FSKS-100 semi-dense module

Maximum horizontal load: 50KG

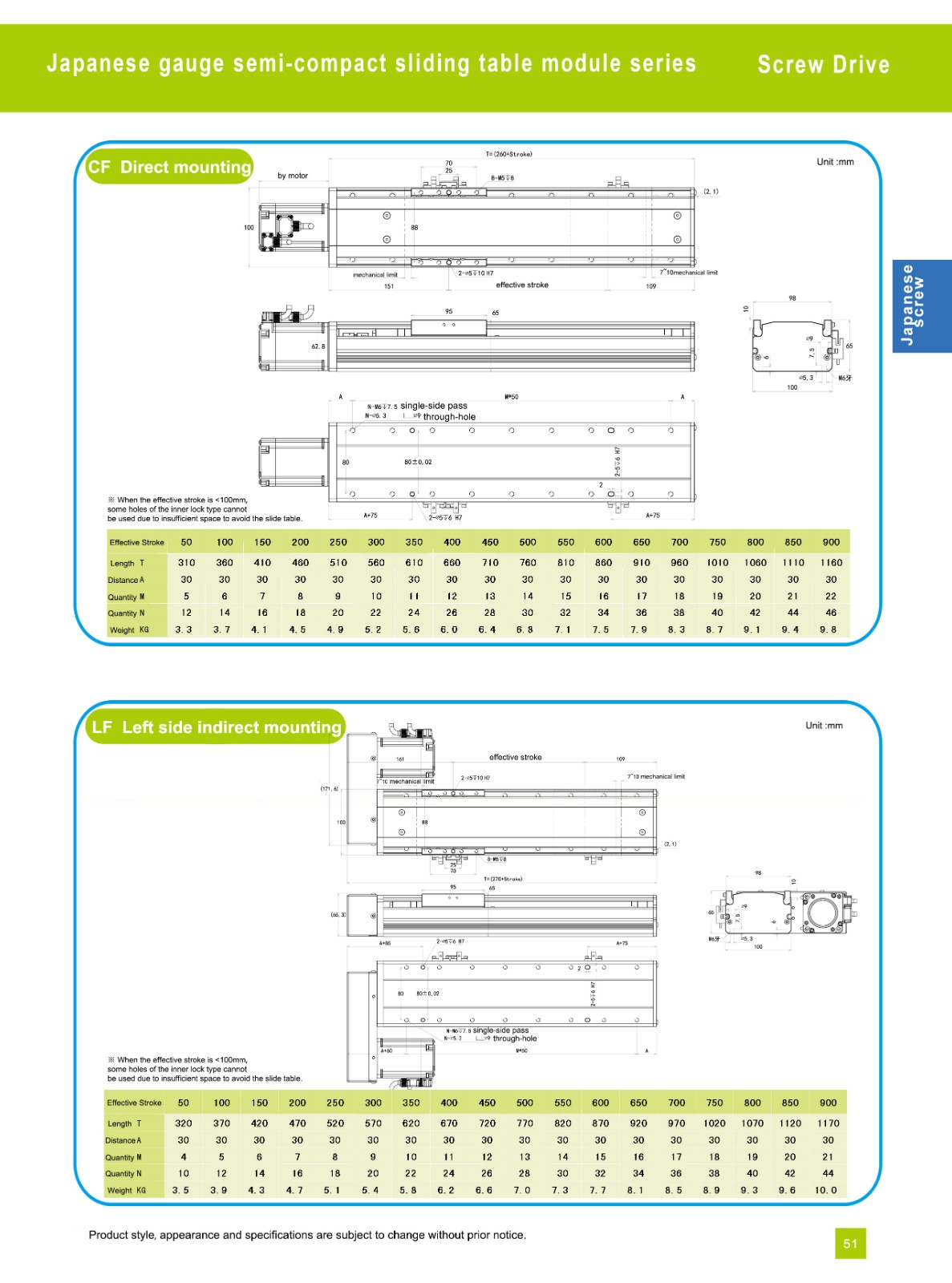

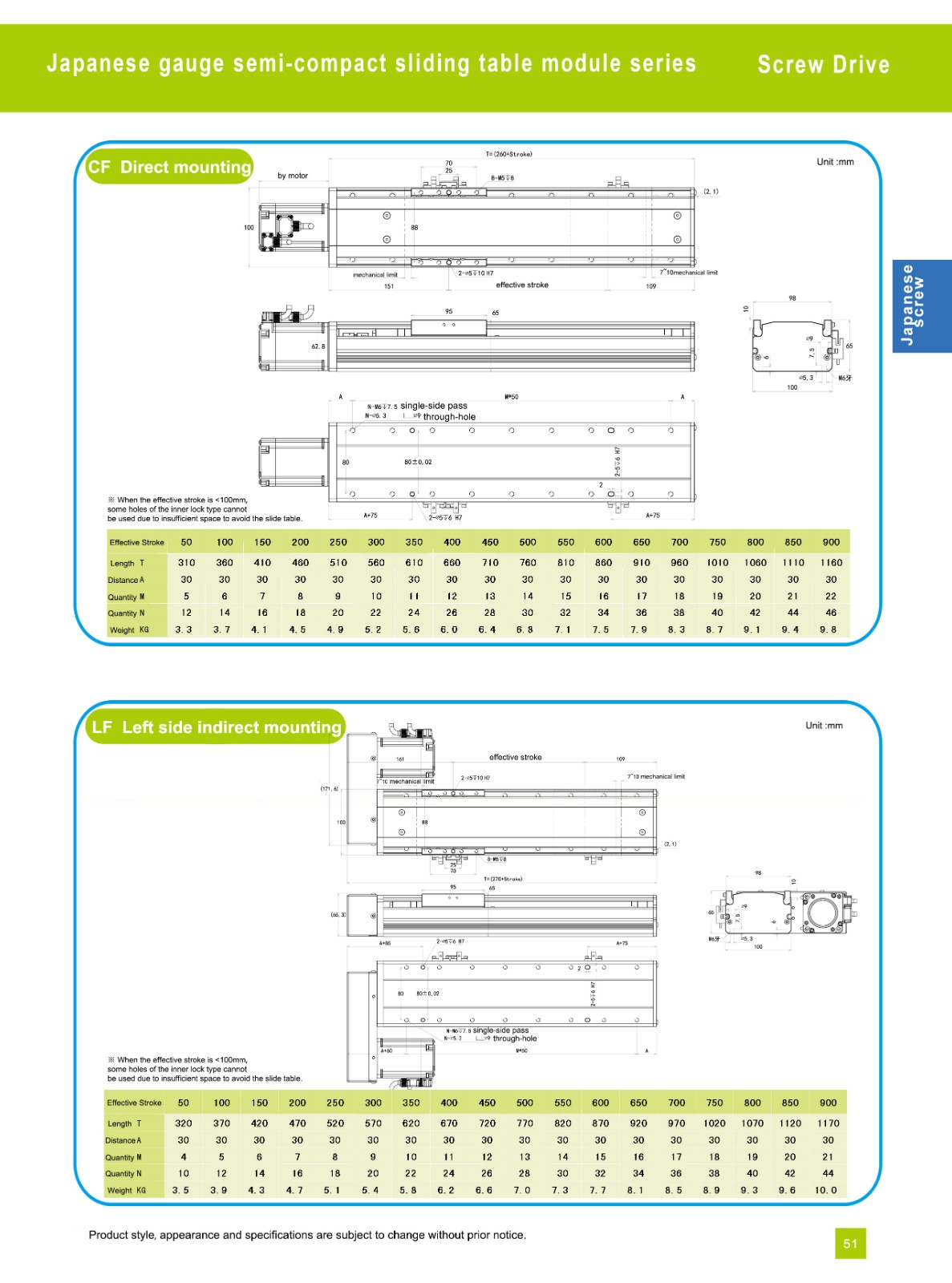

Repeat positioning accuracy: ±0.02/0.01mm

Available stroke: 50-1000mm

Screw outer diameter: Ф16MM

Lead: 05/00/20 MM

Motor power: 200/400W

Positive Negative Screw Double Slide Module FSKS-100 is an industrial-grade double-slide linear

transmission system that adopts positive and negative ball screw design, supports synchronous

bidirectional motion control, and is suitable for high-precision bidirectional positioning scenarios

(such as precision assembly, optical adjustment, etc.). Its core features include:

Structural features

Dual slide layout: Double-sided rigid guide rail design improves motion stability and torsional rigidity,

suitable for eccentric load scenarios; Positive and negative screw: Supports coaxial bidirectional drive,

reduces multi-module coordination errors, and positioning repeatability ≤±0.01mm; Sealed protection:

The guide rail and screw are integrated with dust covers, passed IP54 protection certification, and are

suitable for industrial environments.

Performance parameters

Load capacity: axial dynamic load ≥800N, static load ≥1500N (servo motor required); Travel range:

standard travel 200–1500mm (non-standard customization supported); Speed and accuracy: maximum

moving speed 1.2m/s, with C7-grade ball screw to achieve full-stroke positioning error <0.05mm.

Application scenarios

Mainly integrated in equipment that requires bidirectional synchronous operation, such as:

Semiconductor wafer dual-station detection platform;

Laser cutting machine bidirectional feeding system;

High-precision 3D printing dual-axis synchronous mechanism.