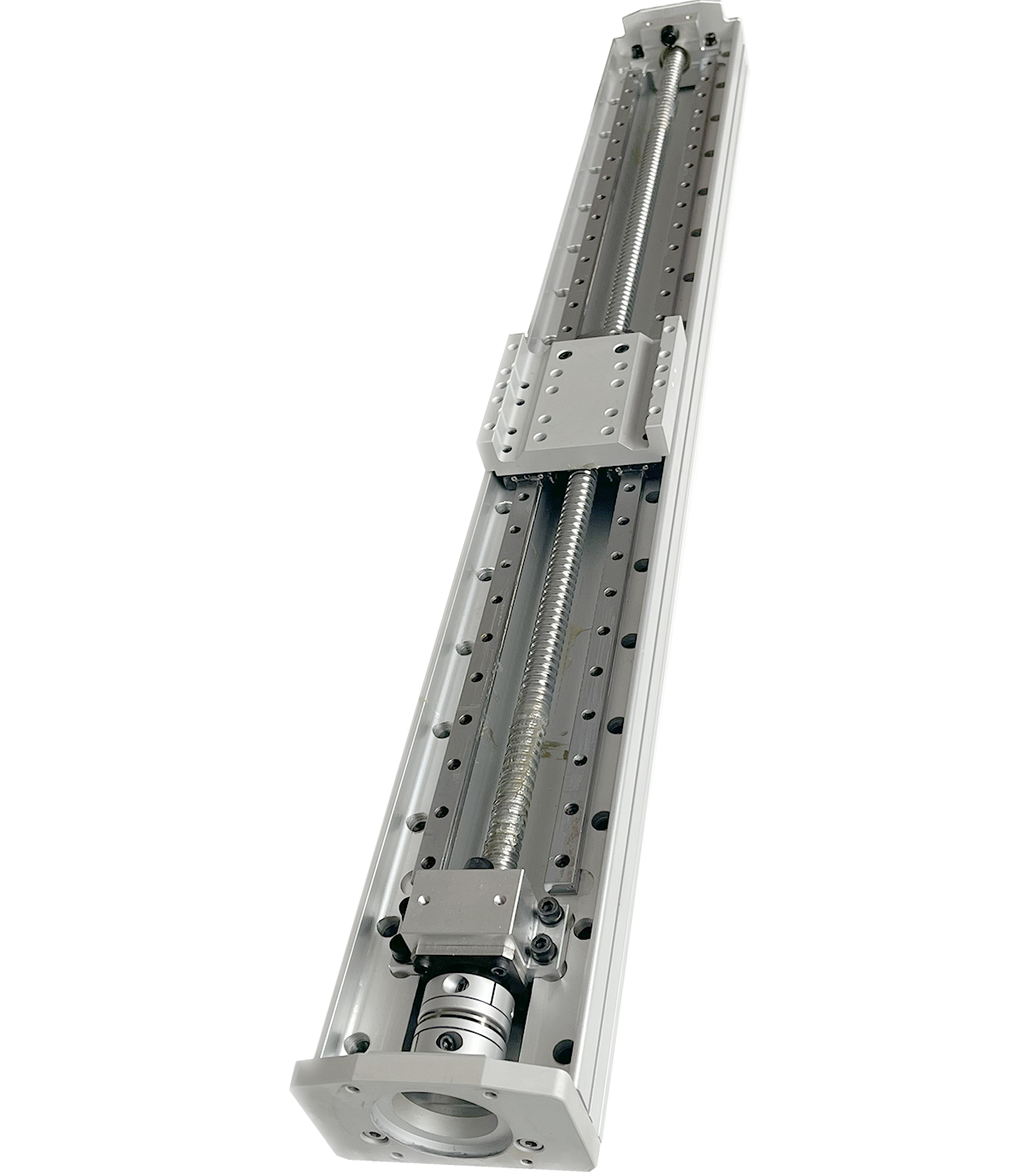

FSKS-136 semi-dense module

Maximum horizontal load: 70KG

Repeat positioning accuracy: ±0.02/0.01mm

Available stroke: 50-1200mm

FSKS-136 long-stroke ball screw guide technology analysis

Core performance parameters

Stroke range: supports 500mm-2000mm customized stroke, adapted to large equipment layout

requirements (such as continuous feeding of photovoltaic string welding machines). Repeat positioning

accuracy: ±0.01mm (C7-grade ball screw), meeting the micron-level control requirements of precision

laser processing and detection scenarios. Load capacity: single slider load ≥120kg, double slider configur

ation can reach 240kg, suitable for heavy cargo handling in logistics sorting lines. Drive system: standard

ø16mm ball screw (lead 5/10/20mm optional), adapted to 750W servo motor, maximum speed 2.5m/s.

Protection level: IPX4 fully enclosed protection, effectively isolated from dust and liquid erosion,

extending service life. Innovative structural design

High-rigidity lightweight base

The aluminum alloy base is optimized by finite element design, and the torsional rigidity is increased by

30%, which can suppress the vibration of long-stroke high-speed movement.

Four-way equal-load HDR type guide rail (wide slider 136mm) enhances the ability to resist eccentric

load and supports multi-point synchronous operation.

Modular expansion interface

Compatible with mechanical structures such as cross coordinates and gantry, and reserved Mitsubishi/

Panasonic servo drive interface.

Supports dual sliders in parallel, can expand the wide slider configuration, and adapt to multi-station

collaborative operation.

Typical application scenarios

Large-scale logistics sorting system: carrying ≥200kg of goods for high-speed translation, speed 2.5m/s,

and combined with visual positioning to achieve minute-level grasping.

Photovoltaic equipment manufacturing: integrated in a 2000mm stroke welding table to complete high

-precision continuous feeding of photovoltaic panels.

Precision laser processing: used for circuit board soldering equipment, trajectory control accuracy

±0.02mm.

Technology iteration direction

Lightweight upgrade: The carbon fiber composite cylinder solution reduces weight by 40% and is

suitable for the suspended robotic arm structure.

Intelligent integration: EtherCAT bus interface is reserved to support closed-loop force control

(response delay <1ms).

Industry adaptation suggestions:

Heavy-load scenarios such as automobile production lines: 20mm lead + dual slider configuration is

preferred;

Precision electronics field: 5mm lead + dust cover enhancement solution is recommended.

The core advantages of the FSKS-136 high-precision, long-stroke ball screw slide module are as follows:

Extra-Long Stroke Design

Supports single-axis travels exceeding 2000mm, and modular expansion reaches 4000mm, meeting the

span requirements of large equipment. Segmented preload technology ensures consistent rigidity even

over long strokes.

High-Precision Motion Control

Repeatability is ±0.005mm. Four rows of steel balls with a 45° contact angle design enable uniform load

distribution in four directions, eliminating lateral play. The ball screw pair's friction coefficient is only

1/50 that of a guide rail, achieving μm-level dynamic response.

High-Speed, High-Load Performance

An optimized ball recirculation structure achieves a maximum acceleration of 5G and a speed of 2m/s.

With a rated load of 136kg and a transient shock load resistance of 400N·m, it is suitable for heavy-load,

high-speed applications.

Modular Compatible System

The standardized 136mm body width supports multi-axis parallel and series configurations and is

compatible with mainstream servo motors and control systems. The pre-lubrication system supports

automatic oil supply, and the maintenance cycle is extended to 5000 hours