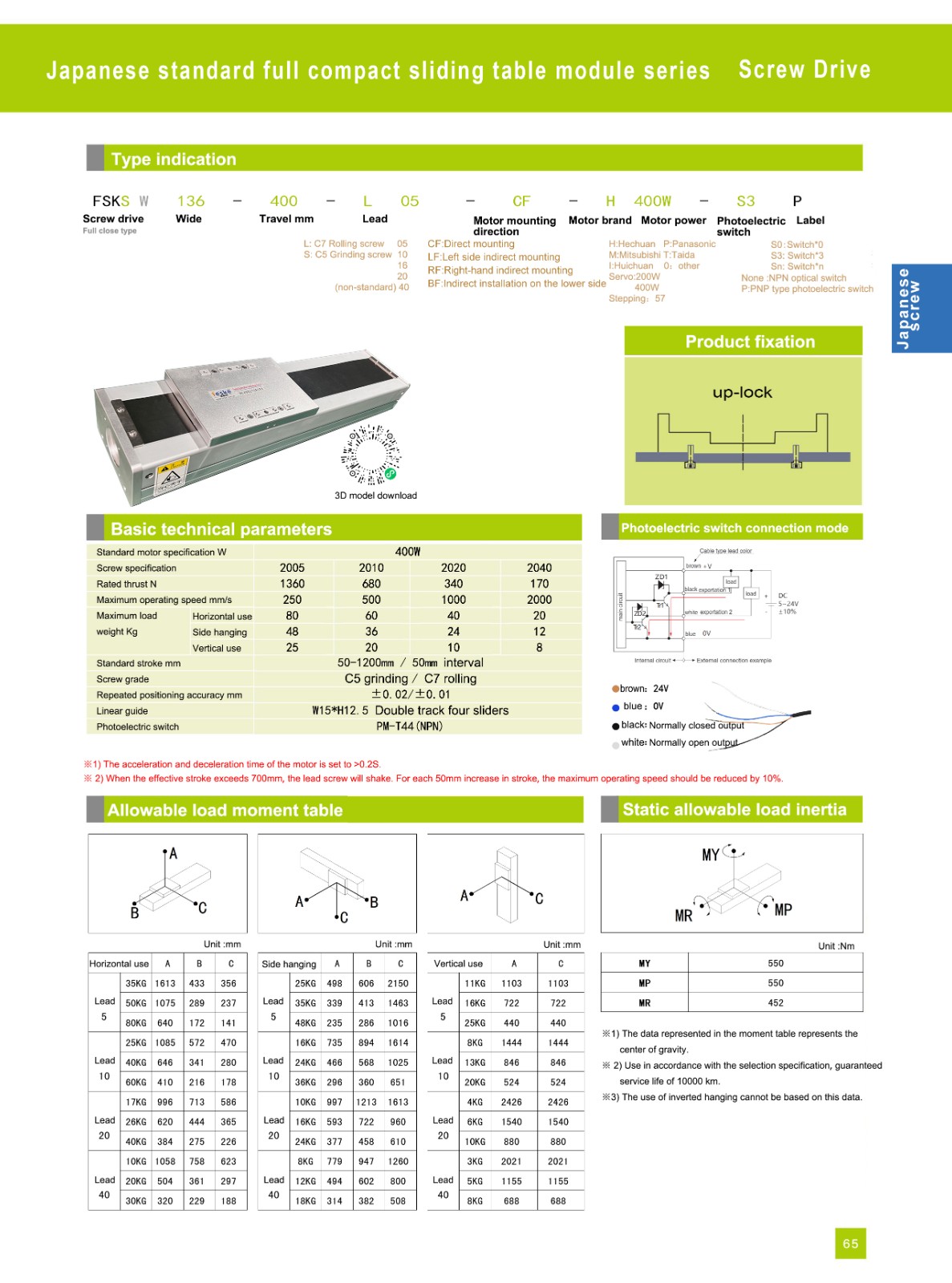

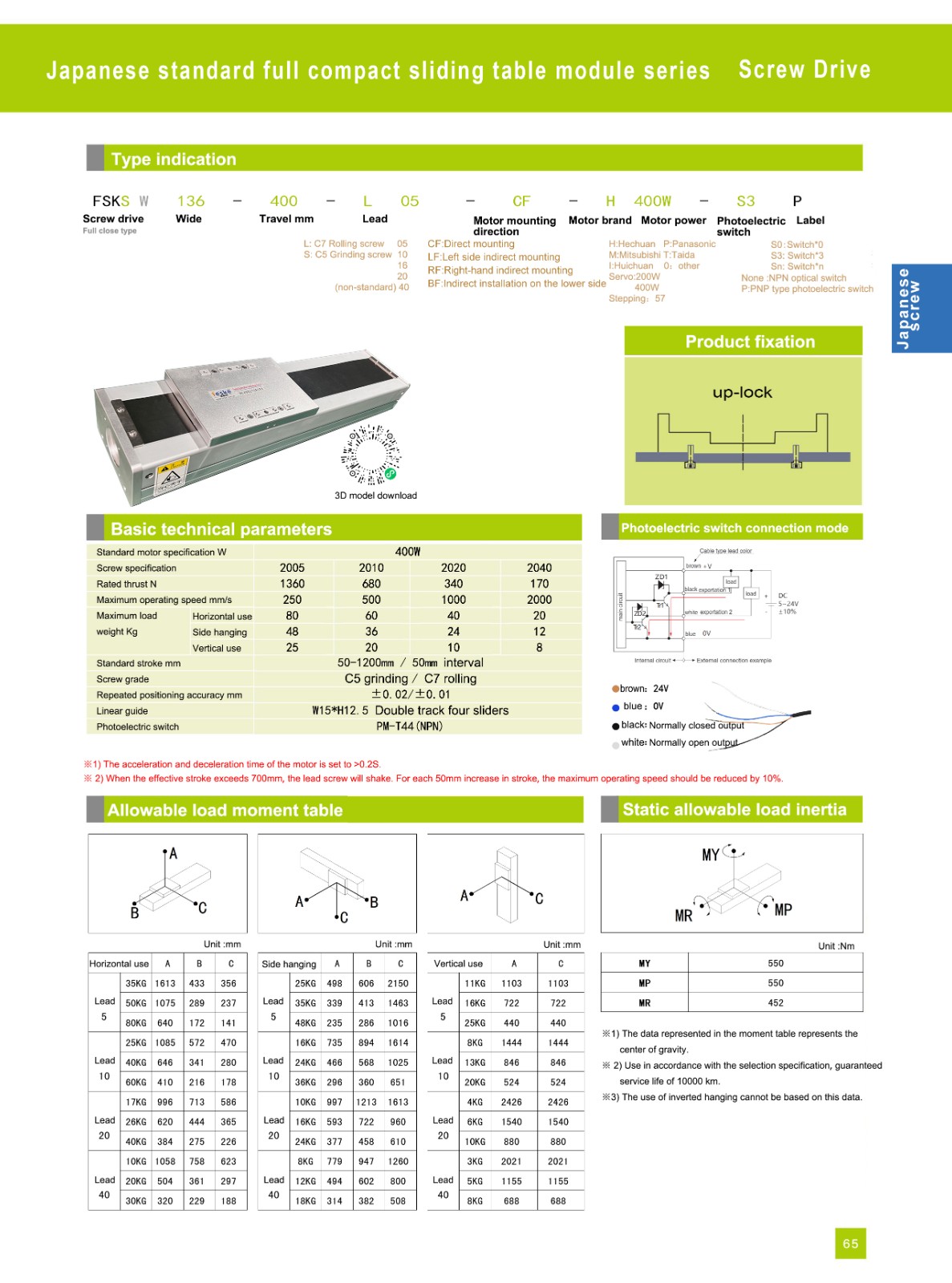

Maximum horizontal load 70 KG

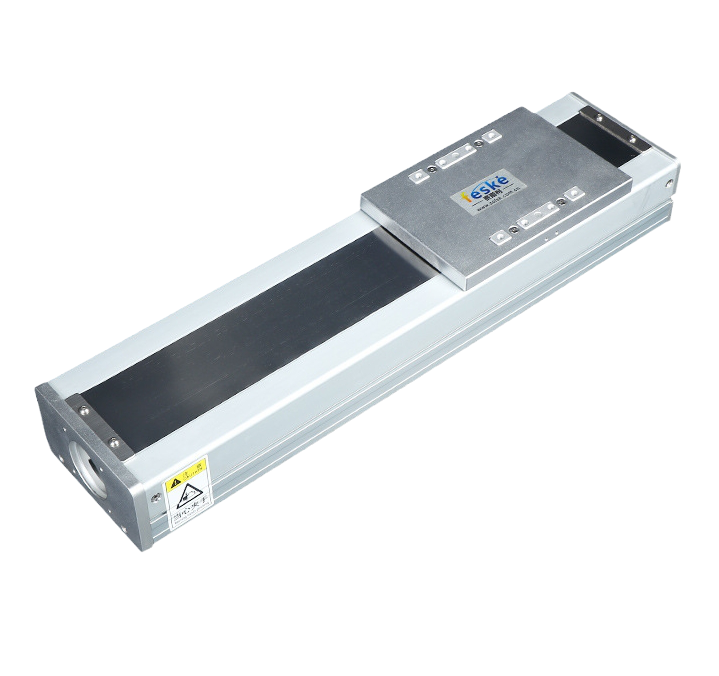

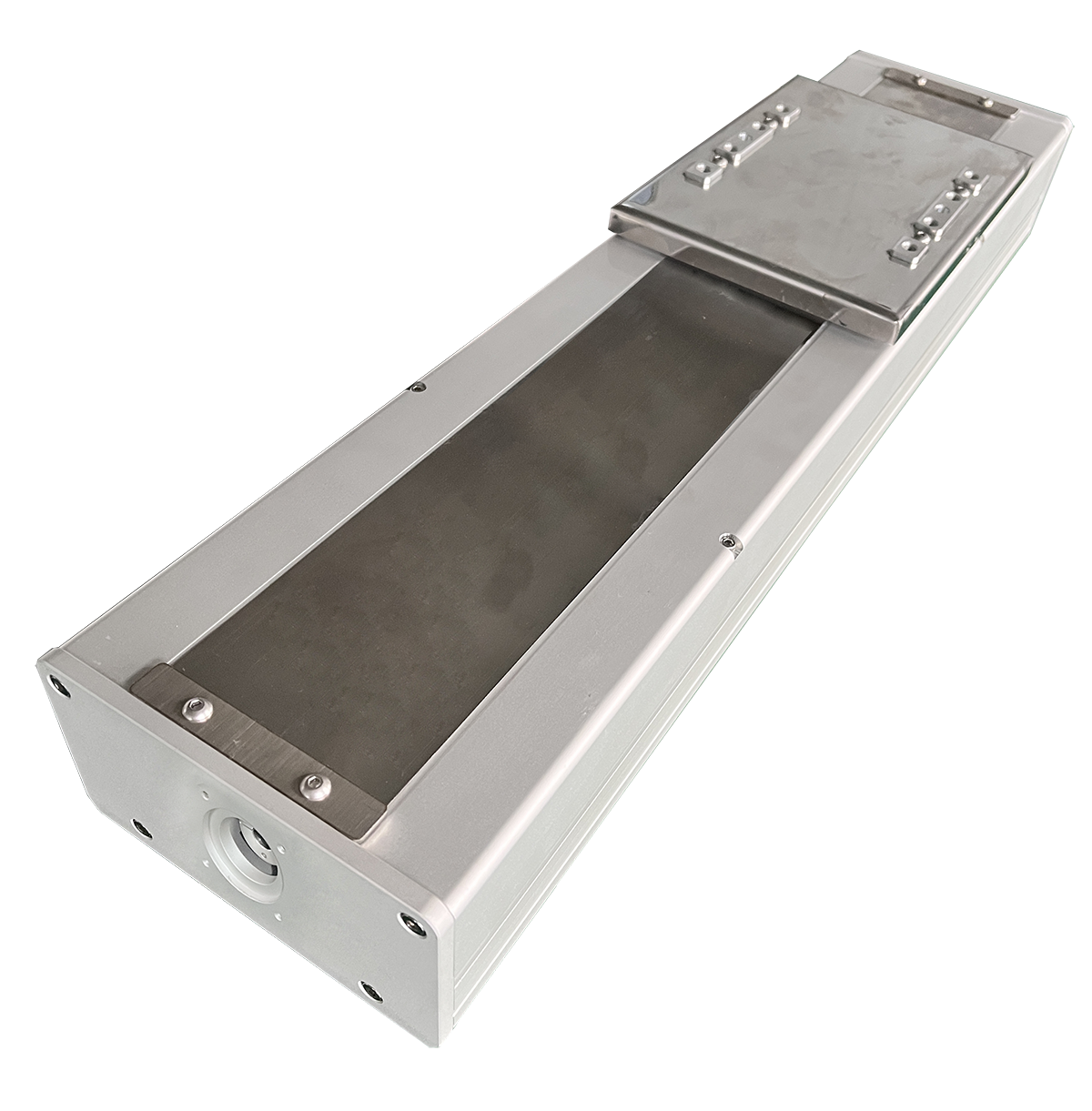

Model: FSKSW-136 screw full-closed module-steel belt

Repeat positioning accuracy: 0.01/±0.02 mm

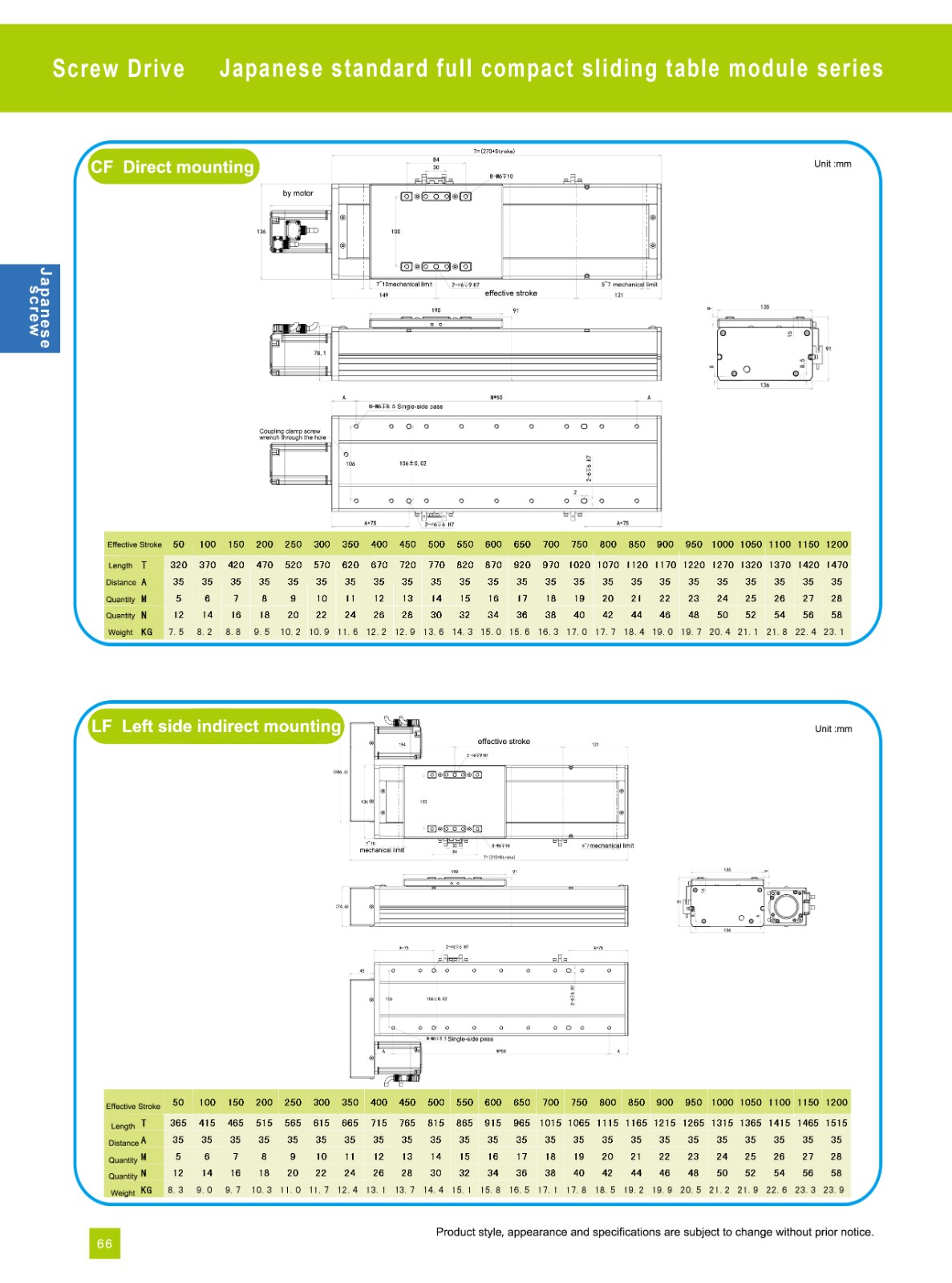

Customizable stroke: 50-1000 mm

Screw outer diameter: φ20 mm

Lead: 05/10/20mm

Motor power: 400W (motor can be customized)

Maximum speed:: 250500V1000 MM/S

Fully Enclosed High Precision Ball Screw Module FSKSW-136 is an industrial-grade linear drive

component designed for precision positioning in harsh environments. It achieves excellent stability and

service life through a fully enclosed structure and high-grade ball screw technology. Its core features are

as follows:

