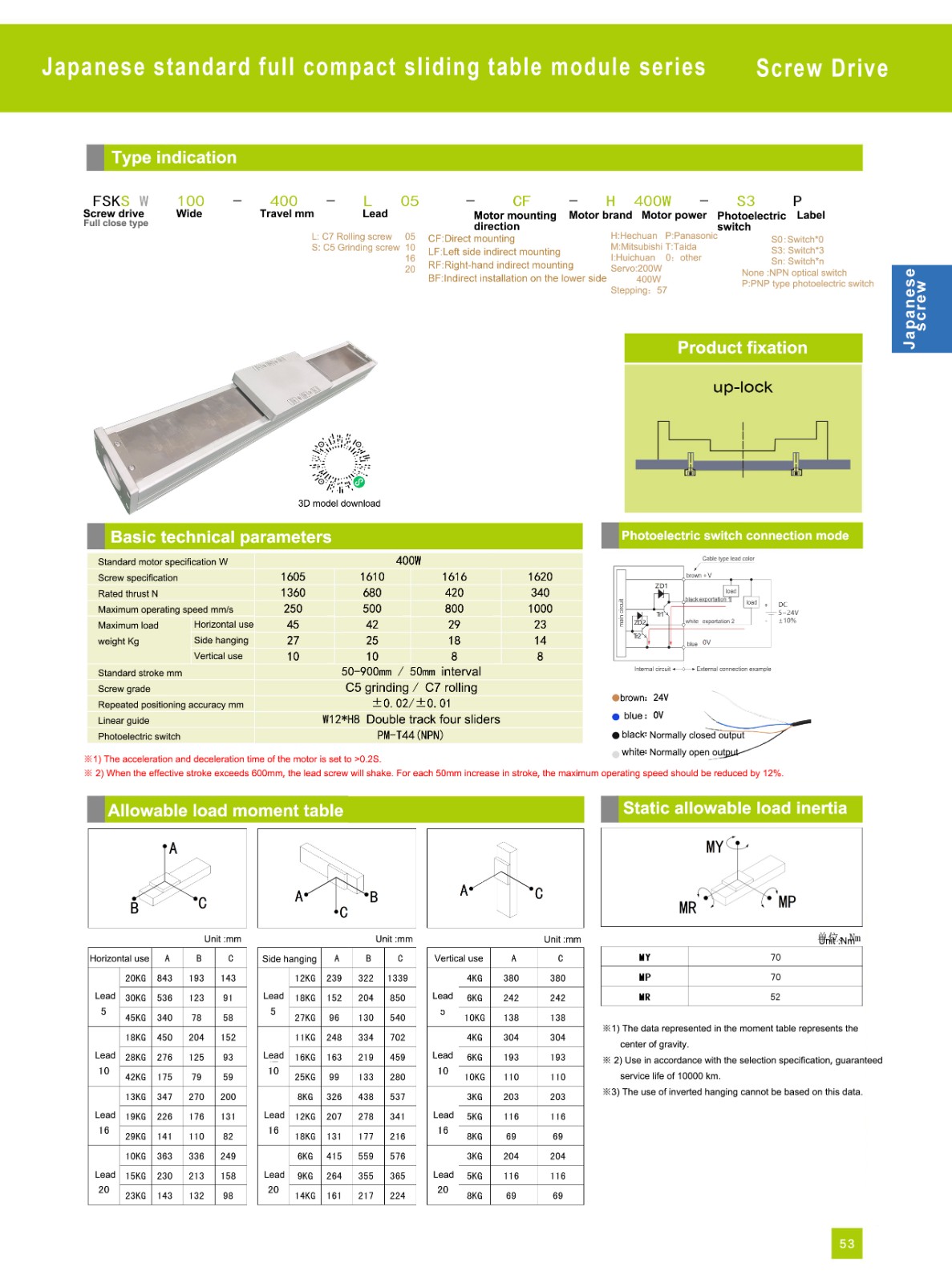

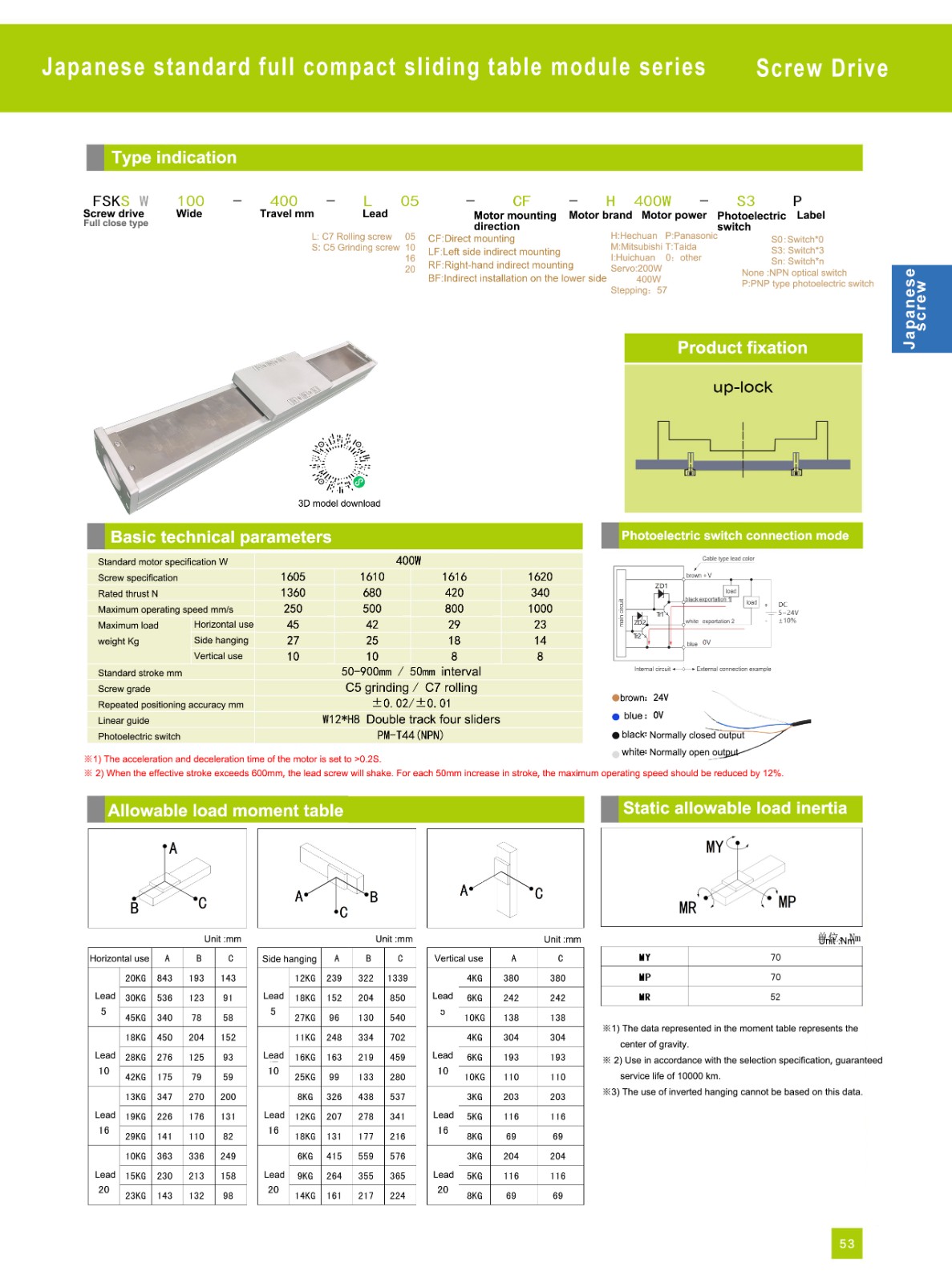

Maximum horizontal load 30 KG

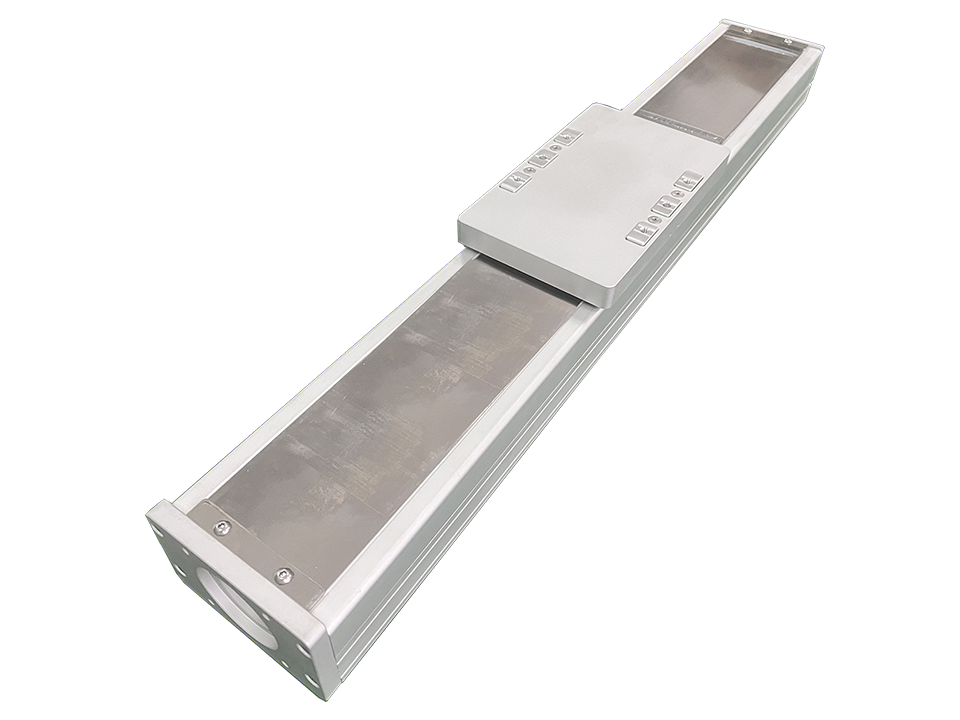

Model: FSKSW-100 screw full-closed module-steel belt

Repeat positioning accuracy: 0.01/±0.02 mm

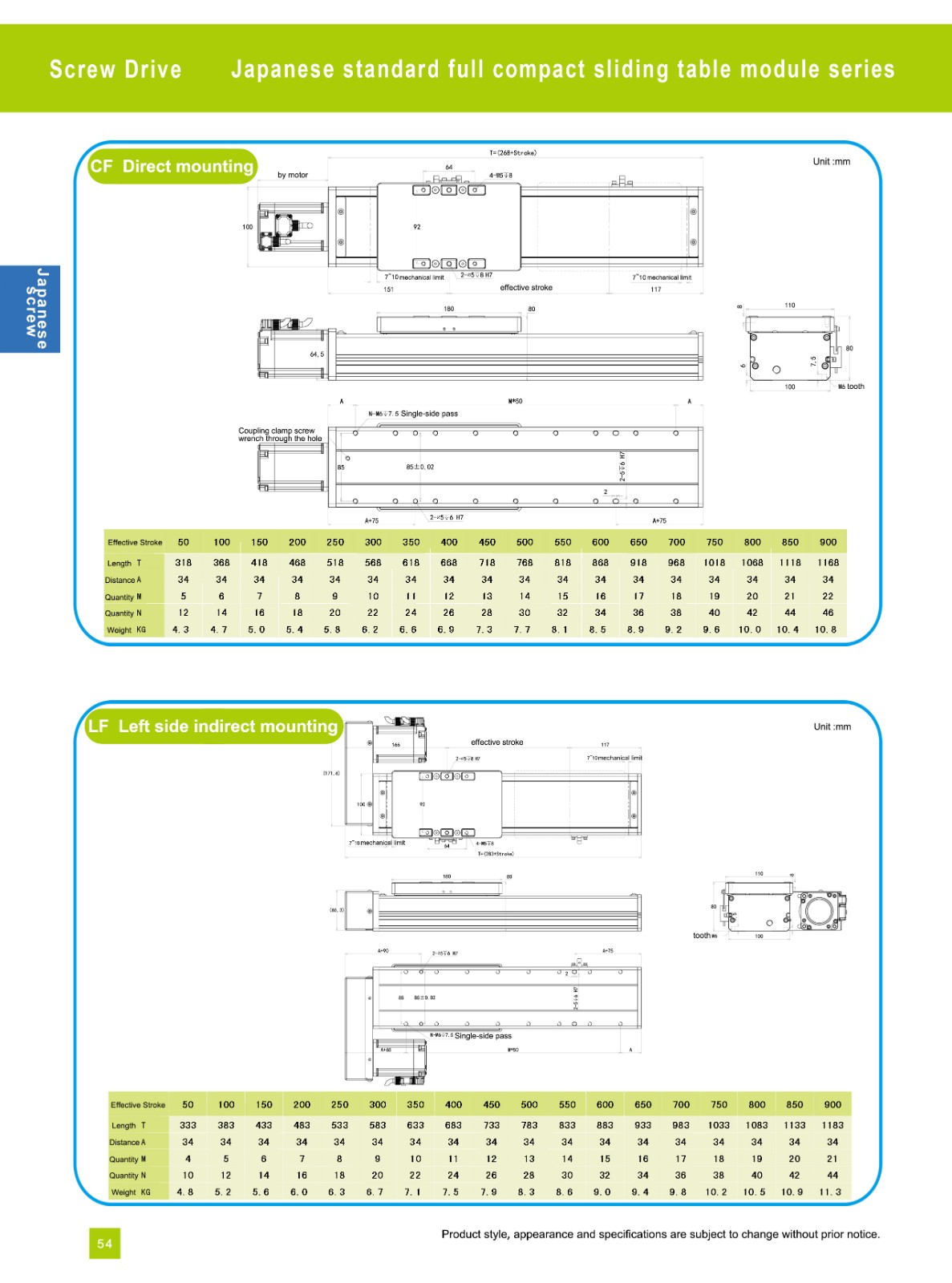

Customizable stroke: 50-1000 mm

Screw outer diameter: φ16 mm

Lead: 05/10/20 mm

Motor power: 200W/400W (motor can be customized)

Maximum speed: 250/500/1000 MM/S

The Fully Enclosed High Load Linear Rail Slide Module FSKSW-100 is an industrial-grade linear motion

component designed to withstand heavy loads and provide reliable sealing protection, suitable for

automation equipment and precision mechanical systems. Its core advantage lies in the combination of

high-rigidity guide rails and fully enclosed structures, which effectively resist dust and moisture

intrusion, extend service life and ensure stable operation.

Main features include:

High load capacity : Supports radial loads up to 800 N and lateral loads of 500 N, suitable for heavy

equipment handling and positioning scenarios, ensuring anti-rollover torque (such as 25 N·m) to

enhance stability .

Excellent precision and rigidity : Adopting a four-row ball circulation design, the contact angle is

optimized to 45°, achieving a repeat positioning accuracy of ≤±0.01 mm, and maintaining high dynamic

rigidity through preload adjustment .

Low friction and high efficiency operation: The friction coefficient is as low as 0.003~0.005, combined

with the ball retainer mechanism to reduce noise and energy consumption, support high-speed operation (such as 6000 min⁻¹ servo motor adaptation), and improve energy efficiency ratio.

Modular sealing protection: Standard double-lip sealing strip or optional metal dust cover, providing

IP54 to IP65 protection level, suitable for harsh industrial environments (such as clean rooms or humid

conditions).

Typical applications include precision gripping arms for electronic assembly lines, testing mechanisms

for medical devices, and wafer transfer systems in semiconductor manufacturing, meeting high clean

liness and low noise requirements

The core advantages of the fully enclosed, high-load linear guide module FSKSW-100 are reflected in

the following aspects:

Industrial-grade protection and high-rigidity structure

The fully enclosed stainless steel housing achieves IP65 dust and water resistance. Four rows of steel

balls with a 45° contact angle achieve four-way equal load characteristics, a rated load of 100 kg, and

instantaneous shock load resistance of 300 N·m. The integrated sealing structure effectively isolates metal debris and liquid corrosion, making it suitable for cleanrooms and high-humidity environments.

Ultra-precision motion control

The rolling friction coefficient is as low as 0.002, with repeatability of ±0.003 mm. Preload technology

eliminates backlash and supports micron-level dynamic response. The enclosed rail design reduces

external vibration interference, improving long-term operating accuracy and stability by 40%.

Long-term corrosion resistance

The 304 stainless steel is passivated and withstands salt spray corrosion for over 2,000 hours. The oper

ating temperature range is -20°C to 80°C. Built-in heat sink fins and a self-lubricating system extend the

maintenance interval to 10,000 hours.

Modular Integrated Design

The 100mm standard width supports multi-axis parallel connection, and pre-installed interfaces are

compatible with mainstream servo systems, increasing installation efficiency by 60%. Non-contact

signal transmission eliminates mechanical wear and reduces failure rates by 75% compared to open

structures.

Wide Temperature Adaptability and Thermal Stability

Special alloy rails combined with dynamic thermal compensation technology keep temperature rise

within ±2°C during high-speed operation, ensuring precision and stability at speeds of 2m/s.