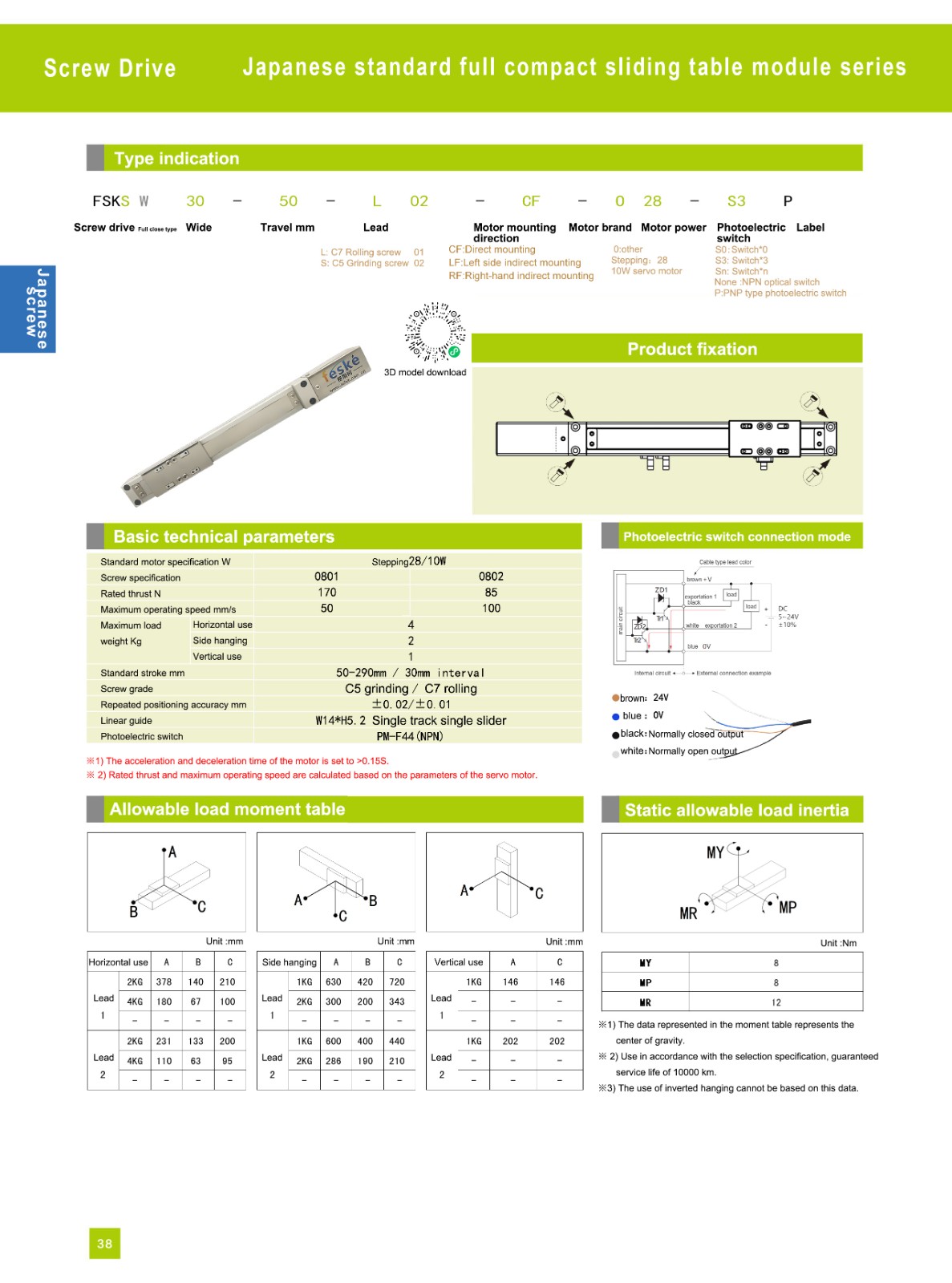

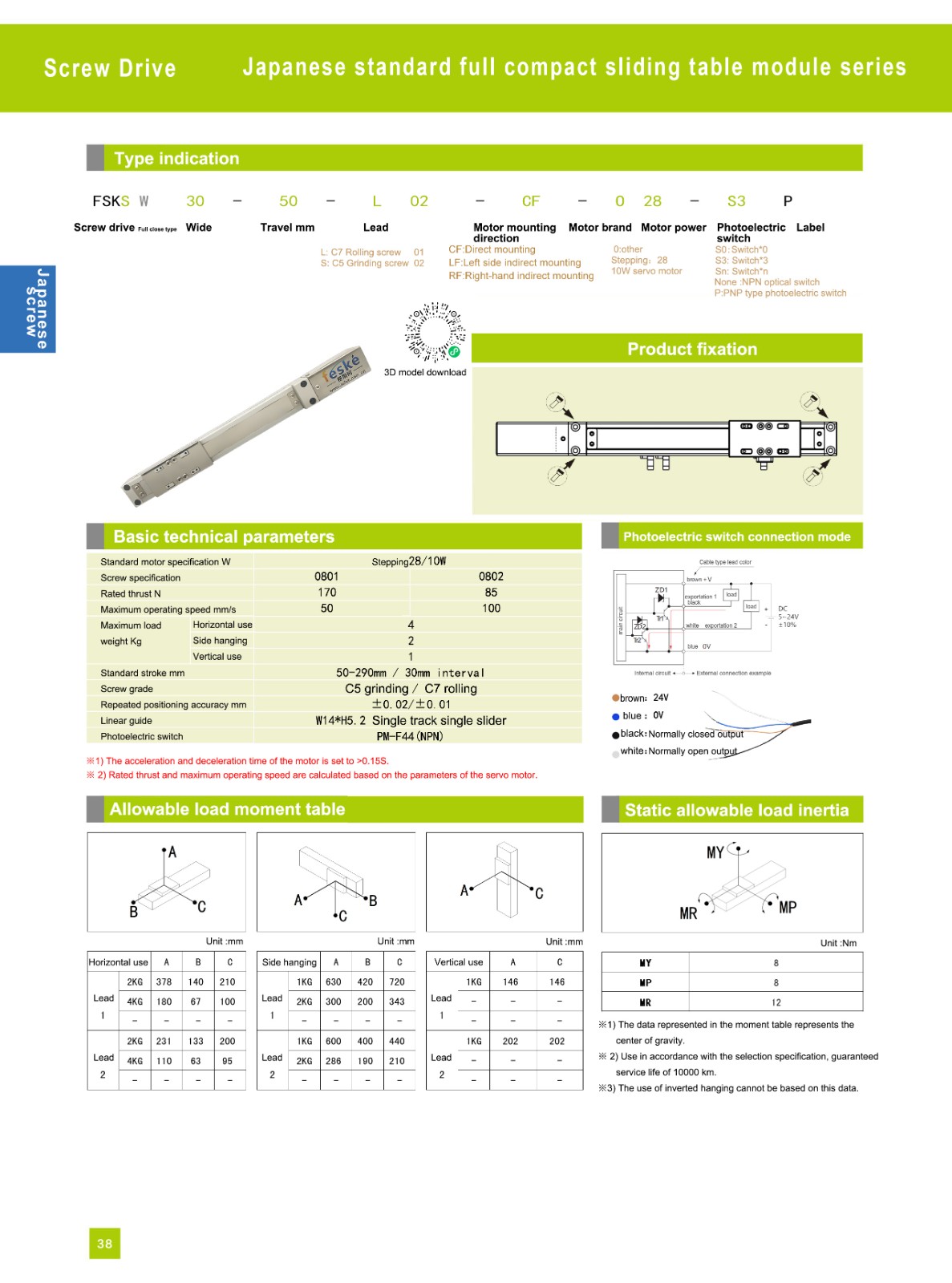

Maximum horizontal load 4 KG

Model: FSKSW-30 screw full-closed module-steel belt

Repeat positioning accuracy: 0.01/±0.02 mm

Customizable stroke: 50-400 mm

Screw outer diameter: φ8 mm

Lead: 01/02 mm

Motor power: 40W/28 steps (motor can be customized)

Maximum speed: 50/100 MM/S

The Fully Enclosed Stainless Steel Belt Screw Module FSKSW-30 is an industrial drive component

designed for efficient motion transmission. It uses stainless steel to provide excellent corrosion

resistance and durability. Its fully enclosed structure effectively prevents the intrusion of external dust,

moisture and contaminants, prolongs the life of the equipment and ensures stable operation.

