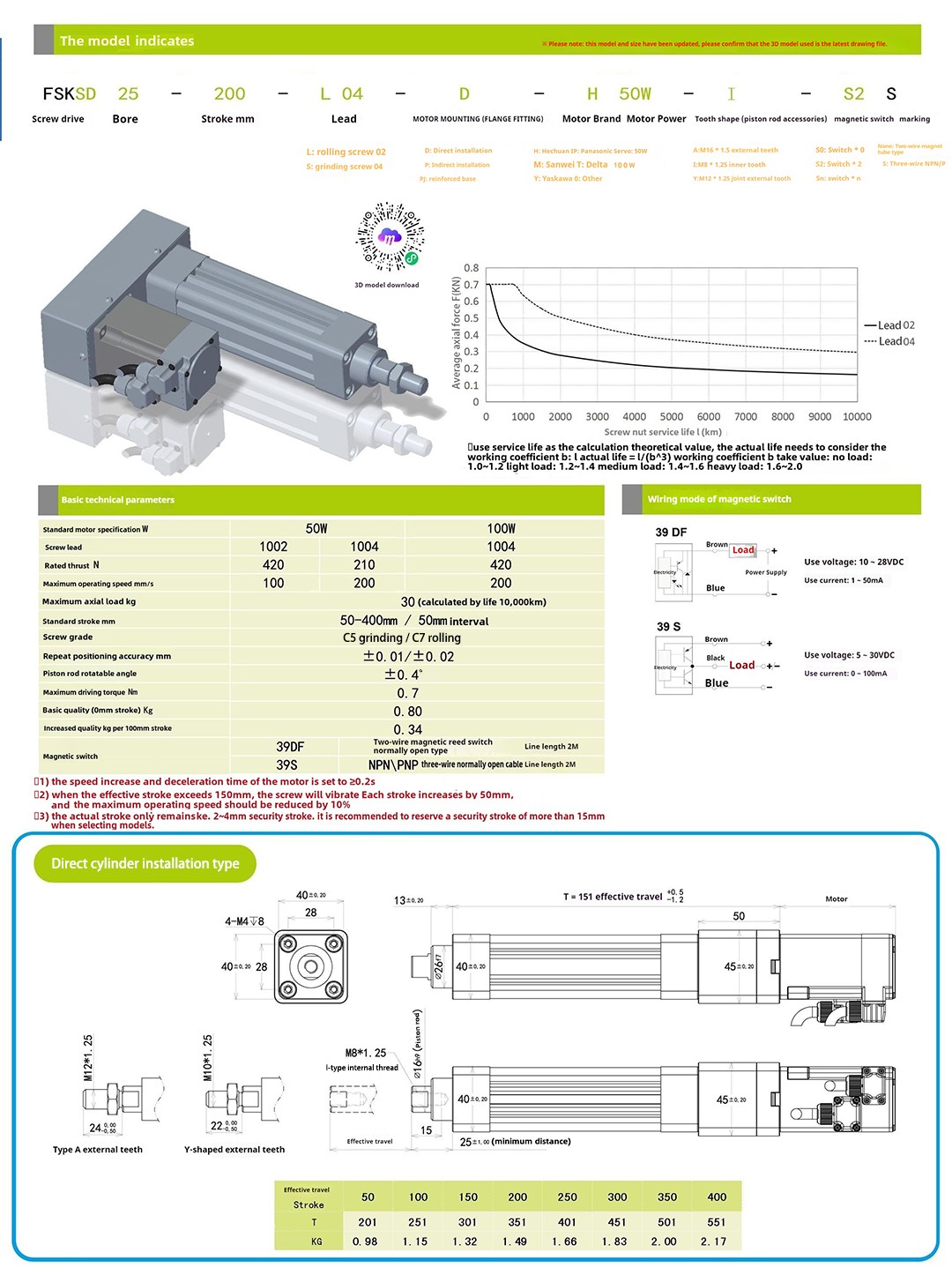

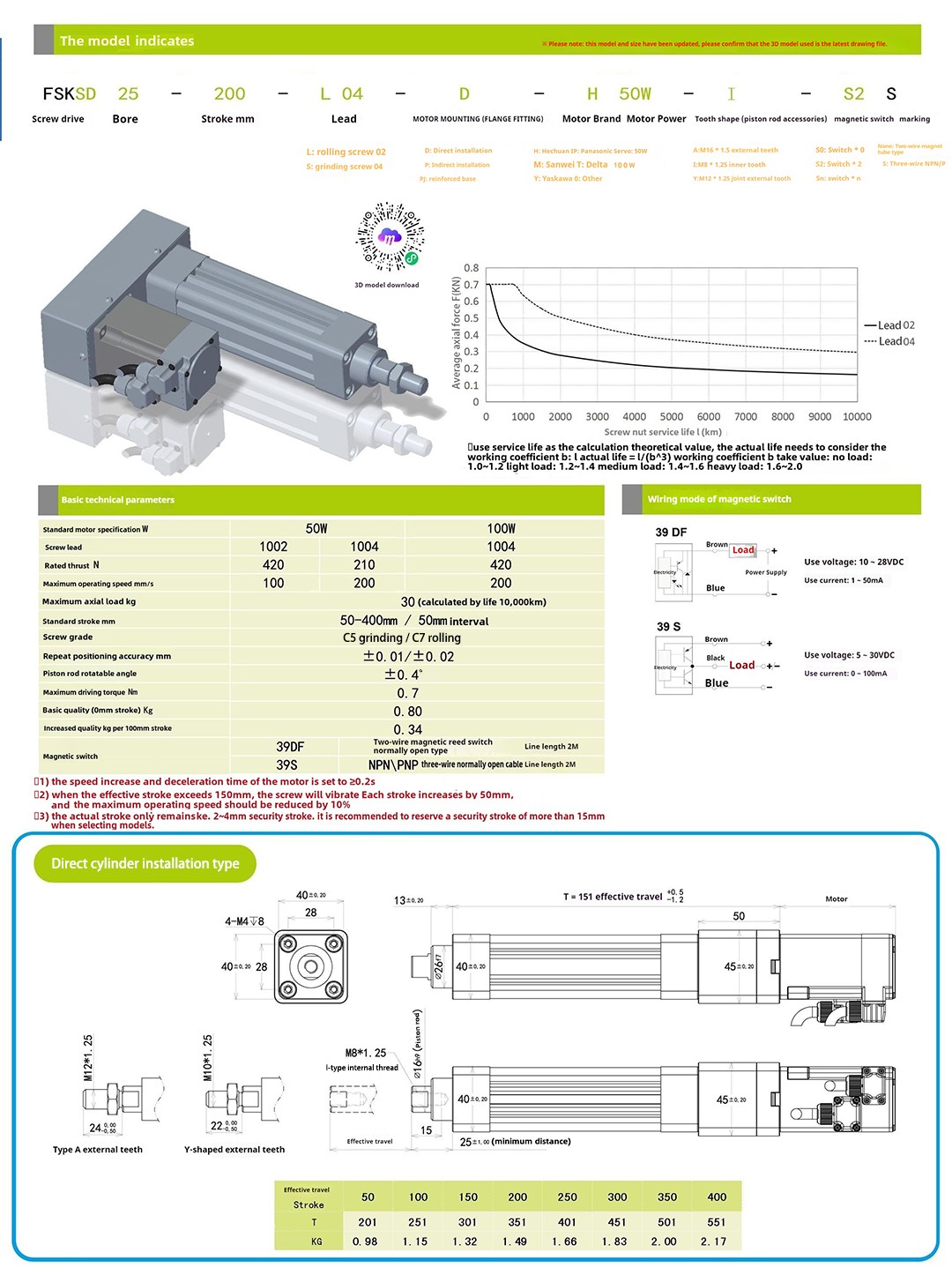

Repeat positioning accuracy:+0.02mm

Customized stroke:50-400MM

Screw outer diameter:φ10MM

Lead:04MM

Maximum speed:200MM/S

Motor power: 100W

(Multiple brands of motors available/customizable)

1. High precision: The servo electric cylinder adopts closed-loop servo control, with a control accuracy of up to 0.01mm and precise thrust control. After adding a pressure sensor, the control accuracy can reach 1%.

2. High speed: The speed range of the servo electric cylinder is 0.1~2m/s, and the maximum acceleration can reach 10m/s². It can quickly respond to control commands and achieve instant start, stop and speed change.

3. Flexible configuration: The installation configuration of the servo electric cylinder is very flexible, providing a full range of installation components, such as front flange, rear flange, side flange, etc., which can be installed in line or parallel with the servo motor, and various accessories can be added, such as limit switches, planetary reducers, preload nuts, etc.

4. Energy saving and environmental protection: Compared with traditional hydraulic and pneumatic systems, servo electric cylinders have higher energy utilization and lower operating costs, and there is no hydraulic oil leakage and exhaust pollution problems in pneumatic systems, which meets environmental protection requirements.

5. Easy maintenance: Servo electric cylinders only need regular grease lubrication when working in complex environments, and there are no wearing parts that need maintenance and replacement, which reduces after-sales service costs.

The FSKSD-25 high-thrust, stable-operation electric cylinder offers the following core advantages:

Its optimized design provides continuous, stable high thrust output, meeting the demands of large-load

precision actuation in industrial applications. Its wide thrust adjustment range (50%-109% of rated

value) accommodates dynamic load variations under diverse operating conditions.

Structural reinforcement and dynamic balancing ensure low vibration and high repeatability (±0.01mm)

during high-speed motion, similar to the stability control logic used in aircraft engines.

Adopting a staged circulation system, key components such as the turbopump and hydraulic actuators

support rapid maintenance, resulting in a mean time between failures (MTBF) exceeding 10,000 hours.

Compared to traditional hydraulic systems, it reduces energy consumption by over 30% and eliminates

oil contamination, meeting green manufacturing standards. Its liquid hydrogen/liquid oxygen hybrid

technology (similar to spacecraft design) further enhances energy conversion efficiency.

Integrated multi-sensor feedback system supports real-time thrust adjustment and fault diagnosis, and

is compatible with Industry 4.0 networked control protocols.