Structural design Fully enclosed protection: The stainless steel shell integrates a double-lip seal to

effectively block dust, liquid and chemical corrosion, with a protection level of IP54/IP65, suitable for

high-demand scenarios such as dust-free workshops.

Modular integration: The compact body (silver/black optional) supports direct or indirect motor

installation (right/left/folding down), which is convenient for rapid deployment and maintenance.

Performance parameters High-precision transmission: Adopts C5-grade ground ball screw (optional C7

rolled screw), with a repeatability accuracy of ≤±0.01 mm, and is compatible with servo motors to

achieve high-speed motion (up to 6000 min⁻¹).

Strong load capacity: radial load up to 800 N, lateral load 500 N, anti-flipping torque 25 N·m, meet the

needs of heavy equipment handling.

Low friction and efficient operation: four-row ball circulation design with 45° contact angle, friction

coefficient as low as 0.003~0.005, energy consumption reduced by more than 30%.

Application scenarios

Widely used in CNC machine tool precision feeding systems, semiconductor wafer transfer equipment,

medical testing instruments and automated assembly lines, especially in the electronic manufacturing

links that require dust and moisture resistance.

Precautions for use

Avoid operating in explosive environments or at supercritical speeds, and regularly check the wear of

seals;

Long-stroke applications require controlled acceleration to reduce inertial impact and ensure rigid

support of the guide rails

The core advantages of the fully enclosed, high-precision ball screw module FSKSW-136 are reflected in

the following technical features:

Ultra-precision Motion Performance

A four-row steel ball design with a 45° contact angle achieves repeatable positioning accuracy of

±0.003mm, a rolling friction coefficient as low as 0.002, and preload technology completely eliminates

backlash. A closed-loop feedback system compensates for thermal deformation in real time, ensuring

consistent positioning accuracy throughout the 136mm travel range.

Industrial-grade, fully enclosed protection

The stainless steel housing achieves IP65 protection, and the built-in labyrinth seal and self-lubricating

system provide over 2,000 hours of salt spray corrosion resistance. Non-contact signal transmission

eliminates mechanical wear and reduces failure rates by 70% compared to open structures.

High-rigidity Structural Design

The Meehanite cast iron base and preloaded ball tracks combine to provide a dynamic load capacity

of 136kg and withstand instantaneous shock loads of 400N·m. Integrated heat sinks control

temperature rise to within ±2°C, supporting a wide operating temperature range of -20°C to 80°C.

Modular Integration and Expansion

The 136mm standard width supports multi-axis parallel connection, and pre-installed interfaces are

compatible with mainstream servo systems, increasing installation efficiency by 60%. AI algorithms

automatically optimize motion trajectories, reducing idle travel by over 15%.

Intelligent Maintenance System

The spindle condition monitoring system achieves 10,000 hours of trouble-free operation, and the

self-lubricating guideway maintenance cycle is extended by three times. Digital twin technology

enables predictive maintenance, reducing downtime by 40%.