Features include:

Fully enclosed stainless steel housing: Provides comprehensive protection for harsh industrial environments.

Belt screw mechanism: Combines belt drive and screw design to achieve high-precision load transmission

and energy efficiency.

Modular construction: Easy to install and maintain, supports multiple configurations to meet different

application requirements.

Applications include elevator lifting systems, automated production lines and precision transmission

equipment, where belt connection fixtures and high-strength design ensure reliable performance.

Pay attention to environmental safety during operation, avoid exposure to explosive conditions, and f

ollow manufacturer guidelines for regular inspections.

The fully enclosed lead screw module (fully enclosed/sealed lead screw module) is a high-precision

linear motion device that converts the motor's rotary motion into precise linear displacement via a ball

screw.

Its core feature is a fully enclosed structural design that completely isolates it from dust and impurities.

It also offers high rigidity, high load capacity, and micron-level positioning accuracy, making it suitable

for industrial applications requiring stringent cleanliness and precision.

Core Features

Dustproof and Sealing

The integrated sealing structure creates a natural dust barrier, specifically designed for cleanrooms and

electronics manufacturing environments, significantly extending equipment life.

High-Precision Positioning

Repeatability reaches ±0.005mm (C5 ground-grade lead screw), meeting the requirements of semicond

uctor die bonders and precision measuring instruments.

Stable Performance

The combination of a reinforced rail and precision transmission system achieves high rigidity (for heavy

loads) while maintaining a lightweight design, achieving a maximum speed of 1600mm/s. Compact and

Efficient

Integrating core components such as ball screws, guide rails, and servo motors reduces equipment

assembly complexity and improves transmission efficiency.

Major Applications

Semiconductor and display panel manufacturing

Used for wafer handling and exposure machine positioning, achieving precision and stability that meet

micron-level process requirements.

Precision Electronics Assembly

Micro-component placement and testing are performed in cleanrooms, with a dust-proof design to

prevent product contamination.

Lithium Battery Equipment

Precision displacement control for electrode coating and slitting machines improves battery consistency

and production capacity.

Medical/Optical Equipment

Positioning testing instruments and laser cutting equipment requiring a high cleanroom environment.

Automated Production Lines

For high-speed, high-load applications such as welding robots and CNC machine tools, achieving three

times the efficiency of traditional equipment.

The core advantages of the fully enclosed stainless steel belt screw module FSKSW-30 are reflected in

the following aspects:

High-rigidity enclosed structure

The fully enclosed stainless steel housing design achieves IP65 dust and splashproof rating. The four

rows of steel balls arranged at a 45° contact angle achieve four-way equal load characteristics, with a

rated load of 30 kg and instantaneous shock load resistance of 120 N·m.

Precision motion performance

The rolling friction coefficient is as low as 0.002, with repeatability accuracy of ±0.005 mm. Preload tec

hnology eliminates backlash and supports μm-level dynamic response. The enclosed structure effectively

isolates external contaminants and ensures stable long-term accuracy.

Corrosion resistance and wide temperature adaptability

The 304 stainless steel is passivated and withstands salt spray corrosion for over 2,000 hours. The oper

ating temperature range is -20°C to 80°C, and the heat sink design enhances thermal stability.

Modular integrated design

The standard 30mm width supports multi-axis parallel connection, and pre-installed interfaces are com

patible with mainstream servo systems, increasing installation efficiency by 50%. The self-lubricating

system has a maintenance interval of 10,000 hours.

Industrial-Grade Reliability

Contactless signal transmission eliminates mechanical wear and tear, making it suitable for cleanrooms

and high-humidity environments. Its failure rate is 70% lower than open structures.